Express mail service envelope maker

A technology for express delivery and making machines, which is applied to envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc. It can solve the problems of large footprint and slow speed of the machine, and achieve reduced floor space, improved work efficiency, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical content of the present invention, the specific embodiments are specifically cited and described as follows in conjunction with the accompanying drawings:

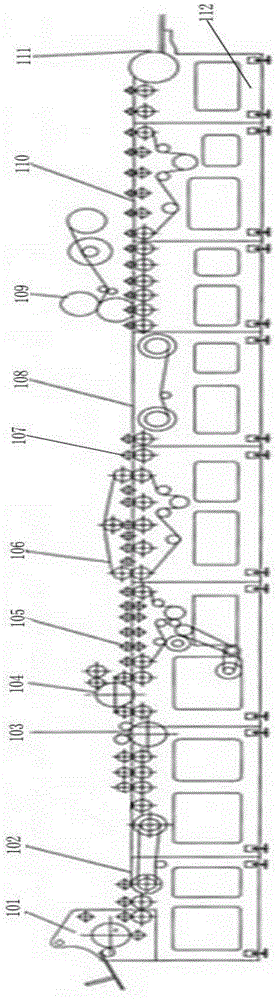

[0022] Such as figure 1 As shown, an EMS envelope making machine of the present invention includes: a paper feeding mechanism 101, a positioning mechanism 102, a horizontal folding mechanism 103, a gluing mechanism 104, a vertical folding mechanism 105, a sticking and pressing mechanism 106, and a 90° paper feed Turning mechanism 107, positioning mechanism two 108, sticking mechanism 109, sticking tongue edge mechanism 110, collecting mechanism 111 and support 112. Among them, paper feeding mechanism 101, positioning mechanism 1 102, horizontal folding mechanism 103, gluing mechanism 104, longitudinal folding mechanism 105, sticking and pressing mechanism 106, paper feeding 90° turning mechanism 107, positioning mechanism 2 108, sticking mechanism 109, sticking tongue The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com