Side-hanging type polymethyl methacrylate rare earth complex luminescent material and preparation method thereof

A technology of polymethyl methacrylate and rare earth complexes, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of difficult coordination, fluorescence quenching, limited types, etc., and achieves elimination of concentration quenching effect and fluorescence. Increased intensity, less interference with purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]The side-hanging polymethyl methacrylate rare earth complex luminescent material is a random copolymer of polymethyl methacrylate with a side-hanging aromatic carboxylic acid as a polymer ligand, and o-phenanthroline as a co-ligand. Coordinated rare earth europium ions in N,N-dimethylformamide; among them, the structural formula of the polymer ligand is Di-poly(MMA-ran-HEA)-92%, and the structure unit of methyl methacrylate The mole fraction is 0.92.

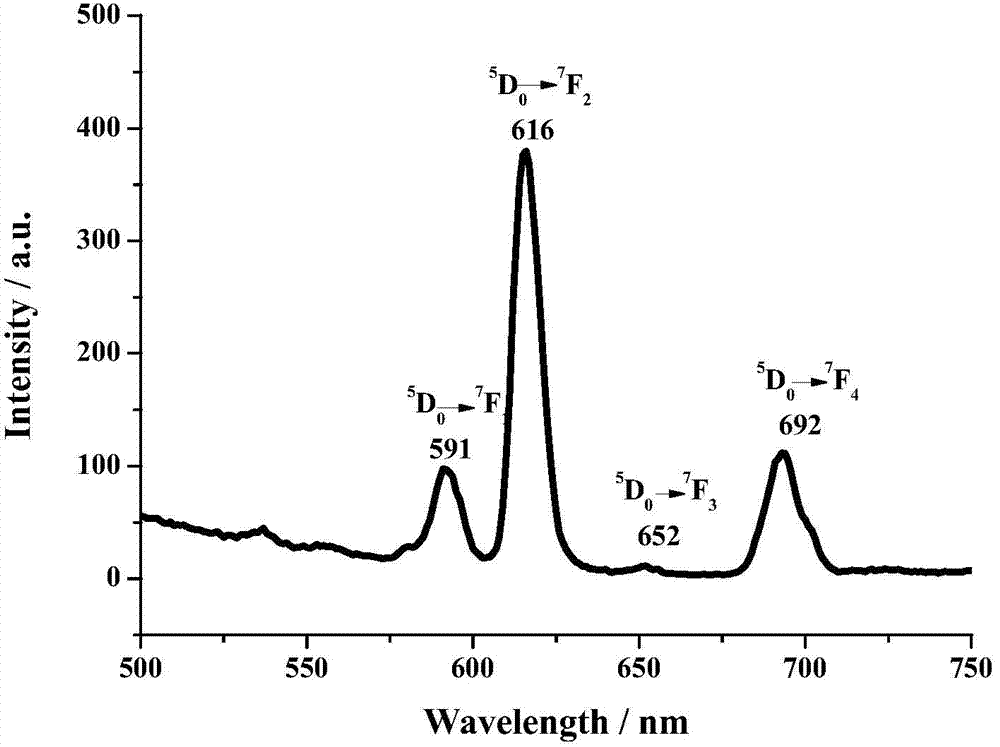

[0037] The preparation method of the above-mentioned side-hanging polymethyl methacrylate rare earth complex luminescent material is as follows: 1g of the polymer ligand Di-poly(MMA-ran-HEA)-92% (containing 1.37mmol of carboxyl groups), 0.247g of phenanthrene Roline (1.37mmol) and 0.354g europium trichloride (1.37mmol) were added in the reaction flask, added 10mLN,N-dimethylformamide, stirred at room temperature to dissolve it; then added 0.15g triethylamine, and Stir and react for 12 hours; after the reaction is complete...

Embodiment 2

[0041] In Example 1, the polymer ligand Di-poly(MMA-ran-HEA)-92% was replaced by the polymer ligand Di-poly(MMA-ran-HEA)-90%, other raw material ratios, reaction conditions and treatment Step is with embodiment 1.

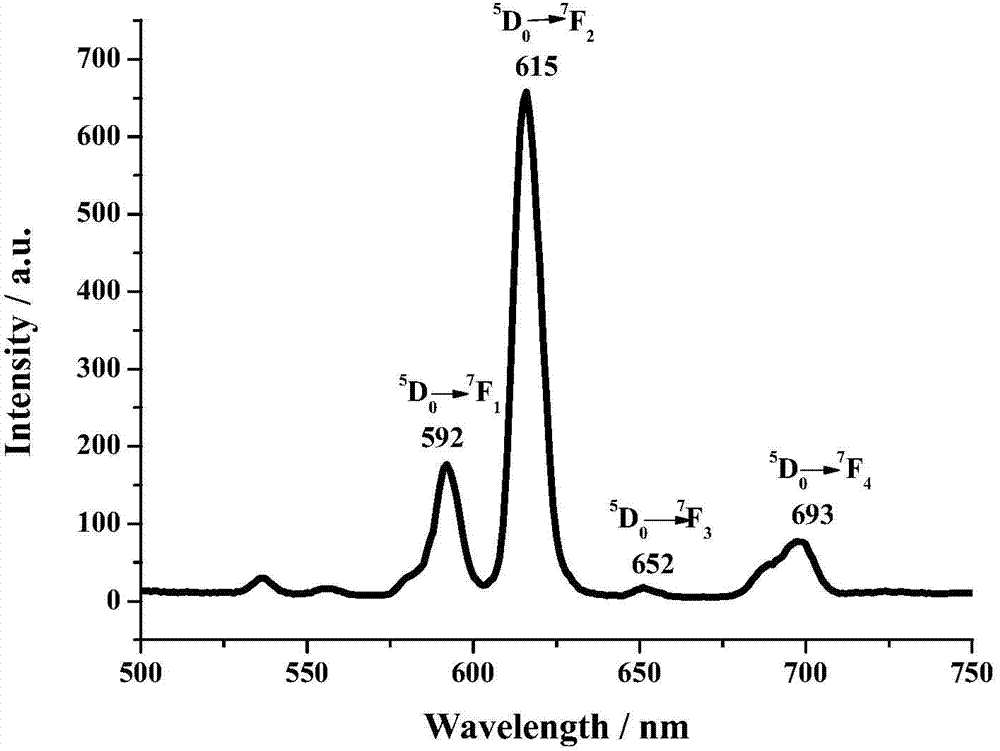

[0042] The side-hanging type polymethyl methacrylate europium complex luminescent material obtained in this example is in the form of powder, with a yield of 94.8%. The fluorescence spectrum is shown in image 3 .

Embodiment 3

[0044] The side-hanging polymethyl methacrylate rare earth complex luminescent material is a random copolymer of polymethyl methacrylate with side-hanging aromatic carboxylic acid as the polymer ligand, and 2,2'-bipyridine as the co-ligand Body, obtained by coordination with rare earth terbium ions in N,N-dimethylacetamide; wherein, the structural formula of the polymer ligand is Tri-poly(MMA-ran-HEA)-92%, methyl methacrylate The mole fraction of the structural unit is 0.92.

[0045] The preparation method of the side-hanging polymethyl methacrylate rare earth complex luminescent material is as follows: 1 g of the polymer ligand Tri-poly(MMA-ran-HEA)-92% (containing 1.37 mmol of carboxyl groups), 0.43 g of 2, 2'-Bipyridine (2.75mmol) and 0.58g terbium trichloride (2.20mmol) were added to the reaction flask, 10mL N,N-dimethylacetamide was added, stirred at room temperature to dissolve; then 0.25g tributyl Amine, stirred and reacted at 60°C for 4 hours; cooled after the complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com