Planar light source device and display apparatus incorporating same

a technology of light source device and display device, which is applied in the direction of planar/plate-like light guide, lighting and heating apparatus, instruments, etc., can solve the problems of insufficient light diffusion, reduced light utilization efficiency, and inability to achieve uniform intensity distribution in some cases, and achieve high light utilization efficiency and high intensity. uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

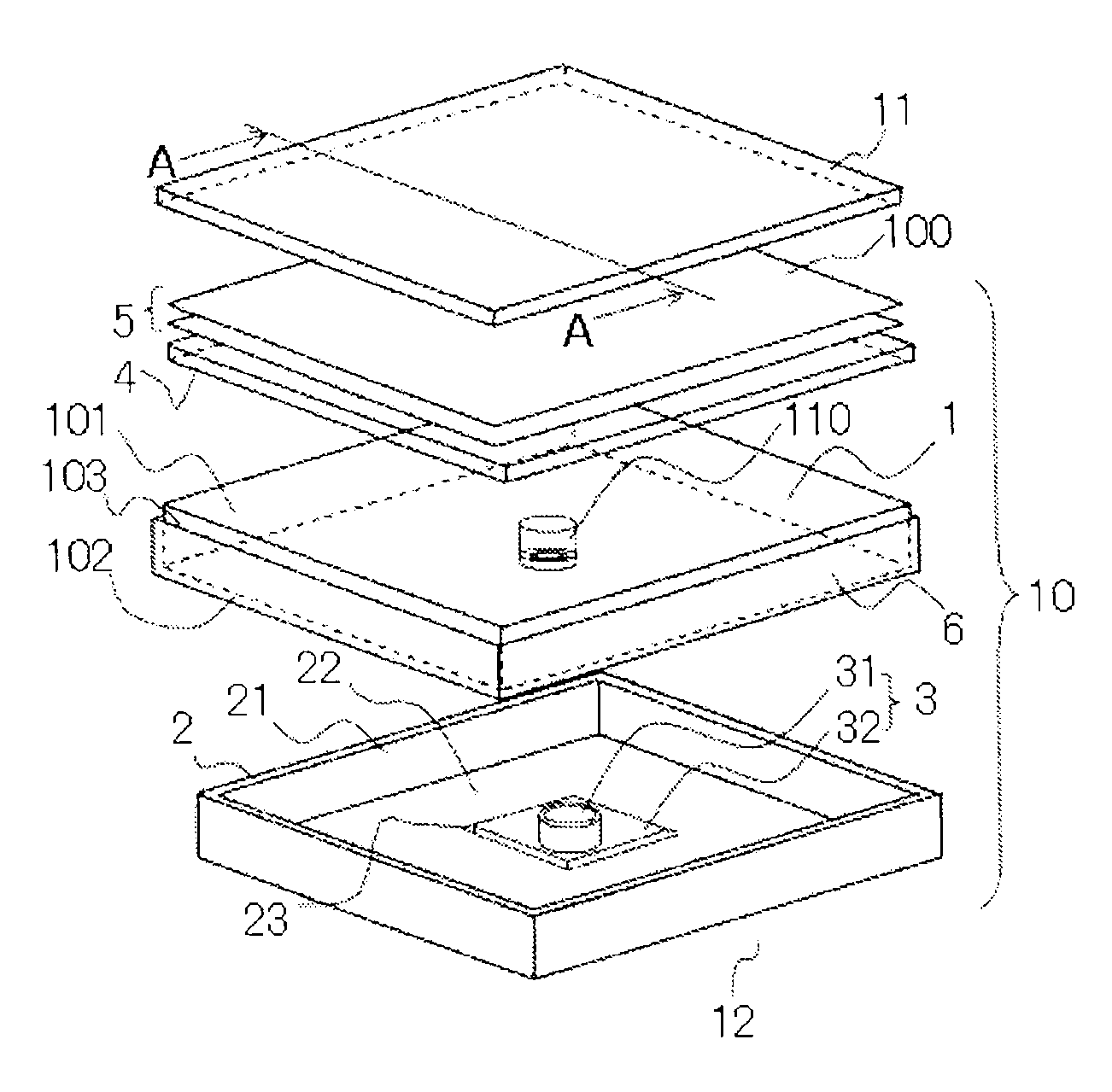

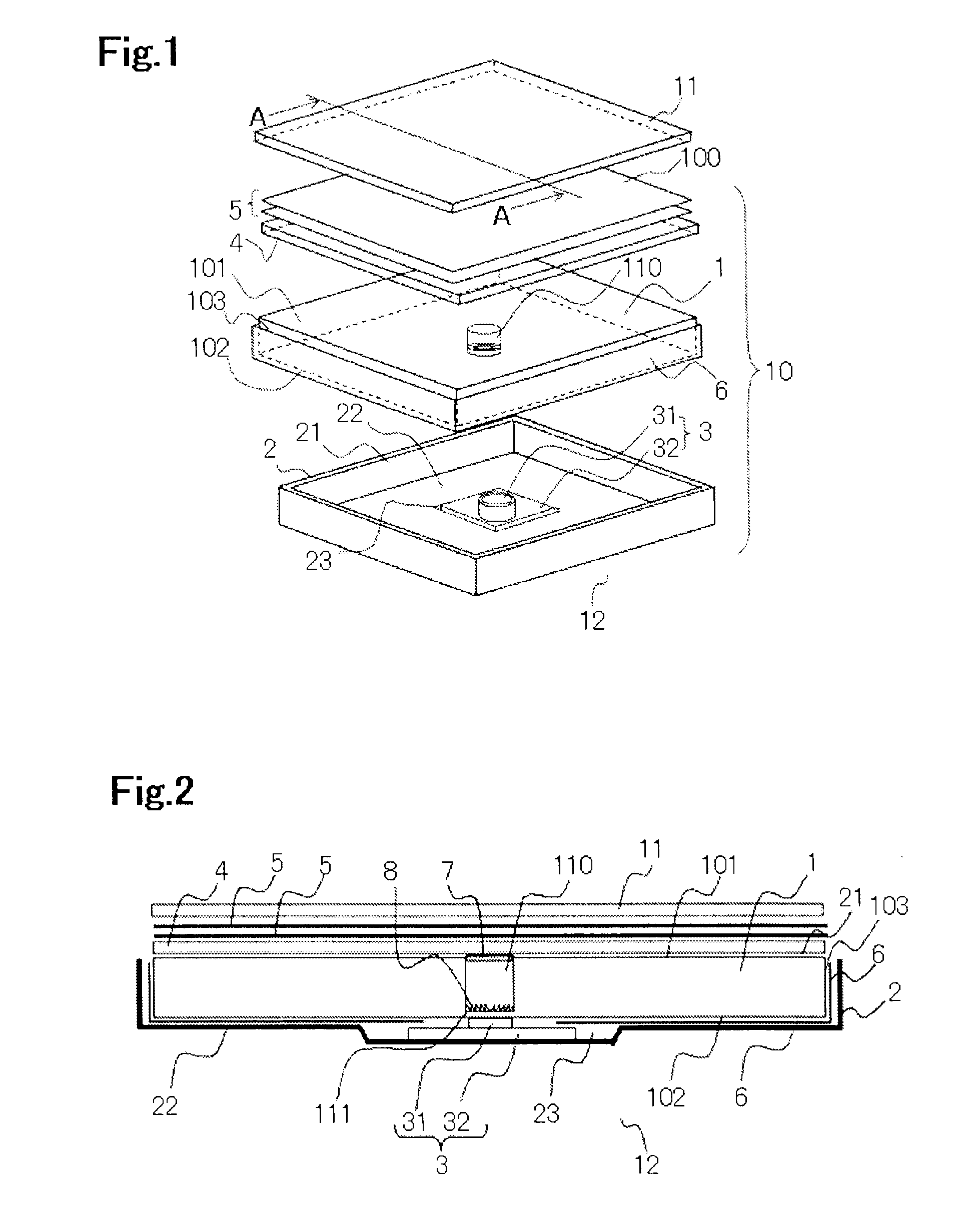

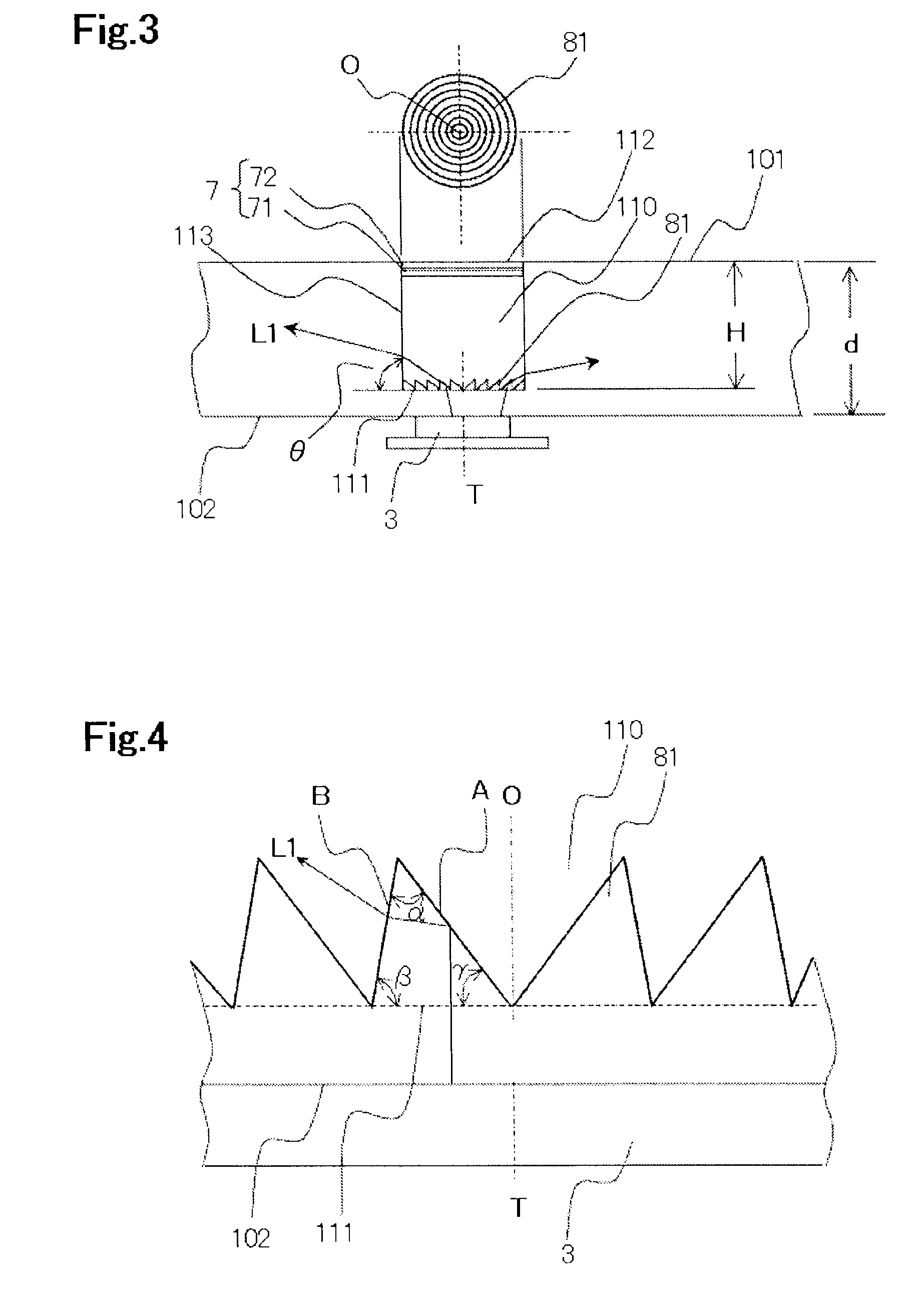

[0034]FIG. 1 is an exploded perspective view of a display device according to the present embodiment; FIG. 2 is a cross sectional view taken along the line A-A of the FIG. 1 with the display device of FIG. 1 assembled. As shown in FIGS. 1 and 2, a planar light source device 10 according to Embodiment 1 includes a light guide plate 1 for guiding light, across the planar area of the light guide plate, to emit it from an exit surface 101 as a surface emitting light; the light guide plate is disposed within a housing having an opening 21. Further, a light source 3 is placed in a recessed space 23 formed on an inside bottom 22 of the housing 2; on a place located toward the exit surface 101 of the light guide plate 1 are disposed a diffuser plate 4 and an optical sheet 5. A reflective sheet 6 for reflecting light is provided on an opposite surface 102, which is a surface located opposite the exit surface 101 of the light guide plate 1, and on sides 103 of the light guide plate. On such t...

embodiment 2

[0063]FIG. 10 shows a cross section of a planar light source device according to Embodiment 2; FIG. 11 shows an enlarged view of the chief part of the device. In Embodiment 1, the exit surface 101 of the light guide plate 1 is formed with the first recess 110, and the light source 3 is disposed so as to face the opposite surface 102 of the light guide plate 1, while in Embodiment 2, as shown in FIG. 10, on the opposite surface 102 is provided a second recess 120 (numeral 120 shown in FIG. 11) that is located opposite the first recess 110 of the light guide plate 1 where the light source 3 is accommodated. The configuration other than what is described above is the same as that in Embodiment 1. An advantage similar to that of the planar light source device according to Embodiment 1 is also achieved except the special advantageous feature associated with the planar light source device according to Embodiment 2, as will be described below.

[0064]The path of light having emitted from the...

embodiment 3

[0068]FIG. 12 shows an enlarged view of the chief part of a planar light source device according to Embodiment 3. The planar light source device according to Embodiment 3 has a convexed portion 123 extending toward an opening 124 formed on the bottom 121 of the second recess 120. Here, the rest of the configuration other than that of providing the convexed portion 123 is the same as that in Embodiment 2. An advantage similar to the planar light source device according to Embodiment 1 and Embodiment 2 is achieved except the advantageous feature associated with the planar light source device according to the present embodiment, as will be described below.

[0069]Next, FIG. 13 shows an enlarged view of the chief part of the convexed portion 123 formed in the light guide plate. As shown in FIG. 13, the convexed portion 123 is formed integral with the bottom 121 of the second recess 120. The convexed portion 123 represents a convex lens whose center portion extends toward the opening 124 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com