Electrochemical treatment method for improving vanadium cell electrode material activity

An electrode material and processing method technology, applied in the field of electrochemical treatment for improving the activity of vanadium battery electrode materials, can solve the problems of decreased stability of electrode materials, decreased battery life, etc. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

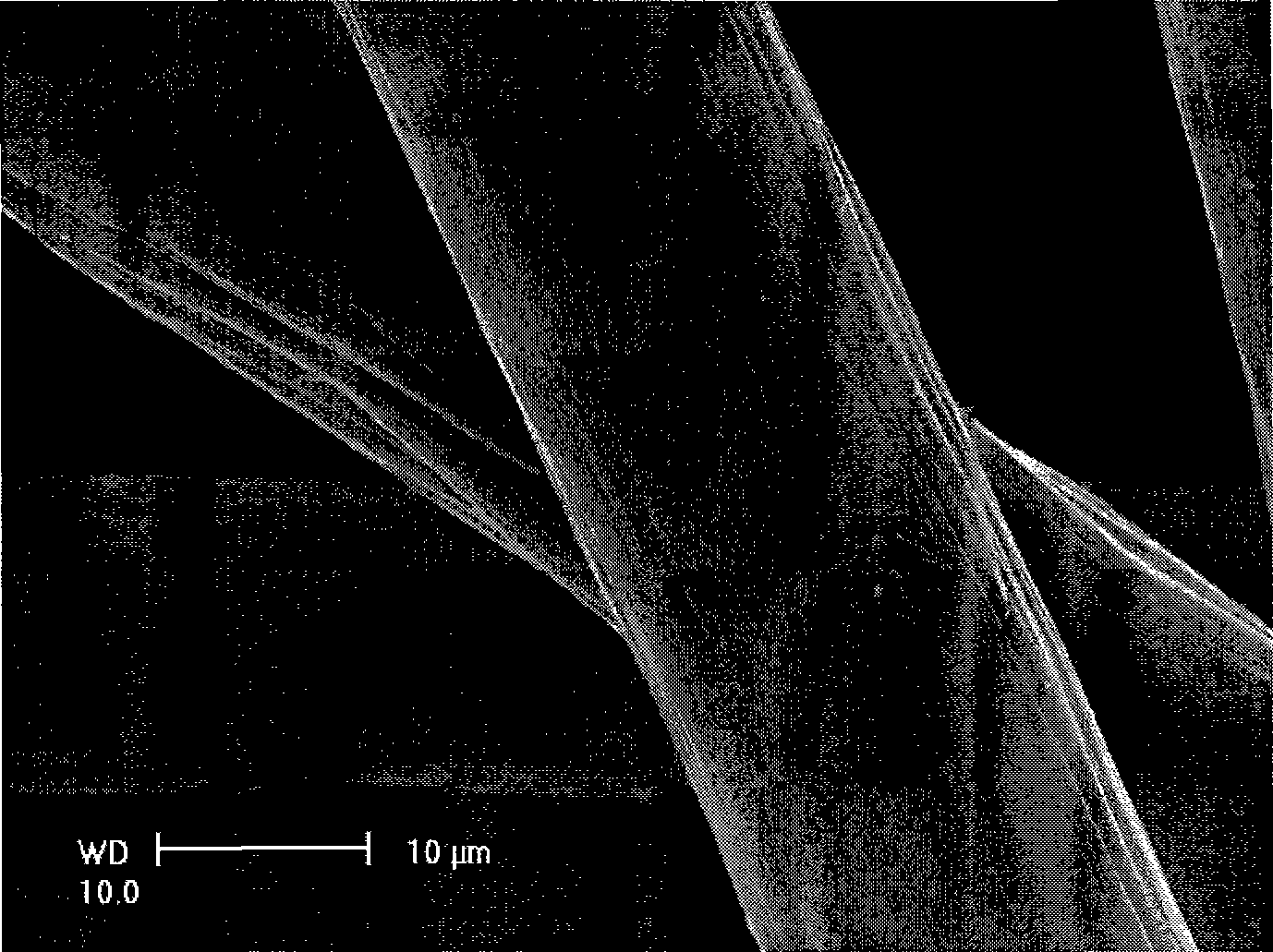

[0021] (1) Soak a polyacrylonitrile-based graphite felt or carbon felt material with a thickness of 4mm in distilled water for 24 hours, put it in a vacuum oven at 75°C for 3 hours, and store it in a desiccator filled with color-changing silica gel for later use .

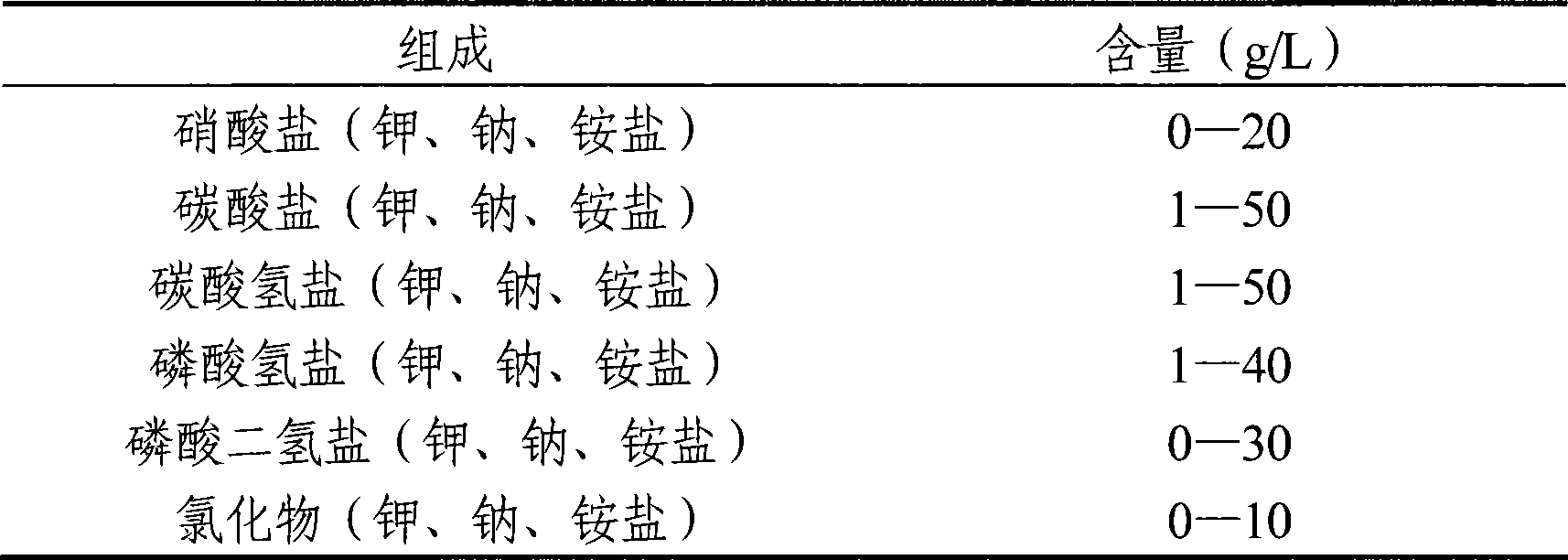

[0022] (2) Put the pretreated graphite felt or carbon felt into the electrolytic cell filled with the following electrolyte (the rest is water):

[0023]

[0024] Using graphite felt or carbon felt as anode and graphite plate as cathode, electrochemical activation treatment is carried out under ultrasonic vibration, and the current density is 1.5mA / cm 2 , the treatment time is 3min, and the treatment temperature is 30°C.

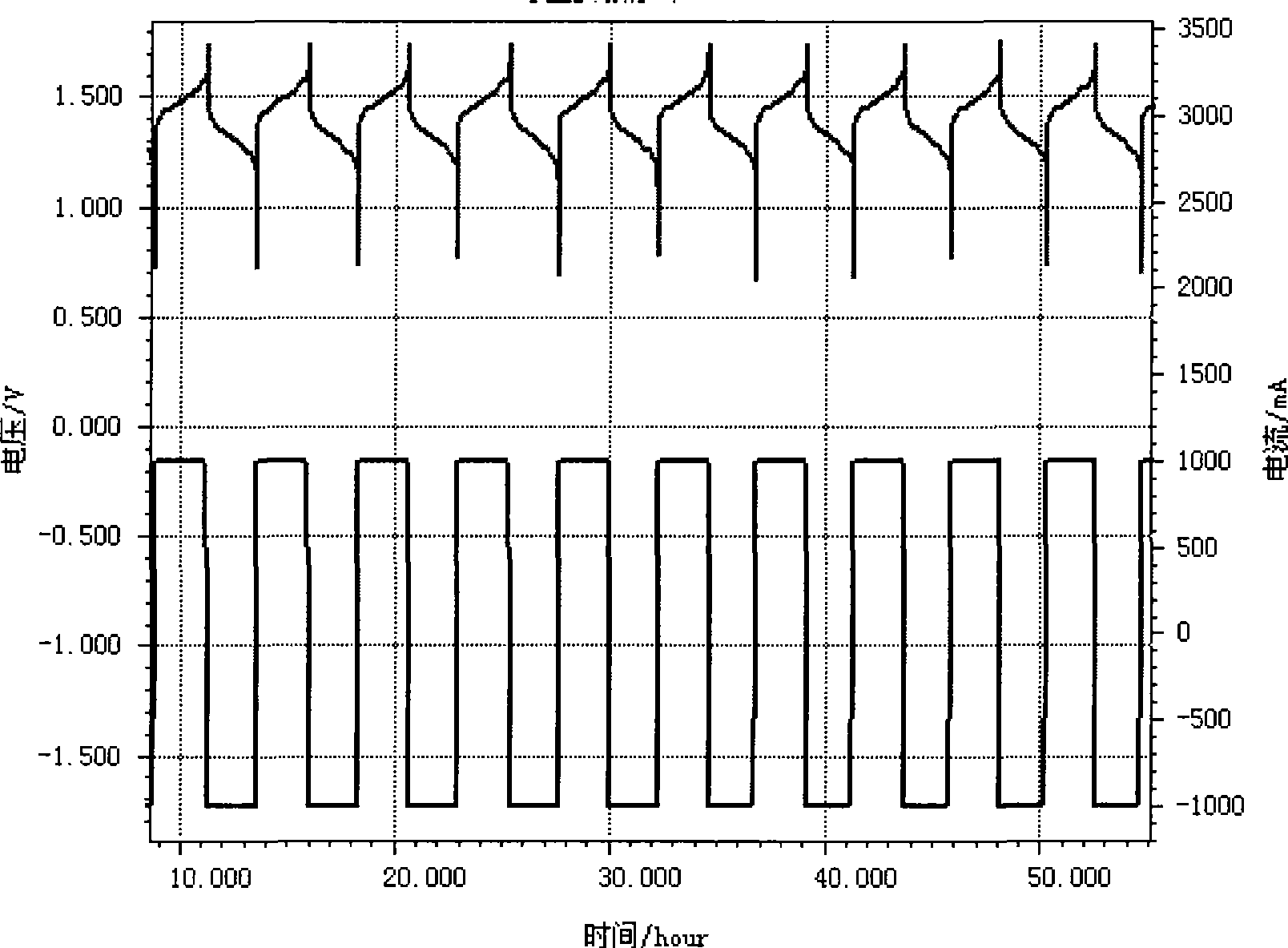

[0025] (3) Soak the electrochemically activated graphite felt or carbon felt material in distilled water, ultrasonically vibrate for 10 minutes, then soak for 48 hours, then dry it in an oven at 80°C for 3 hours, and use it as an electrode material for a vanadium battery. The cation exchange...

Embodiment 2

[0029] (1) Put the viscose-based graphite felt or carbon felt material with a thickness of 5mm into distilled water for 48 hours, put it into a vacuum oven and dry it at 60°C for 5 hours, and store it in a desiccator filled with color-changing silica gel for later use.

[0030] (2) Put the pretreated graphite felt or carbon felt into the electrolytic cell filled with the following electrolyte (the rest is water):

[0031]

[0032] Using graphite felt or carbon felt as anode and DSA electrode as cathode, electrochemical activation treatment is carried out under ultrasonic vibration, and the current density is 2.0mA / cm 2 , the treatment time is 15min, and the treatment temperature is 40°C.

[0033] (3) Soak the electrochemically activated graphite felt or carbon felt material in distilled water, ultrasonically vibrate for 30 minutes, then soak for 24 hours, then dry it in an oven at 90°C for 5 hours, and use it as an electrode material for a vanadium battery. The cation exch...

Embodiment 3

[0035] (1) Soak cellulose-based graphite felt or carbon felt material with a thickness of 10mm in distilled water for 20 hours, put it in a vacuum oven at 120°C for 6 hours, and store it in a desiccator filled with color-changing silica gel for later use.

[0036] (2) Put the pretreated graphite felt or carbon felt into the electrolytic cell filled with the following electrolyte (the rest is water):

[0037]

[0038] With graphite felt or carbon felt as anode and platinum electrode as cathode, electrochemical activation treatment is carried out under ultrasonic vibration, and the current density is 3.0mA / cm 2 , the treatment time is 45min, and the treatment temperature is 25°C.

[0039] (3) Soak the electrochemically activated graphite felt or carbon felt material in distilled water, ultrasonically vibrate for 10 minutes, then soak for 30 hours, then dry it in an oven at 120°C for 3 hours, and use it as an electrode material for a vanadium battery. The cation exchange memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com