Patents

Literature

1762 results about "Bisphenol-A-polycarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA).

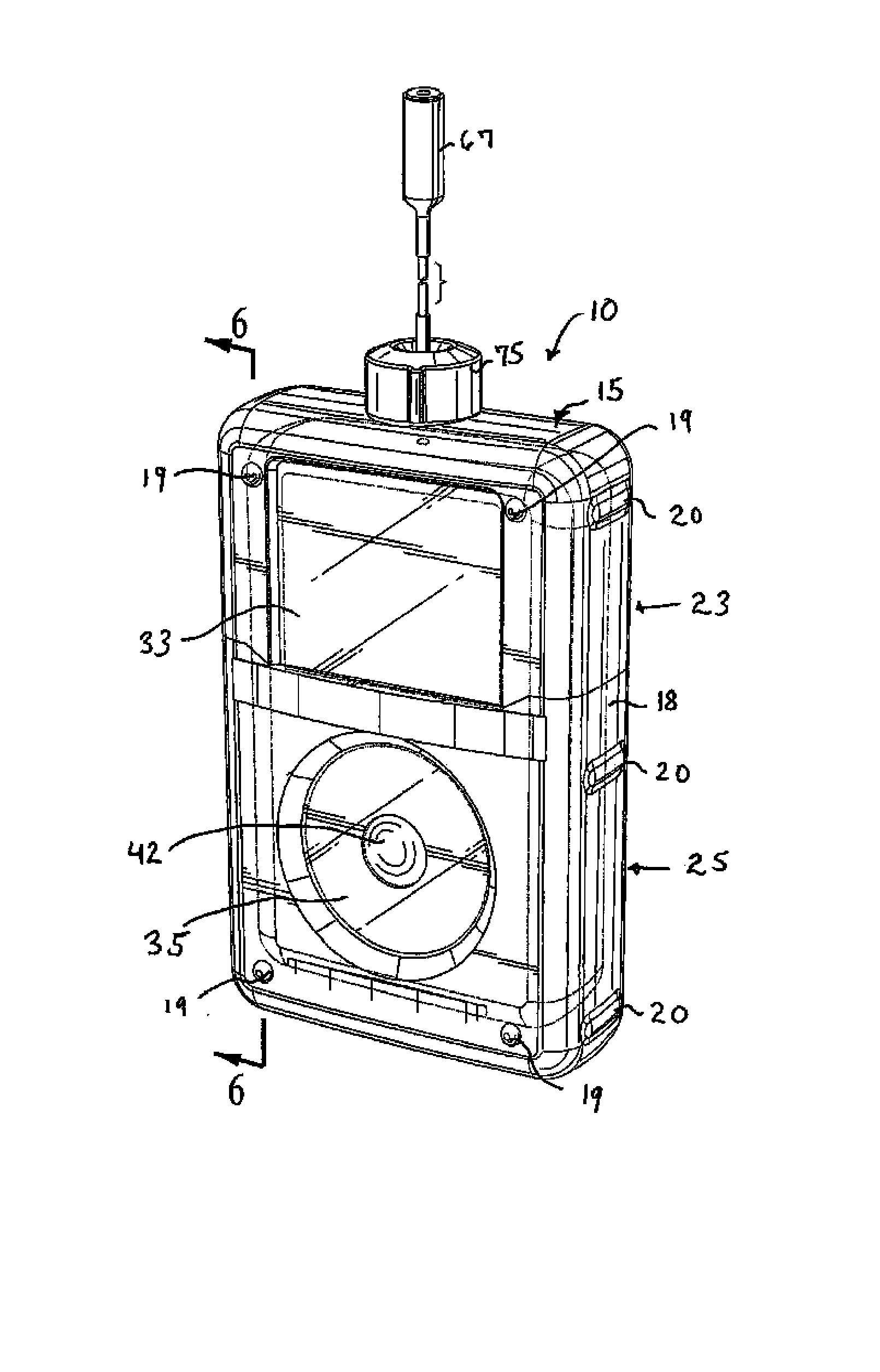

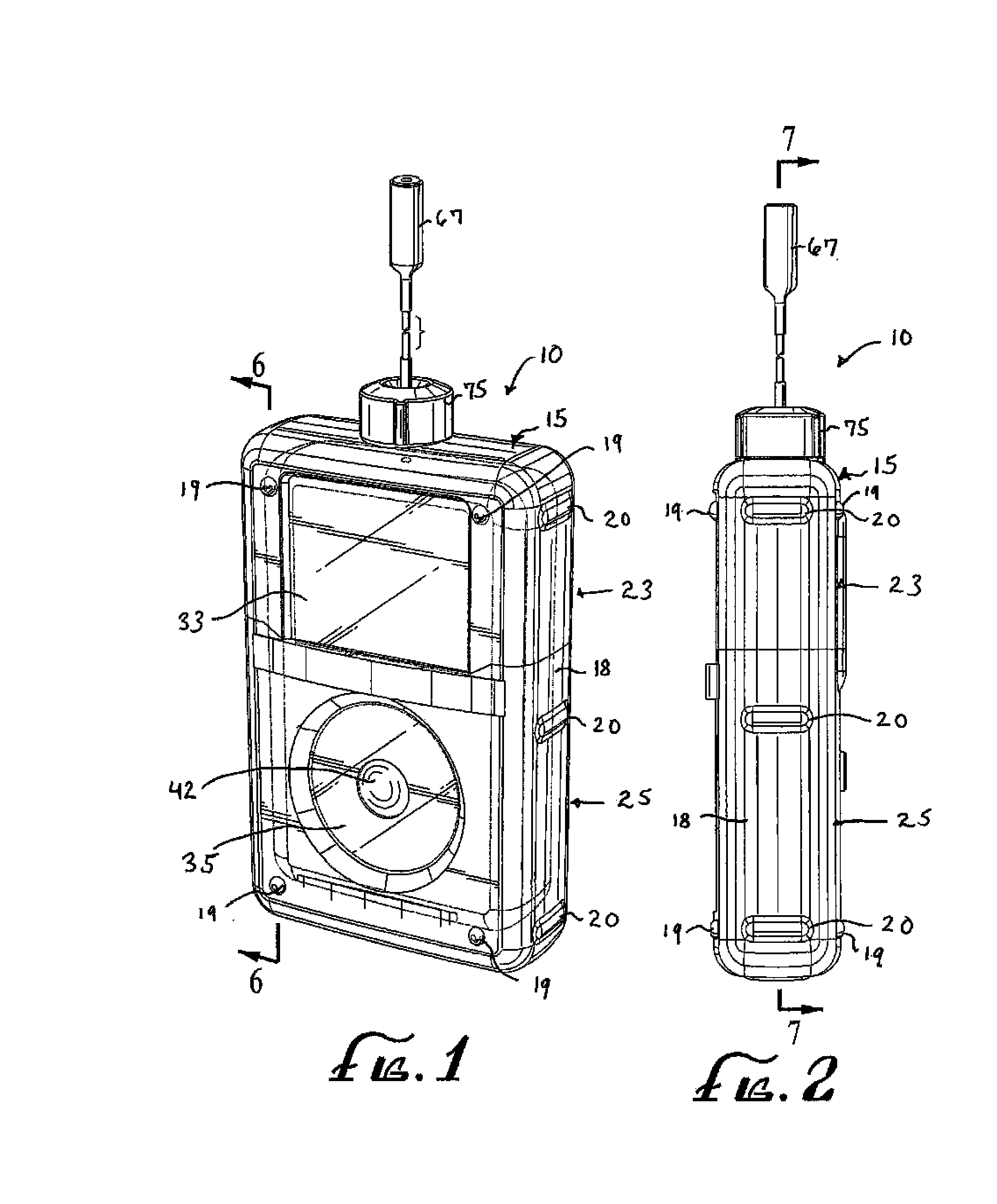

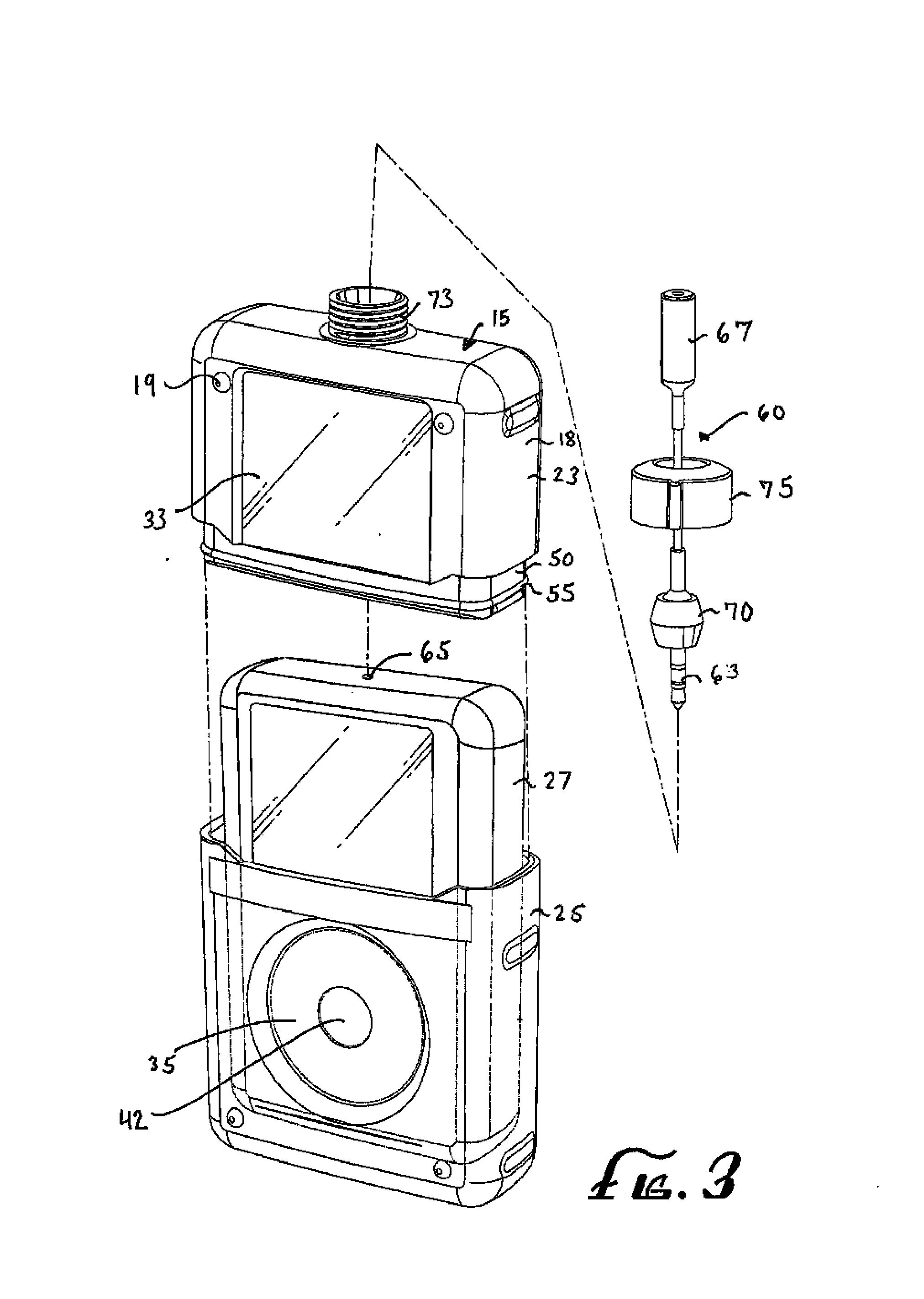

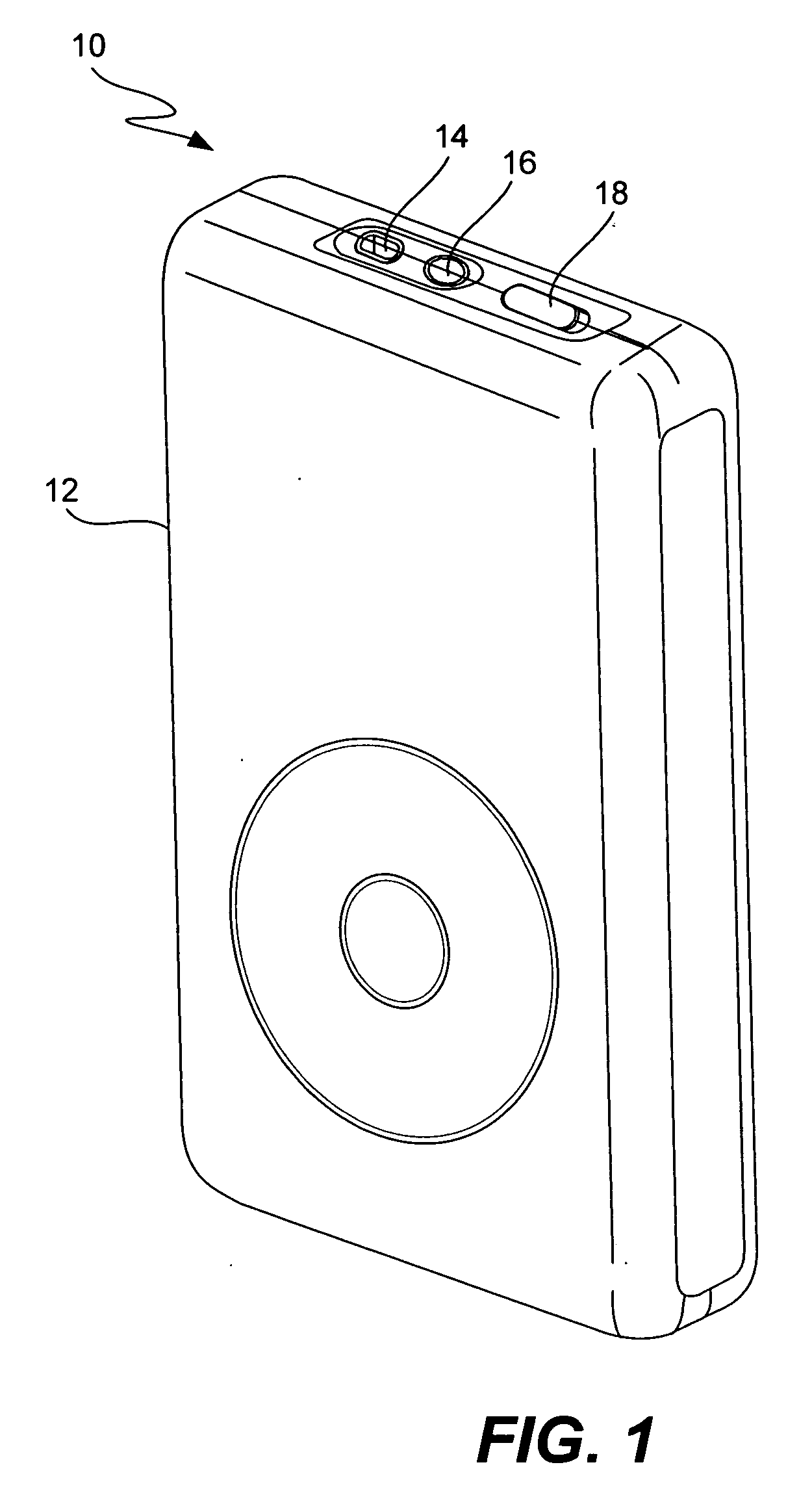

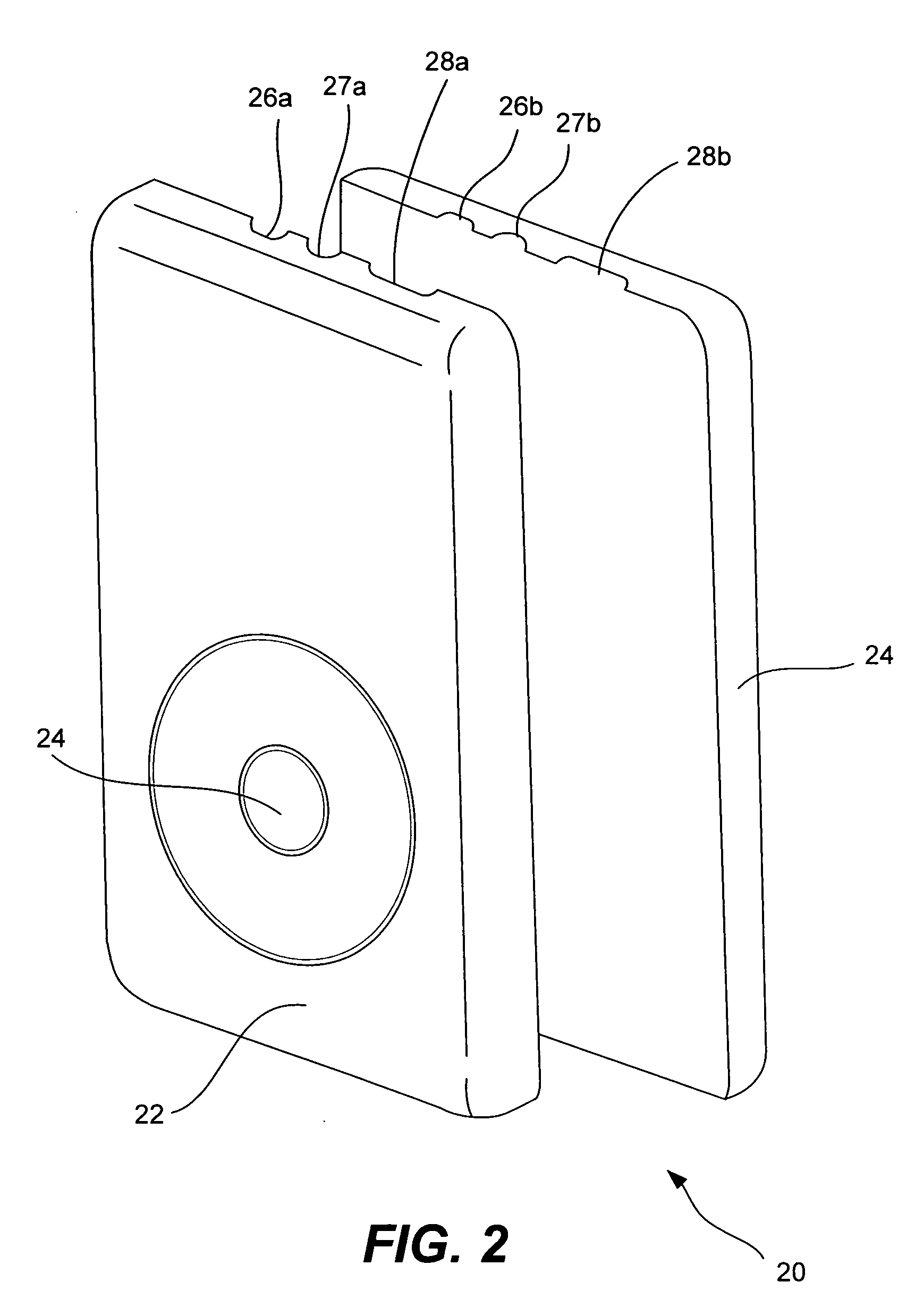

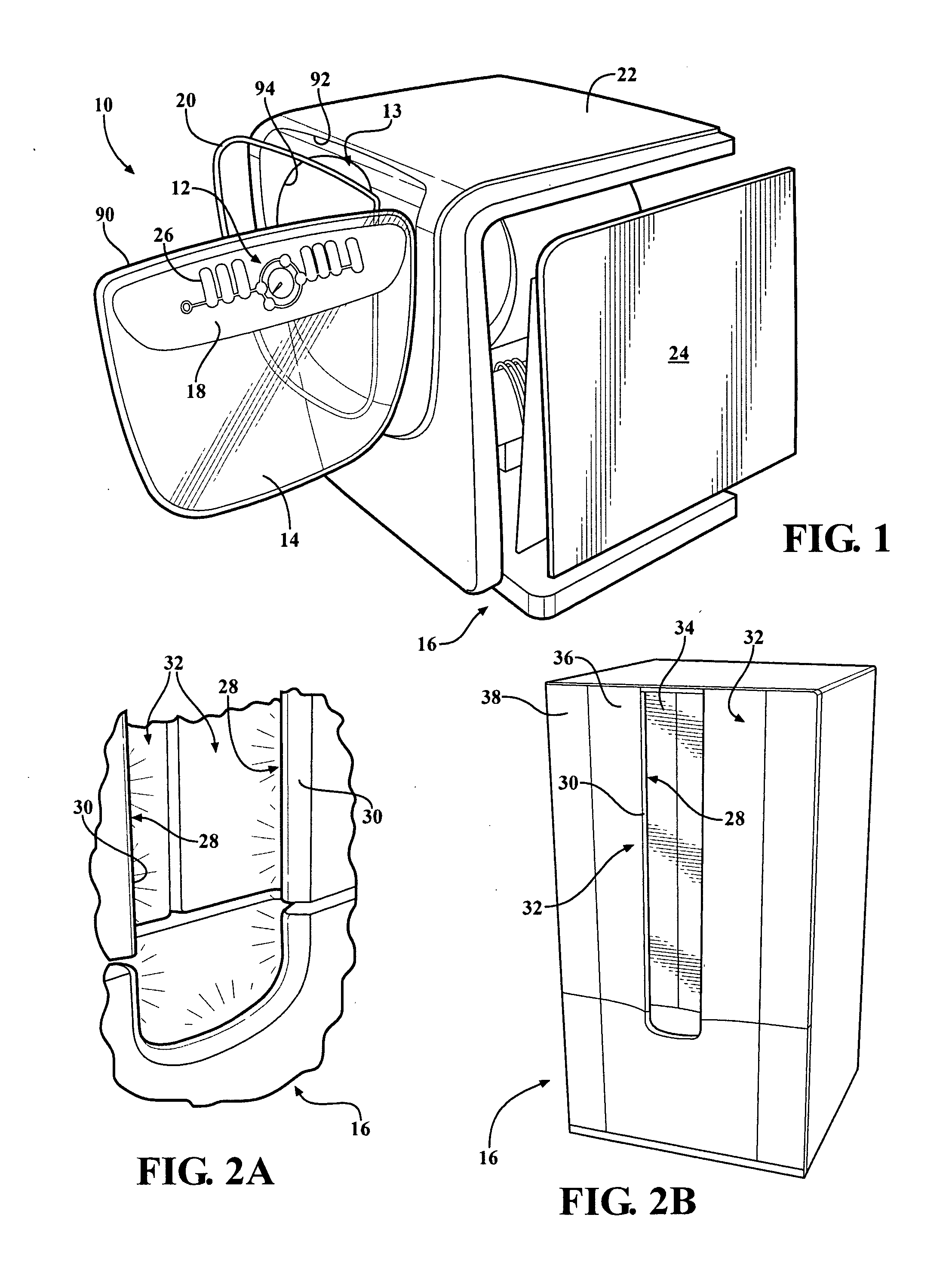

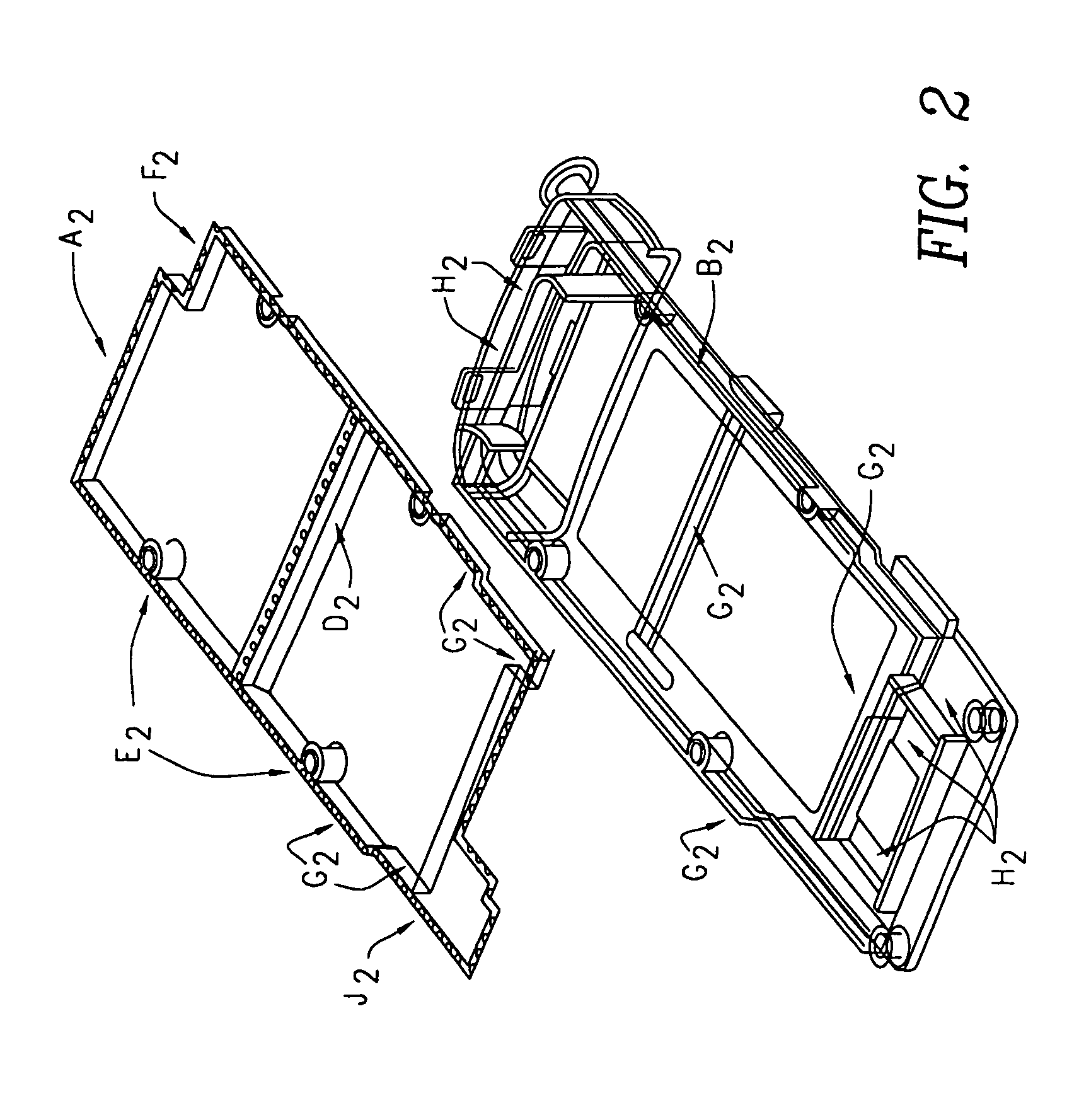

Waterproof case for electronic devices

The present invention provides protective waterproof cases for portable media players such as iPods. In an exemplary embodiment, the waterproof case comprises a transparent polycarbonate shell having an interior compartment formed therein and comprising upper and lower portions that can be detached for placing a portable player in the interior compartment. A polyurethane overmold is molded over selected portions of the shell to form protective layers on the exterior and interior surfaces of the shell. The waterproof case also comprises a window through which the screen of the player can be viewed, and a flexible pad for operating the player while it is in the waterproof case. The waterproof case further comprises a gasket for forming a watertight seal between the upper and lower portions of the shell when they are attached, and a compressible fitting for forming a watertight seal for a headphone connected to the player in the case.

Owner:SKB CORP

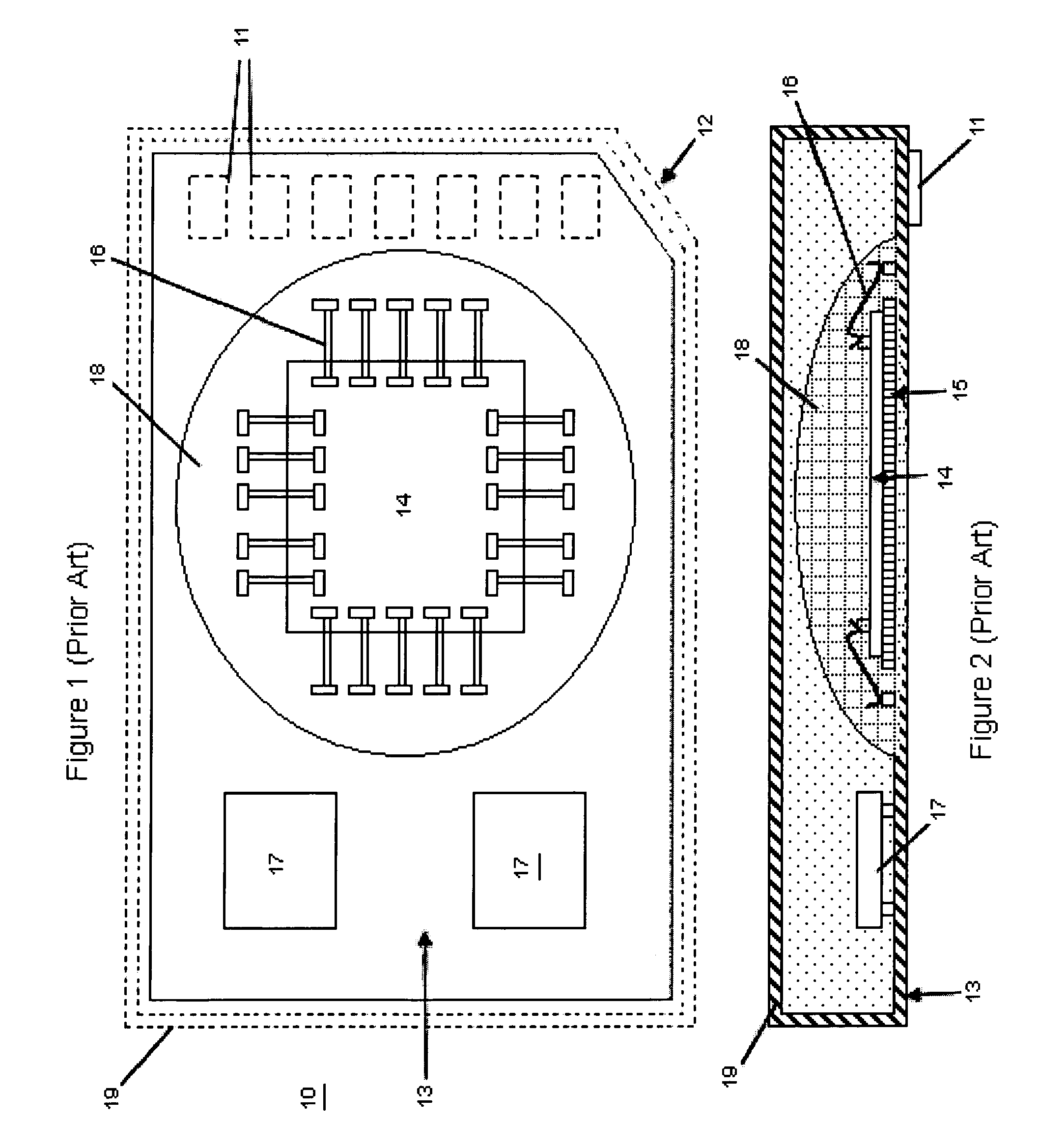

Method for making memory cards and similar devices using isotropic thermoset materials with high quality exterior surfaces

InactiveUS7225537B2Shorten the timeQuality improvementPrinted circuit assemblingLine/current collector detailsEngineeringInjection moulding

Memory Cards containing Integrated Circuits and other electronic components (e.g. resistors) in a variety of form factors having high quality external surfaces of polycarbonate, synthetic paper (e.g. Teslin), or other suitable material (e.g. PVC) can be made through use of injection molded thermoplastic material or thermosetting material that becomes the core layer of said Memory Cards and similar devices. The object of the invention is to provide the following properties to Memory Cards: rapid production cycle, high volume manufacturing throughput, security, electronics protection, better tamper resistance, durability, and highly reliable complex electronics encapsulation, achieved through a process utilizing low temperature and low pressure.

Owner:CARDXX

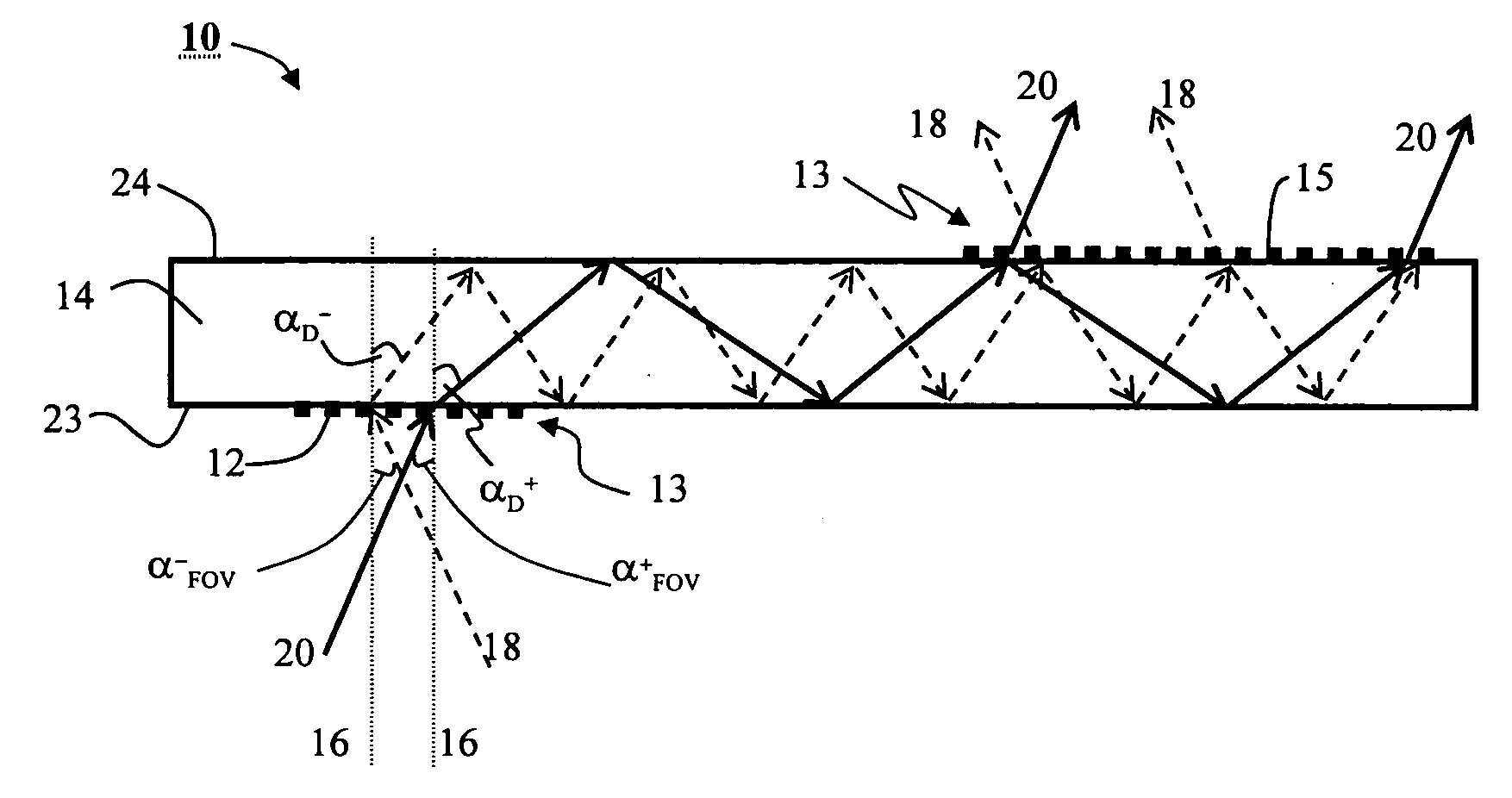

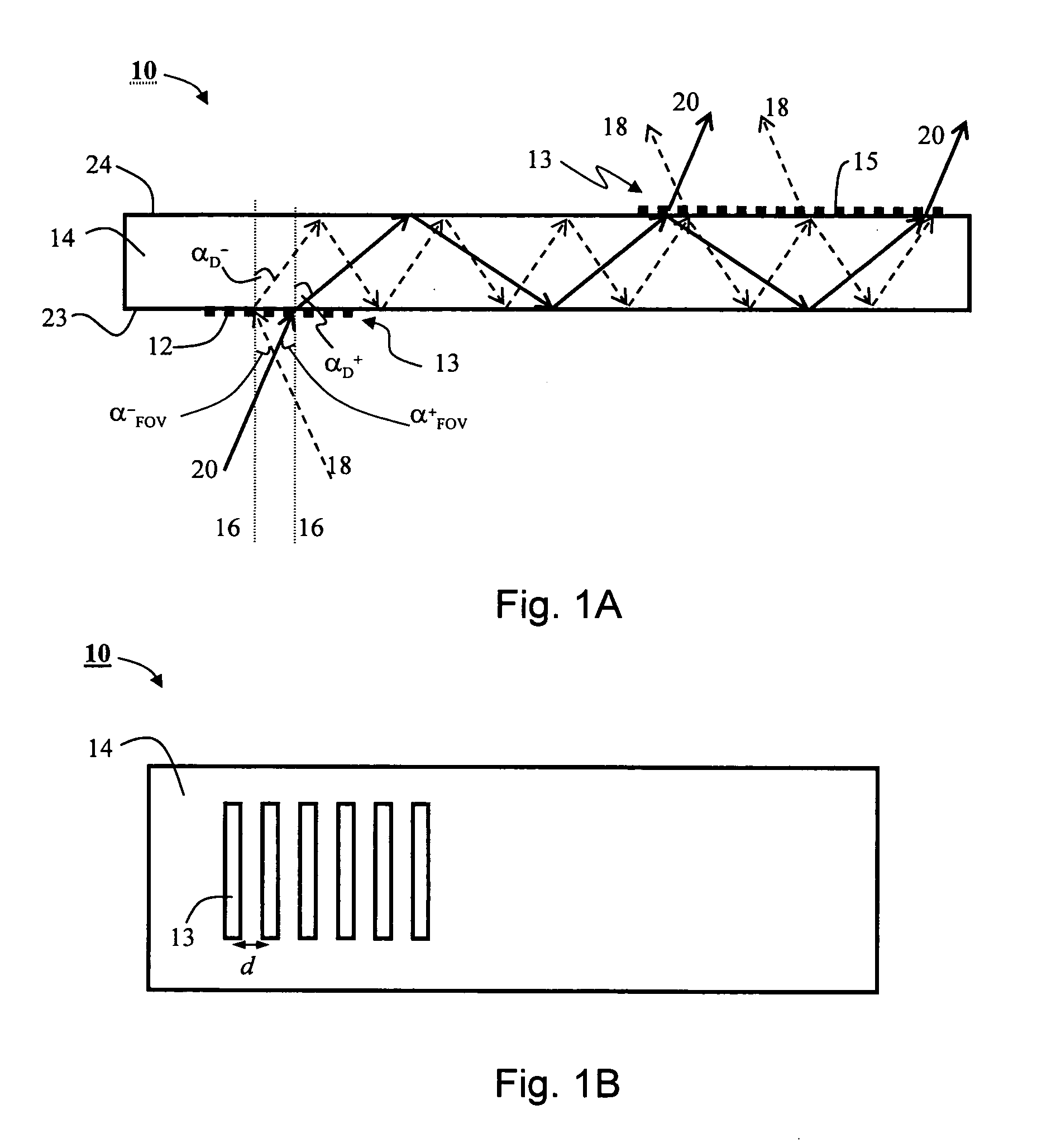

Diffractive optical relay and method for manufacturing the same

InactiveUS20080043334A1Diffraction gratingsPlanar/plate-like light guidesRefractive indexCyclo olefin polymer

An optical relay device, comprising a substrate, and at least one diffractive optical element is disclosed. The substrate is made, at least in part, of a light transmissive polymeric material characterized by a birefringence, Δn, satisfying the inequality |Δn|<ε, where ε is lower than the birefringence of polycarbonate. In a preferred embodiment, the light transmissive polymeric material comprises a cycloolefin polymer or a cycloolefin copolymer.

Owner:MIRAGE INNOVATIONS

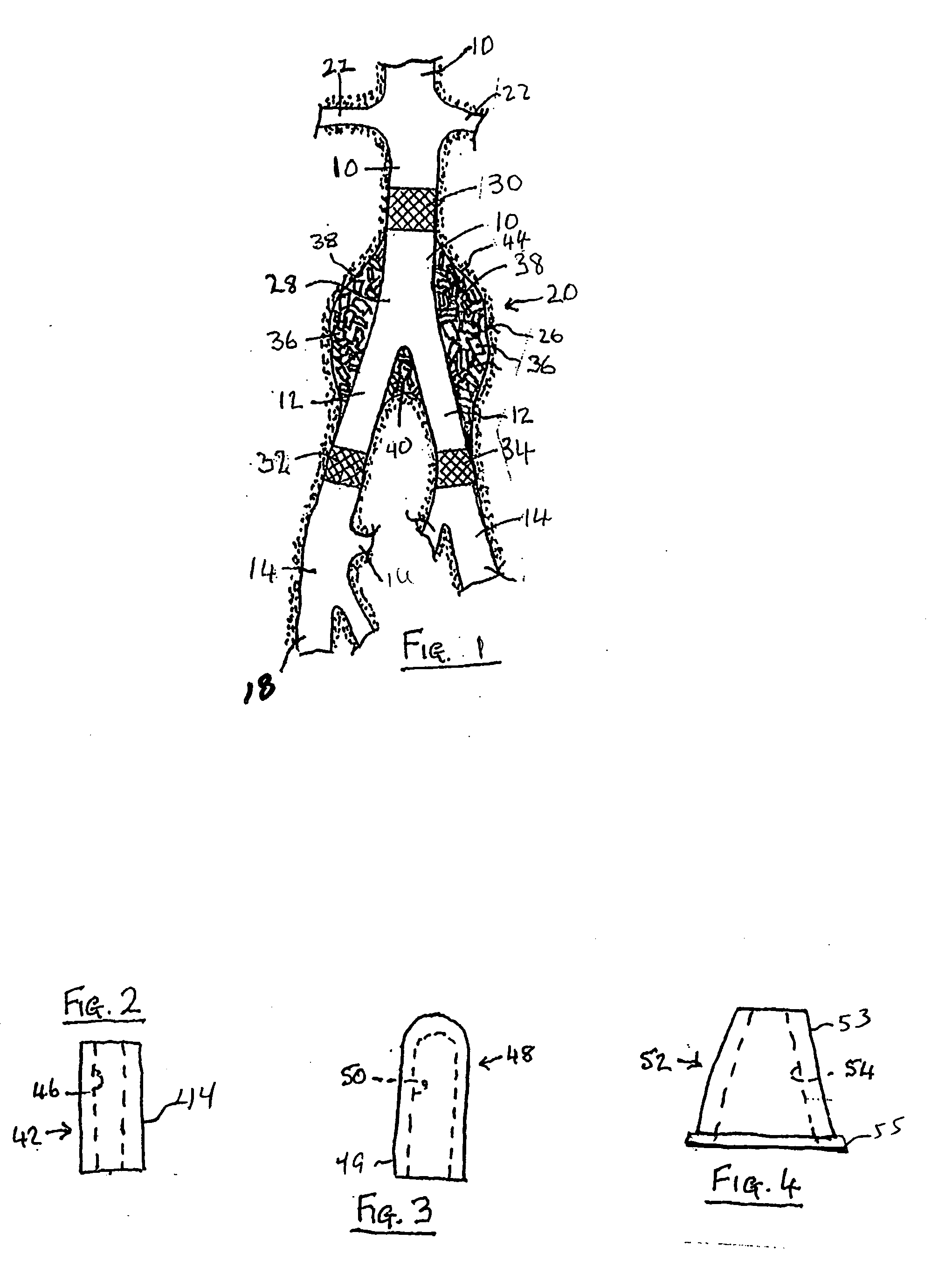

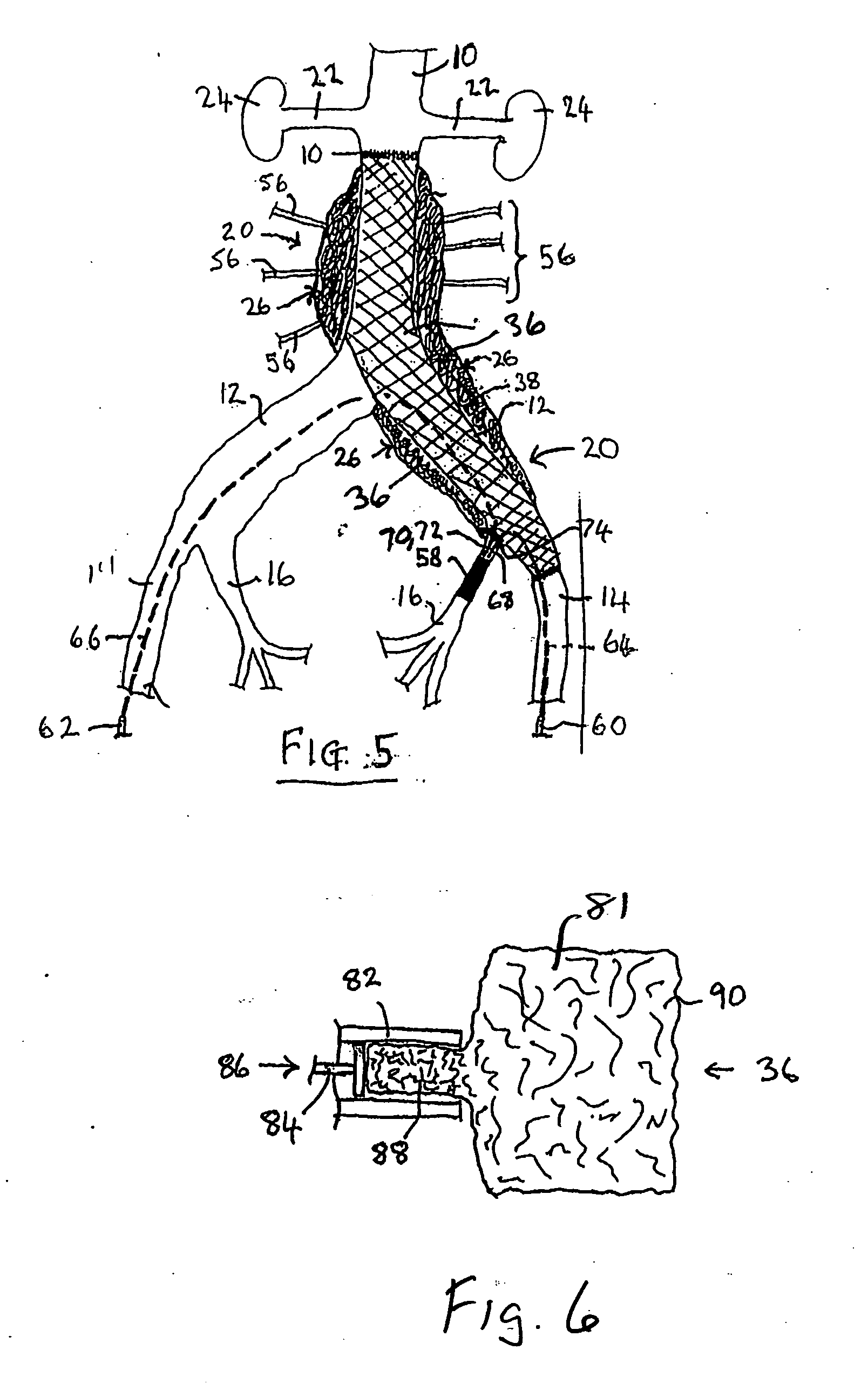

Bioabsorbable polymeric implants and a method of using the same to create occlusions

A new embolic agent, bioabsorbable polymeric material (BPM) is incorporated to a Guglielmi detachable coil (GDC) to improve long-term anatomic results in the endovascular treatment of intracranial aneurysms. The embolic agent, comprised at least in part of at least one biocompatible and bioabsorbable polymer and growth factors, is carried by hybrid bioactive coils and is used to accelerate histopathologic transformation of unorganized clot into fibrous connective tissue in experimental aneurysms. An endovascular cellular manipulation and inflammatory response are elicited from implantation in a vascular compartment or any intraluminal location. Thrombogenicity of the biocompatible and bioabsorbable polymer is controlled by the composition of the polymer. The coil further is comprised at least in part of a growth factor or more particularly a vascular endothelial growth factor, a basic fibroblast growth factor or other growth factors. The biocompatible and bioabsorbable polymer is in the illustrated embodiment at least one polymer selected from the group consisting of polyglycolic acid, poly˜glycolic acid / poly-L-lactic acid copolymers, polycaprolactive, polyhydroxybutyrate / hydroxyvalerate copolymers, poly-L-lactide. Polydioxanone, polycarbonates, and polyanhydrides.

Owner:RGT UNIV OF CALIFORNIA

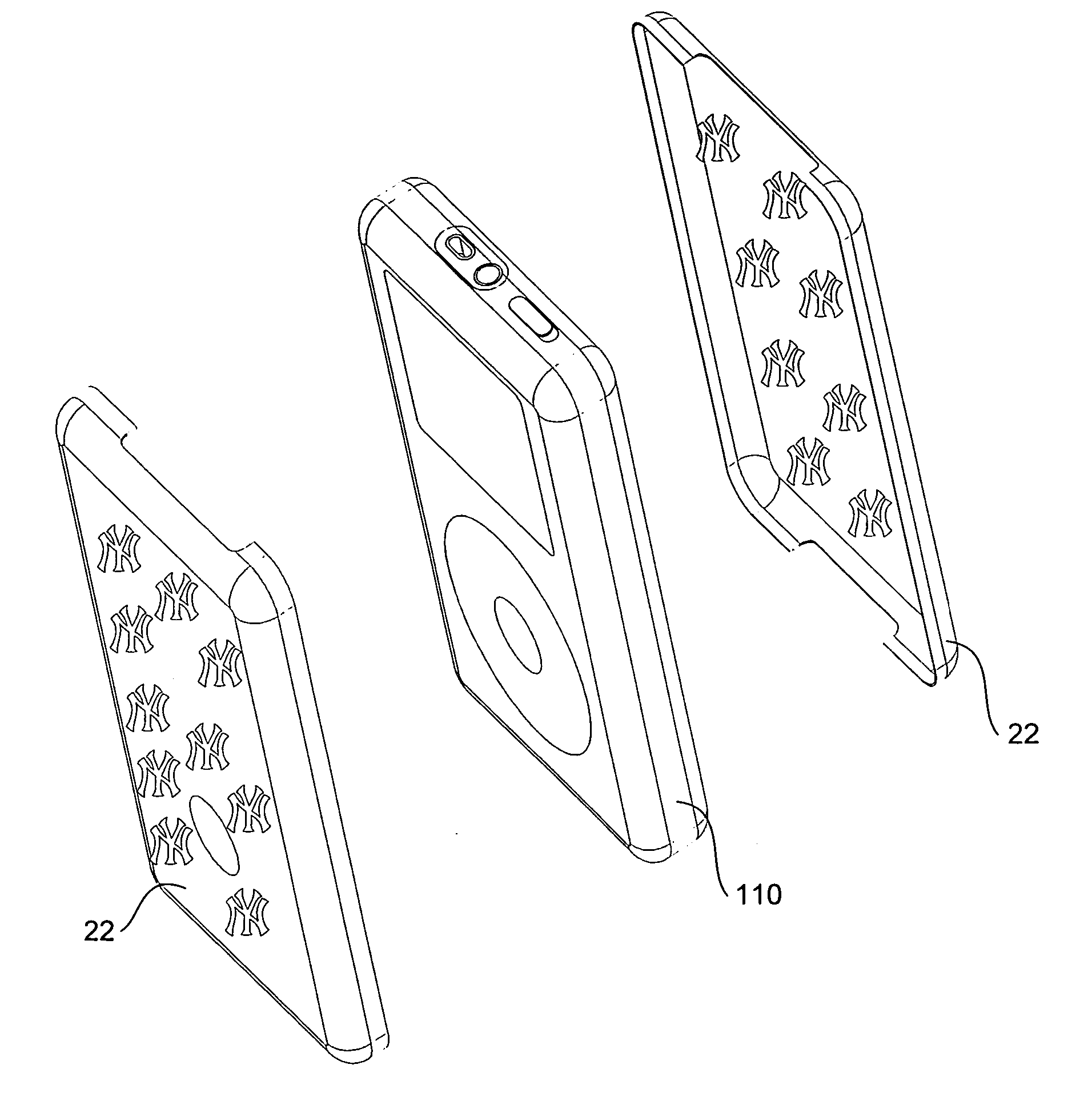

Apparatus and method for making form-fitted molded protective cases for products

A method and apparatus for making inexpensive, form-fitted, protective cases of thermal plastic or polycarbonate material that can be easily printed with decorative imagery and / or electronic circuitry for a variety of products, such as portable music players or radios, cell phones, lap-top computers, and the like. The method involves creating a tool having substantially the same surface dimensions of a product. An element is then molded from bulk film of thermoplastic material using the tool. Once the element is molded, it is trimmed from the bulk film. The resulting apparatus is a protective case intended to form-fit over the surface features and dimensions of the actual product used to define the tool.

Owner:SIK

Biodegradable polymer coils for intraluminal implants

An endovascular cellular manipulation and inflammatory response are elicited from implantation in a vascular compartment or any intraluminal location of a separable coil comprised at least in part of at least one biocompatible and absorbable polymer or protein and growth factors. Typically a catheter associated with the separable coil is used to dispose the coil into a selected body lumen. The biocompatible and absorbable polymer or protein is thrombogenic. The coil further is comprised at least in part of a growth factor or more particularly a vascular endothelial growth factor, a basic fibroblast growth factor or other growth factors. The biocompatible and absorbable polymer is in the illustrated embodiment at least one polymer selected from the group consisting of polyglycolic acid, poly~glycolic acid poly-L-lactic acid copolymers, polycaprolactive, polyhydroxybutyrate / hydroxyvalerate copolymers, poly-L-lactide. Polydioxanone, polycarbonates, and polyanhydrides. The biocompatible and absorbable protein is at least one protein selected from the group consisting of collagen, fibrinogen, fibronectin, vitronectin, laminin, and gelatin. In one embodiment the coil is composed of the biocompatible and absorbable polymer or protein with a radio-opaque material is disposed thereon. Alternatively, the coil is composed of a radio-opaque material, and the biocompatible and absorbable polymer or protein is disposed thereon. This apparatus may be positioned within intracranial aneurysms or any aneurysm in the body as well as within other body cavities.

Owner:RGT UNIV OF CALIFORNIA

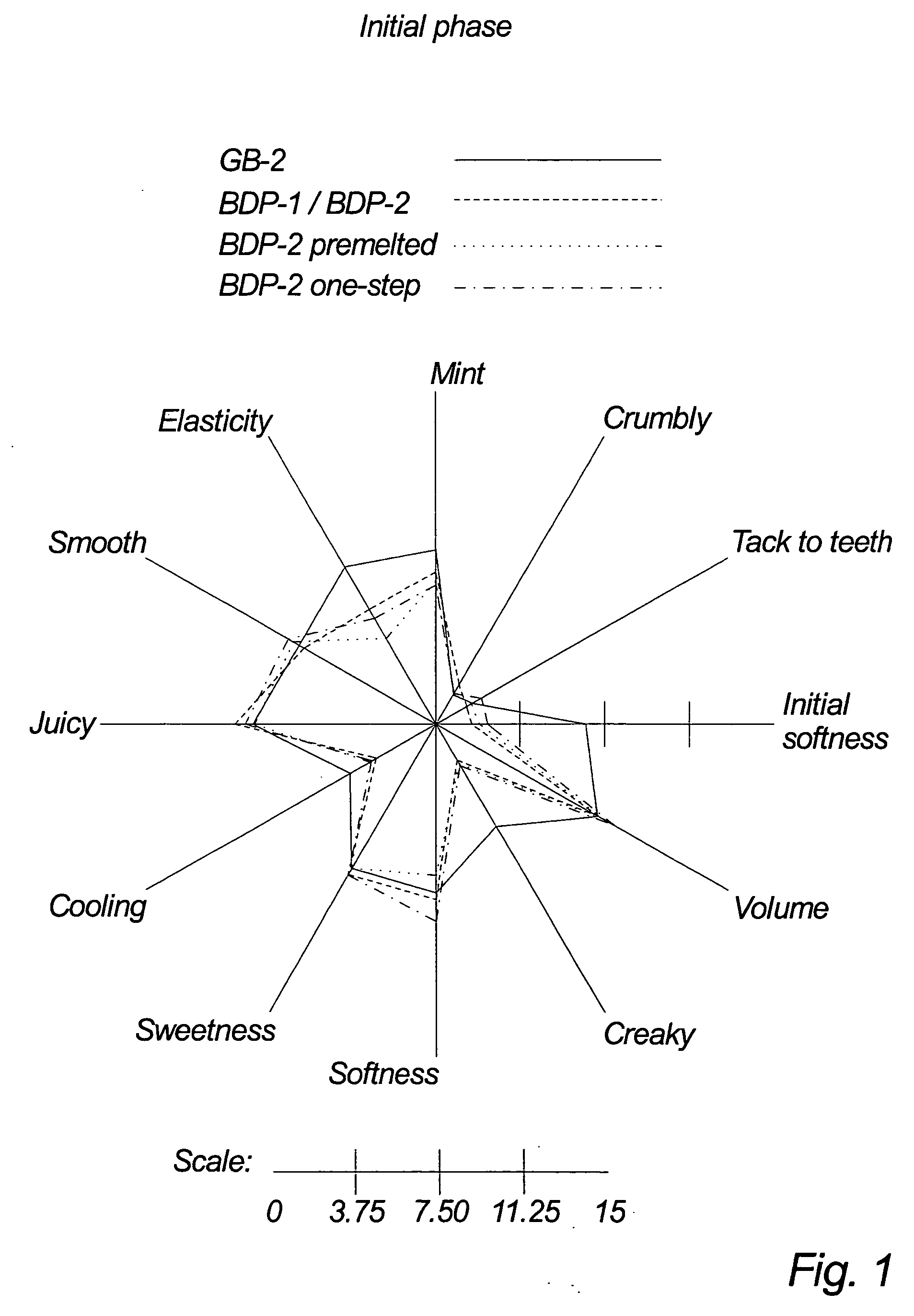

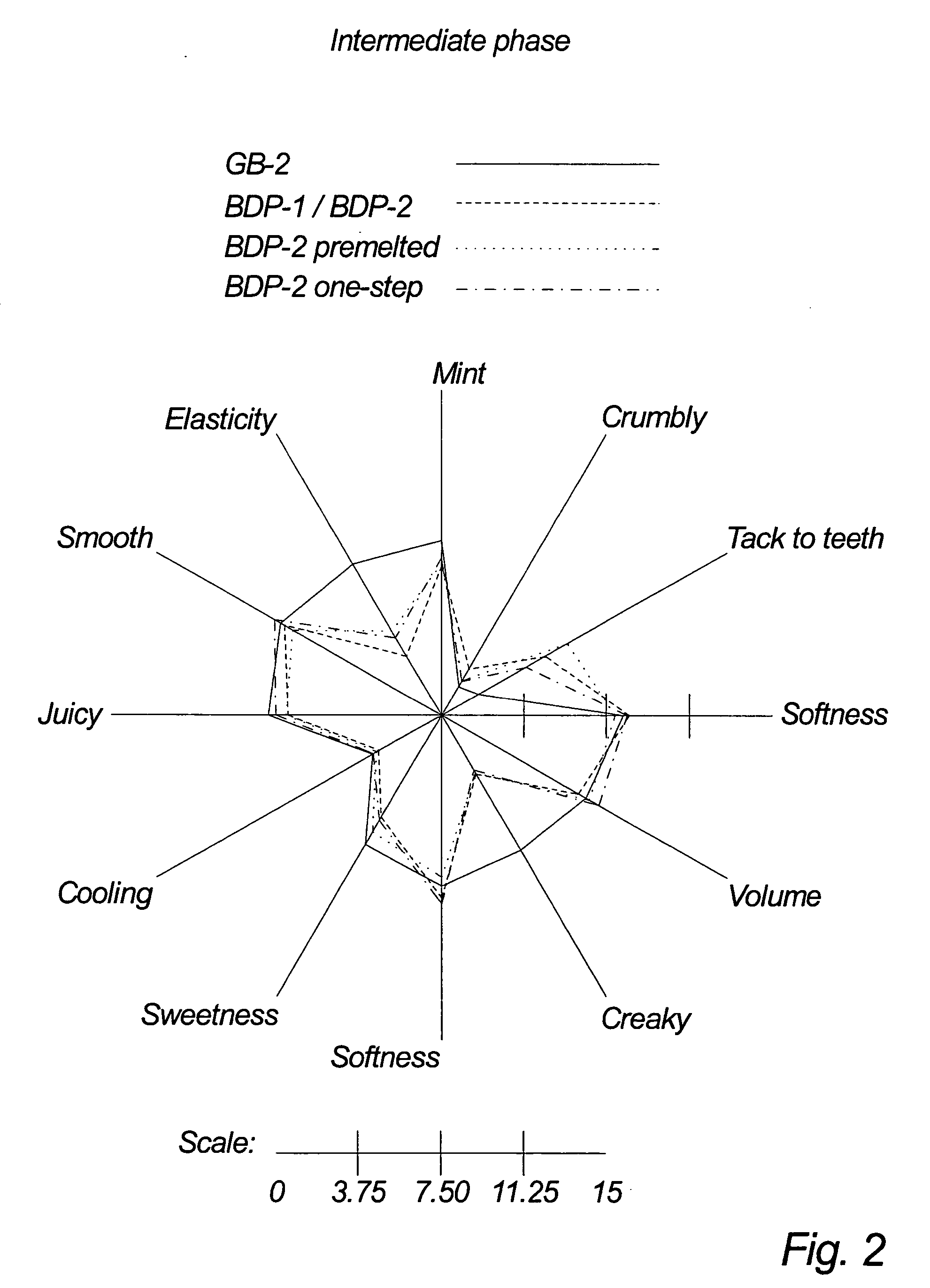

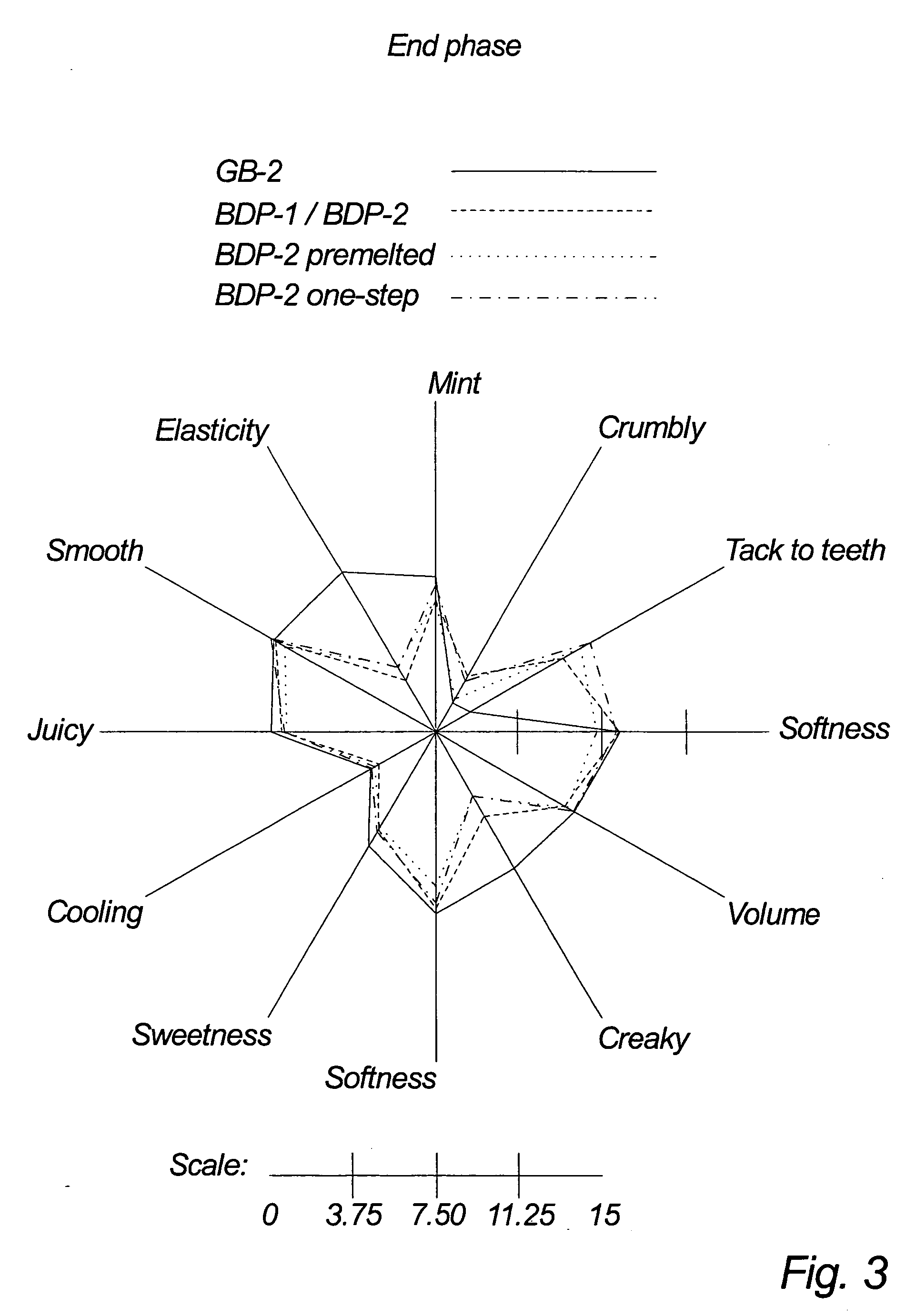

One-step process for preparing chewing gum

InactiveUS20040115305A1More cost-effectivelyLess process equipmentOrganic active ingredientsNervous disorderPolyesterPolymer science

A process for preparing a chewing gum wherein all of the gum base components and all of the chewing gum additives are charged, in any appropriate order, into a mixing apparatus and the apparatus operated at atmospheric pressure to obtain the chewing gum, subject to the limitation that the gum base does not contain a vinyl polyester as the sole polymer. In certain embodiments, the gum base comprises at least one environmentally or biodegradable polymer such as a polyester, a polycarbonates, a polyester amide, a polypeptide and a protein.

Owner:GUMLINK AS

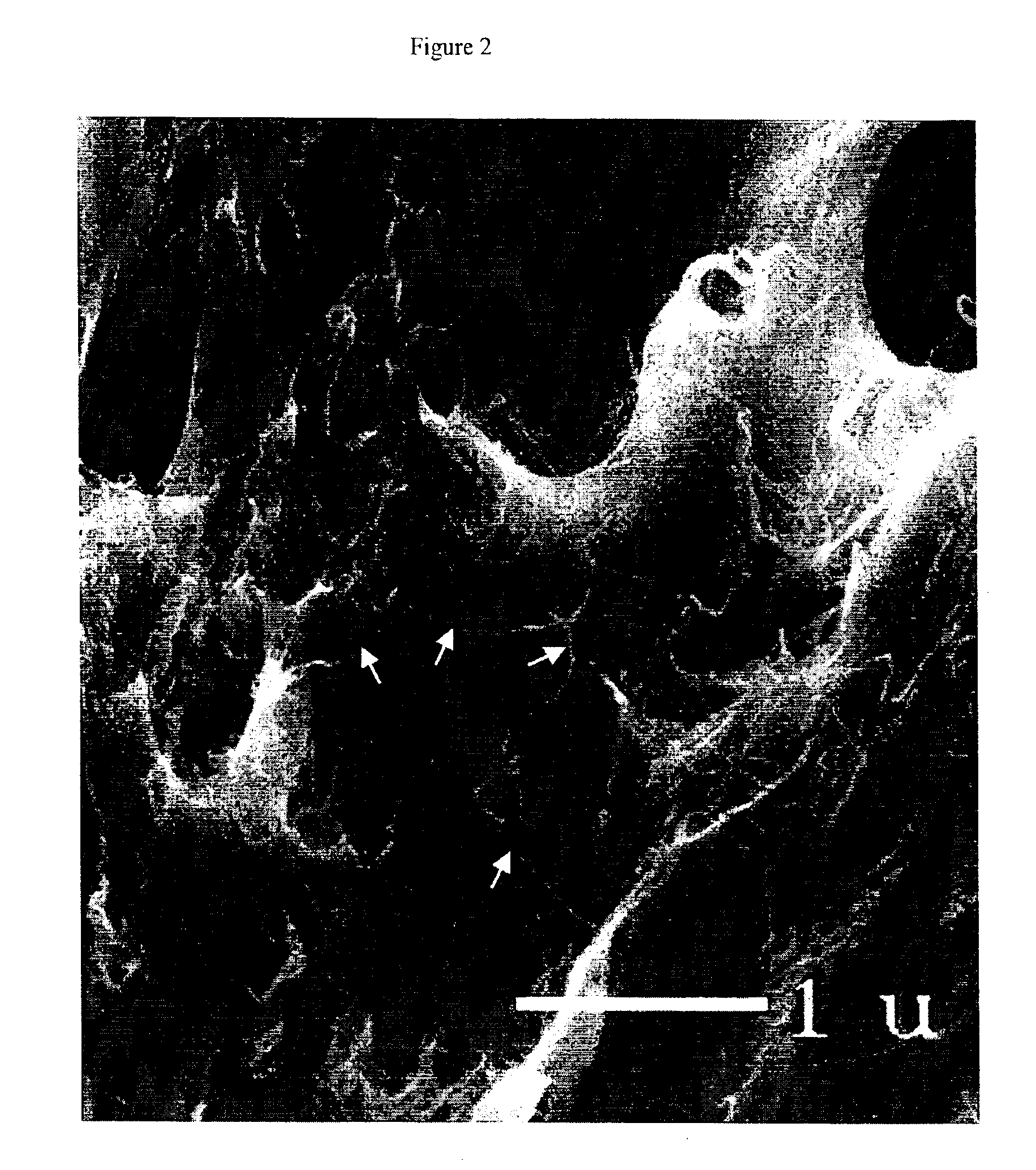

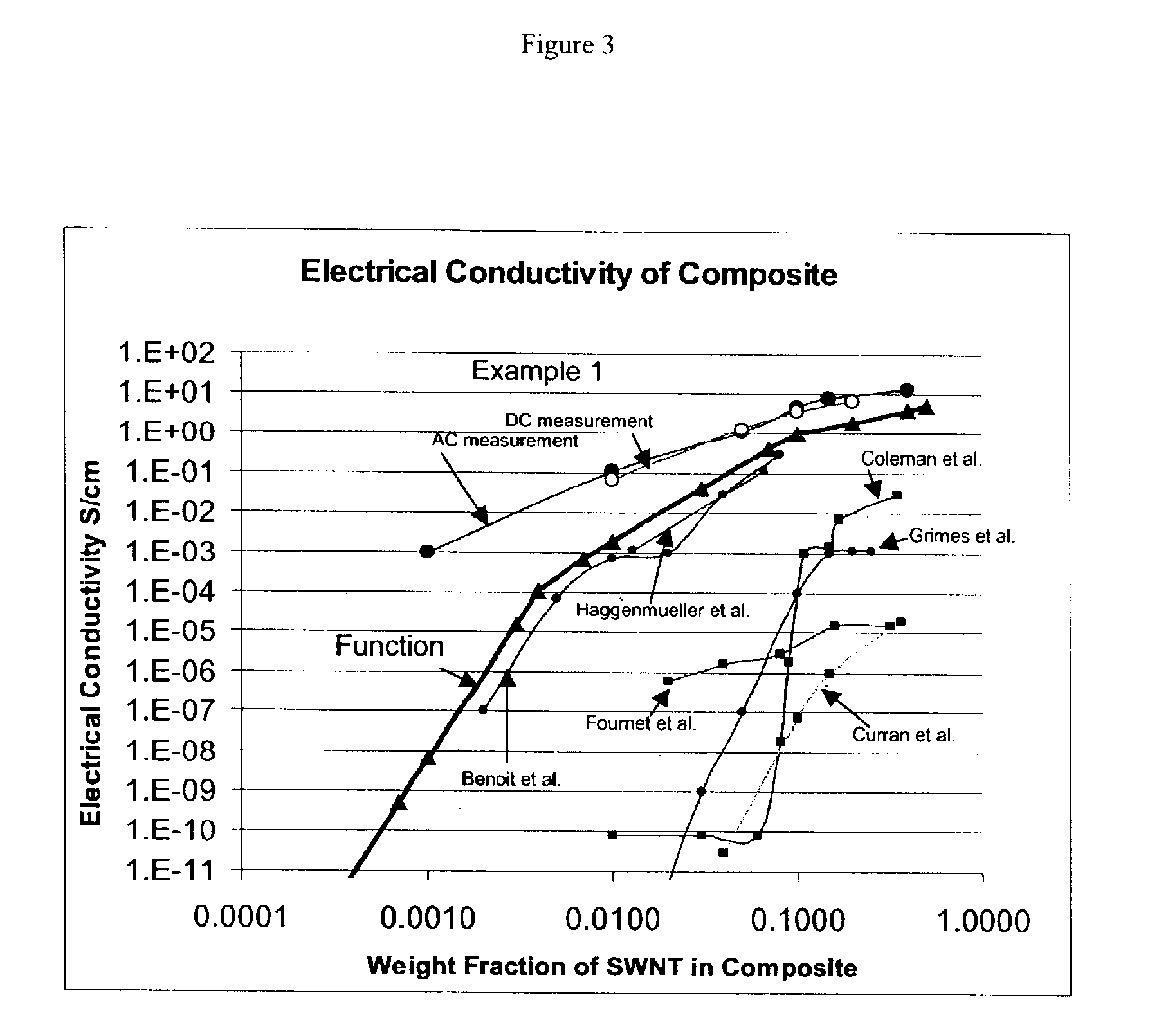

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

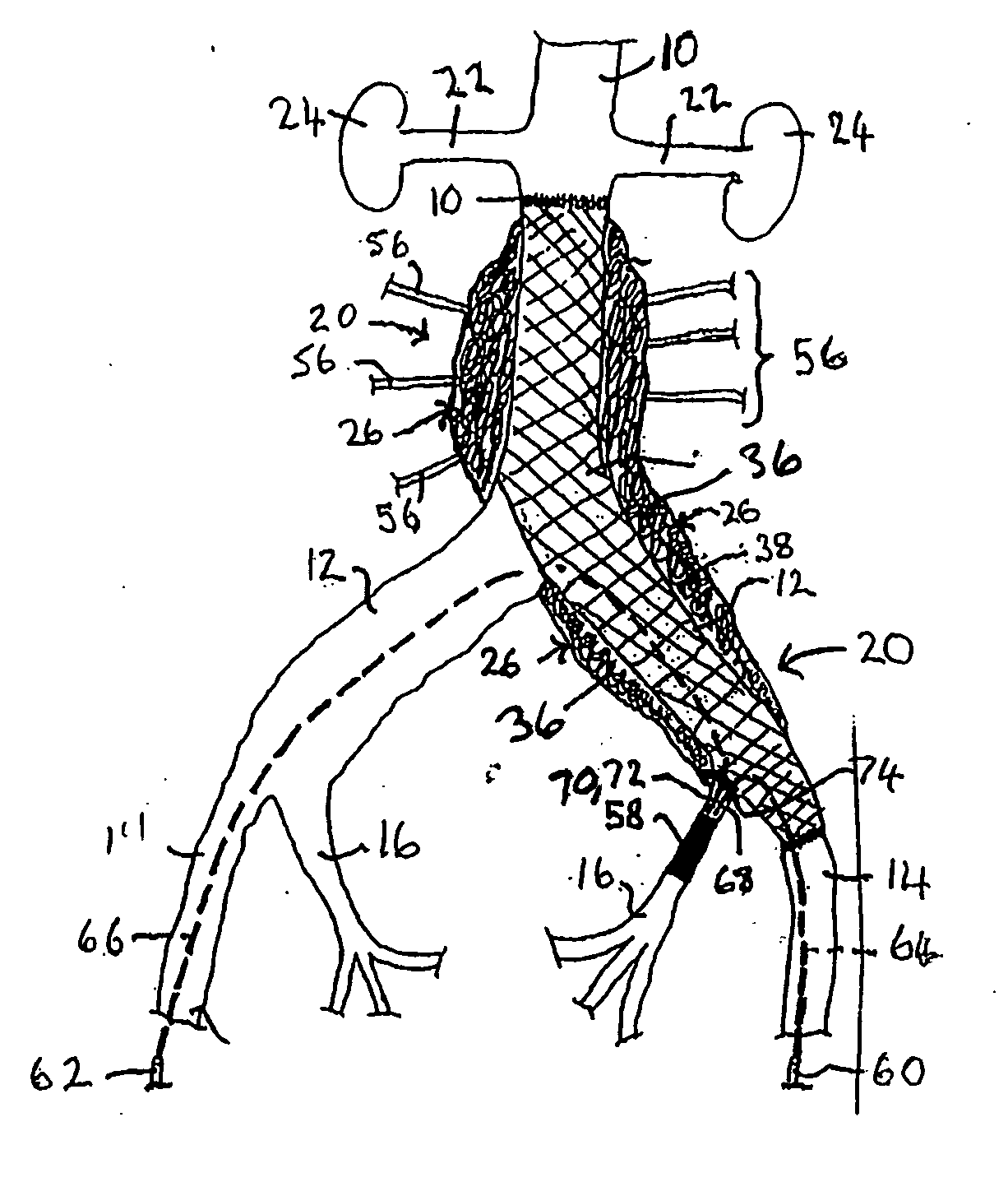

Endovascular treatment devices and methods

InactiveUS20050165480A1Simple and potentially effective treatmentTreating and preventing endoleakageTracheaeOcculdersEndovascular treatmentElastomer

A device for treating or preventing a vascular condition at a mammalian vascular site, comprises an implant formed from a compressible, reticulated elastomeric matrix in a shape conducive to delivery through a delivery instrument. One or more implants are delivered in a compressed state to the mammmalian vascular site where each implant recovers substantially to its uncompressed state following deployment from a delivery instrument. In a preferred embodiment the matrix comprises cross-linked polycarbonate polyurethane-urea or cross-linked polycarbonate polyurea-urethane. In another preferred embodiment the matrix comprises a cross-linked polycarbonate polyurethane. In a yet further embodiment, the matrix comprises thermoplastic polycarbonate polyurethane or thermoplastic polycarbonate polyurethane-urea.

Owner:THE BIOMERIX CORP

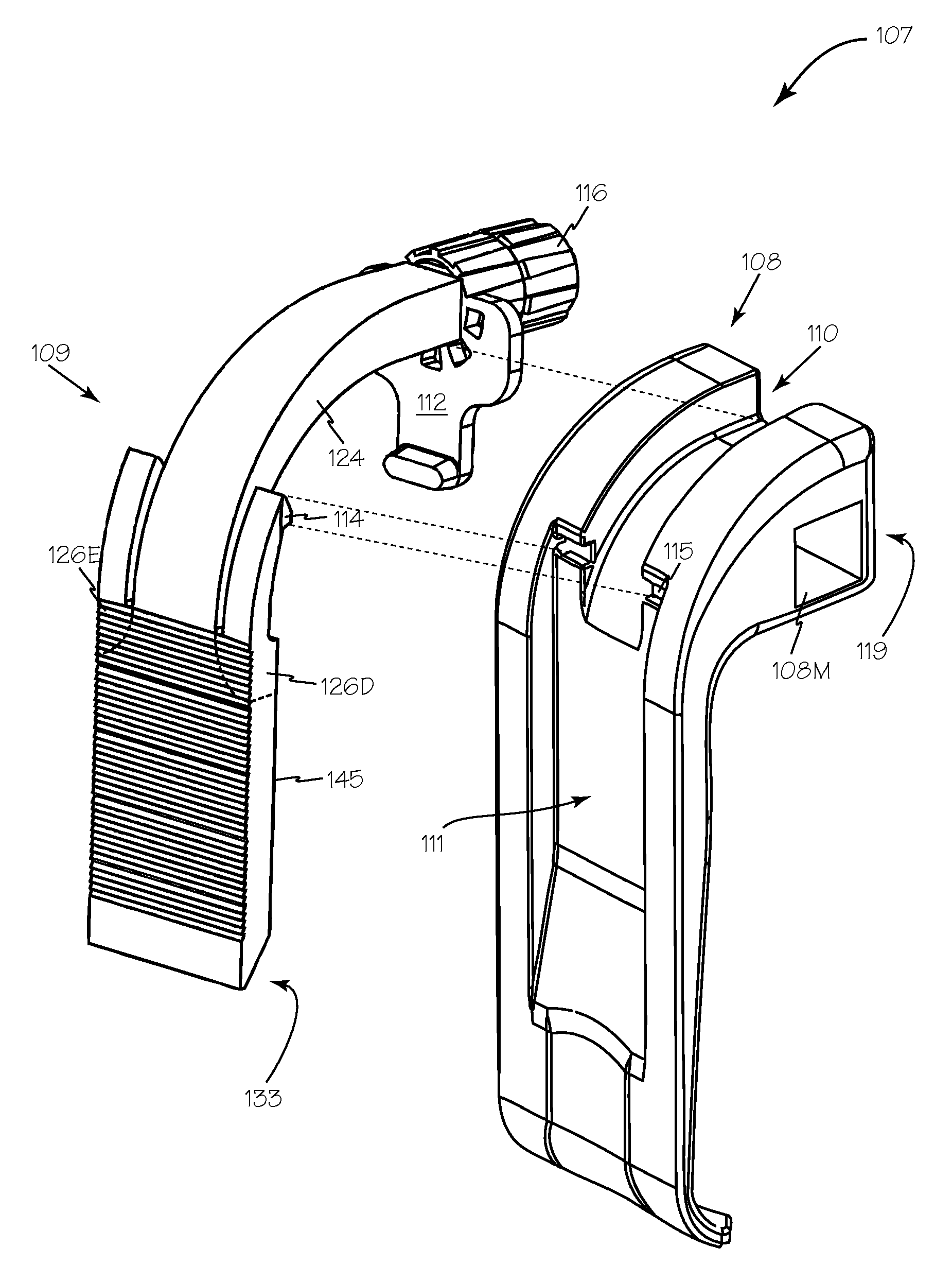

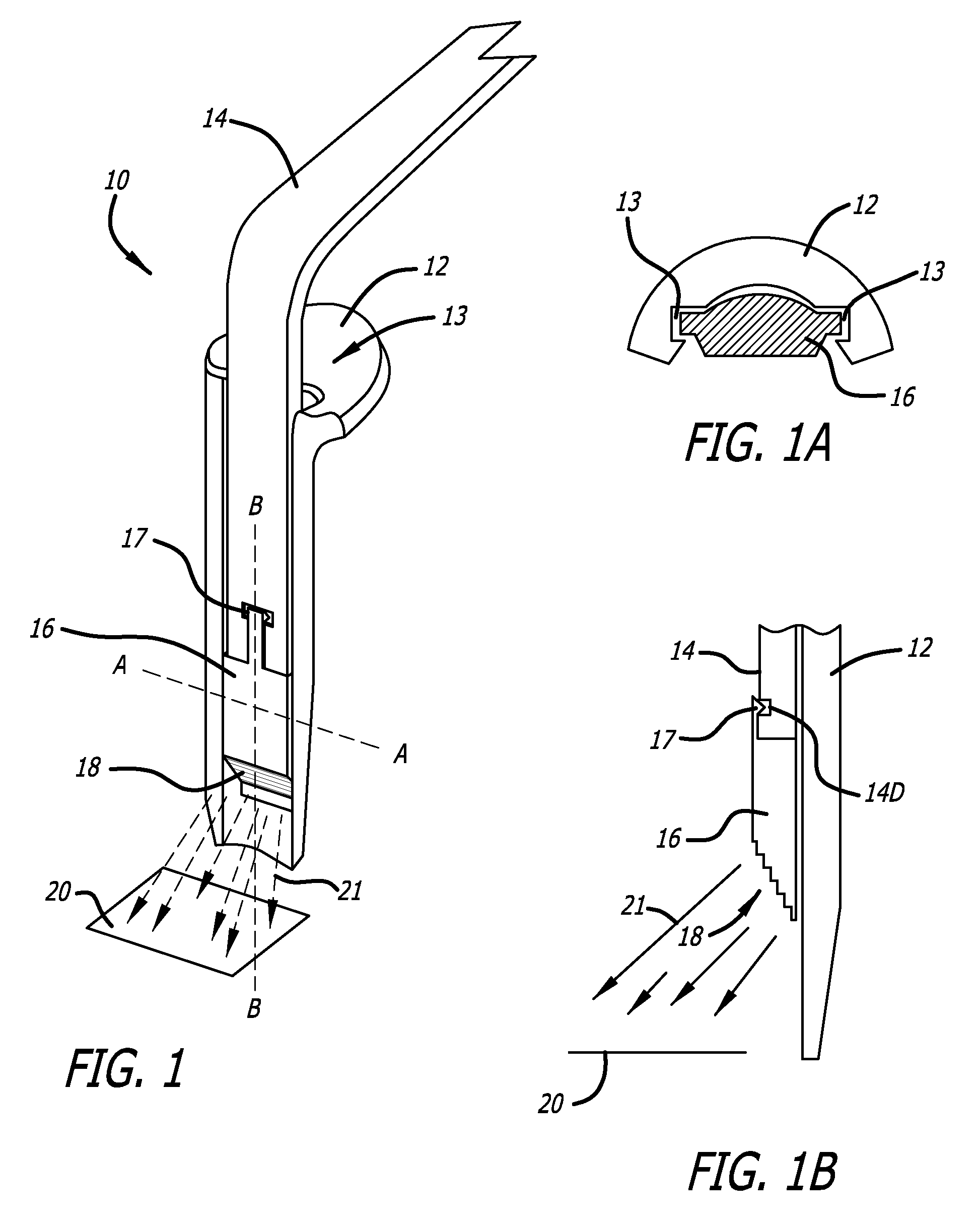

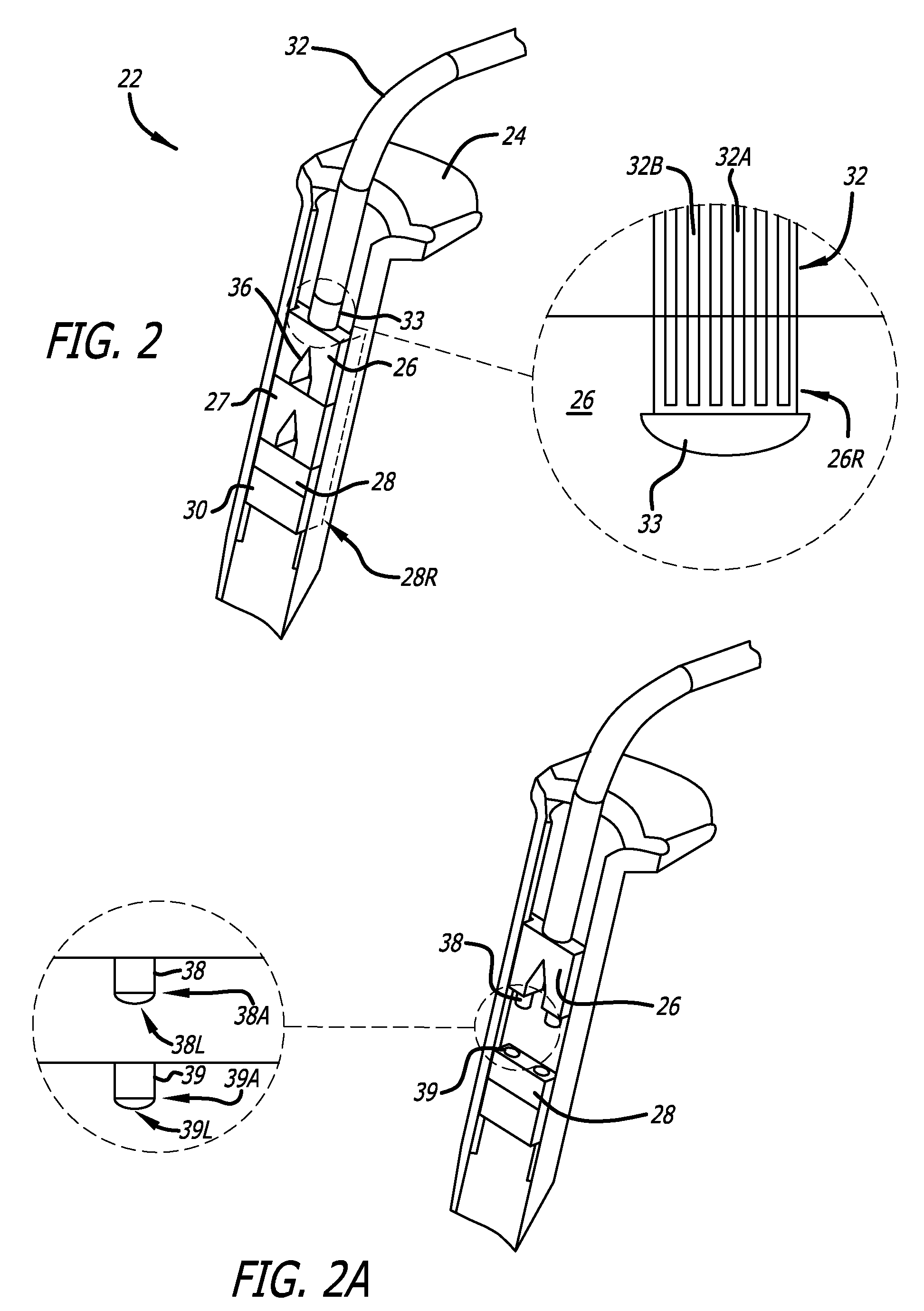

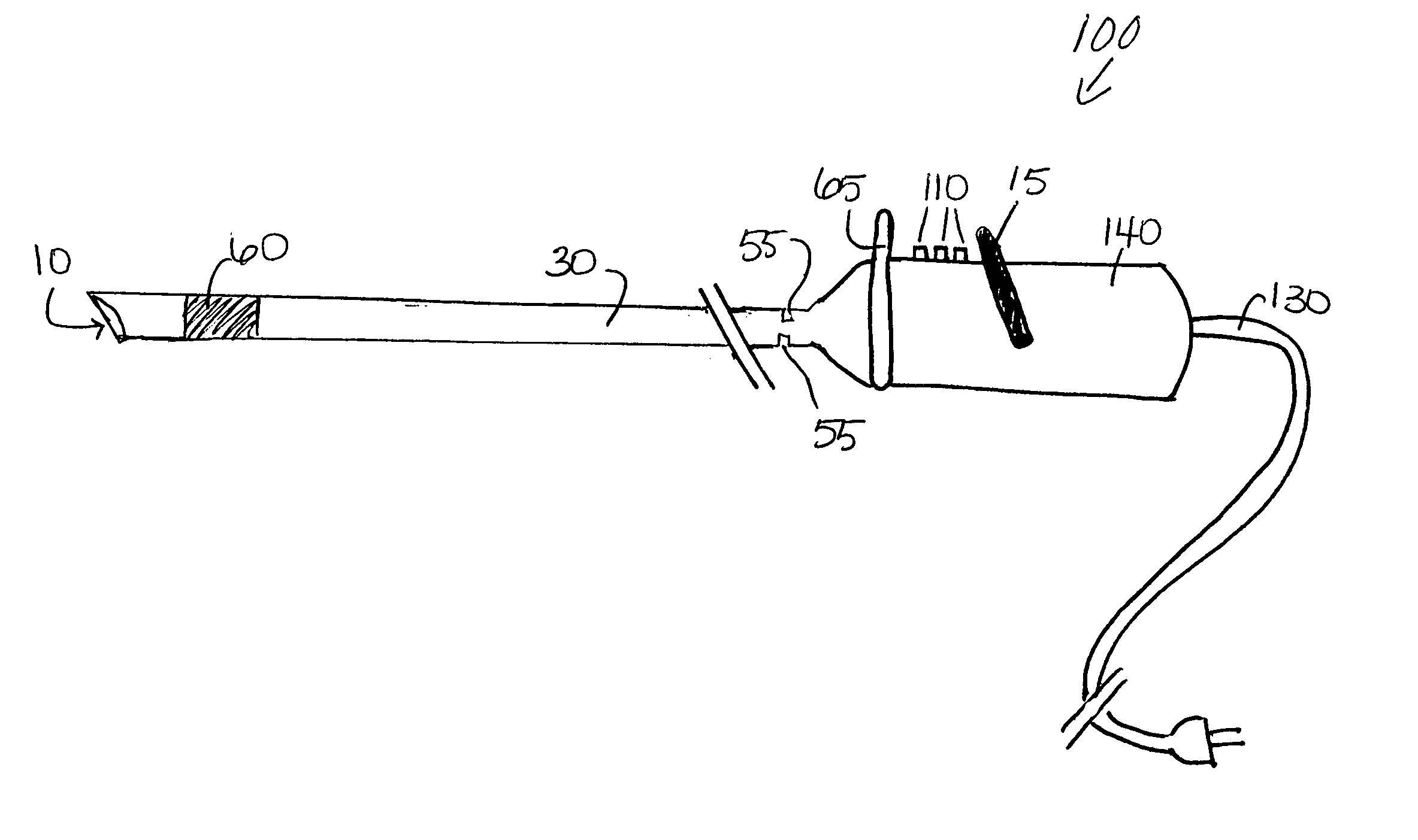

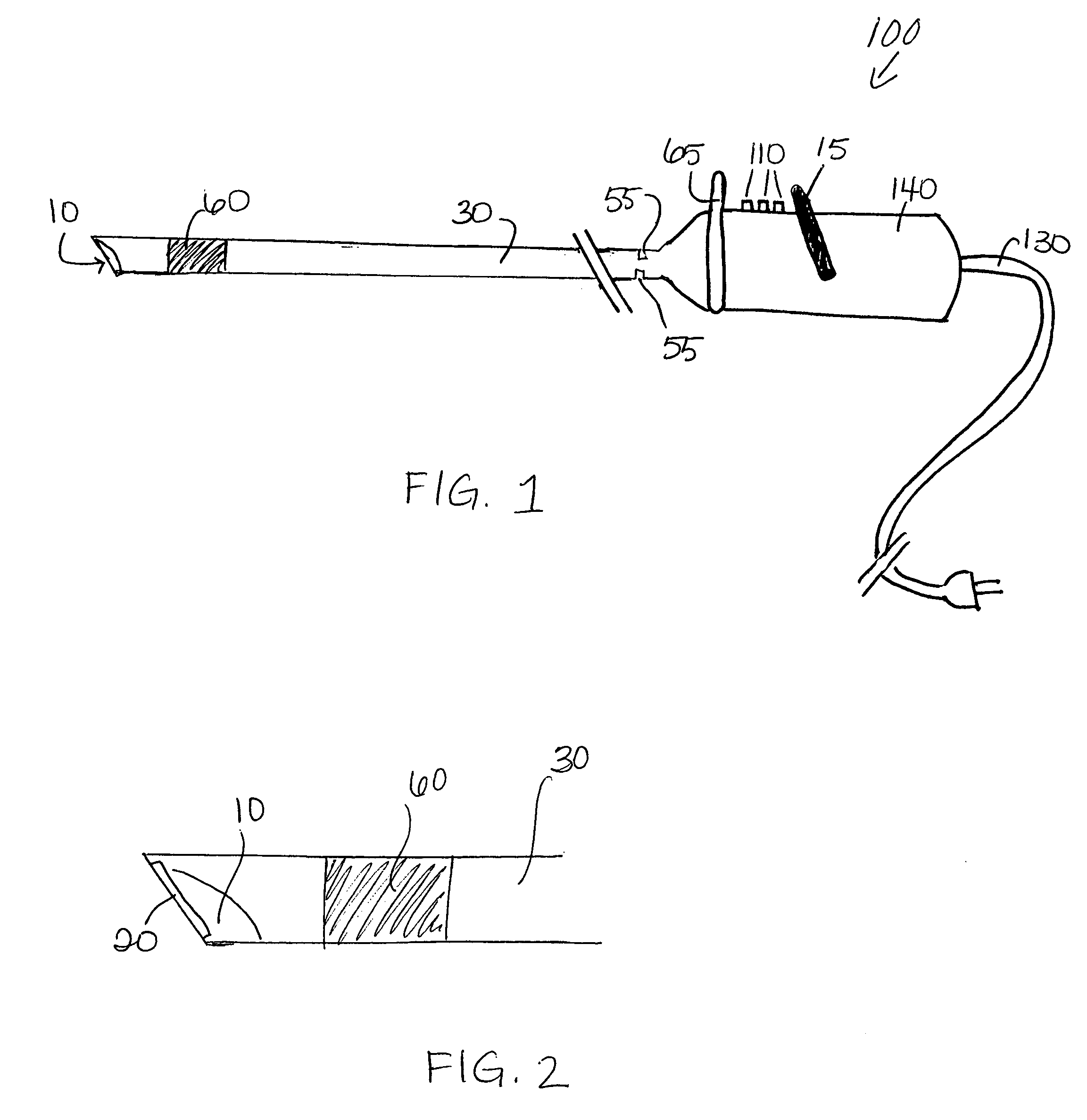

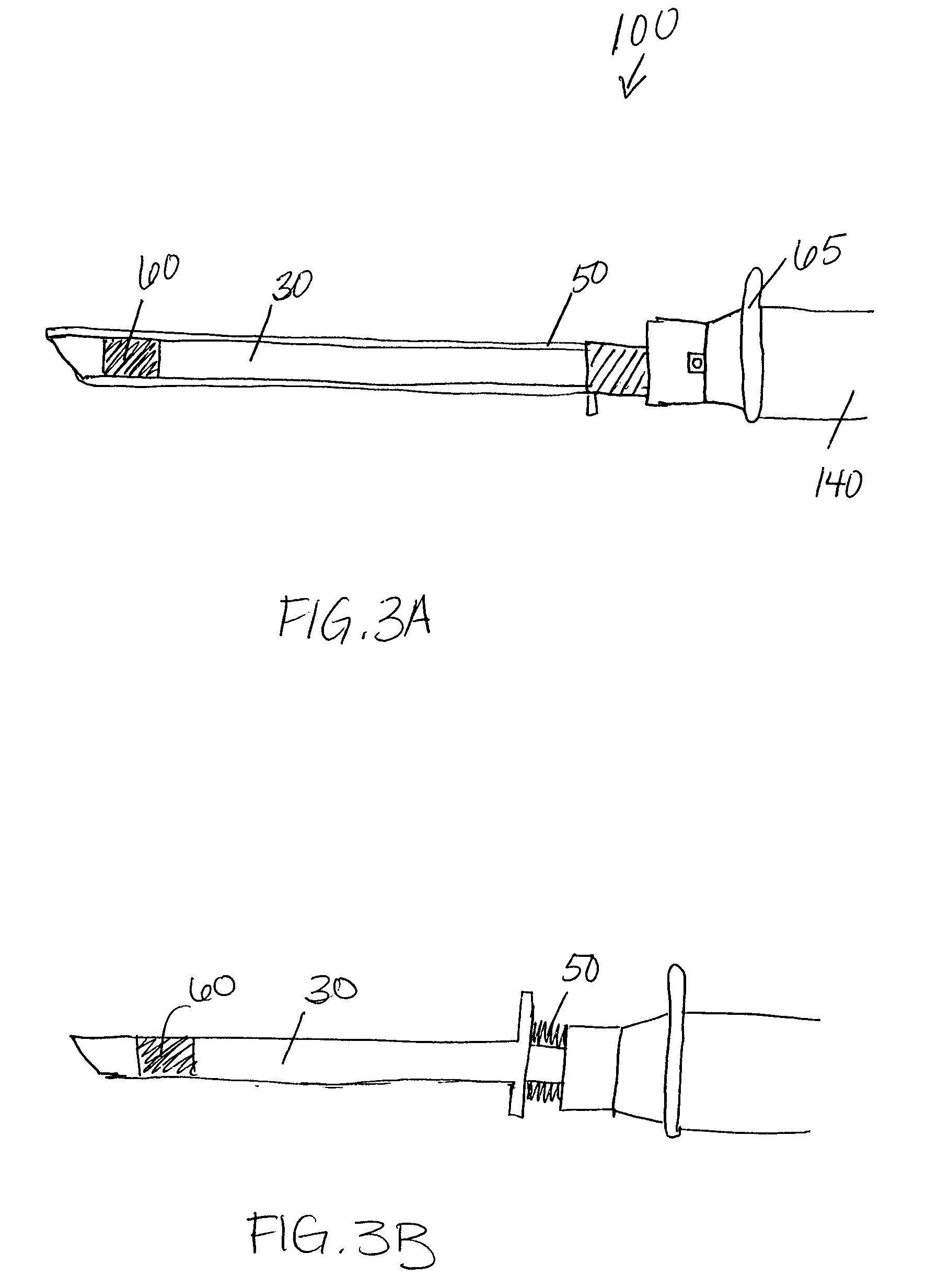

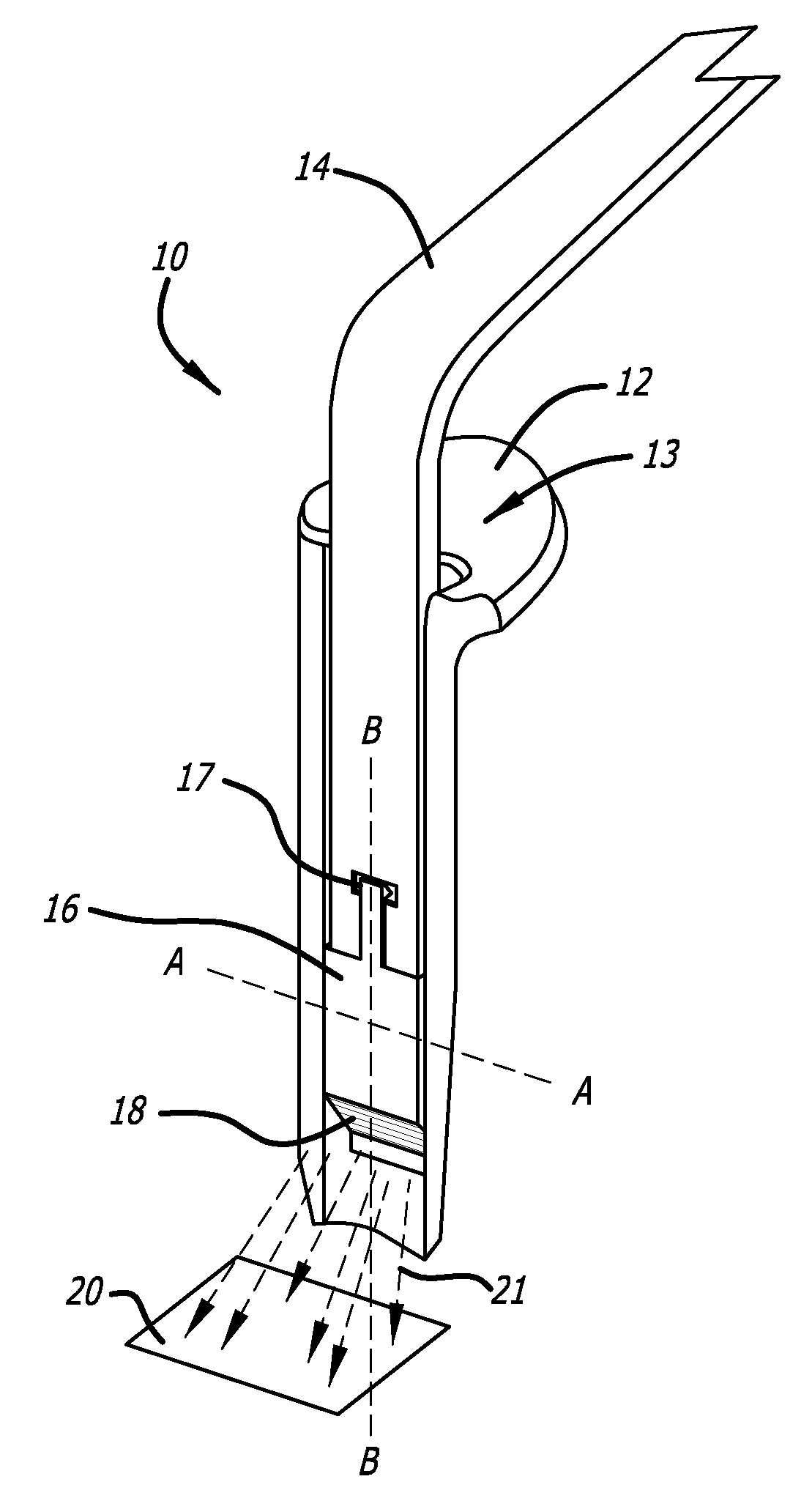

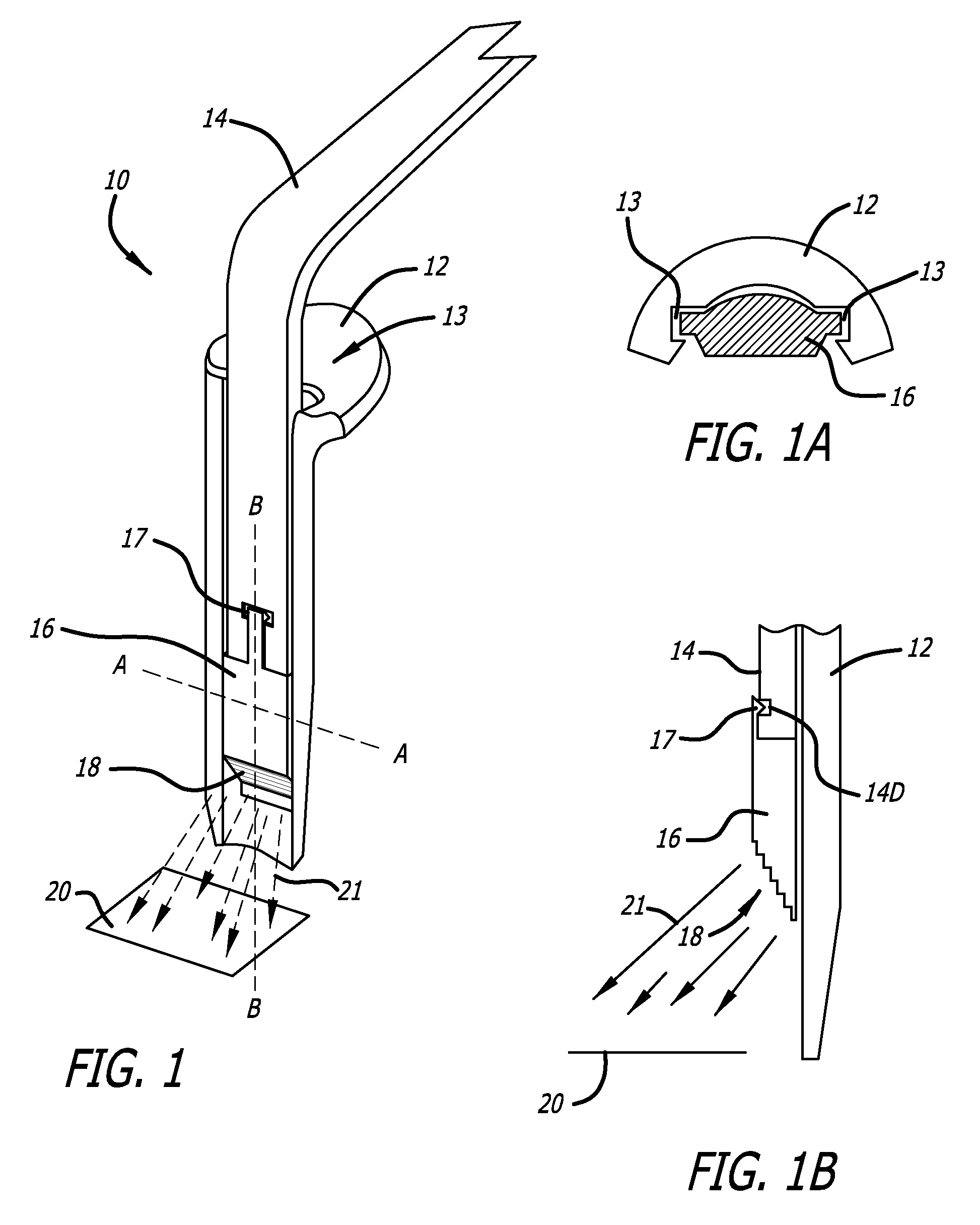

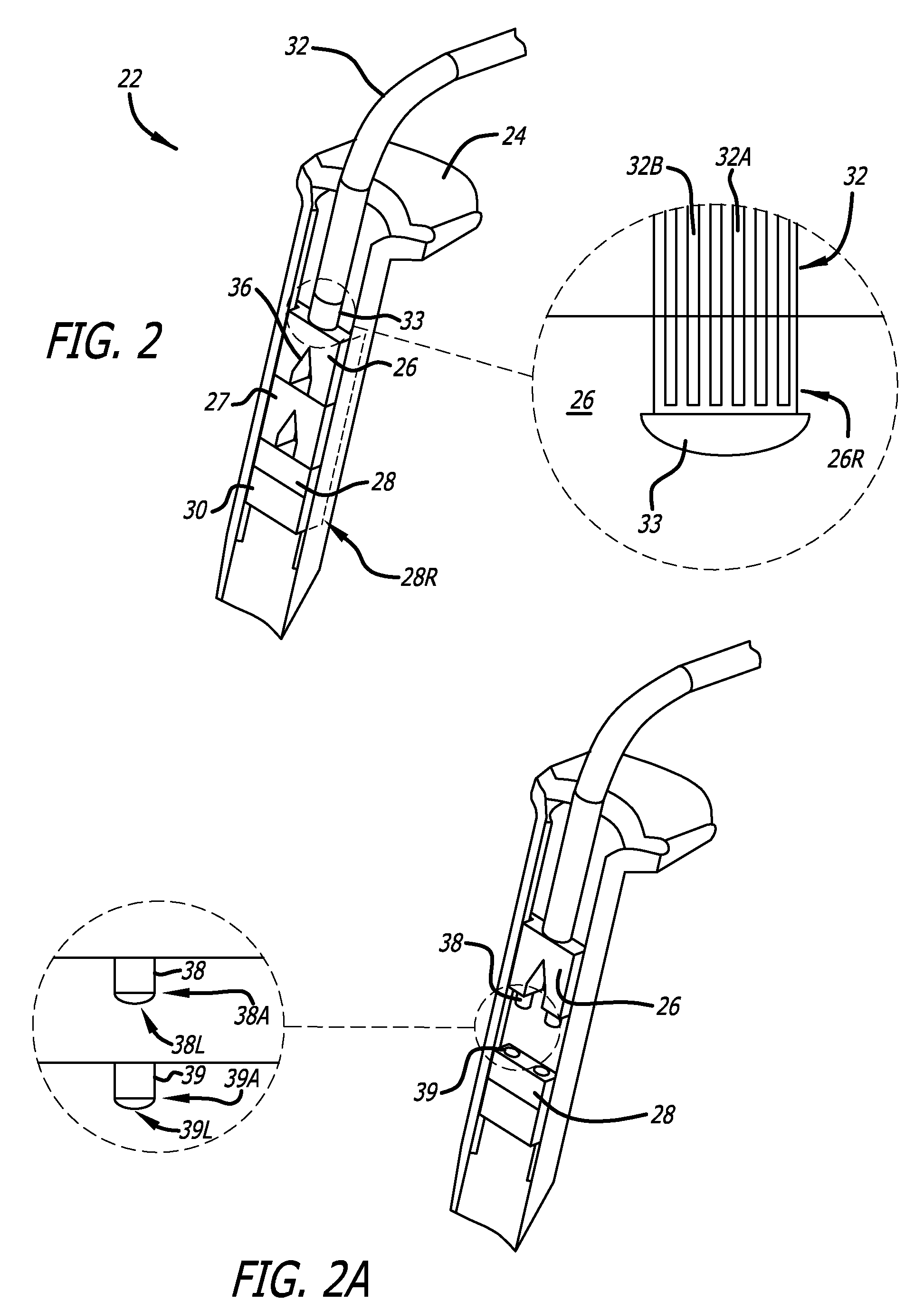

Blade insert illuminator

ActiveUS8088066B2Maximize light transferReduce light lossEndoscopesSurgical field illuminationPlastic materialsEngineering

An air gap retractor illumination system includes any suitable retractor such as a McCulloch with a channel in the blade to accommodate an air gap illuminator. The illuminator is preferably made from a suitable light conducting plastic material such as acrylic or polycarbonate or silicone. The illuminator has active portions in which light passes and inactive or dead zones in which light does not pass as a result of the configuration and orientation of the input, output and surfaces of the illuminator. The illuminator is formed to have an air gap surrounding any active portion of the illuminator extending from the light input to the light output portion. The dead zones may include elements to allow the illuminator to securely engage the retractor. The light output portion of the illuminator contains from two to eight output zones, each zone having specially designed output optical structures that control and direct light to escape the illuminator to shine onto a predetermined area of interest or to form one or more predetermined shapes or footprints.

Owner:INVUITY

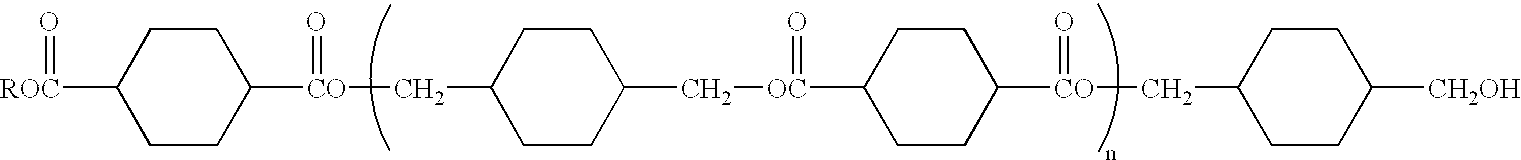

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

ActiveUS20070275242A1Useful performance propertyPlastic recyclingSpecial tyresPolytetramethylene terephthalatePolyethylene terephthalate glycol

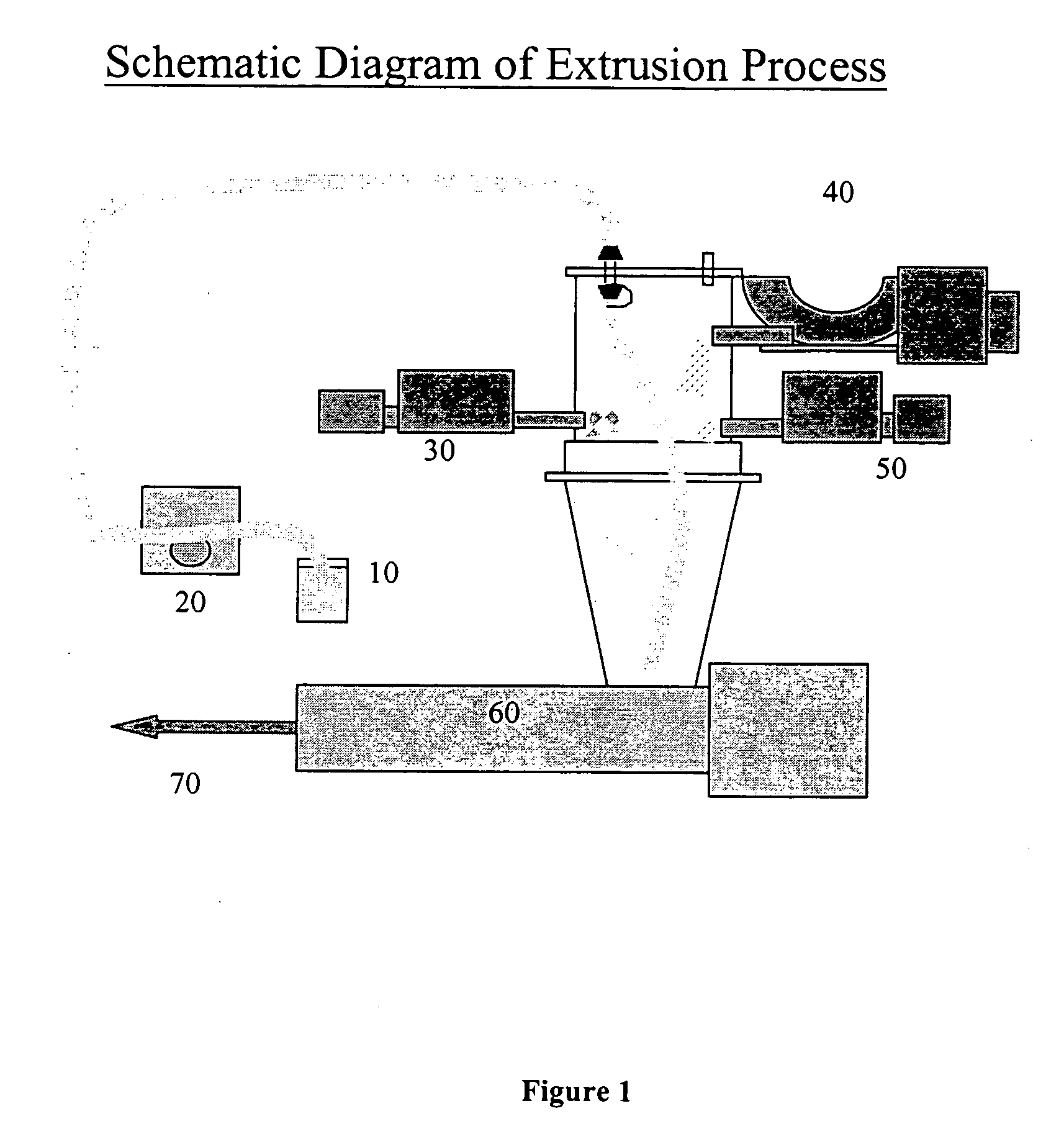

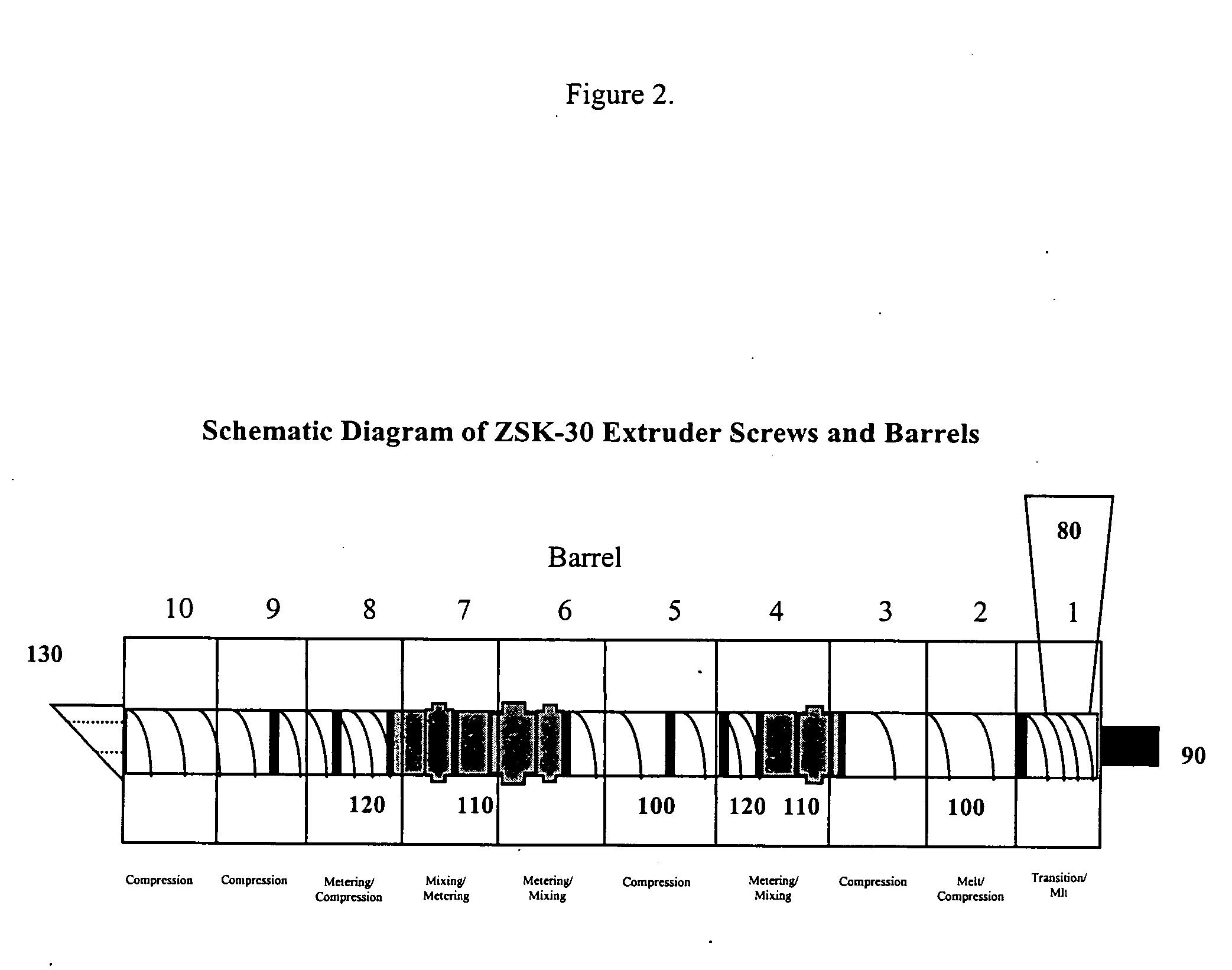

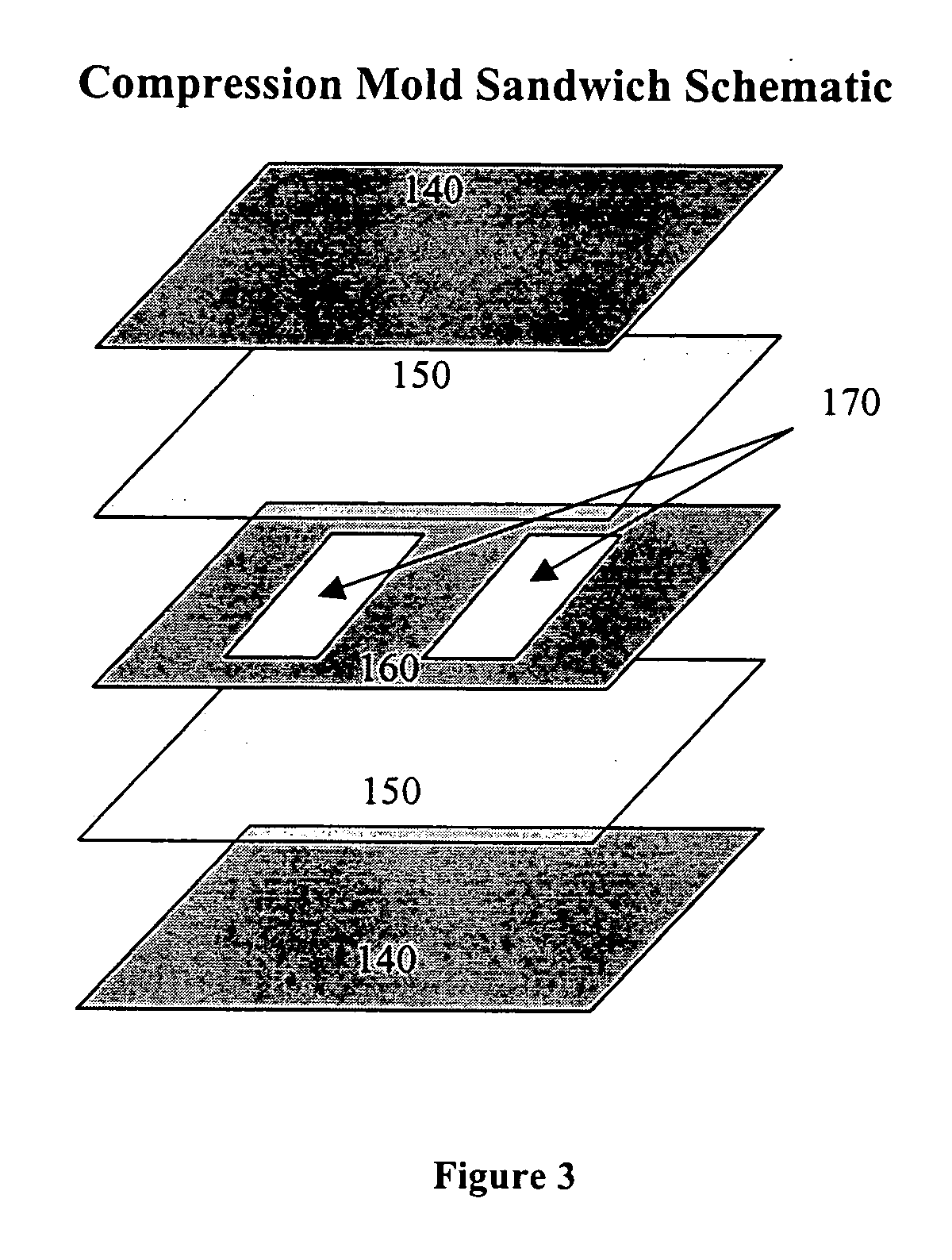

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

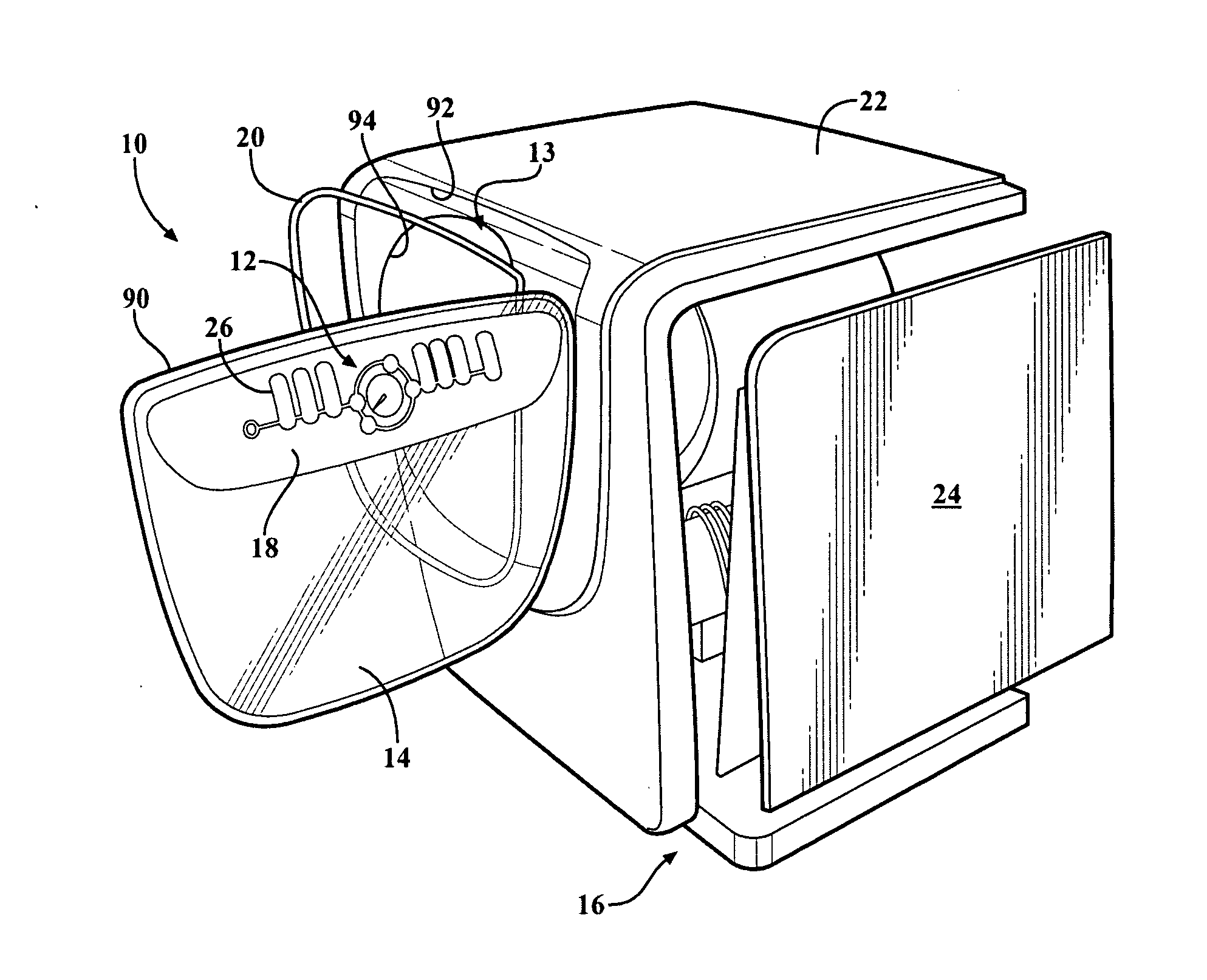

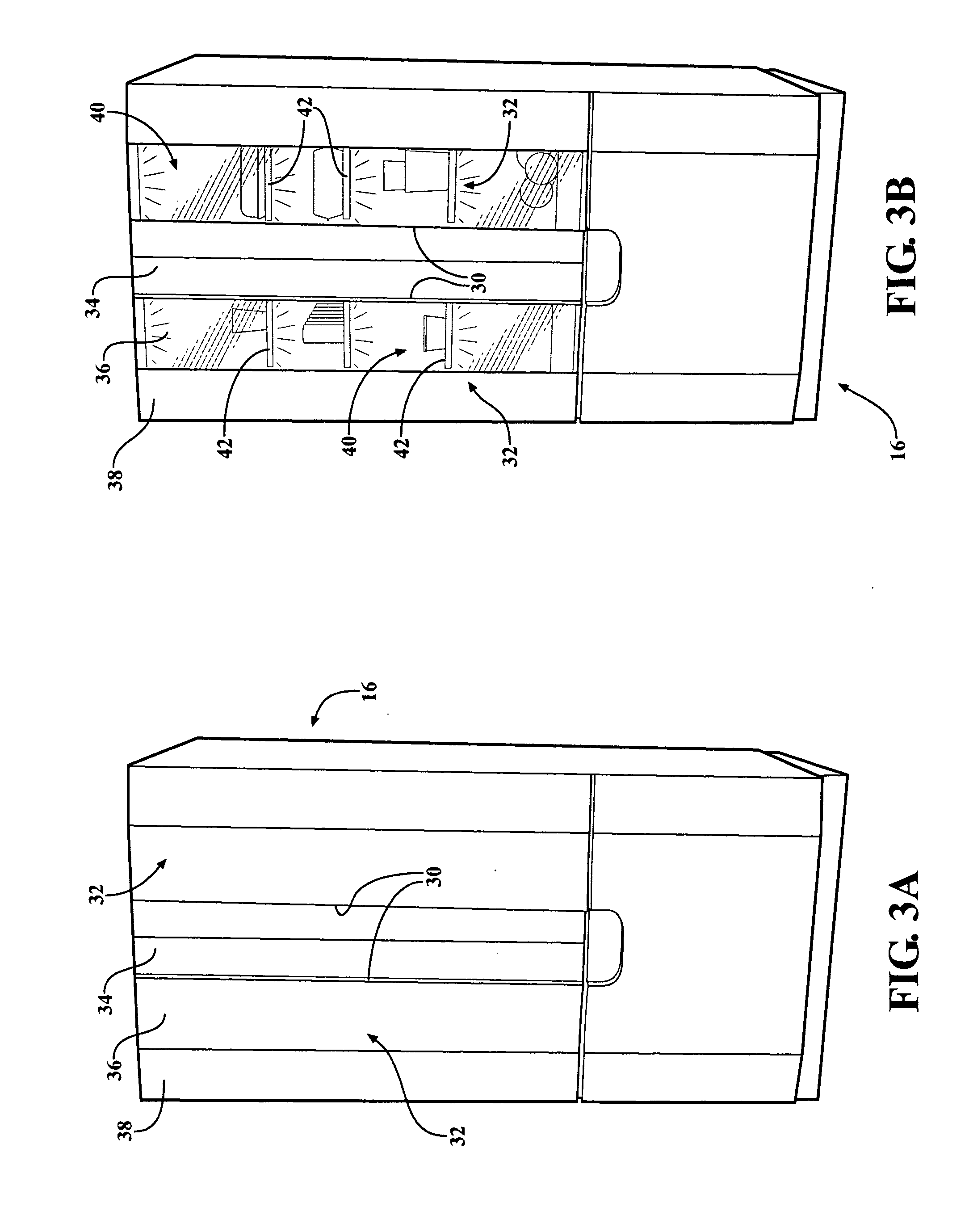

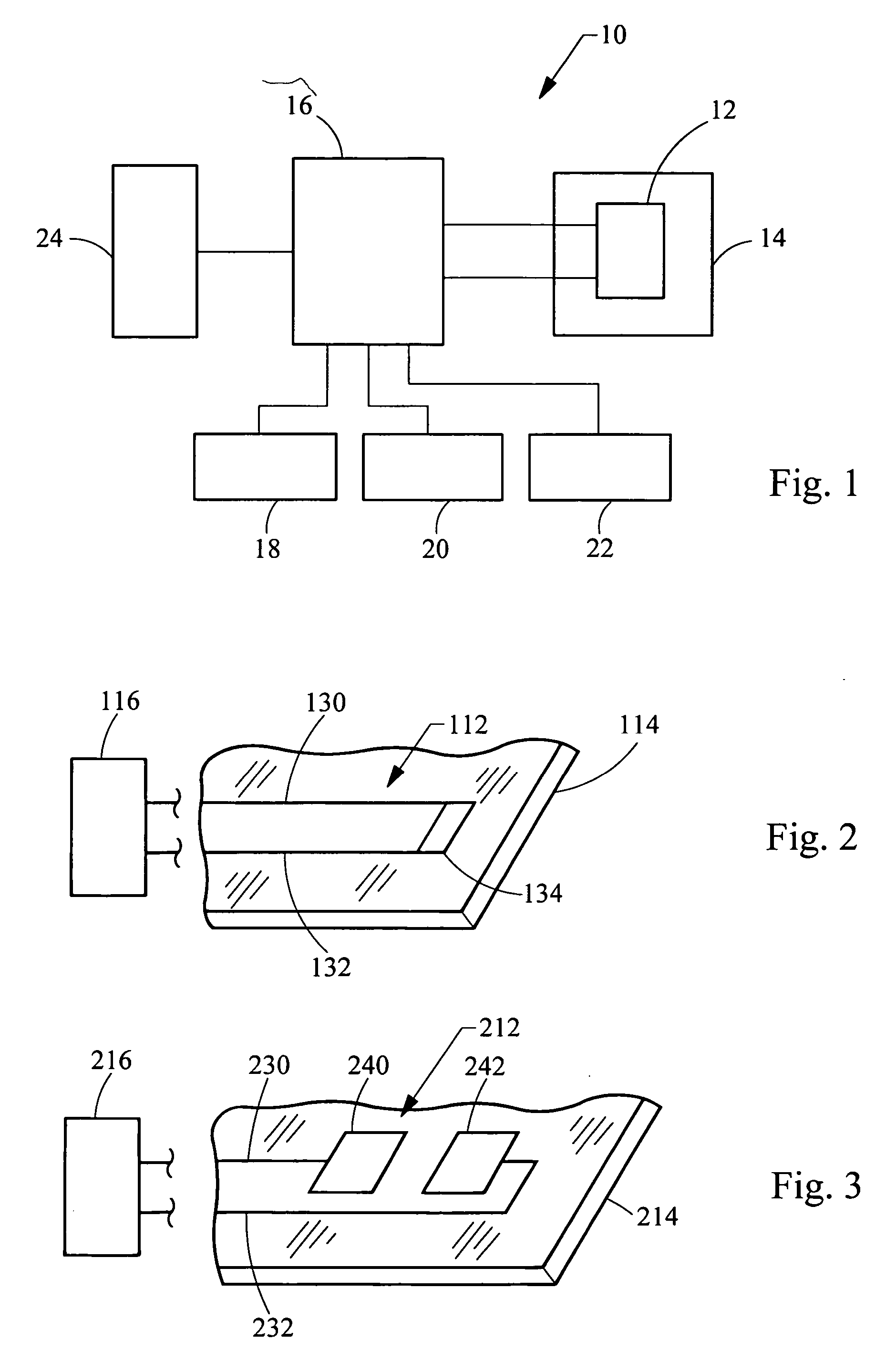

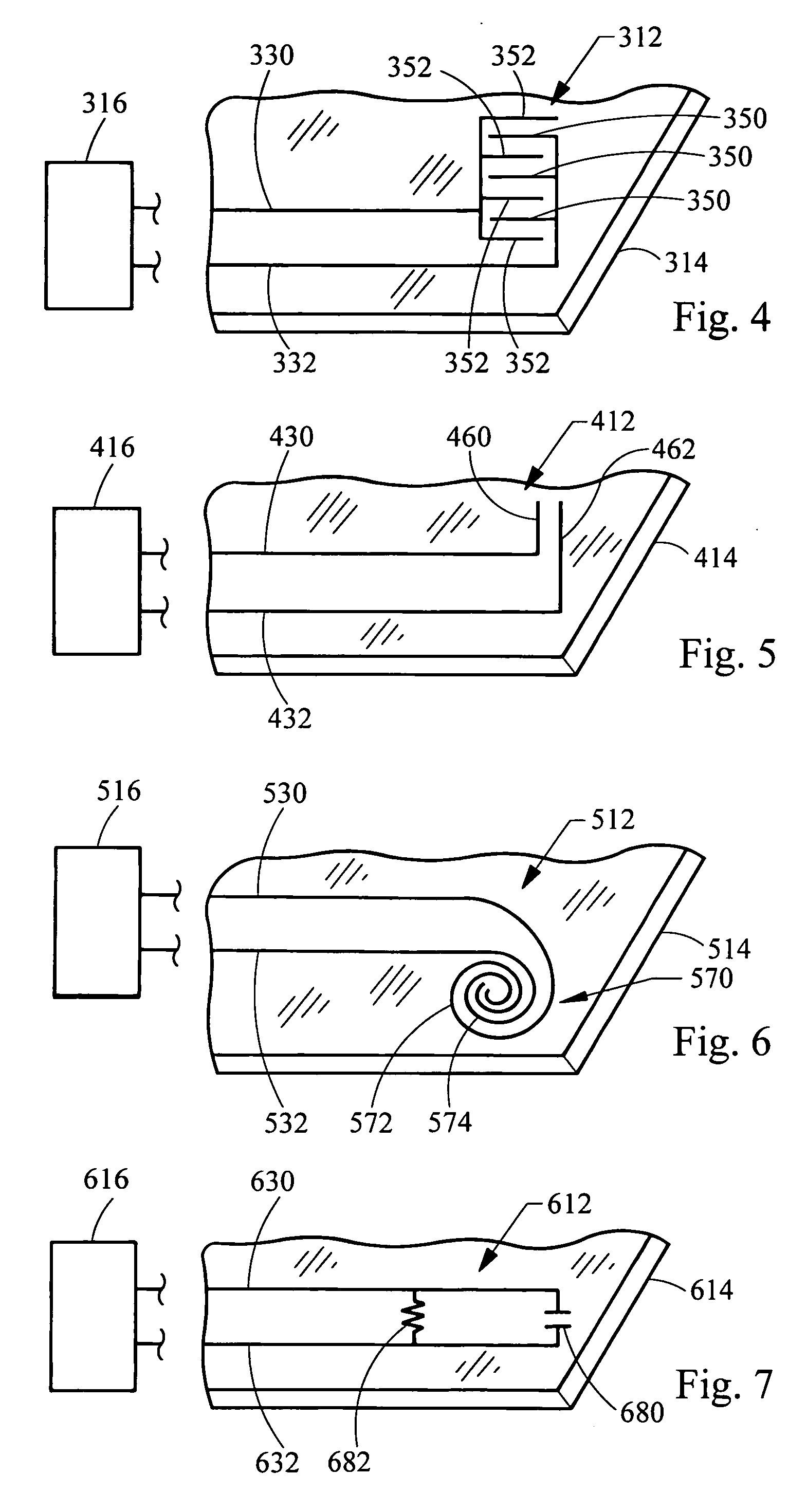

Appliance doors having integrated lighting and controls

ActiveUS20110134627A1Reduce the amount requiredImprove the finishFurnace componentsLighting support devicesControl systemEffect light

The present invention is an integrated control system for use with various home appliances, such as washing machine, dryers, refrigerators, dishwashers, and the like. In a first embodiment of the present invention, the integrated controls are incorporated into a polycarbonate clear door panel, and incorporate proximity switches and controls to provide control and operation of the applicance. Light emitting diodes (LEDs) are optionally incorporated into a door handle for the appliance in an area out of sight such that only the light produced by the LEDs is seen and illuminates a handle for opening the door of the appliance. Additionally, opaque glass technology may be incorporated into one or more surfaces of the appliance which enables an opaque panel to become transparent to view the content of the interior of the appliance, such as a refrigerator.

Owner:MAGNA INTERNATIONAL INC

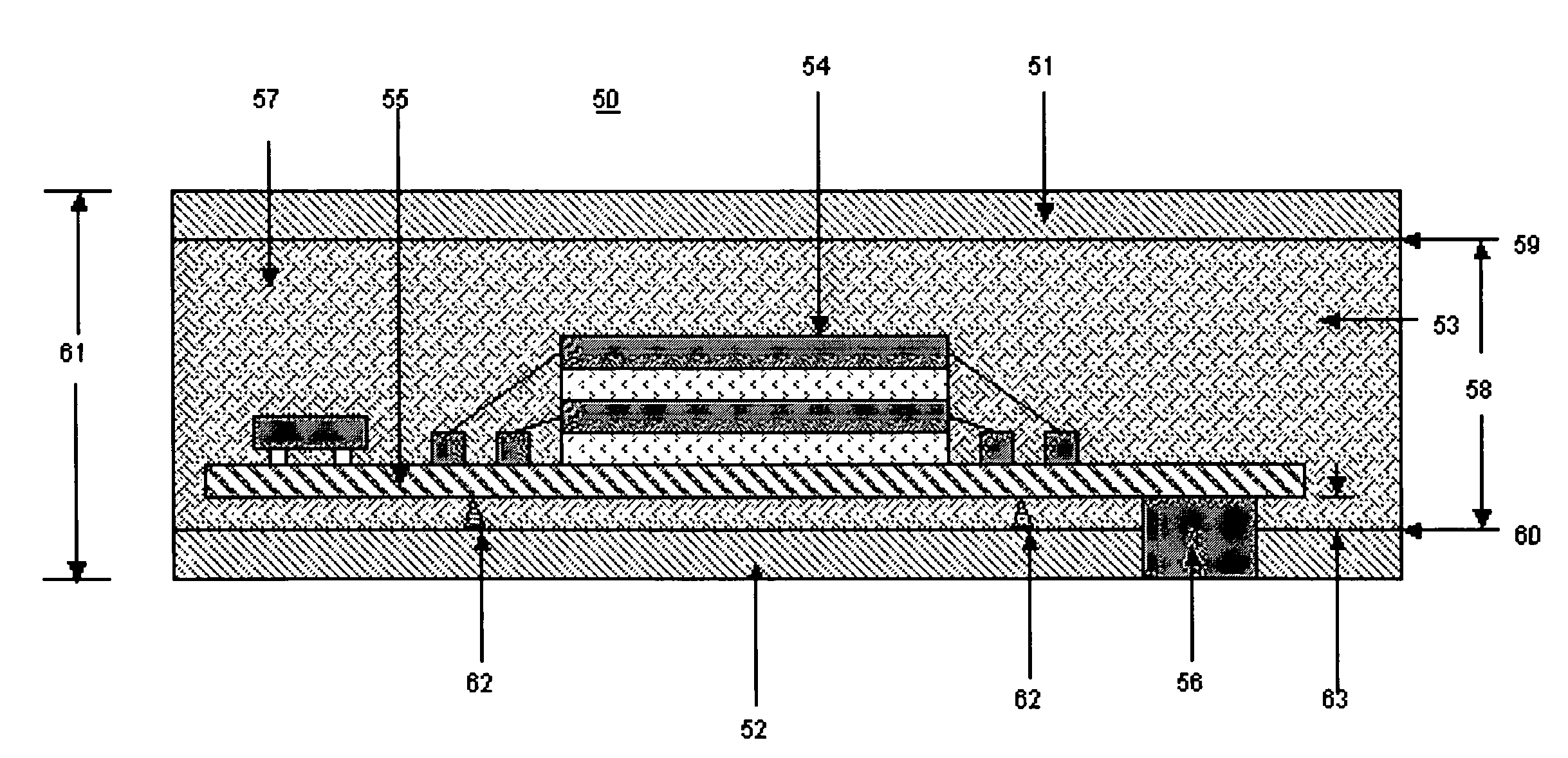

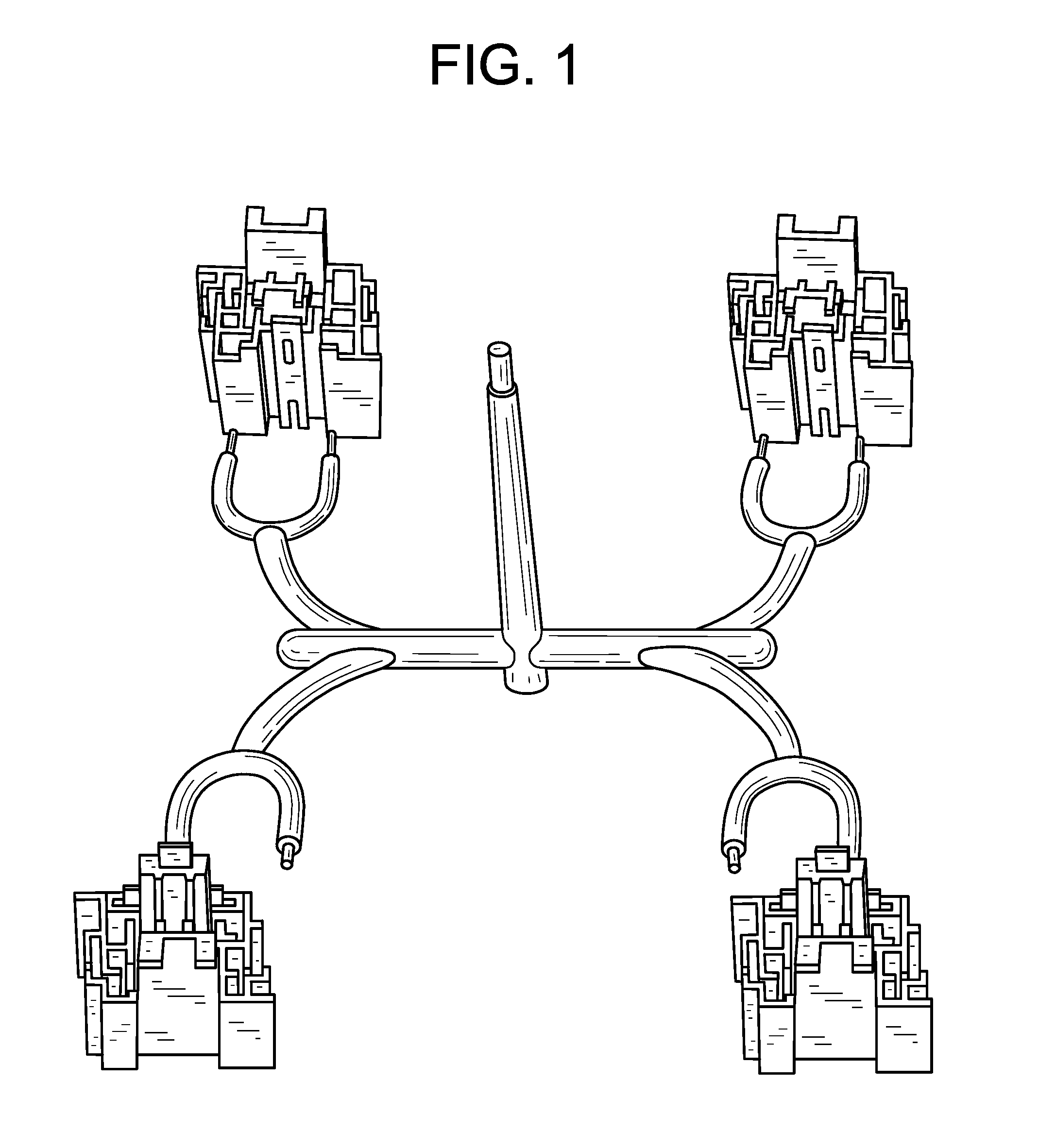

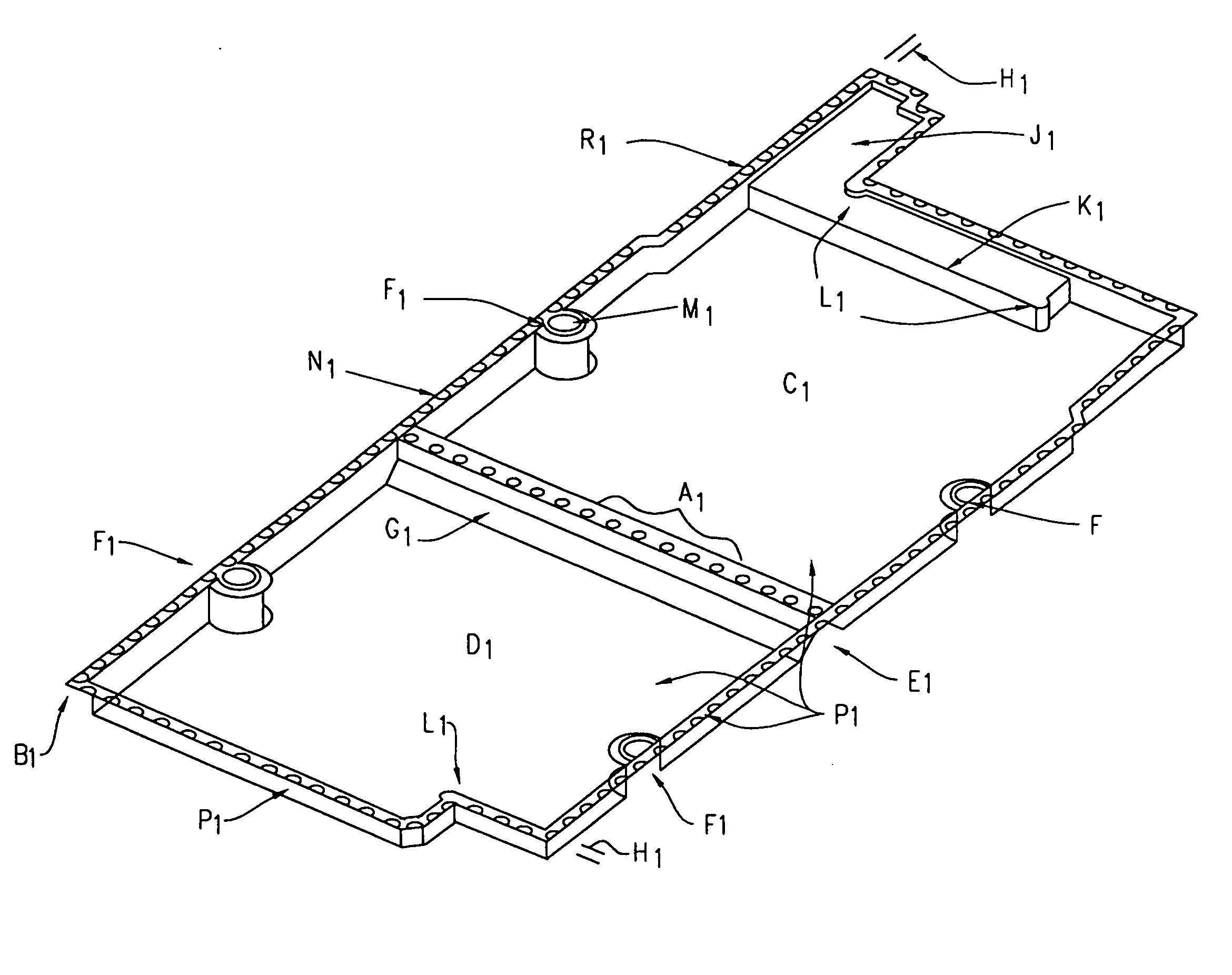

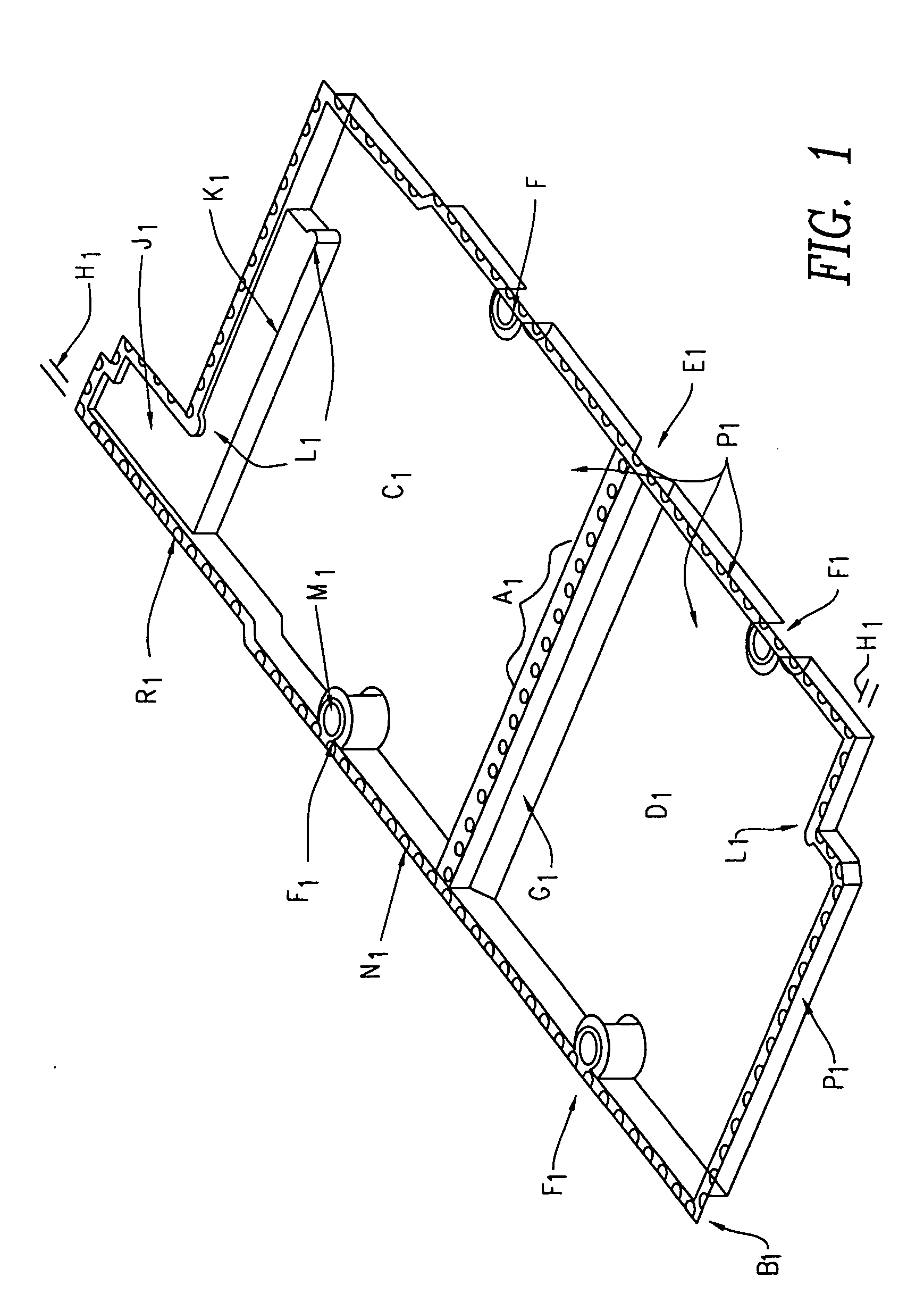

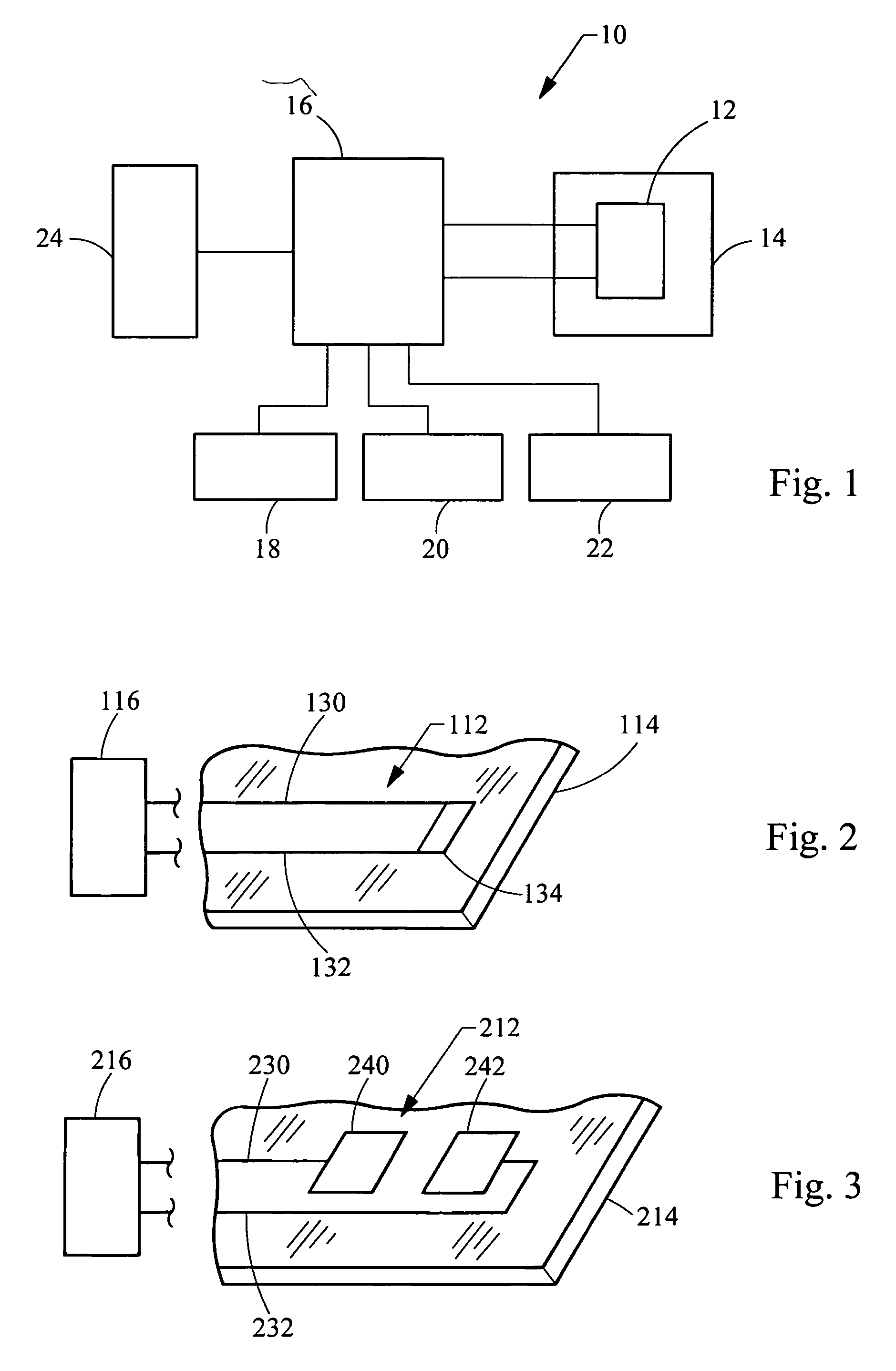

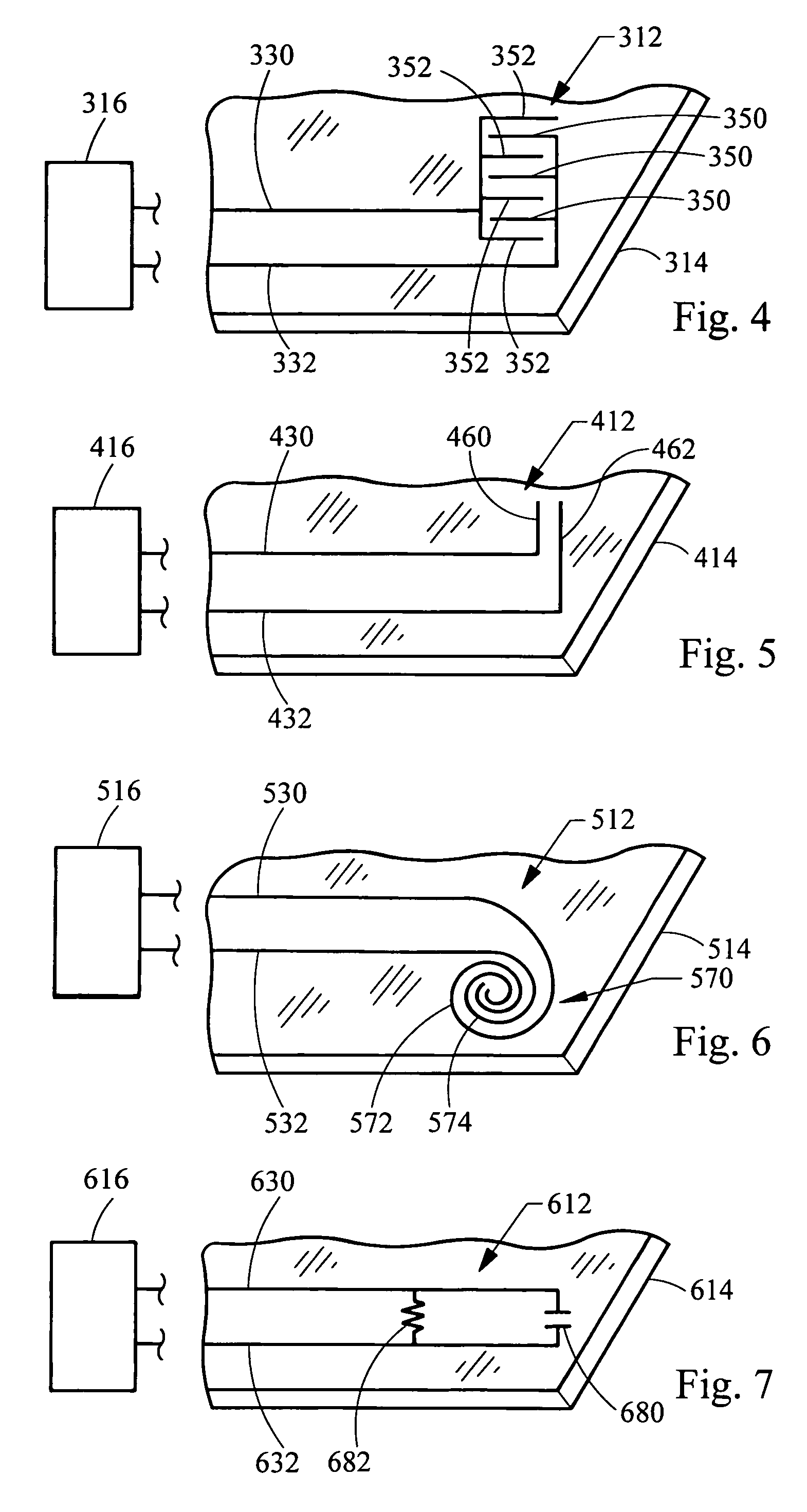

Conforming shielded form for electronic component assemblies and methods for making and using same

The present invention is directed to electronic components shielded from electromagnetic interference through the use of conforming shield enclosures. Conforming shield enclosures are flexible metalized thermoformed thin-wall polycarbonate polymer film substrates used to shield a radiation source. The present invention relates to conforming shielded forms for electronic component assemblies and specifically to electronic component assemblies which are shielded to protect against electromagnetic and radiofrequency interference. Specifically, the shielded electronic component assembly comprises (a) a semiconductor device to be shielded from electromagnetic frequencies; (b) a reference potential source; (c) a housing enclosing the semiconductor device within the assembly; and (d) a conforming shield enclosure electrically connected to the reference potential source. The conforming shield enclosure comprises a flexible, metalized thermoformable polymer having dimensions conforming to the inside of the housing and enclosing and thereby shielding the semiconductor device from electromagnetic frequencies. The conforming shield enclosure is prepared by paint metalization.

Owner:PPG IND OHIO INC

Deflectable tip videoarthroscope

ActiveUS20070249899A1Good light transmissionReduce scope repair costSurgeryLaproscopesIrrigation channelBisphenol-A-polycarbonate

A deflectable tip videoarthroscope of 5.4 mm diameter or smaller, comprising a miniaturized chip-in-tip CCD with four-way angulations mounted on the distal end of the arthroscope. The deflectable tip videoarthroscope may be provided with a replaceable distal window made of a thin material (such as polycarbonate or acrylic) or a glass (sapphire or other) with very high light transmission properties, connected to a sheathing system that is disposable or limited-reusable, which could be discarded if a shaver burr or ablation probe contacts the lens. This design protects the distal window of the videoarthroscope during use and reduces scope repair costs and system down-time. The deflectable tip videoarthroscope may additionally include a steering wheel, which allows 360 degree rotation of the instrument during arthroscopic procedures. The videoarthroscope may further include an irrigation channel or a wireless imager control system.

Owner:ARTHREX

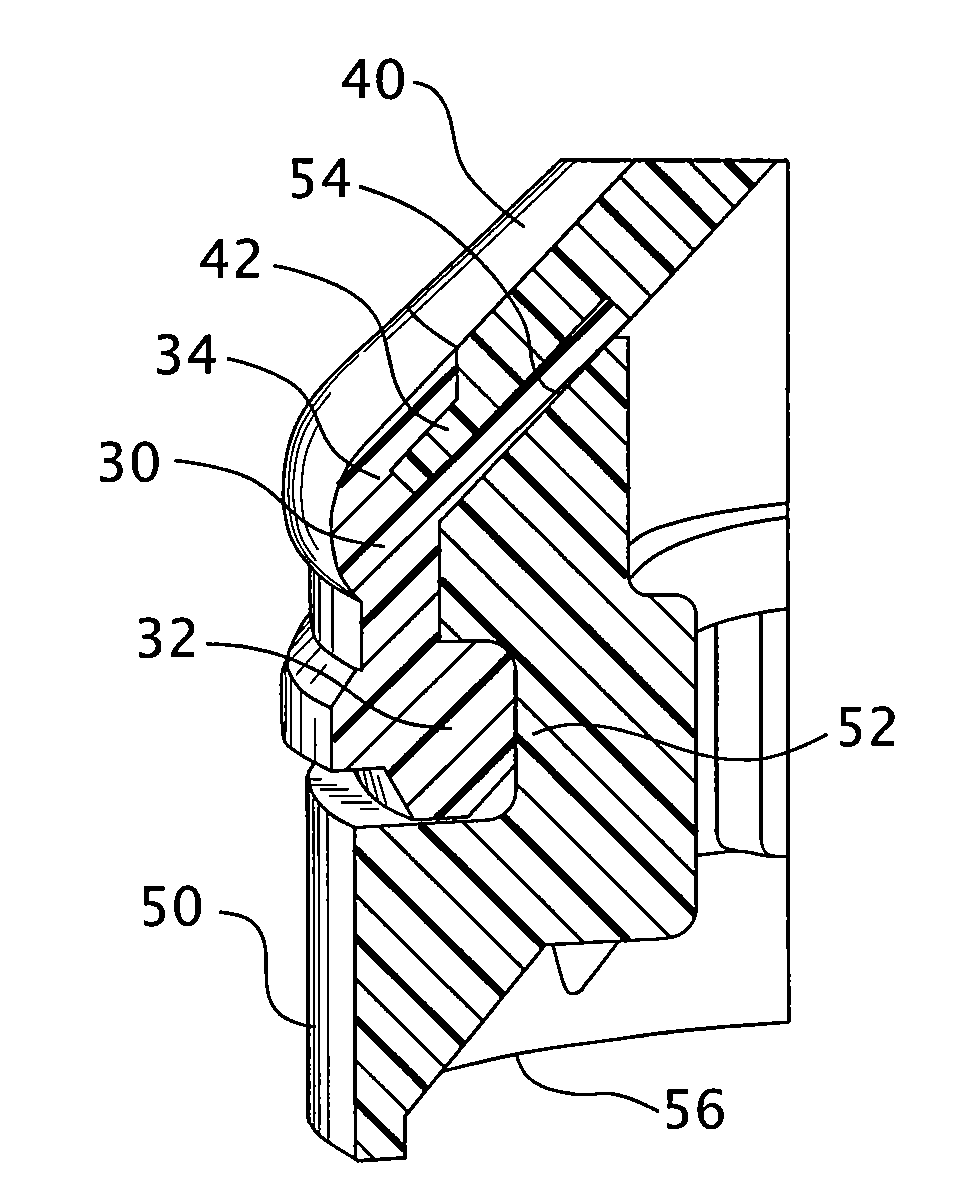

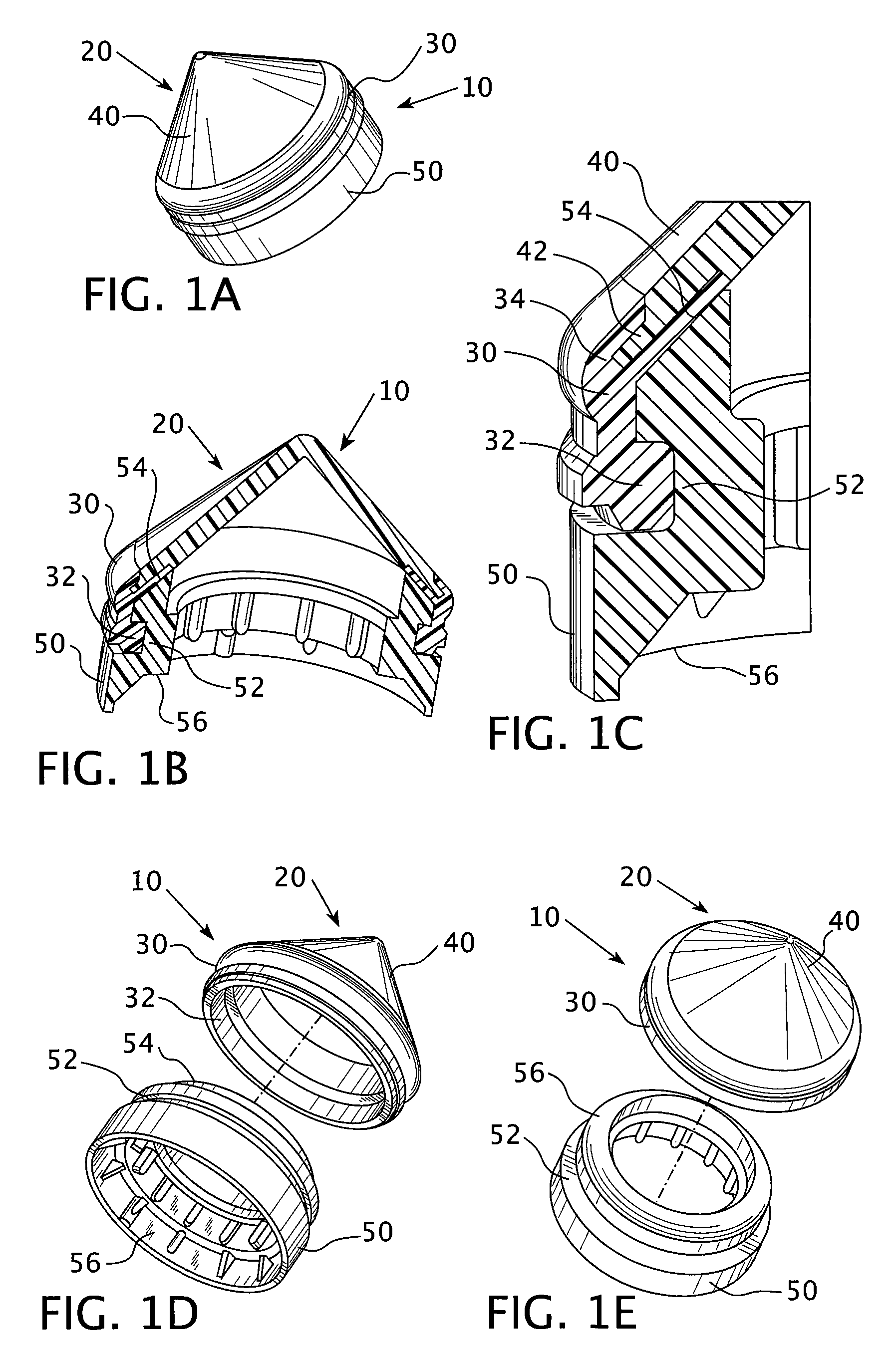

Plunger Covers and Plungers for Use in Syringes and Methods of Fabricating Plunger Covers and Plungers for Use in Syringes

A plunger cover for use with a syringe includes a sealing portion adapted to form a seal with the syringe and a central portion adapted to contact fluid within the syringe. The central portion can, for example, be more rigid than the sealing portion. The sealing portion and the central portion are connected in an overmolding process. The sealing portion can, for example, be formed from a thermoplastic elastomer or a thermoplastic polyurethane. The central portion can, for example, be formed from polypropylene, acrylonitrile butadiene styrene, polycarbonate or copolymers thereof.

Owner:BAYER HEALTHCARE LLC

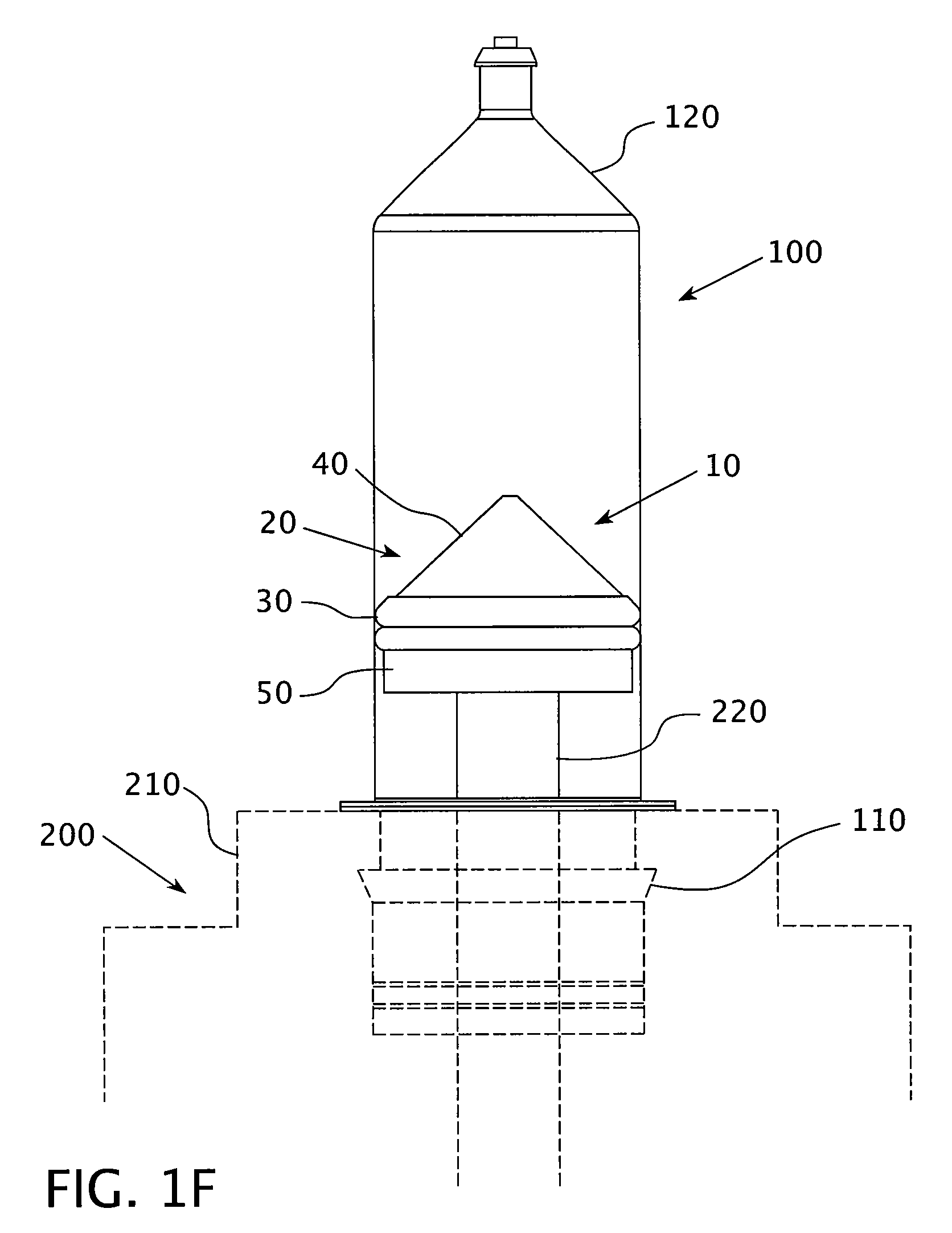

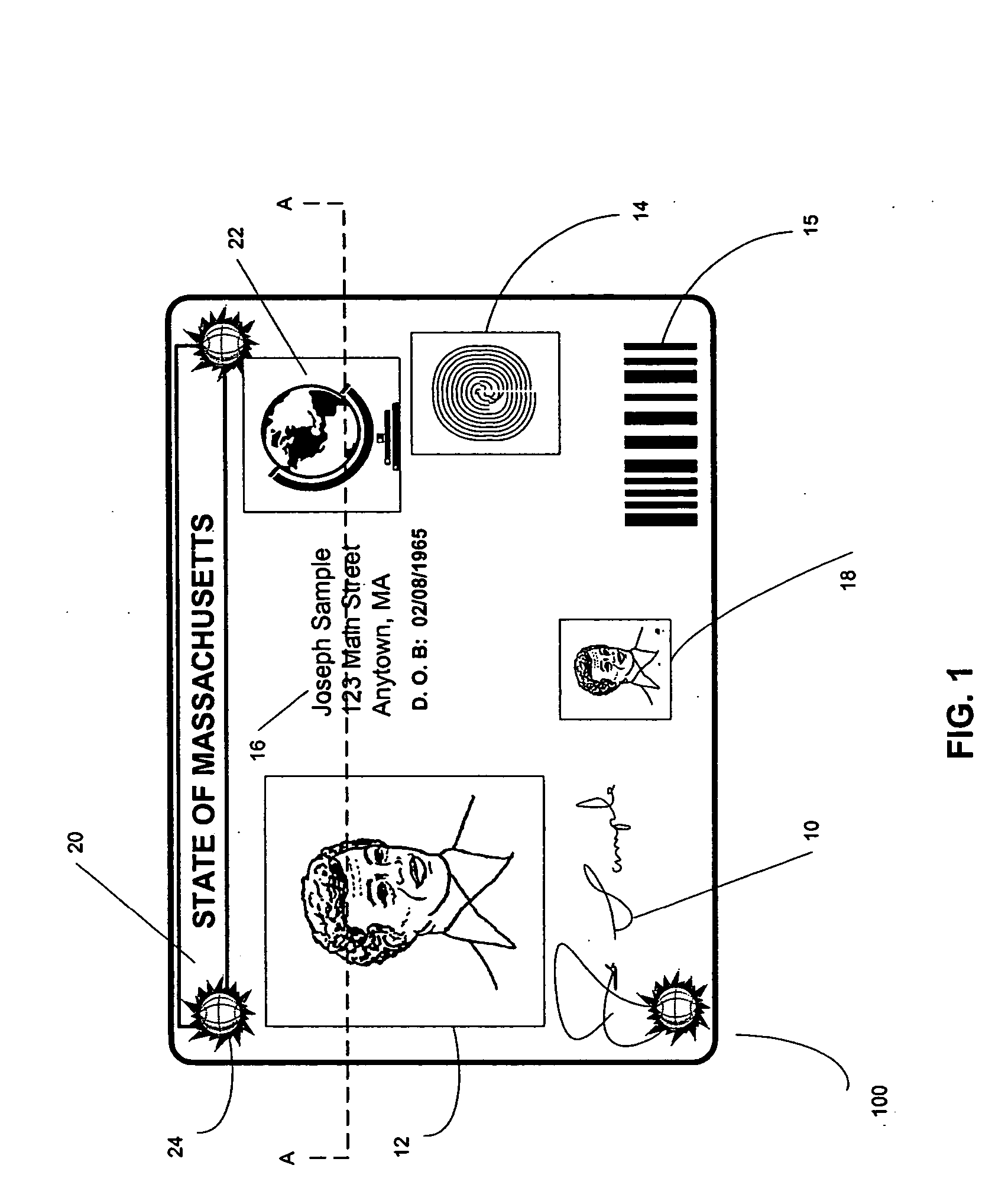

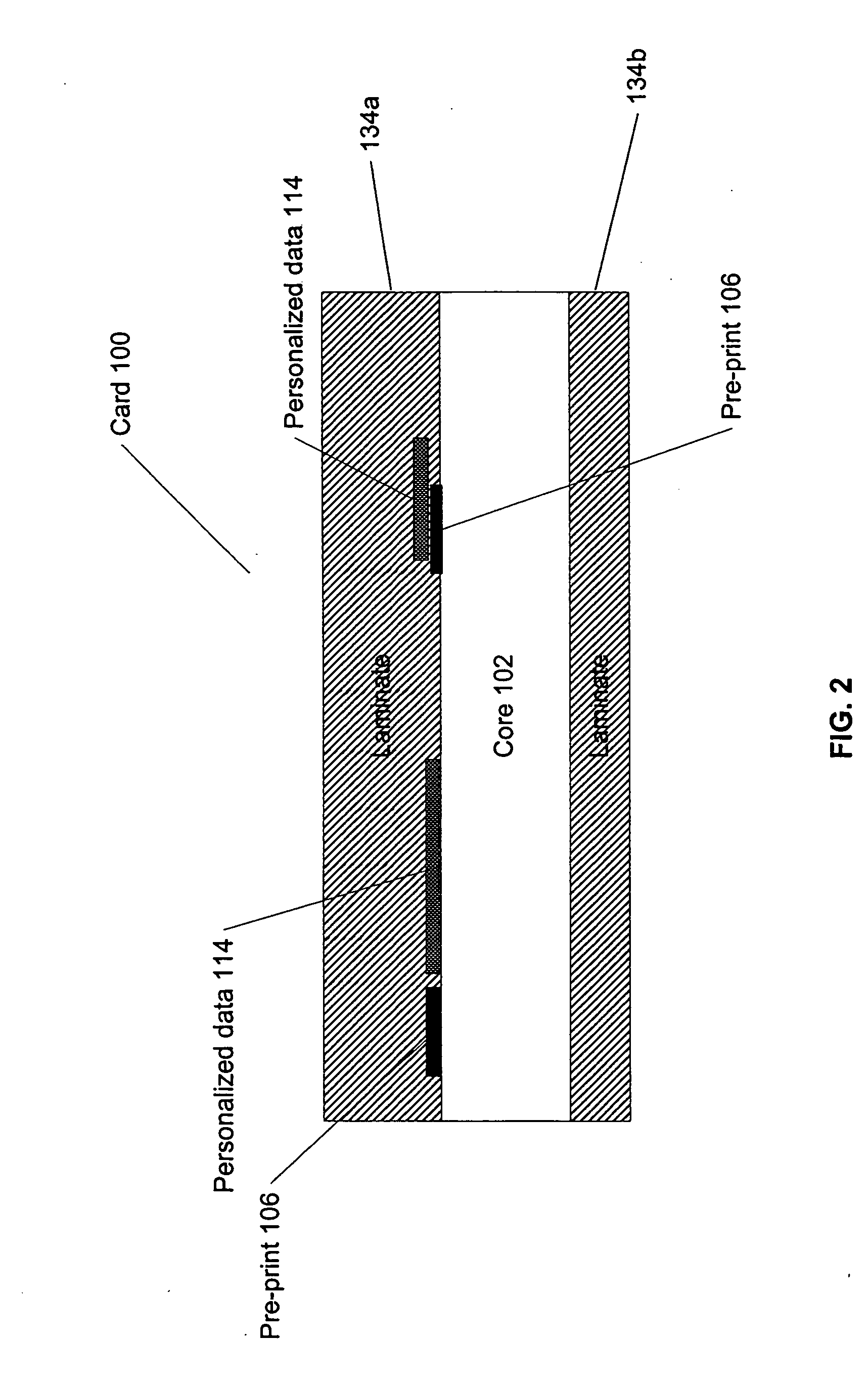

Identification document having intrusion resistance

InactiveUS20050247794A1Improve security levelUltimate in durabilityOther printing matterRecord carriers used with machinesAdhesiveEngineering

An identification document is provided, comprising a core layer, such as TESLIN, laminated directly to a laminate layer, such as polycarbonate, without the use of an adhesive. The core layer has at least one indicium formed thereon and has a first surface. The first layer of laminate is affixed to the core layer by a press lamination process where the press lamination process is sufficient to couple the core layer to the first layer such that an attempt to separate the first layer from the core layer causes at least a partial destruction of the core layer.

Owner:DIGIMARC CORP

Flame retardant thermoplastic polycarbonate compositions, use, and method of manufacture thereof

Owner:SABIC INNOVATIVE PLASTICS IP BV

Environmentally friendly polylactide-based composite formulations

Polymeric materials and products, including sheet flooring materials prepared from the polymeric materials, and processes for preparing the polymeric materials, are disclosed. The polymeric materials include a polylactic acid-based polymer in combination with plasticizer and a compatibilizer, and optionally include a filler. The polymeric material can include between about 30 to about 50 percent by weight polyvinyl chloride, polyethylene glycol, polyglycolide, ethylene vinyl acetate, polycarbonate, polycaprolactone, polyhydroxyalkanoates, or polyolefins modified with polar groups, for example, ionomers. The plasticizer is typically an epoxidized vegetable oil or esterified and epoxidized vegetable oil and is typically present in an amount of between about 10 and about 50% by weight. In some embodiments, the compatibilizer is a polyolefin modified with one or more polar functional groups, and is typically present in an amount of between about 5 and about 10% by weight. The material can be used in decorative surface coverings, such as a floor coverings, particularly when it is in the form of a polymeric sheet. The polymeric material can be present in at least one layer of a floor covering, which floor covering can also include one or more additional layers such as wear layers, foamed or foamable layers, top coat layers and design layers. The additional layers can also include the polymeric material.

Owner:AFI LICENSING

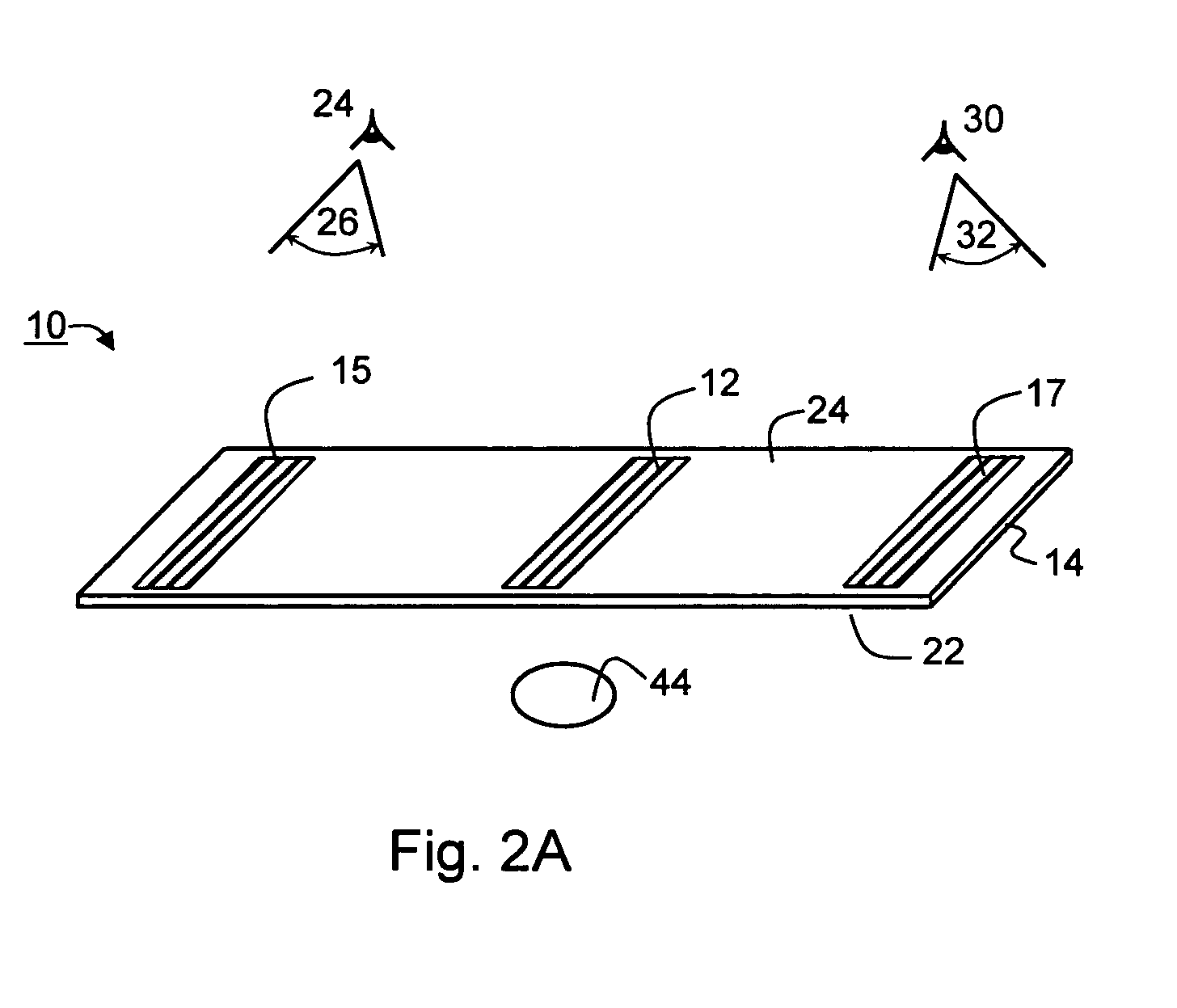

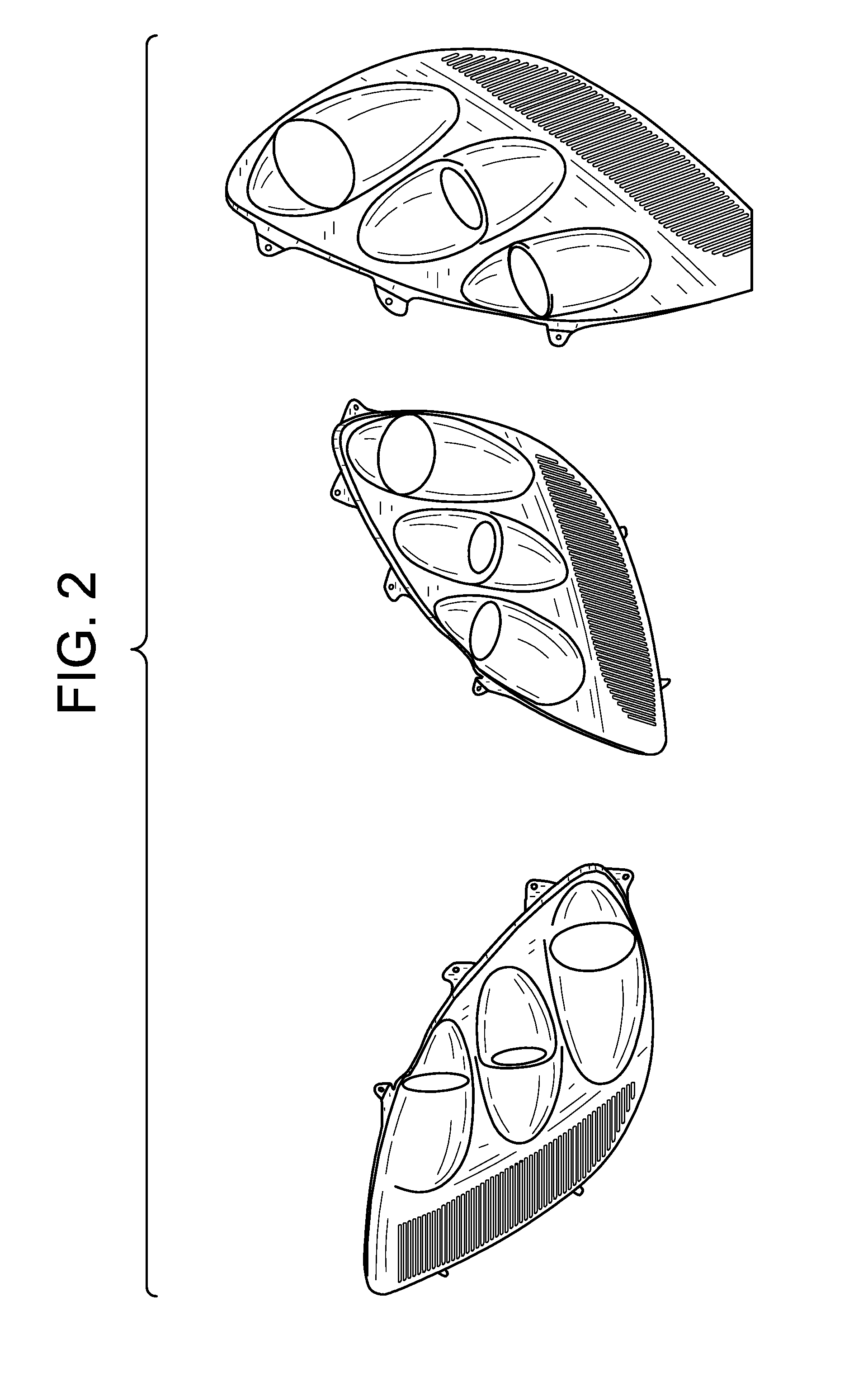

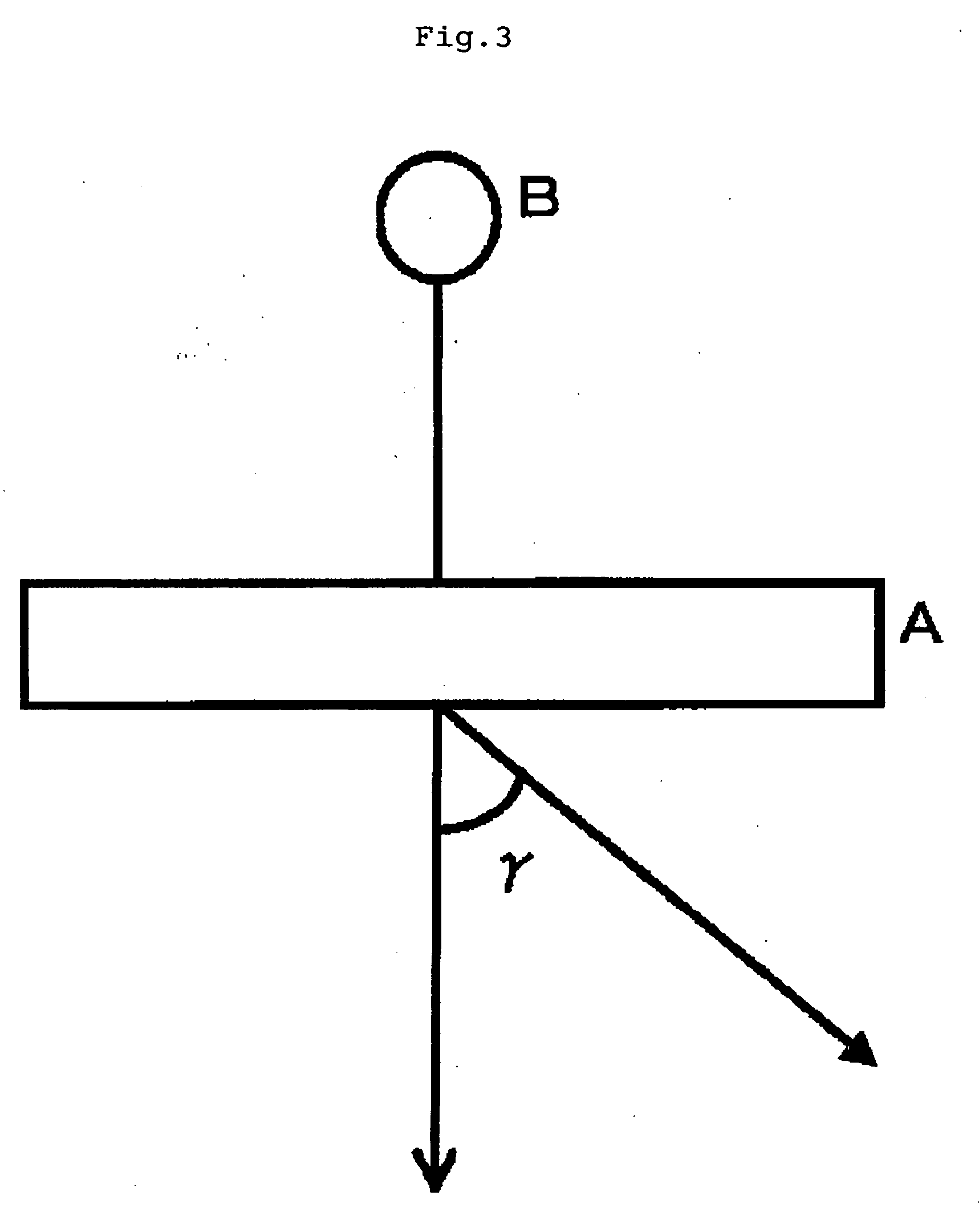

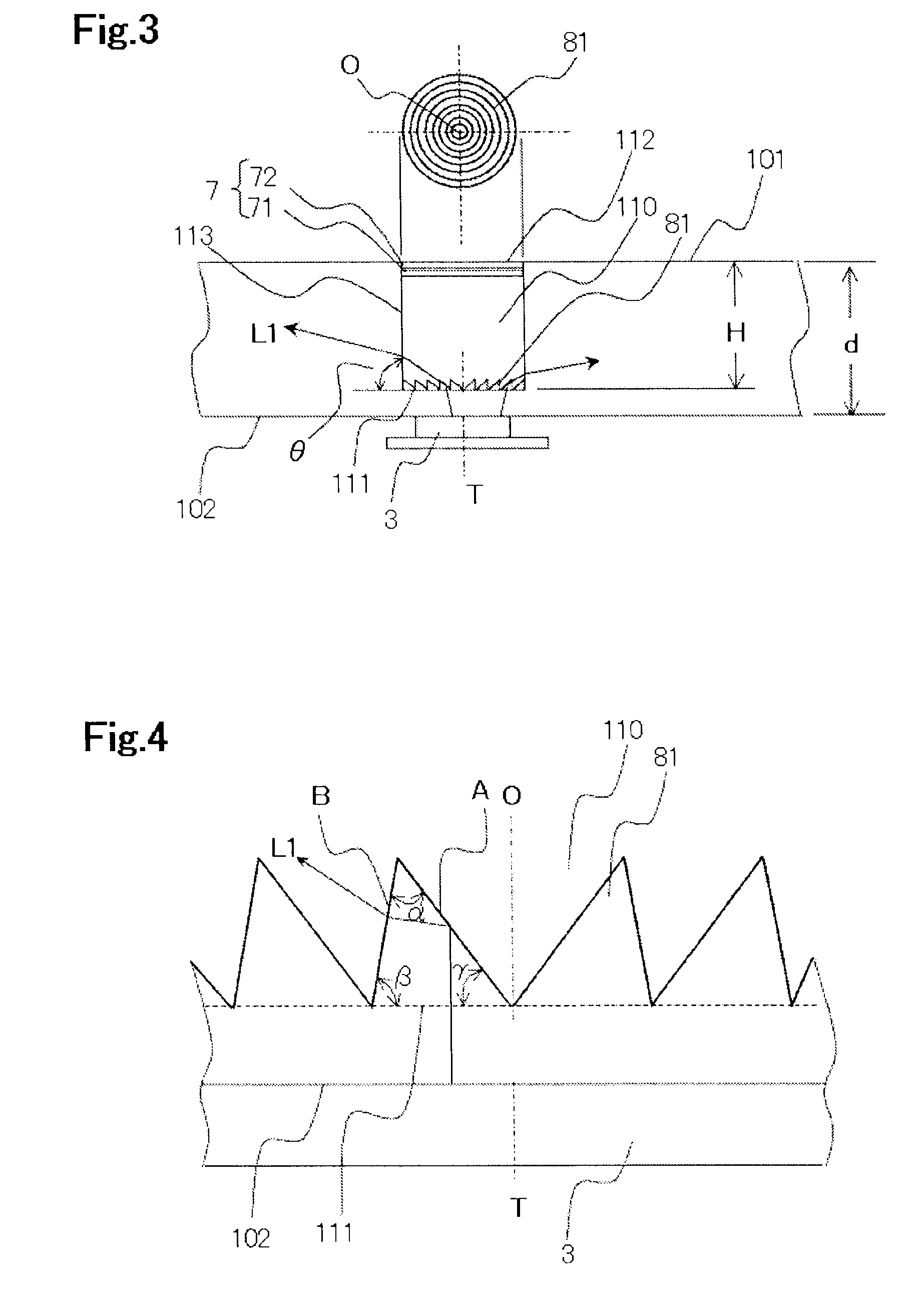

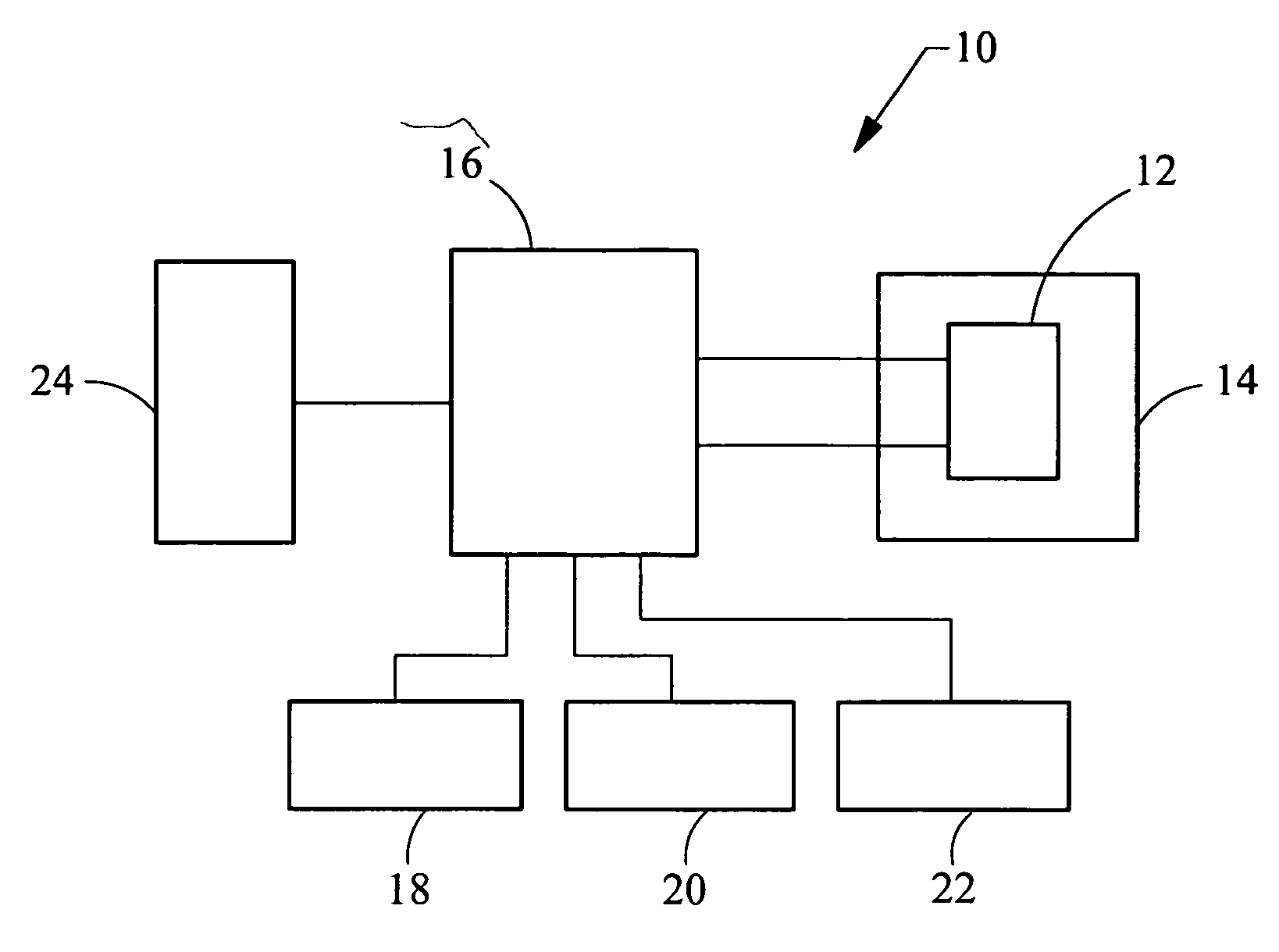

Printable sensors for plastic glazing

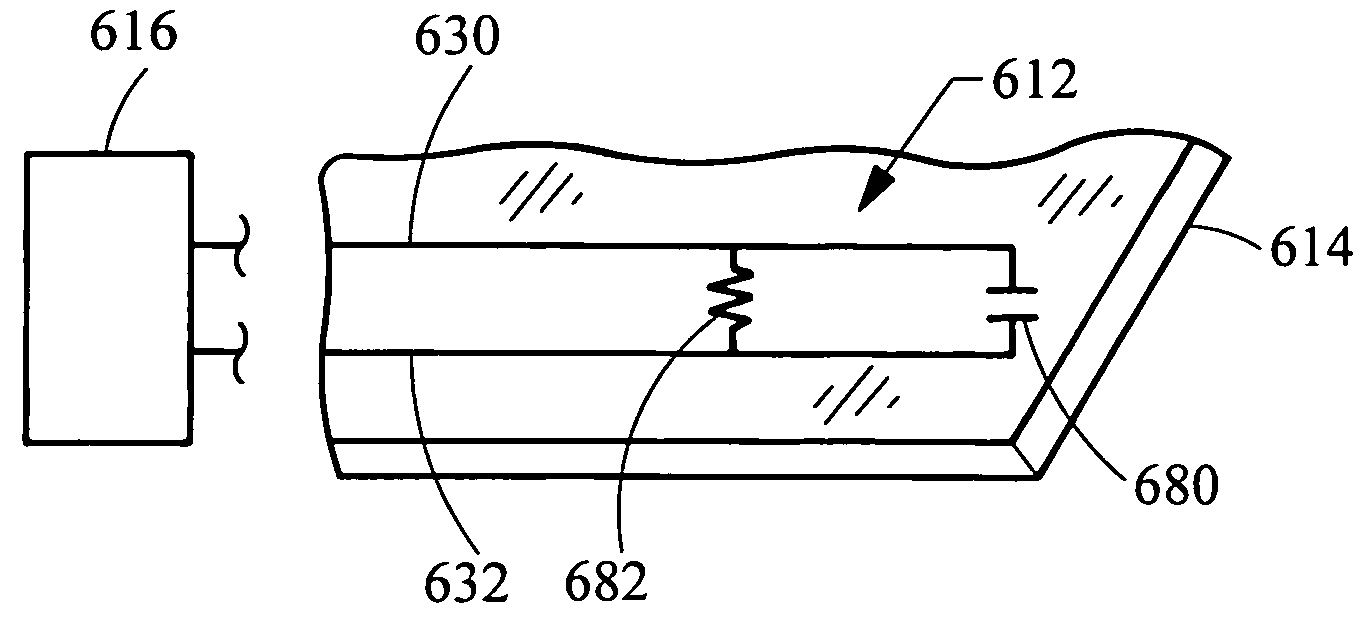

ActiveUS7567183B2Level indicatorsUsing reradiationElectrical resistance and conductanceCapacitive sensing

A system for sensing environmental conditions on a window assembly. The system includes a transparent panel and a sensor integrated onto the panel. The sensor being configured to sense environmental changes on the panel. The sensor may comprise conductive inks that are printed onto the window assembly. The window assembly may comprise a plastic panel, such as a multilayer polycarbonate panel such that a portion of the sensor may be located on the one layer of the panel while another portion of the sensor overlaps the first portion on a second layer of the window. The sensor may be a resistive or capacitive sensor and may be configured to detect changes in one or more environmental conditions, such as temperature or moisture. Further, the sensor may be in electrical communication with a controller configured for control various vehicle subsystems based on the sensor.

Owner:EXATEC LLC

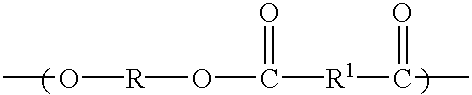

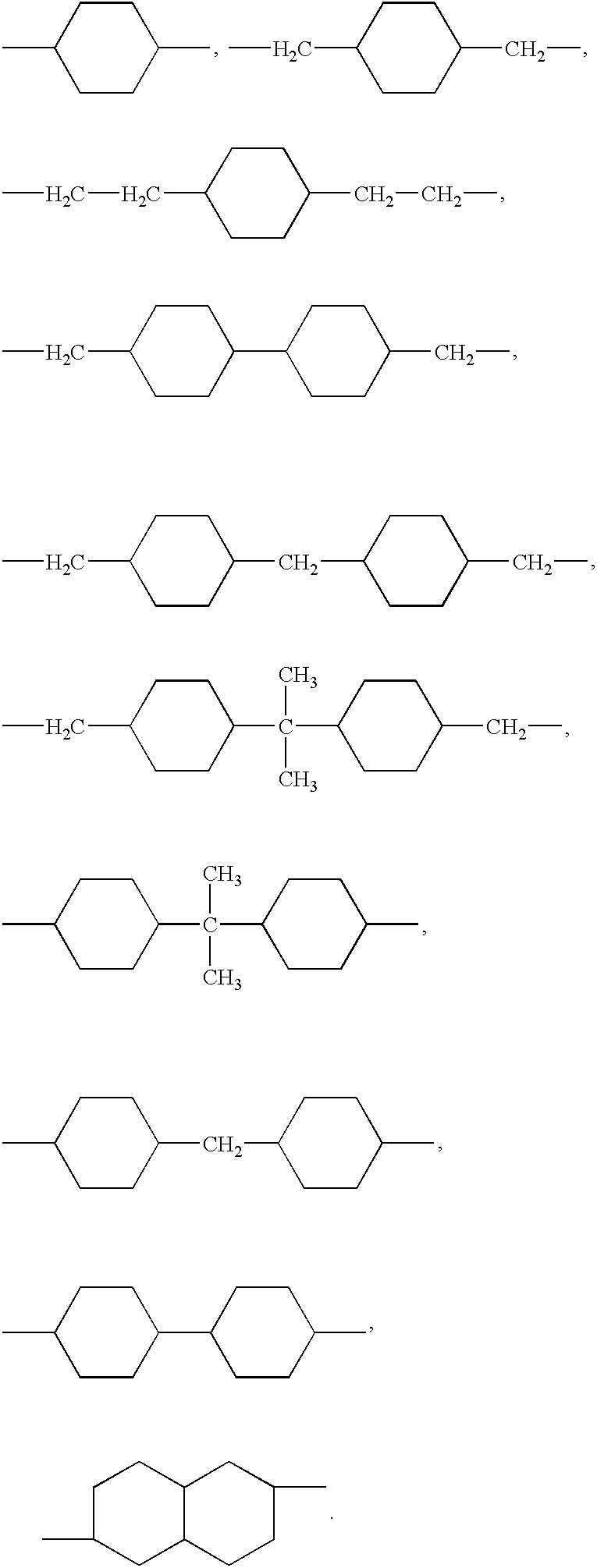

Flame retardant polycarbonate polyester composition

InactiveUS20020128357A1Improve performanceImprove impact performancePlastic/resin/waxes insulatorsDyeing processPass ratePolyester resin

A transparent / translucent flame redardant composition comprises a uniform blend of a miscible resin blend of a polycarbonate resin and a cycloaliphatic polyester resin wherein the composition has at least a 80% pass rate in 10 test specimen in the Norme Francaise NF-P-92-505 flammability test of L'Association Francaise de Normalisation using test specimens with weight between about 1.0 to about 6.0 kilograms per square meter.

Owner:GENERAL ELECTRIC CO

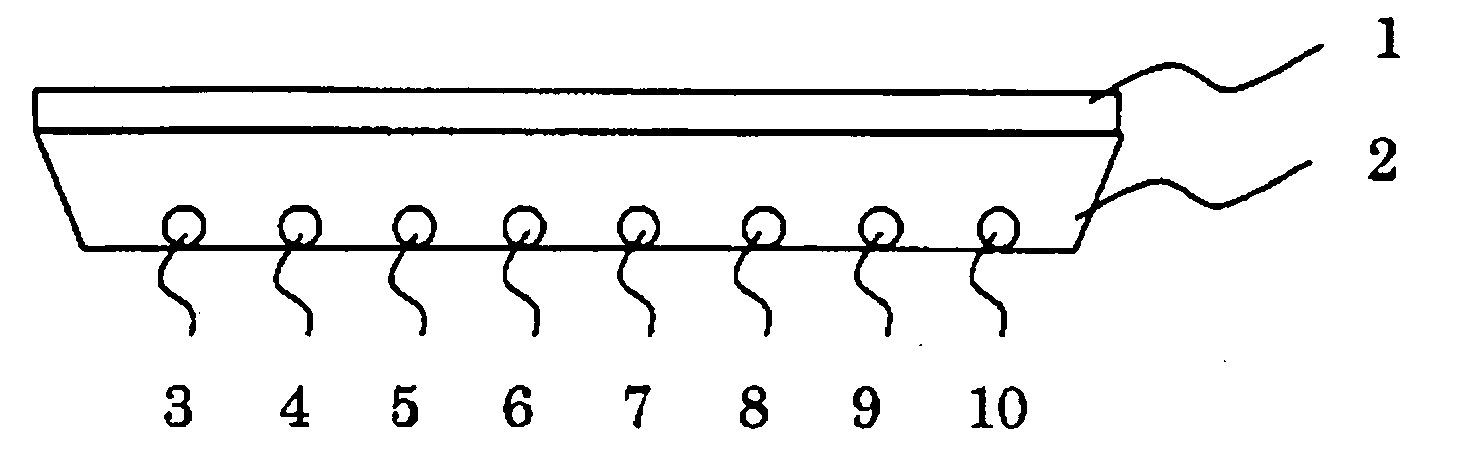

Direct back light type liquid crystal display and light diffuse plate

InactiveUS20060146228A1Good light diffusion effectPrevent discolorationLiquid crystal compositionsMeasurement apparatus componentsWhitening AgentsPhosphate

There is provided a direct backlight type liquid crystal display device having high light diffusability, keeping excellent color and having high brightness. The direct backlight type liquid crystal display device is a direct backlight type liquid crystal display device comprising: a backlight source, a light diffusion sheet which may have a protective film on a surface thereof which faces the backlight source or both surfaces thereof as desired, a light ray adjusting film, and a liquid crystal panel, wherein the light diffusion sheet is formed from a composition comprising predetermined amounts of (C) at least one heat stabilizer (component C) selected from the group consisting of a phosphate compound (component C-1), a phosphate compound (component C-2) and a phosphonite compound (component C-3), (D) an ultraviolet absorber (component D) and (E) a fluorescent whitening agent (component E), based on 100 parts by weight of the total of (A) an aromatic polycarbonate resin (component A) and (B) polymeric fine particles (component B) having an average particle diameter of 0.01 to 50 μm.

Owner:TEIJIN KASEK KK

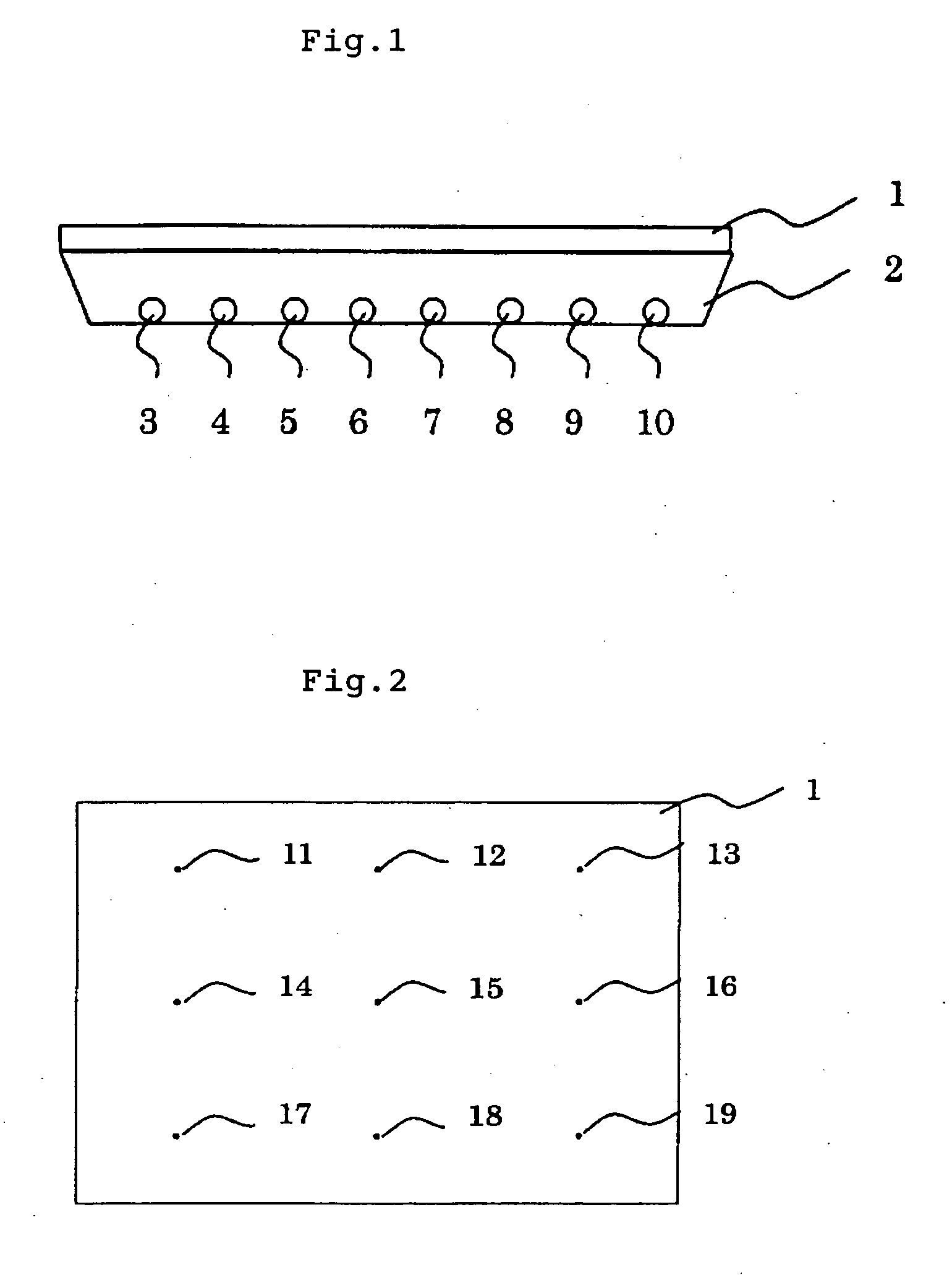

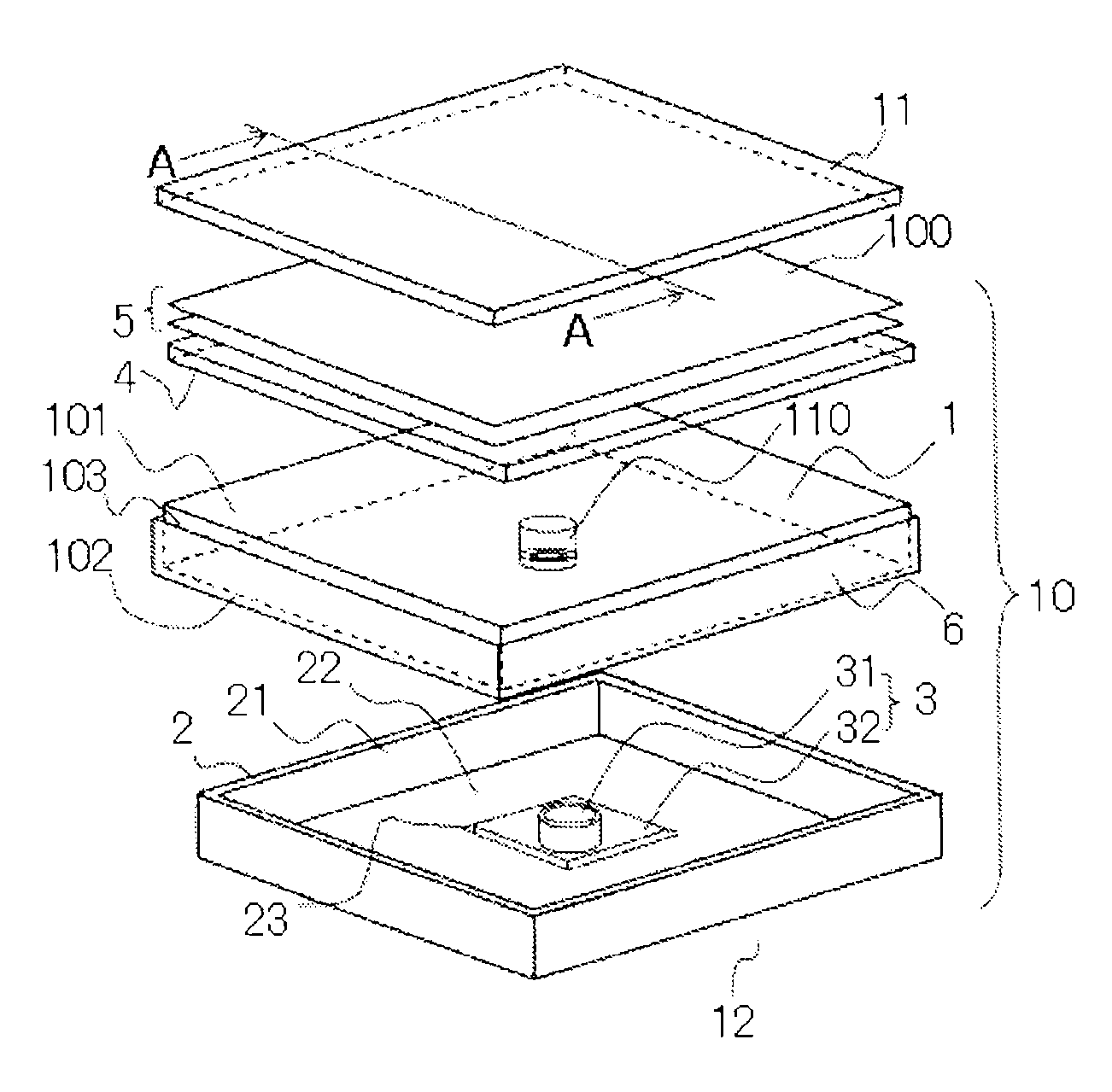

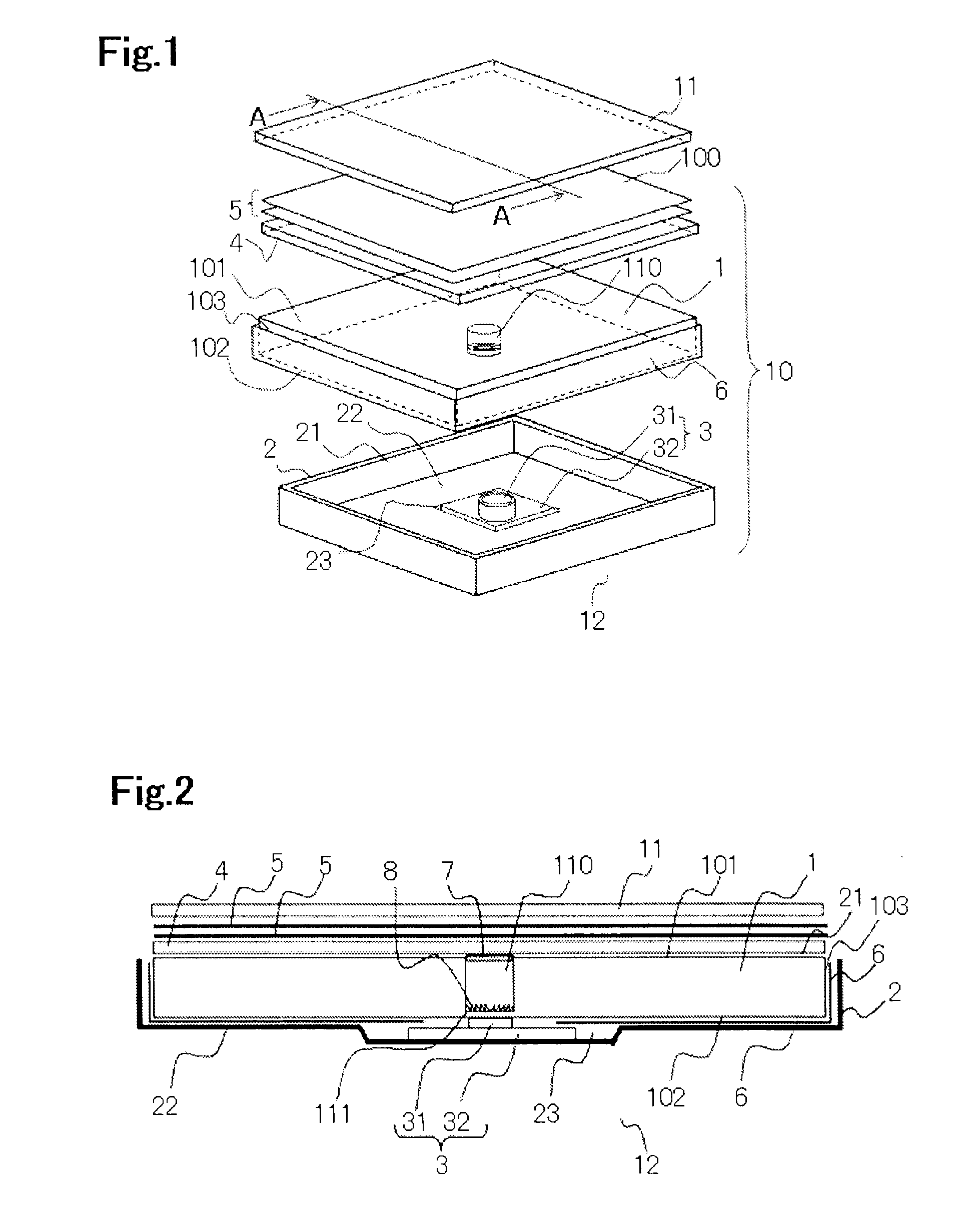

Planar light source device and display apparatus incorporating same

InactiveUS20100079980A1Highly uniform intensityImprove utilization efficiencyPlanar/plate-like light guidesGlobesLight guideOptoelectronics

A planar light source device with highly uniform intensity and high light utilization efficiency, and a display apparatus incorporating the same, are provided. A light guide plate, configured by a material such as plate-shaped and transparent acryl resin, polycarbonate resin, or glass, causes incident light to propagate within the light guide plate and then to exit the light through an exit surface as a surface emitting light. A first recess is formed substantially in the center of the exit surface. The first recess is cylinder-shaped, and on a bottom thereof is provided a lens that refracts incident light from a light source, in a direction away from the center of a circle on the bottom.

Owner:TRIVALE TECH LLC

Printable sensors for plastic glazing

A system for sensing environmental conditions on a window assembly. The system includes a transparent panel and a sensor integrated onto the panel. The sensor being configured to sense environmental changes on the panel. The sensor may comprise conductive inks that are printed onto the window assembly. The window assembly may comprise a plastic panel, such as a multilayer polycarbonate panel such that a portion of the sensor may be located on the one layer of the panel while another portion of the sensor overlaps the first portion on a second layer of the window. The sensor may be a resistive or capacitive sensor and may be configured to detect changes in one or more environmental conditions, such as temperature or moisture. Further, the sensor may be in electrical communication with a controller configured for control various vehicle subsystems based on the sensor.

Owner:EXATEC LLC

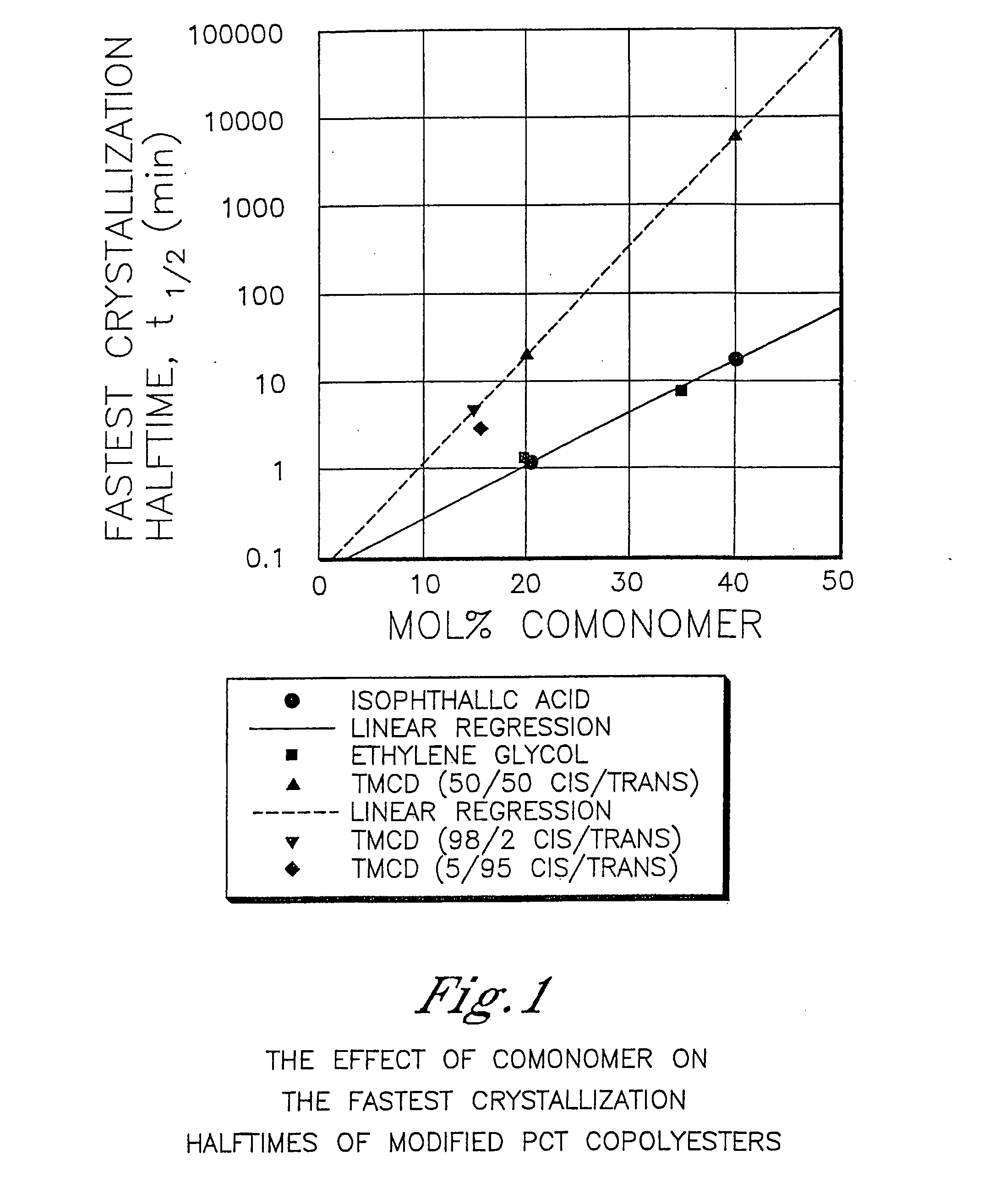

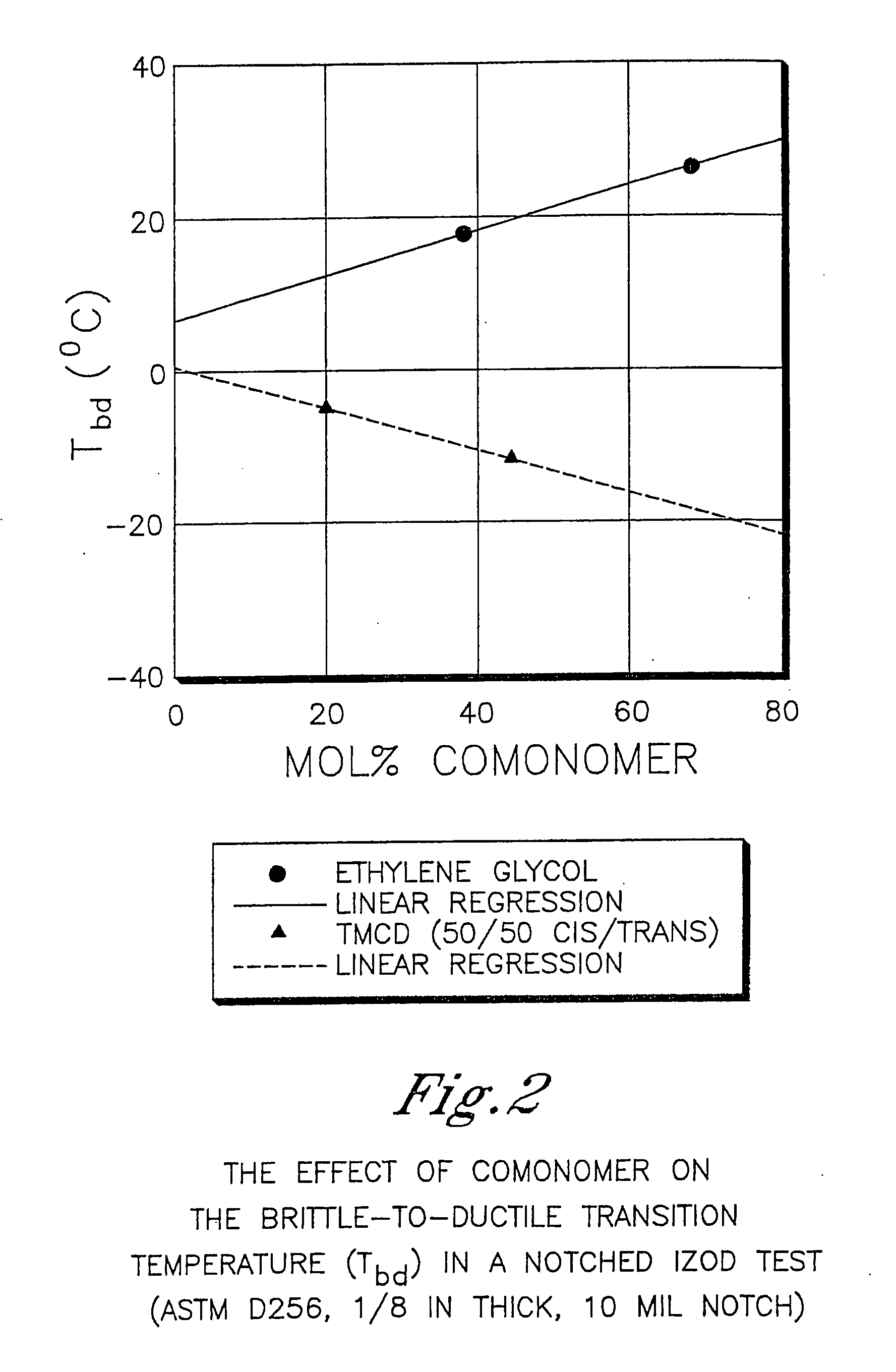

Polyester-polycarbonate blends for diffuser sheets with improved luminance

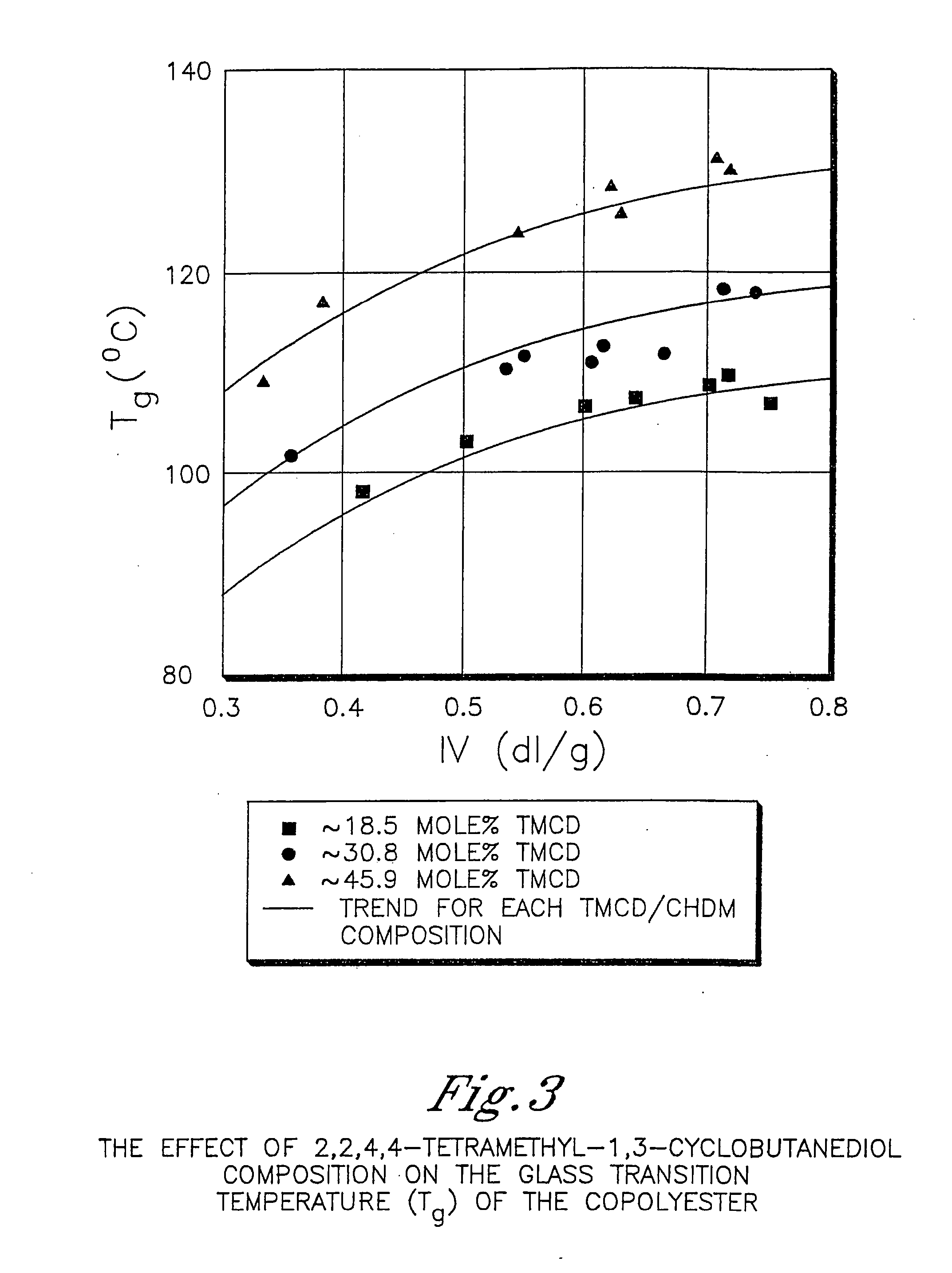

InactiveUS20060270773A1Inherent viscosityIncrease temperatureSpecial tyresOptical light guidesPolyesterParticulates

Disclosed is a composition for a diffuser sheet or film with improved luminance or brightness. The composition comprises about 80 to about 99.8 percent by weight of a miscible blend of a polycarbonate with a polyester, and about 0.2 to about 20 percent by weight of a particulate light diffusing component, and about 10 to about 1000 ppm of a brightness enhancing agent. Also disclosed is a process for the preparation of a diffuser film or sheet from this composition. Diffuser films and sheets prepared from this composition are useful for bulk light diffusers for backlight displays.

Owner:EASTMAN CHEM CO

Thermoplastic polycarbonate compositions with improved mechanical properties, articles made therefrom and method of manufacture

A thermoplastic composition comprising a polycarbonate resin, a mineral filler and an acid or an acid salt, and optionally an aromatic vinyl copolymer and / or an impact modifier, has been found to exhibit improved characteristics and less degradation than filled thermoplastic compositions without the acid or acid salt. In some embodiments the composition exhibits improved impact and ductility, as well as molecular weight retention. An article may be formed by molding, extruding, shaping or forming such a composition to form the article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Thermoplastic polycarbonate compositions, method of manufacture, and method of use thereof

InactiveUS20060004154A1Improve hydrolytic stabilityImprove thermal stabilityThermoplasticThermal stability

A thermoplastic composition comprising in combination a polycarbonate component; and an impact modifier composition wherein the components of the impact modifier composition are substantially free of a species that degrades a polycarbonate, the components comprising a bulk polymerized ABS; and an impact modifier different from the ABS. The compositions have significantly increased hydrolytic stability, in combination with good thermal stability and / or impact strength.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Process for the preparation of transparent shaped articles

ActiveUS20060197246A1Improve claritySuitable for preparationEnvelopes/bags making machineryFilament/thread formingPolyesterPolymer science

Disclosed is a process for the preparation of shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles, having high transparency and low haze comprising immiscible blends of one or more thermoplastic polymers selected from polyesters, polycarbonates, and polyarylates, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The components of the immiscible blend which have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into the compositions to produce shaped articles having oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

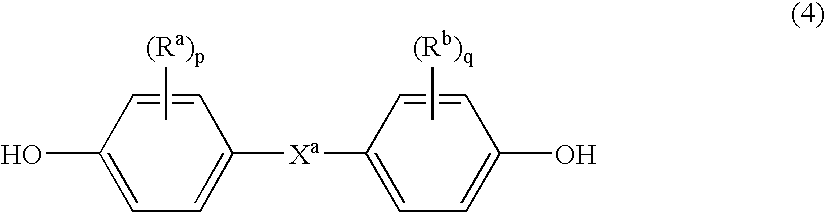

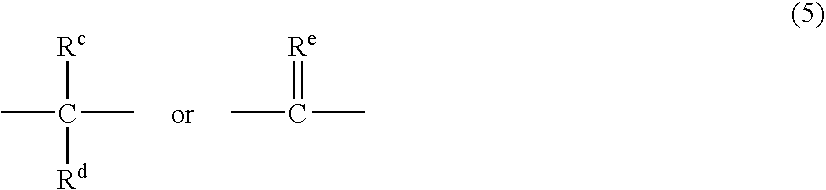

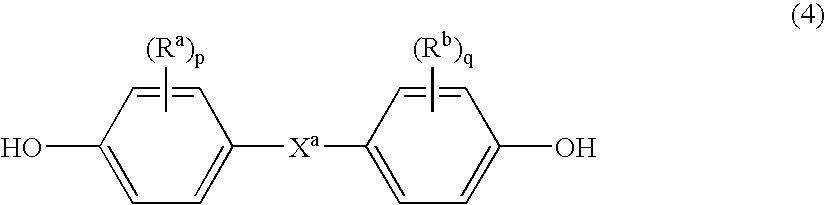

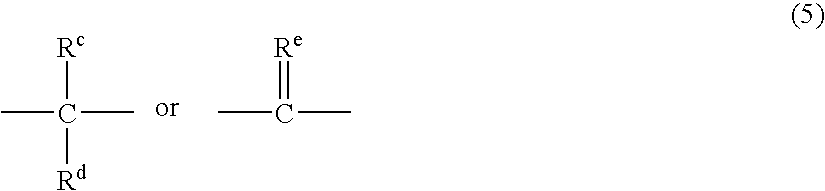

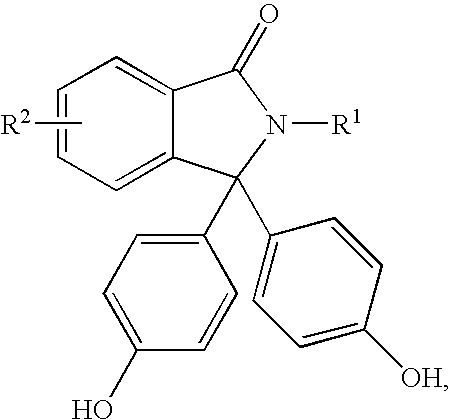

Methods for producing and purifying 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine monomers and polycarbonates derived therefrom

Disclosed herein is a method for producing a 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine. The method comprises forming a reaction mixture comprising at least one substituted or unsubstituted phenolphthalein, at least one substituted or unsubstituted primary hydrocarbyl amine, and an acid catalyst; and heating the reaction mixture to a temperature of less than 180° C. to remove a distillate comprising water and form a crude 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine product; where the 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine has a formula: where R1 is selected from the group consisting of a hydrogen and a hydrocarbyl group, and R2 is selected from the group consisting of a hydrogen, a hydrocarbyl group, and a halogen.

Owner:SHPP GLOBAL TECH BV

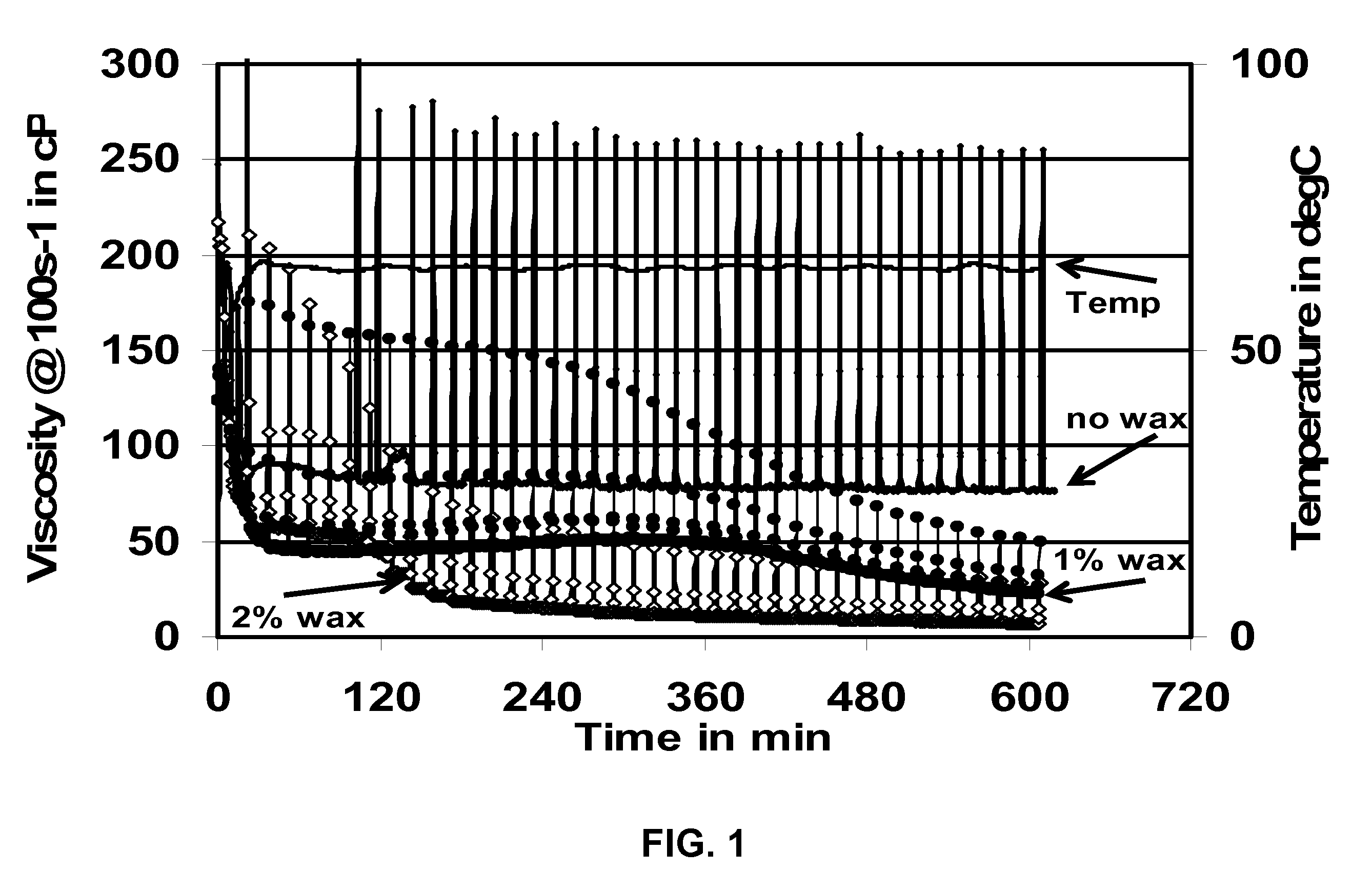

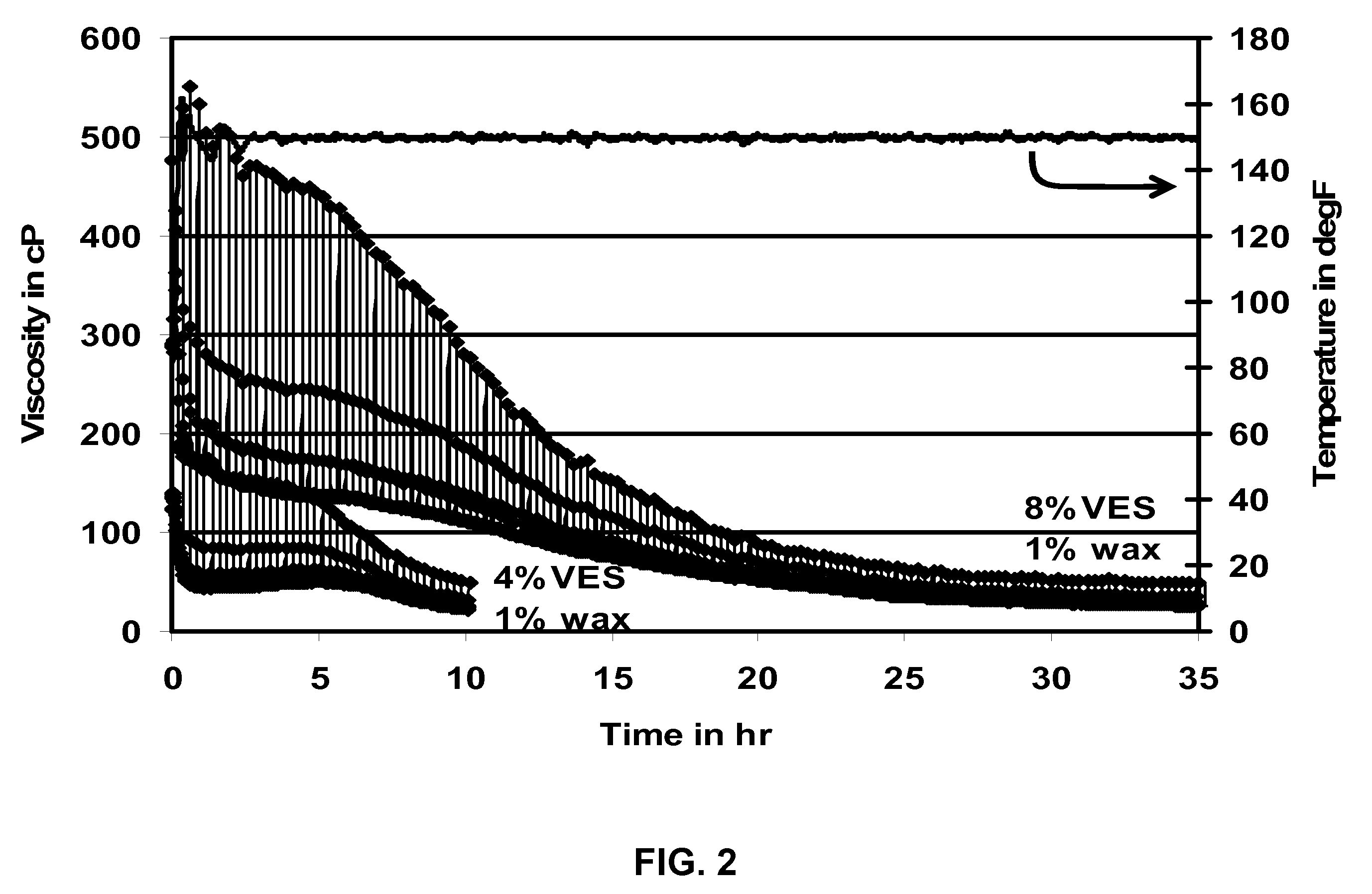

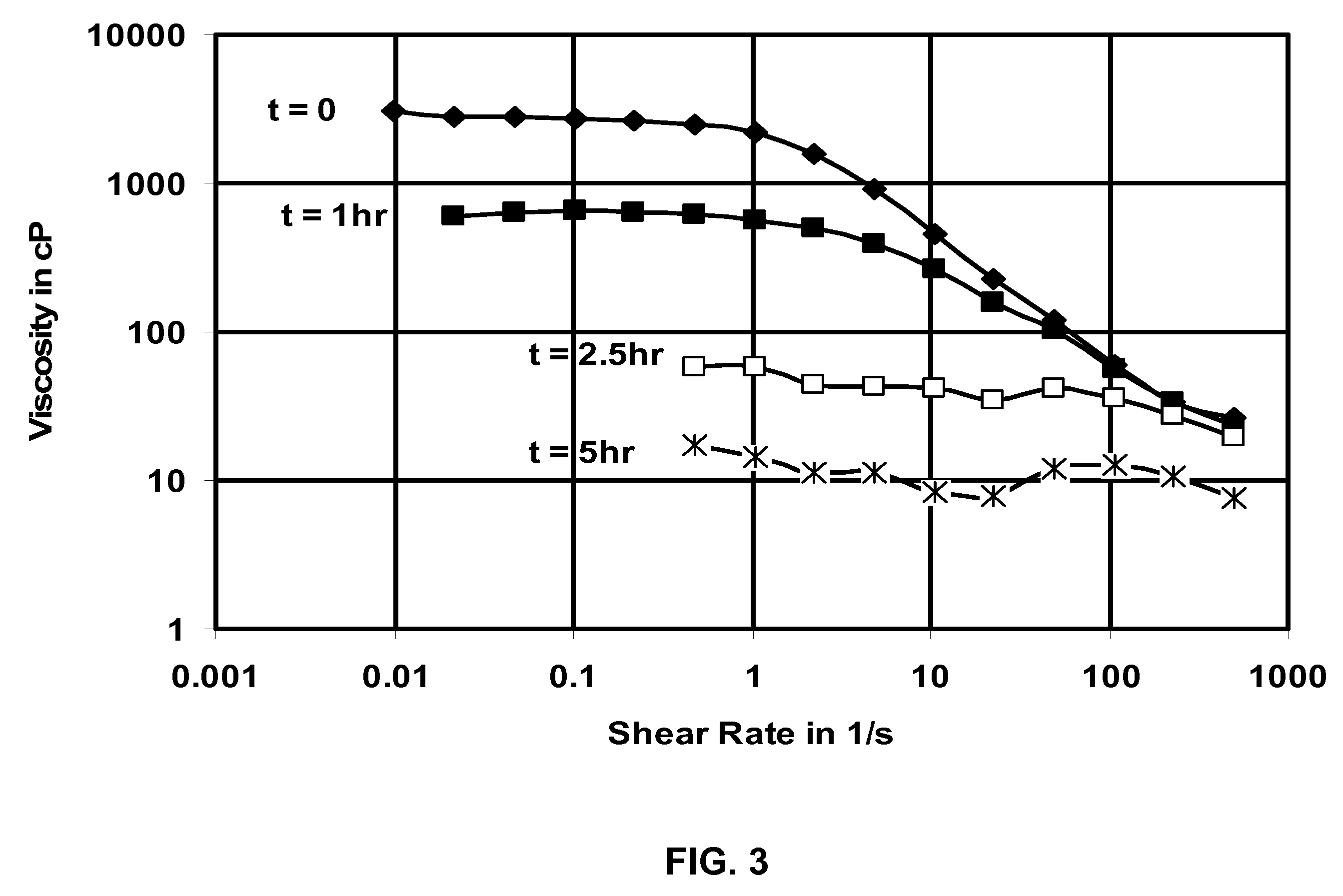

Internal Breaker for Oilfield Treatments

A composition and method for improving the fluid efficiency of many oilfield treatments is given. The composition is a solid additive, in a viscosified fluid, in a size range small enough that it enters formation pores; it optionally bridges there to form an internal filter cake, and then decomposes to provide a breaker for the viscosifying system for the fluid. Examples of suitable additives include waxes, polyesters, polycarbonates, polyacetals, polymelamines, polyvinyl chlorides, and polyvinyl acetates. Degradation of the additive may be accelerated or delayed.

Owner:SCHLUMBERGER TECH CORP

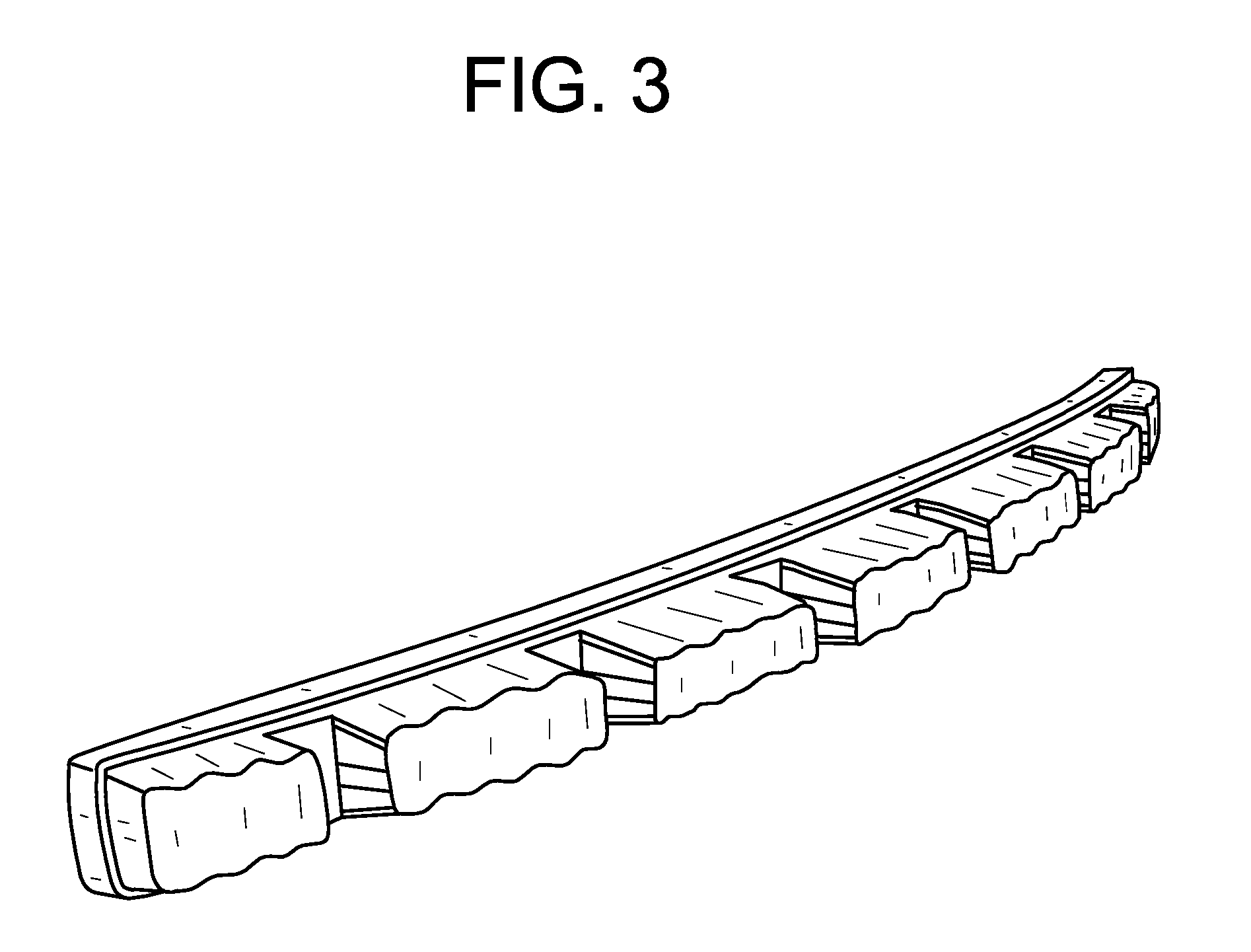

Blade Insert Illuminator

ActiveUS20090112068A1Maximize light transferReduce light lossEndoscopesSurgical field illuminationBlind zonePlastic materials

An air gap retractor illumination system includes any suitable retractor such as a McCulloch with a channel in the blade to accommodate an air gap illuminator. The illuminator is preferably made from a suitable light conducting plastic material such as acrylic or polycarbonate or silicone. The illuminator has active portions in which light passes and inactive or dead zones in which light does not pass as a result of the configuration and orientation of the input, output and surfaces of the illuminator. The illuminator is formed to have an air gap surrounding any active portion of the illuminator extending from the light input to the light output portion. The dead zones may include elements to allow the illuminator to securely engage the retractor. The light output portion of the illuminator contains from two to eight output zones, each zone having specially designed output optical structures that control and direct light to escape the illuminator to shine onto a predetermined area of interest or to form one or more predetermined shapes or footprints.

Owner:INVUITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com