Preparation method for flexible inorganic/organic composite proton exchange membrane

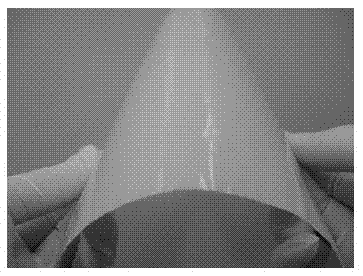

A proton exchange membrane, inorganic technology, applied in the field of composite materials, can solve the problems of difficulty in preparing large-area membranes, application limitations, lack of flexibility of proton exchange membranes, etc., to overcome inflexibility, high proton conductivity, and high heat resistance. Effects of Sexuality and Dimensional Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

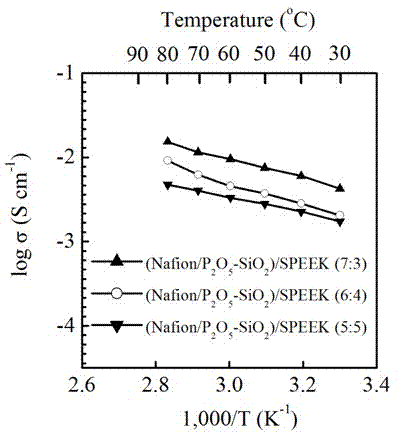

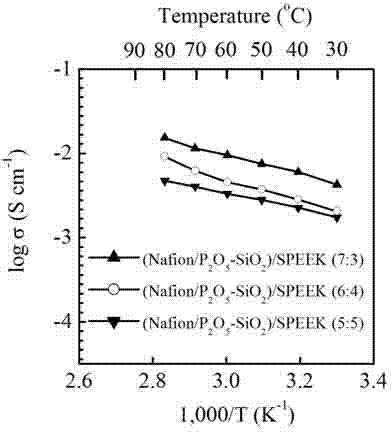

[0018] Step 1: Dissolving sulfonated polyetheretherketone (SPEEK) in dimethylformamide (DMF) to obtain a sulfonated polyetheretherketone (SPEEK) (10wt%) solution.

[0019] Step 2: Add Nafion-containing phosphosilicate glass powder (Nafion / P 2 O 5 -SiO 2 ) mixed with sulfonated polyether ether ketone (SPEEK) solution, the weight ratio of Nafion phosphosilicate glass powder to sulfonated polyether ether ketone (SPEEK) is 5:5. Perform mechanical ball milling to obtain a mixture containing Nafion phosphosilicate glass powder dispersed in sulfonated polyether ether ketone (SPEEK) solution.

[0020] Phosphosilicate glass containing Nafion was prepared by sol-gel method (Nafion / P 2 O 5 -SiO 2 ). First, tetraethyl orthosilicate, deionized water and hydrochloric acid were mixed according to the ratio of 1:4:4×10 -3 The molar ratio was vigorously stirred at room temperature for 30 minutes. Then add Nafion solution to the solution according to the ...

Embodiment 2

[0023] Step 1: Dissolving sulfonated polyetheretherketone (SPEEK) in dimethylformamide (DMF) to obtain a sulfonated polyetheretherketone (SPEEK) (10wt%) solution.

[0024] Step 2: Add Nafion-containing phosphosilicate glass powder (Nafion / P 2 O 5 -SiO 2 ) mixed with sulfonated polyetheretherketone (SPEEK) solution, the weight ratio of Nafion-containing phosphosilicate glass powder to sulfonated polyetheretherketone (SPEEK) is 6:4. Perform mechanical ball milling to obtain a mixture containing Nafion phosphosilicate glass powder dispersed in sulfonated polyether ether ketone (SPEEK) solution.

[0025] Phosphosilicate glass containing Nafion was prepared by sol-gel method (Nafion / P 2 O 5 -SiO 2 ). First, tetraethyl orthosilicate, deionized water and hydrochloric acid were mixed according to the ratio of 1:4:4×10 -3 The molar ratio was vigorously stirred at room temperature for 30 minutes. Then add Nafion solution to the solution according ...

Embodiment 3

[0028] Step 1: Dissolving sulfonated polyetheretherketone (SPEEK) in dimethylformamide (DMF) to obtain a sulfonated polyetheretherketone (SPEEK) (10wt%) solution.

[0029] Step 2: Add Nafion-containing phosphosilicate glass powder (Nafion / P 2 O 5 -SiO 2 ) mixed with sulfonated polyether ether ketone (SPEEK) solution, the weight ratio of Nafion phosphosilicate glass powder to sulfonated polyether ether ketone (SPEEK) is 7:3. Perform mechanical ball milling to obtain a mixture containing Nafion phosphosilicate glass powder dispersed in sulfonated polyether ether ketone (SPEEK) solution.

[0030] Phosphosilicate glass containing Nafion was prepared by sol-gel method (Nafion / P 2 O 5 -SiO 2 ). First, tetraethyl orthosilicate, deionized water and hydrochloric acid were mixed according to the ratio of 1:4:4×10 -3 The molar ratio was vigorously stirred at room temperature for 30 minutes. Then add Nafion solution to the solution according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com