Waste denitration catalyst regeneration zero-discharge wastewater treatment system

A wastewater treatment system and denitrification catalyst technology, which is applied in the direction of gaseous effluent wastewater treatment, dehydration/drying/thickened sludge treatment, neutralization water/sewage treatment, etc., can solve the problems of unreusable discharge water and waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

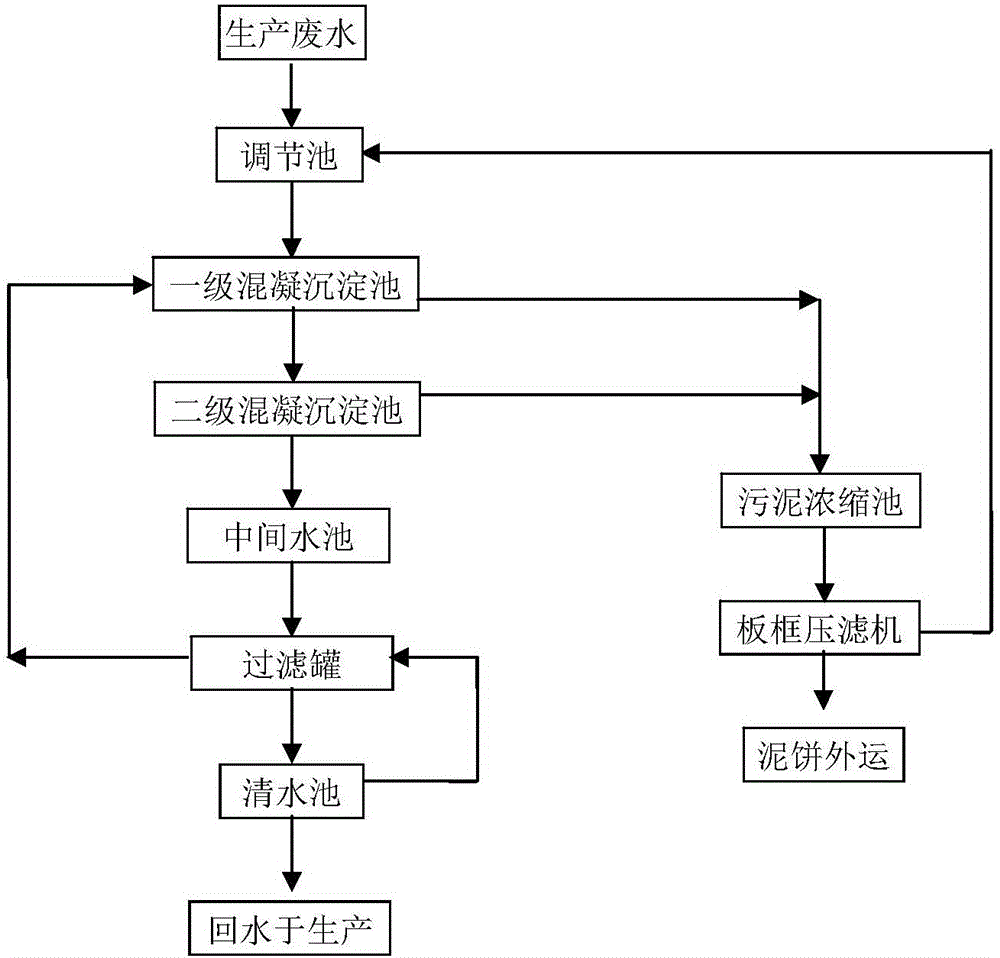

[0032] like figure 1 As mentioned above, the production wastewater treatment process is briefly described as follows:

[0033] (1) Centrally collect the production wastewater and enter it into the adjustment pool to adjust the water volume and quality, provide stable operating conditions for the sewage treatment system, and balance the quality of the sewage after entering the water treatment system;

[0034] Preferably, the pH value of the pool is adjusted to 3-4 before water intake.

[0035] (2) The wastewater regulated by the regulating tank is lifted by the pump and enters the primary coagulation sedimentation tank.

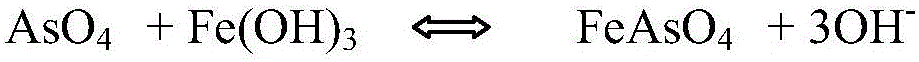

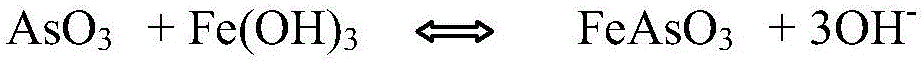

[0036] Chemical method for arsenic removal: using co-precipitation method, Fe 3+ Add it to waste water containing heavy metal ions, then add alkali to adjust the pH value to 8.50-9.0, and produce brown magnetic ferrite slag after blast oxidation for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com