Method for preparing V-Ti-Si-O composite catalyst used in methanol oxidation for synthesizing methylal

A composite catalyst, v-ti-si-o technology, applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as complex processes, and achieve The effect of simple preparation process, good performance, improved thermal stability and molding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

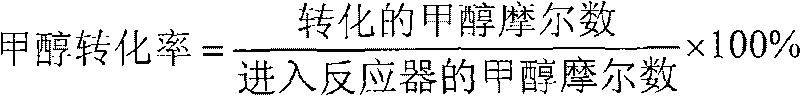

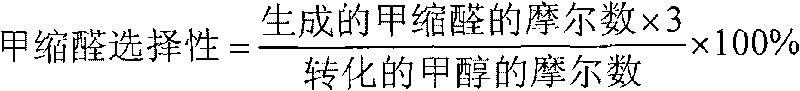

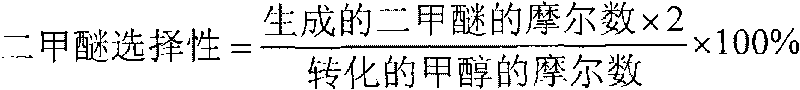

[0013] 13.52g of titanium sulfate and 0.90g of vanadyl sulfate were ultrasonically dissolved in 450mL of water to obtain a blue solution A, and 35mL of ammonia water (25%) was added to 700mL of water to form an ammonia solution, and the vanadium-titanium solution A was dissolved in 3 mLmin -1 Add it dropwise into the ammonia solution at a high speed. After the addition is complete, continue to stir for 1 hour, age at room temperature for 8 hours, filter, and roast the obtained filter cake in air at 350°C for 3 hours to obtain a solid sample. The vanadium content was determined to be 9.8% (by mass percentage of vanadium pentoxide), the titanium content was 86.4% (by mass percentage of titanium dioxide), and the sulfur was 3.8% (by mass percentage of sulfate). The prepared V 2 o 5 The composite catalyst is crushed and sieved, and the 20-40 mesh sample is taken in a U-shaped tube reactor with an external diameter of 8mm, and the ratio of the amount of the substance is methanol 5...

Embodiment 2

[0022] 9.62g of titanium sulfate and 1.40g of vanadyl sulfate were ultrasonically dissolved in 350mL of water to obtain a blue solution A. Take 30mL of ammonia water (25%) and add 180mL of water to form an ammonia solution. -1 Add it dropwise into the ammonia solution at a high speed. After the dropwise addition is complete, continue to stir for 3 hours, age at room temperature for 10 hours, filter, and roast the obtained filter cake in air at 400°C for 6 hours to obtain a solid sample. The vanadium content was determined to be 18.9% (by mass percentage of vanadium pentoxide), the titanium content was 79.5% (by mass percentage of titanium dioxide), and the sulfur was 1.6% (by mass percentage of sulfate radical). The prepared V 2 o 5 The composite catalyst is crushed and sieved, and the 20-40 mesh sample is taken in a U-shaped tube reactor with an external diameter of 8mm, and the ratio of the amount of the substance is methanol 5%, O 2 15%, N 2 80% of the mixed gas was pr...

Embodiment 3

[0024] 7.21g of titanium sulfate and 2.87g of vanadyl sulfate were ultrasonically dissolved in 370mL of water to obtain a blue solution A. Take 30mL of ammonia water (25%) and add 180mL of water to make an ammonia solution. The vanadium-titanium solution A was dissolved in 4 mL min -1 Add it dropwise into the ammonia solution at a high speed. After the dropwise addition is complete, continue to stir for 5 hours, age at room temperature for 10 hours, filter, and roast the obtained filter cake in air at 400°C for 6 hours to obtain a solid sample. The vanadium content was determined to be 38.9% (by mass percentage of vanadium pentoxide), the titanium content was 59.8% (by mass percentage of titanium dioxide), and the sulfur was 1.3% (by mass percentage of sulfate). The prepared V 2 o 5 The composite catalyst is crushed and sieved, and the 20-40 mesh sample is taken in a U-shaped tube reactor with an external diameter of 8mm, and the ratio of the amount of the substance is methan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com