Pressure regulation system of ultra-low temperature refrigerating device

A technology for ultra-low temperature refrigerators and pressure regulation, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve the problems that the system cannot work normally, it is difficult to achieve the expected effect, and the filling pressure is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

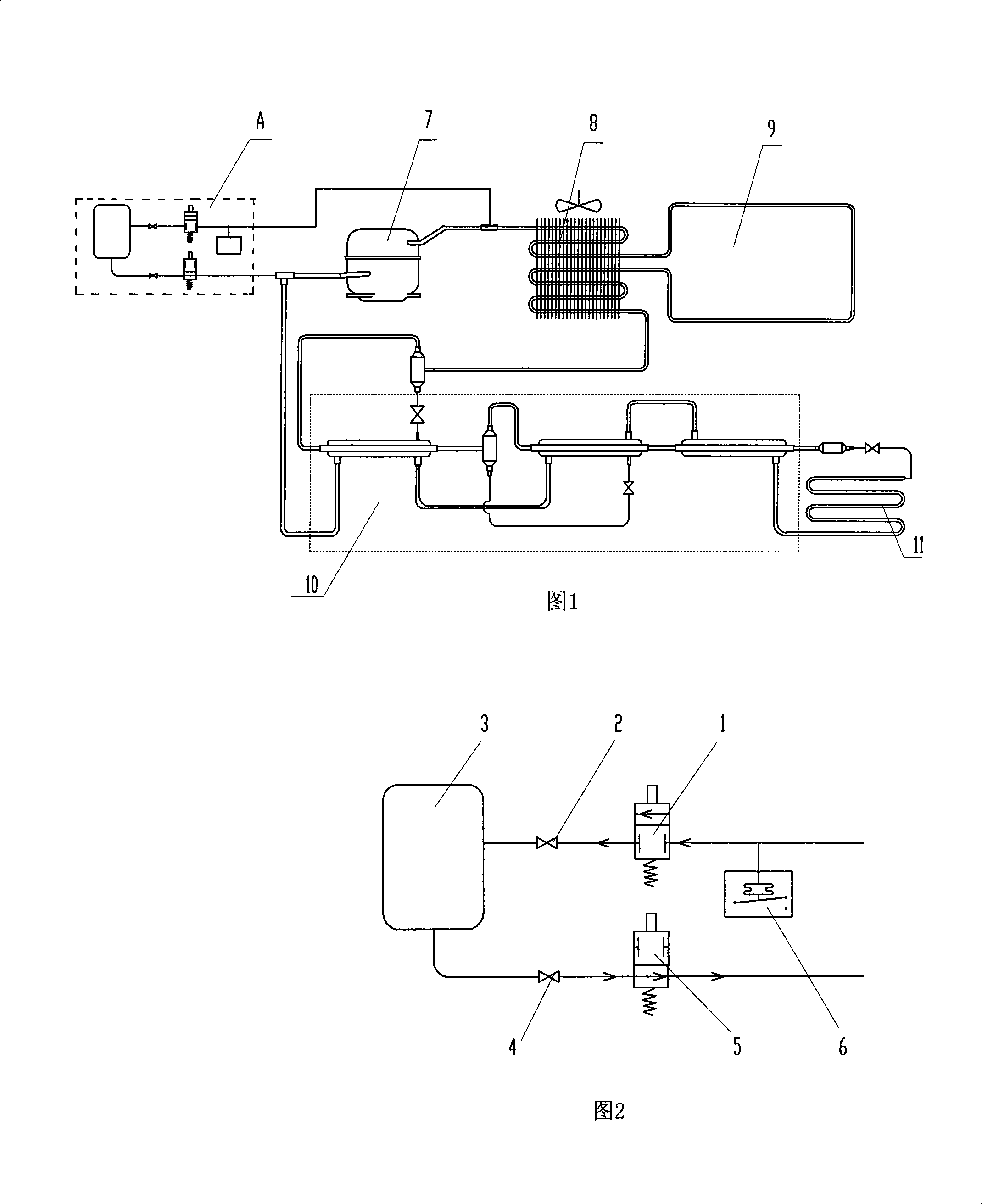

[0008] Referring to Fig. 1, a pressure regulating system for ultra-low temperature refrigerators is composed of a balance tank 3, a pressure controller 6, solenoid valves 1 and 5, and throttling elements 2 and 4, and the balance tank 3 passes through the solenoid valves 1 and 5. The throttling elements 2 and 4 are respectively connected to the high-pressure end and low-pressure end of the compressor 7, and the pressure controller 6 is installed in the high-pressure part of the refrigeration system to control the opening and closing of the solenoid valves 1 and 5. The opening and closing pressure points of the pressure controller 6 can be set according to the state of the refrigeration system. In order to achieve the purpose of controlling the excessive starting pressure of the system, when the refrigeration system is shut down, the solenoid valve 1 is in the closed state, that is, the high pressure part of the compressor is not connected to the balance tank 3; and the solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com