Prepn of nano barium sulfate

A nano-barium sulfate, nano-scale technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of wide particle size distribution, unstable conditions, large particle size of powder, etc., and achieve good resolubility and dispersibility , the effect of stable operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

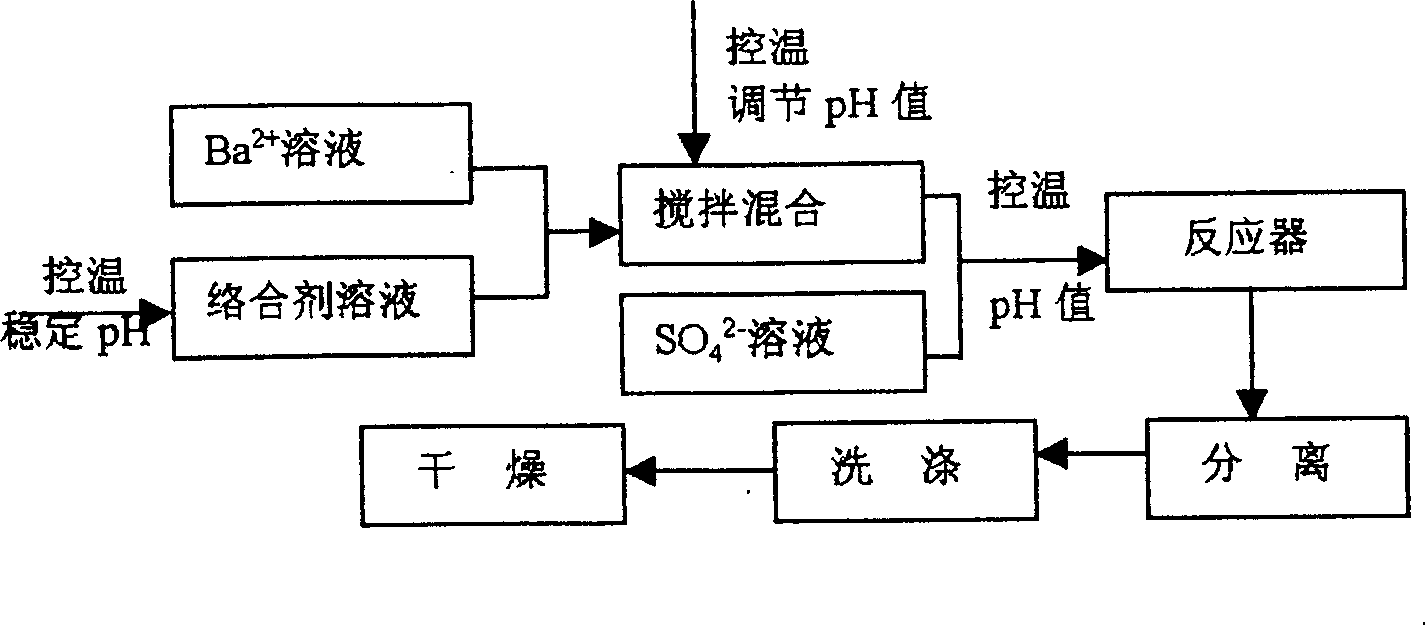

[0028] Adopt technological process of the present invention to attach figure 1 , prepare 0.6mol / L barium chloride solution and 0.6mol / L LEDTA solution and mix them under 400rpm stirring state, use ammonia water to adjust pH to 6~8, complexation time is 20min, add 0.6mol / L sodium sulfate solution, the whole reaction system Gradually from transparent to light blue, and finally bright milky white. The reaction product was separated by sedimentation to obtain a transparent gel, which was dried in an oven at 150° C. to obtain a transparent glassy solid. The average particle size of the barium sulfate particles obtained under this process condition is 25nm, the particle size distribution is 20-40nm, and the hexagonal crystal form is the main form.

Embodiment 2

[0030] Prepare 1.0mol / L barium chloride solution and 1.0mol / L LEDTA solution and mix them under 400rpm stirring state, use ammonia water to adjust pH to 6-8, complexation time is 20min, gradually pour 1.0mol / L sodium sulfate solution, the whole reaction system Gradually from transparent to light blue, and finally bright milky white. The reaction product was separated by sedimentation to obtain a transparent gel, which was dried in an oven at 150° C. to obtain a transparent glassy solid. The average particle size of the barium sulfate particles obtained under this process condition is 25nm, the particle size distribution is 20-40nm, and the hexagonal crystal form is the main form.

Embodiment 3

[0032] Prepare 2.0mol / L barium chloride solution and equimolar EDTA solution and mix them under low-speed stirring, use ammonia water to adjust the pH to 6-8, stir at 400rpm, after complexing for 20min, gradually pour into 2.0mol / L sodium sulfate solution , the whole reaction system gradually changed from transparent to light blue, and finally showed bright milky white. The reaction product was separated by sedimentation in a centrifuge to obtain a transparent gel, which was dried in an oven at 150° C. to obtain a transparent glassy solid. The average particle size of the barium sulfate particles obtained under this process condition is 25nm, the particle size distribution is 20-40nm, and the hexagonal crystal form is the main form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com