Novel bean product production wastewater treating and recycling system

A production wastewater and recycling technology, which is applied in food industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., to achieve high load rate, strengthen water quality balance, and good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

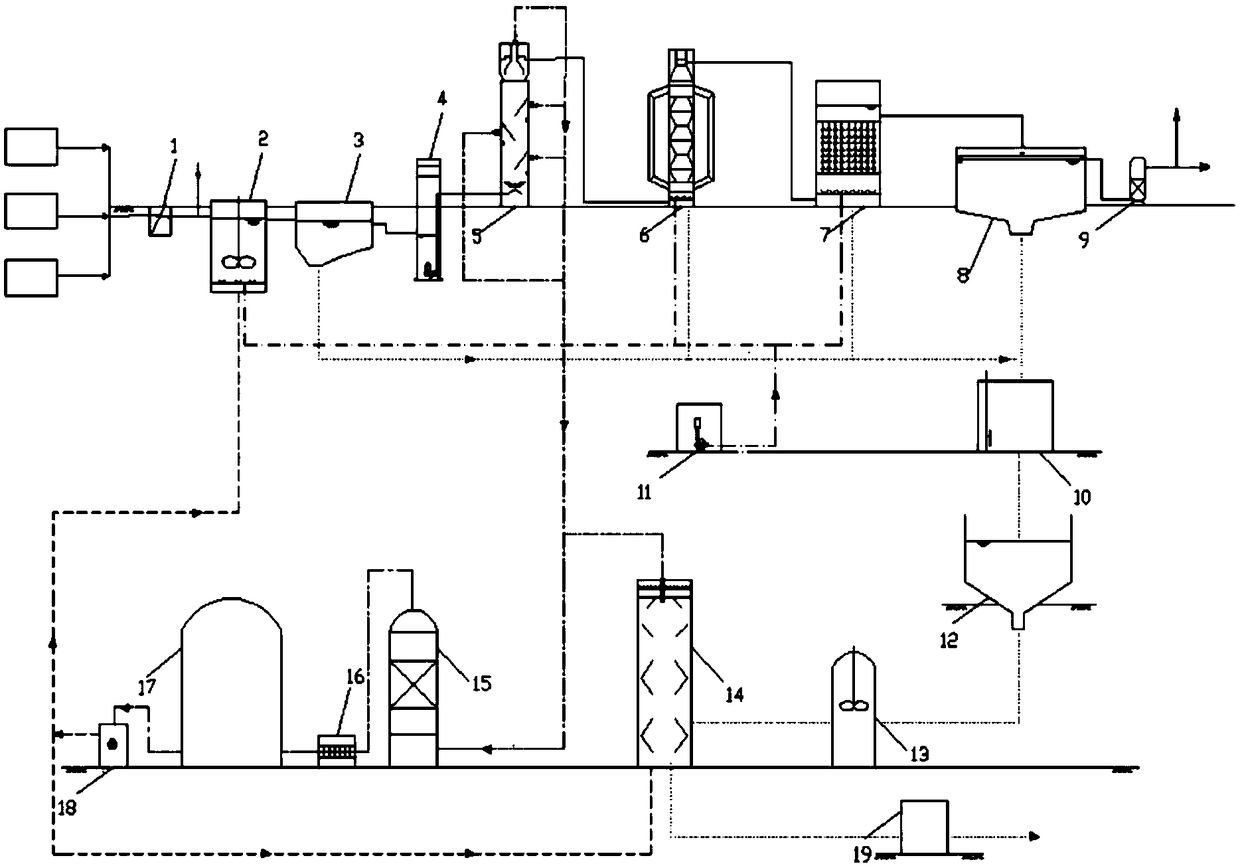

[0026] Such as figure 1 As shown, a new soybean product production wastewater treatment and resource recovery system, including wastewater treatment system, sludge treatment system and biogas resource recovery system;

[0027] The wastewater treatment system includes grid well 1, regulating tank 2, primary sedimentation tank 3, pump room 4, anaerobic fluidized bed 5, aerobic fluidized bed 6, aerobic contact oxidation reactor 7, secondary sedimentation tank 8 , activated carbon filter tank 9 and blower 11, the outlet pipe of the grid well 1 is connected with the inlet pipe of the regulating tank 2 through a sewage pipeline, and the outlet pipe of the regulating pond 2 is connected with the inlet pipe of the primary sedimentation tank 3 through a sewage pipeline , the outlet pipe of the primary sedimentation tank 3 is connected with the inlet pipe of the pump room 4 through a sewage pipeline, the outlet pipe of the pump room 4 is connected with the inlet pipe of the anaerobic fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com