Hydrogenation catalyst with active metal component concentration in gradient increase and distribution and preparation method thereof

A technology for hydrogenation catalyst and active metal, applied in the field of hydrogenation catalyst and preparation, can solve the problems of poor gradient distribution of active metal components, difficult to control the gradient distribution of active metal components, etc., and achieves good hydrogenation activity and stability, The effect of reduced manufacturing costs and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

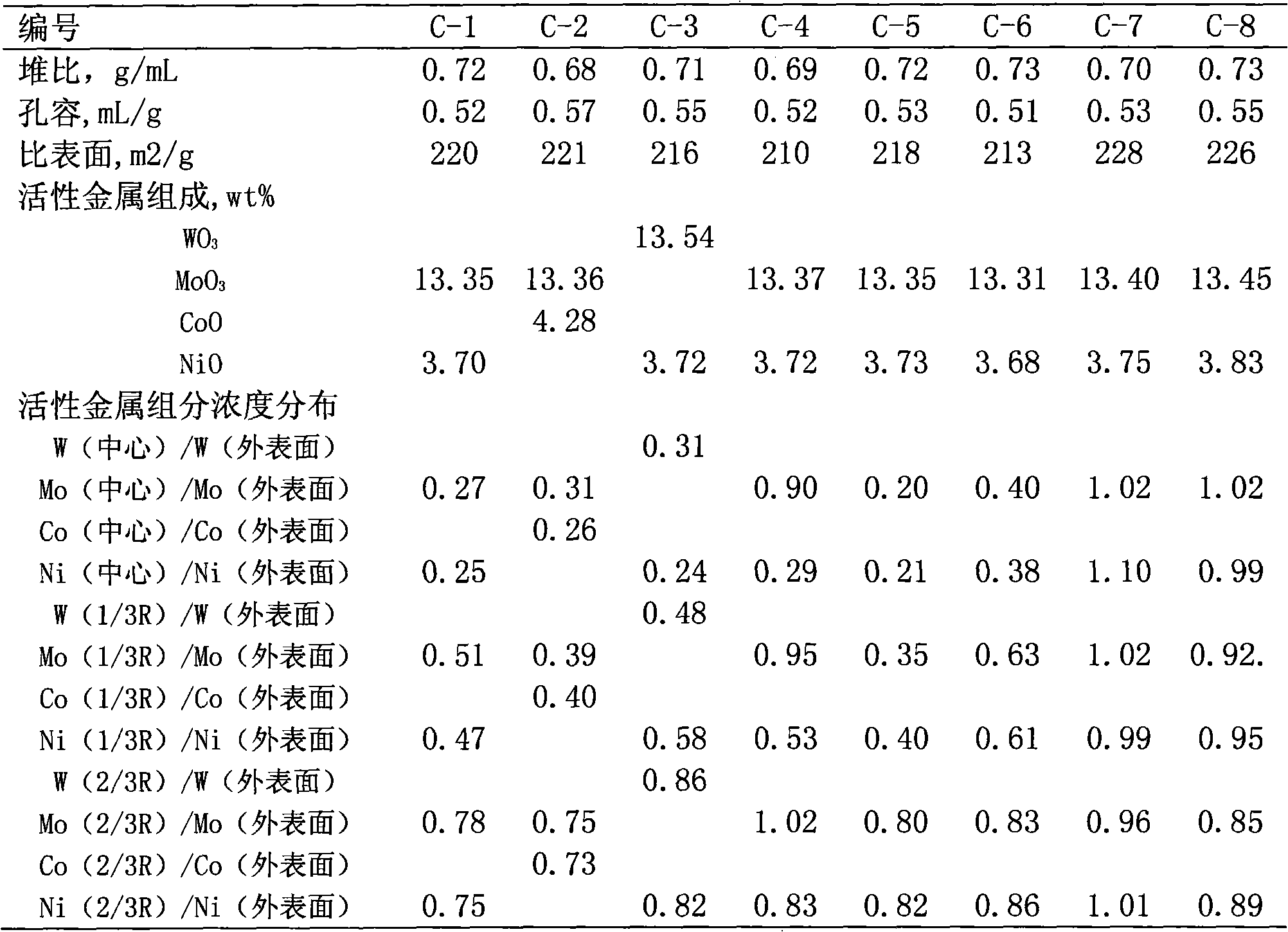

[0024] In this example, Al 2 o 3 As a carrier, the water absorption rate is 1.10mL / g. Catalysts with active metal components of Mo and Ni were prepared by saturated spray immersion method.

[0025] Weigh 150g of Al 2 o 3 Carrier, spray immersion 100mL ammonia solution with a concentration of 5%, drop 65mL containing 29.8g ammonium molybdate (containing MoO 3 82m%) and 27.0g of nickel nitrate (containing NiO 25.2m%) ammonia solution in the impregnating solution and stirred, dripping while spraying, 15 minutes to complete the spraying. After homogenizing in the spraying equipment for 10 minutes, dry at 60°C for 2 hours, take it out and dry at 120°C for 4 hours, and then bake in air at 500°C for 3 hours to obtain the catalyst, coded as C-1.

Embodiment 2

[0027] This example uses 1.5m% SiO 2 Al 2 o 3 As a carrier, the water absorption rate is 1.10mL / g. Catalysts with active metal components of Mo and Co were prepared by saturated spray immersion method.

[0028] Weigh 150g carrier, spray 100mL concentration of 5% ammonia solution, drop 65mL containing 29.8g ammonium molybdate (containing MoO 3 82m%) and 27.0g of ammonia solution of cobalt nitrate (containing CoO25.2m%) in the impregnating solution and stirred, and sprayed while dripping, and the spraying was completed in 10 minutes. After being homogenized for 10 minutes in the spray-dipping equipment, it was dried at 120°C for 5 hours, and then calcined in air at 500°C for 4 hours to obtain a catalyst, coded as C-2.

Embodiment 3

[0030] In this example, 1.0m% SiO 2 and 1.5m%TiO 2 Al 2 o 3 As a carrier, the water absorption rate is 1.10mL / g. The catalyst with active metal components of W and Ni was prepared by saturated spray immersion method.

[0031] Weigh 150g carrier, spray 100mL containing 10g ammonium metatungstate (containing WO 3 82m%) and 8g of nickel nitrate (containing NiO 25.2m%) ammonia solution, drop into 65mL containing 19.8g of ammonium metatungstate (containing WO 3 82m% mass) and 19.0g nickel nitrate (containing NiO 25.2m%) ammonia solution in the impregnation solution and stirred, while spraying while dripping, 20 minutes to complete the spraying. After homogenizing in the spraying equipment for 5 minutes, dry at 60°C for 2 hours, take it out and dry at 120°C for 6 hours, and then bake it in air at 500°C for 5 hours to obtain the catalyst, coded as C-3. vExample 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com