Non-ionic aqueous HDI polyurethane curing agent preparation method

A polyurethane curing agent, non-ionic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult to popularize water-based paint, high cost, high price, etc., achieve high fullness, good yellowing resistance , The effect of strong pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

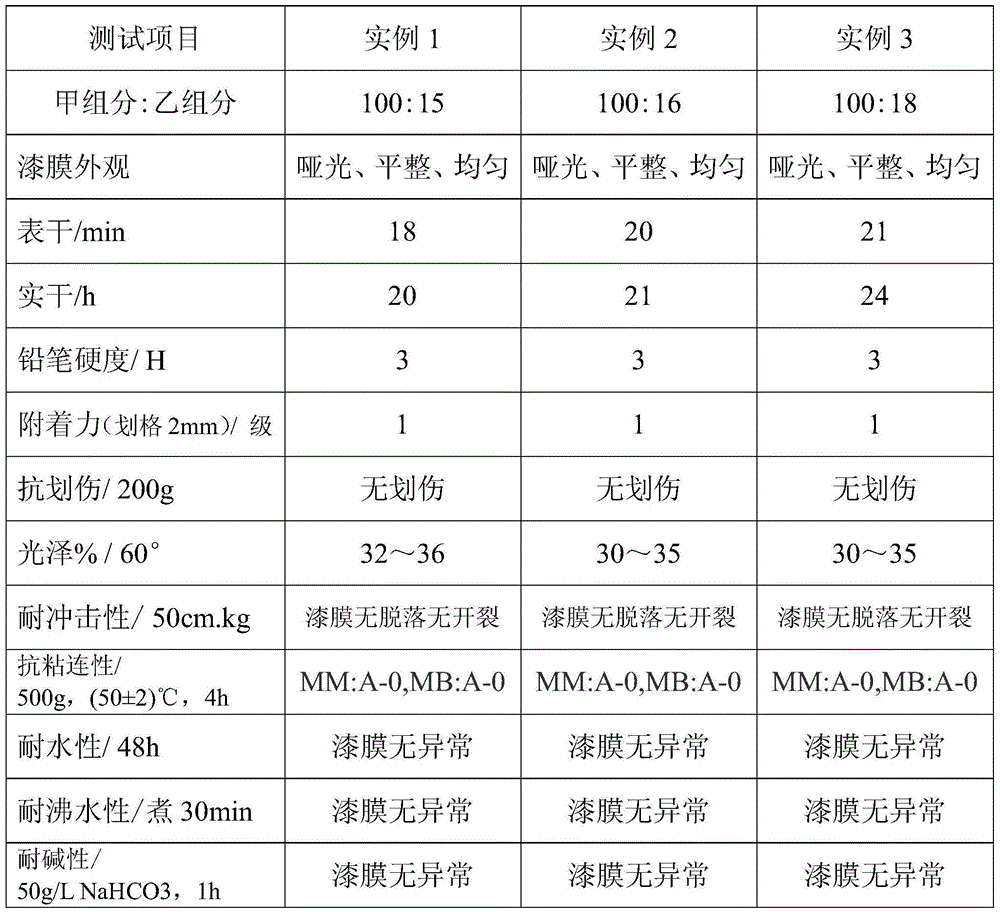

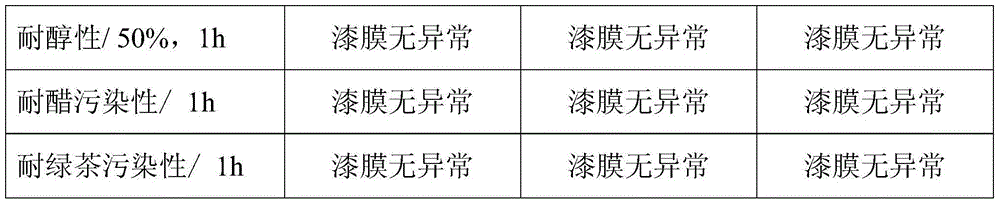

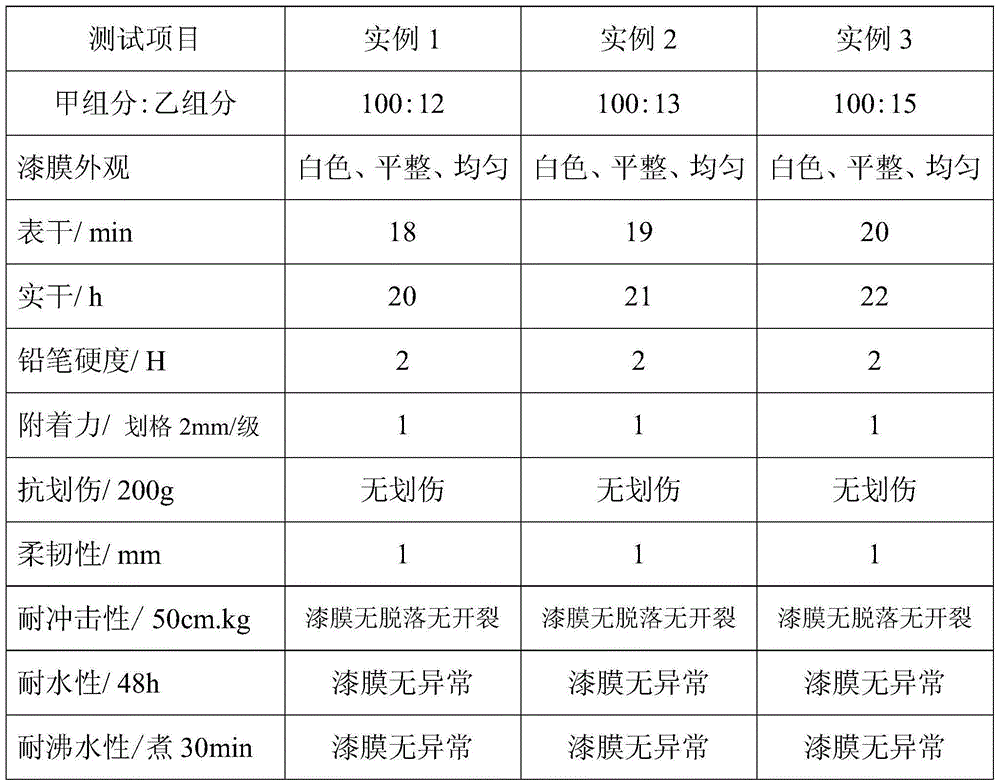

Examples

Embodiment 1

[0010] In the synthesis kettle, add 20 parts of dried diethylene glycol ethyl ether acetate, after heating and dissolving 68 parts of HDI trimer (NCO content 21.5%), add 12 parts of polyethylene glycol monobutyl ether (Mr1000), Introduce N2 protection, react at 50-55°C for 1 hour, keep constant temperature at 105-110°C for 2.5 hours, cool and filter to obtain a solid content of 80%, NCO content of 18.2%, and viscosity of 2500mPa·s Non-ionic water-based HDI polyurethane curing agent.

Embodiment 2

[0012] In the synthesis kettle, add 25 parts of dried propylene glycol methyl ether acetate, after heating and dissolving 65 parts of HDI trimer (NCO content 20.6%), add 10 parts of polyethylene glycol (Mr1000) and feed N2 protection, in After reacting at 60°C for 1 hour, keep the constant temperature reaction at 100°C for 2.5-3 hours, cool and filter to prepare a non-ionic water-based HDI polyurethane curing agent with a solid content of 75%, an NCO content of 17.5%, and a viscosity of 2300mPa·s .

Embodiment 3

[0014] In the synthesis kettle, add 20 parts of dried dipropylene glycol butyl ether, heat and dissolve 60 parts of HDI trimer (NCO content 21.6%), then add 10 parts of polyethylene glycol monomethyl ether (Mr600) and 10 parts of poly Oxypropylene glycol (Mr1000), N 2 Protection, after reacting at 60°C for 1 hour, keep the constant temperature reaction at 100°C for 2.5-3 hours, cool and filter to obtain a non-ionic water-based HDI with a solid content of 80%, an NCO content of 15.6%, and a viscosity of 2400mPa·s Polyurethane curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com