Vanadium cell nafion proton membrane and preparation method thereof

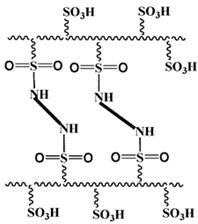

A technology of perfluorosulfonic acid and perfluorosulfonic acid resin, applied in the field of proton exchange membrane, can solve the problems of reducing the proton conductivity of proton membrane, unstable physical cross-linking, hindering the transfer of hydrated protons, etc. Vanadium has the effect of good performance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1). Dissolve 1kg of perfluorosulfonic acid resin (with an exchange capacity of 1.0mmol / g) and 5g of N,N-dimethyl-4-aminopyridine in 19kg of dimethylformamide at a temperature of 200°C. The pressure is 0.5MPa, the dissolution time is 2h, and a transparent solution with a mass fraction of 5% is obtained;

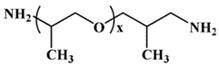

[0045] 2). Weigh 11.5 g of D230 polyetheramine (number average molecular weight 230) and dissolve it in the transparent solution prepared in step 1), and stir at 50°C for 3 hours to perform pre-crosslinking;

[0046] 3). Put the pre-crosslinking solution prepared in step 2) into a thin film evaporator for concentration to a gel state substance with a mass fraction of about 25%; the effective evaporation area of the thin film evaporator is 1m 2 , the cooling area of the condenser is 20m 2 , the evaporation temperature is 50°C, and the concentration time is 0.5h; in addition to the thin film evaporator, other evaporators with the same function can also be used for the ...

Embodiment 2

[0051] 1). Dissolve 1.5kg perfluorosulfonic acid resin (exchange capacity: 0.9mmol / g) and 10.5g N,N-dimethyl-4-aminopyridine in a mixed solution of 18.5kg dimethylformamide and 5kg ethanol , the dissolution temperature is 220°C, the dissolution pressure is 2.5MPa, and the dissolution time is 2h, a transparent solution with a mass fraction of 6% is obtained;

[0052] 2). Weigh 25g of D400 polyetheramine (number-average molecular weight: 400) and dissolve it in the transparent solution in step 1), and stir at 70°C for 3 hours to perform pre-crosslinking;

[0053] 3). Put the pre-crosslinking solution prepared in step 2) into a thin-film evaporator for concentration to a gel-state substance with a mass fraction of about 20%; the effective evaporation area of the thin-film evaporator is 1m 2 , the cooling area of the condenser is 20m 2 , the evaporation temperature is 80°C, and the concentration time is 1 hour; in addition to the thin film evaporator, other evaporators with t...

Embodiment 3

[0057] 1). Dissolve 1.5kg of perfluorosulfonic acid resin (with an exchange capacity of 1.1mmol / g) in a mixed solution of 22.5kg of N-methylpyrrolidone and 26kg of isopropanol at a temperature of 220°C and a pressure of 1.5MPa. Dissolving time is 3h, obtains the transparent solution that mass fraction is 3%;

[0058] 2). Weigh 150g of D2000 polyetheramine (number average molecular weight: 2000) and dissolve it in the transparent solution prepared in step 1), and stir at 80°C for 4 hours to perform pre-crosslinking;

[0059] 3). Put the pre-crosslinking solution prepared in step 2) into a thin-film evaporator for concentration to a gel-state substance with a mass fraction of about 15%; the effective evaporation area of the thin-film evaporator is 1m 2 , the cooling area of the condenser is 20m 2 , the evaporation temperature is 80°C, and the concentration time is 1 hour; in addition to the thin film evaporator, other evaporators with the same function can also be used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com