Combined chemical-electrochemical method for preparing vanadium redox flow battery electrolyte

A vanadium redox flow battery and electrolyte technology, which is applied to chemical instruments and methods, electrochemical generators, vanadium compounds, etc., can solve the problems of low vanadium extraction rate, high inclusions, and increased costs, and achieve high product purity and reagent cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

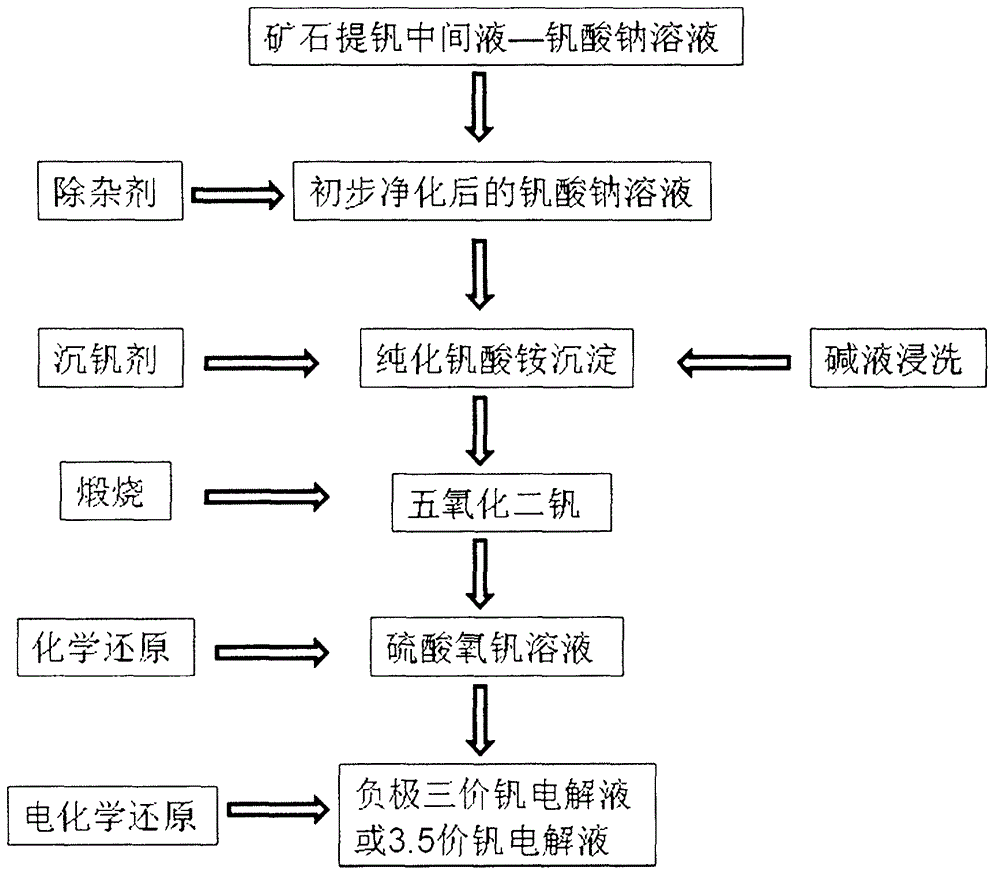

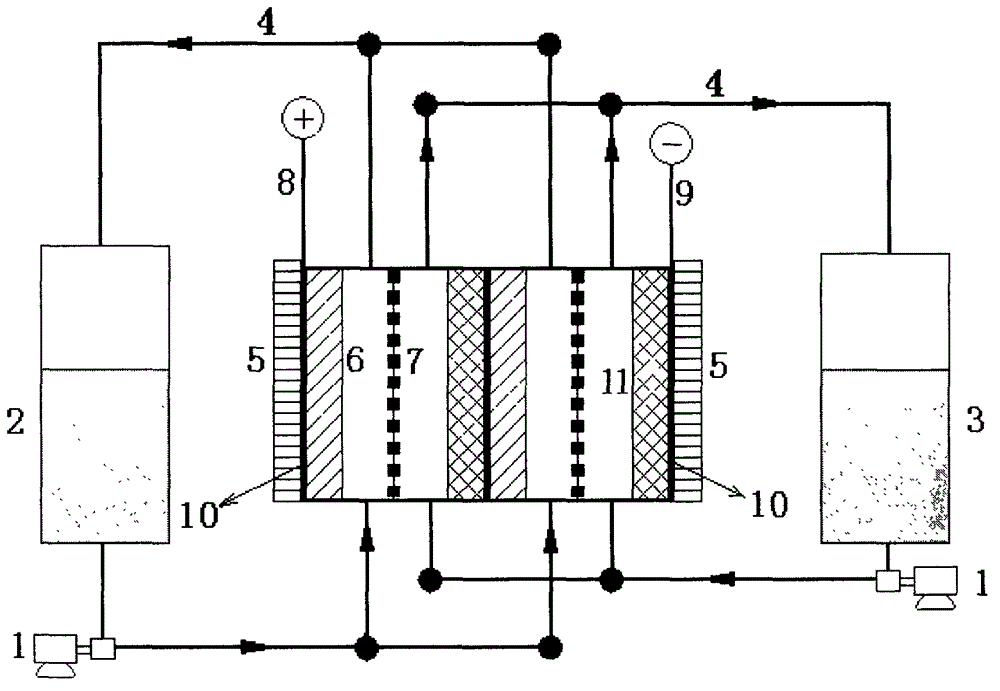

Method used

Image

Examples

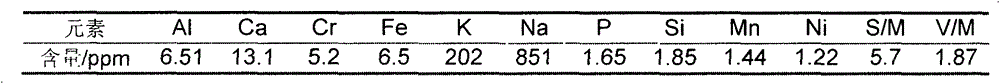

Embodiment 1

[0026] Take 5000 ml of NaVO containing vanadium 0.4M 3 solution, adjust the pH value of the solution to 9, add aluminum sulfate (according to the molar ratio of Si:Al=1:1.2), heat and stir for 2 hours, then let it stand for 12 hours, and filter the precipitate. According to Ca:CO in the filtrate 32- =1:1 molar ratio Add sodium carbonate, adjust the pH of the filtrate to 10, heat to boil and then cool slowly, let stand for 12h, precipitate and filter. Add the above-mentioned NaVO after preliminary impurity removal and purification into the reaction kettle 3 solution, adjust the acidity of the solution to pH 5, according to NH 4 + : Add ammonium chloride at a molar ratio of V=1:3, after stirring for 1h, adjust the pH=2 of the solution, stir for 2h under the condition of a constant temperature of 90°C, leave it for 24h, filter to obtain NH 4 VO 3 precipitation. Add an appropriate amount of purified water with ammonia water to adjust the pH value of the solution to 9, stir f...

Embodiment 2

[0029] Take 6000 ml of NaVO containing vanadium 0.3M 3 solution, adjust the pH value of the solution to 9, add aluminum sulfate (according to the molar ratio of Si:Al=1:1.4), heat and stir for 2 hours, then let stand for 12 hours, and filter the precipitate. According to Ca:CO in the filtrate 3 2- =1:1.2 molar ratio Add sodium carbonate, adjust the pH value of the filtrate to 10, heat to boil and then cool slowly, let stand for 12h, precipitate and filter. Add the above-mentioned NaVO after preliminary impurity removal and purification into the reaction kettle 3 solution, adjust the acidity of the solution to pH 5, according to NH 4 + Ammonium chloride was added at a molar ratio of V=2:3, and after stirring for 1 h, the pH of the solution was adjusted=2, stirred for 2 h at a constant temperature of 80° C., left to stand for 12 h, filtered to obtain NH 4 VO 3 precipitation. Add an appropriate amount of pure water with ammonia water to adjust the pH value of the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com