Patents

Literature

262 results about "Cyclo olefin polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

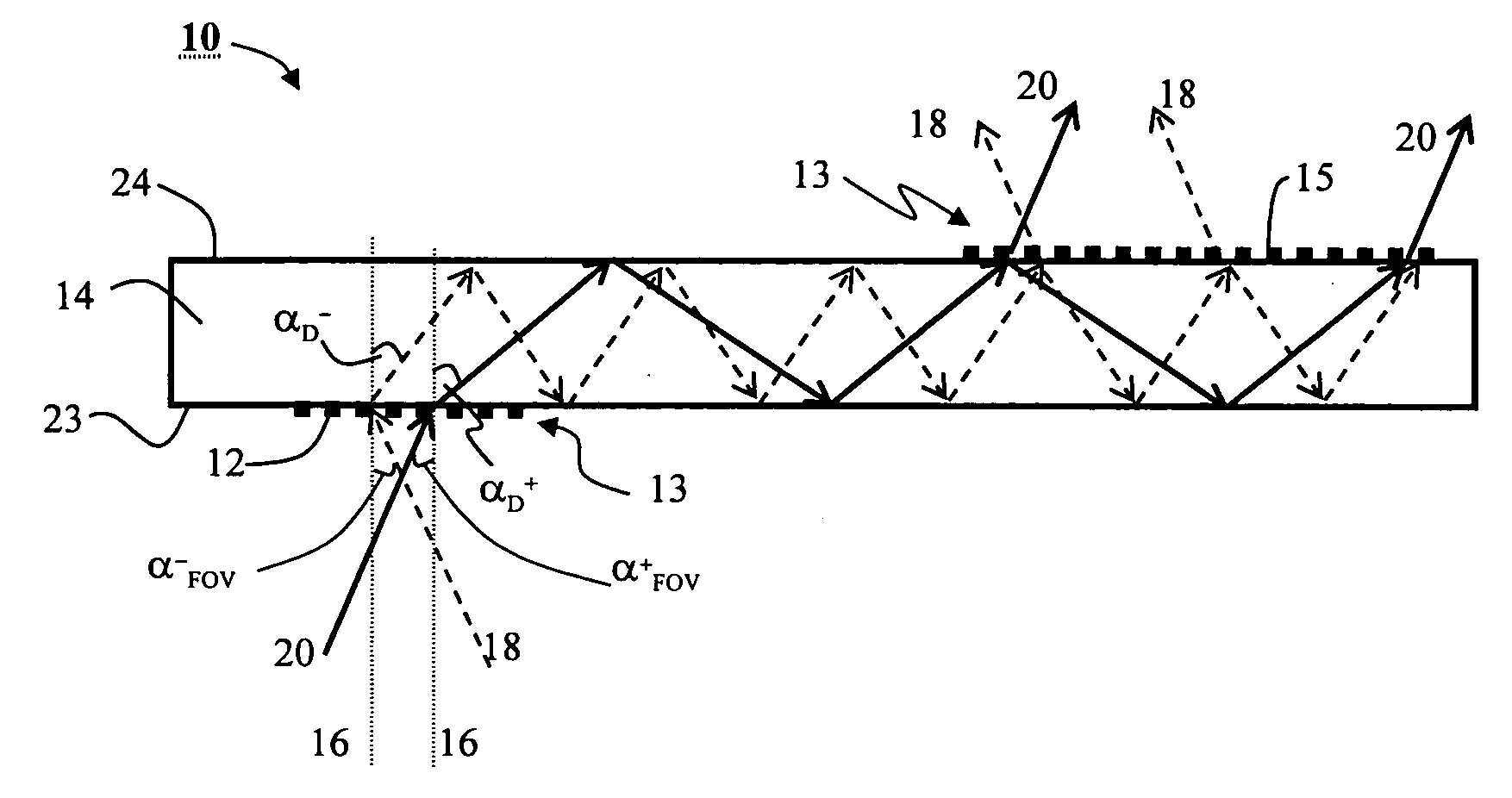

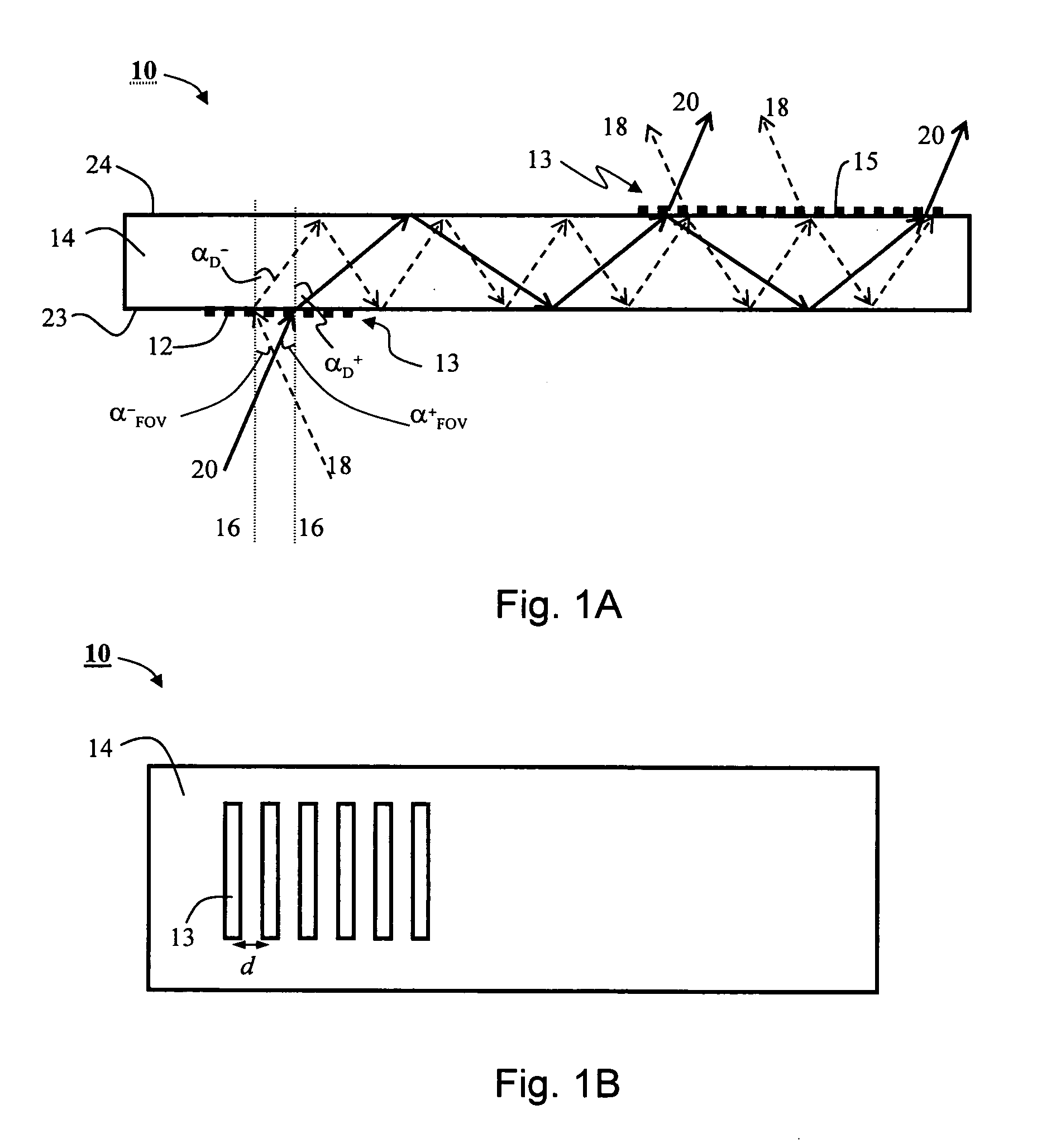

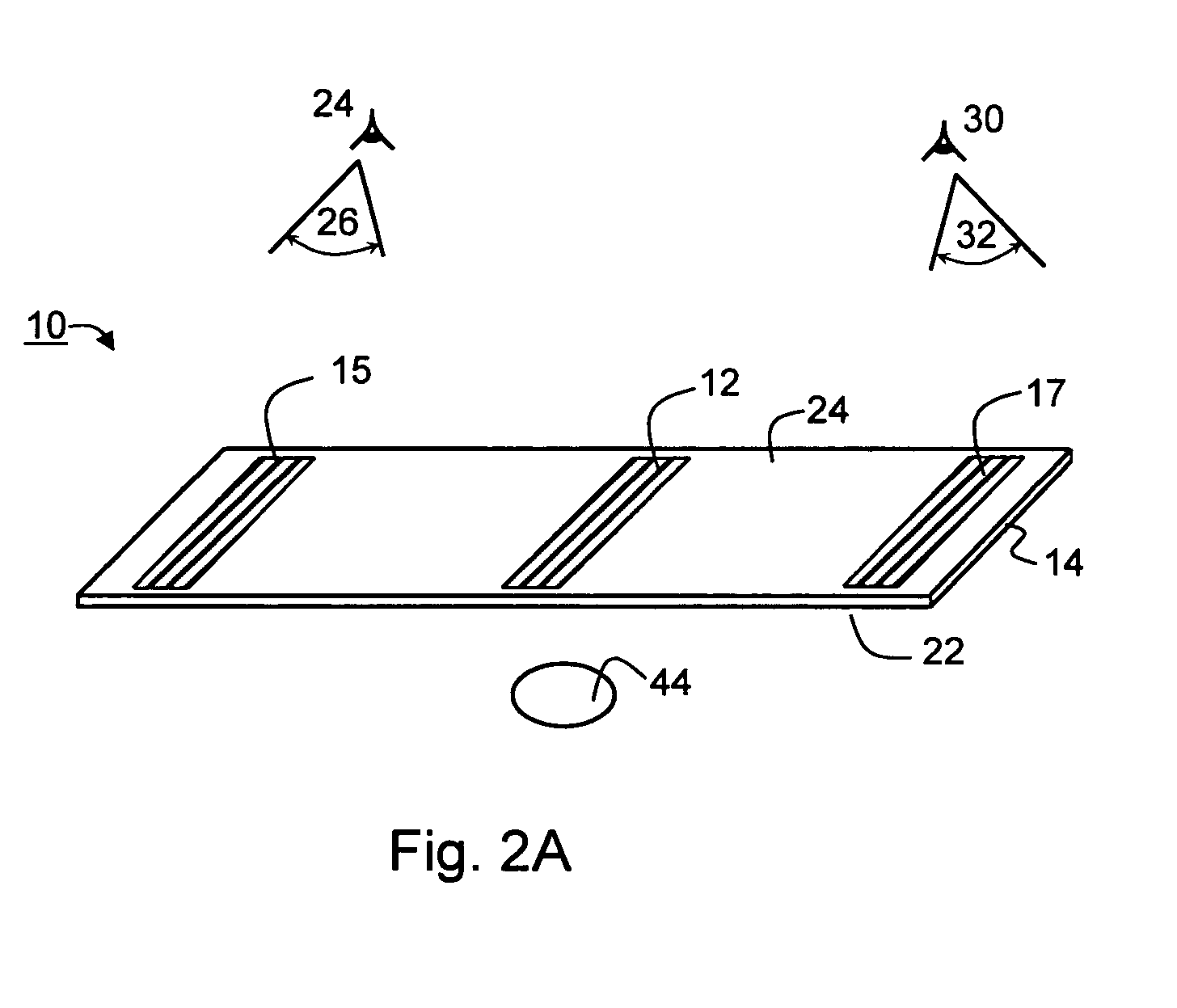

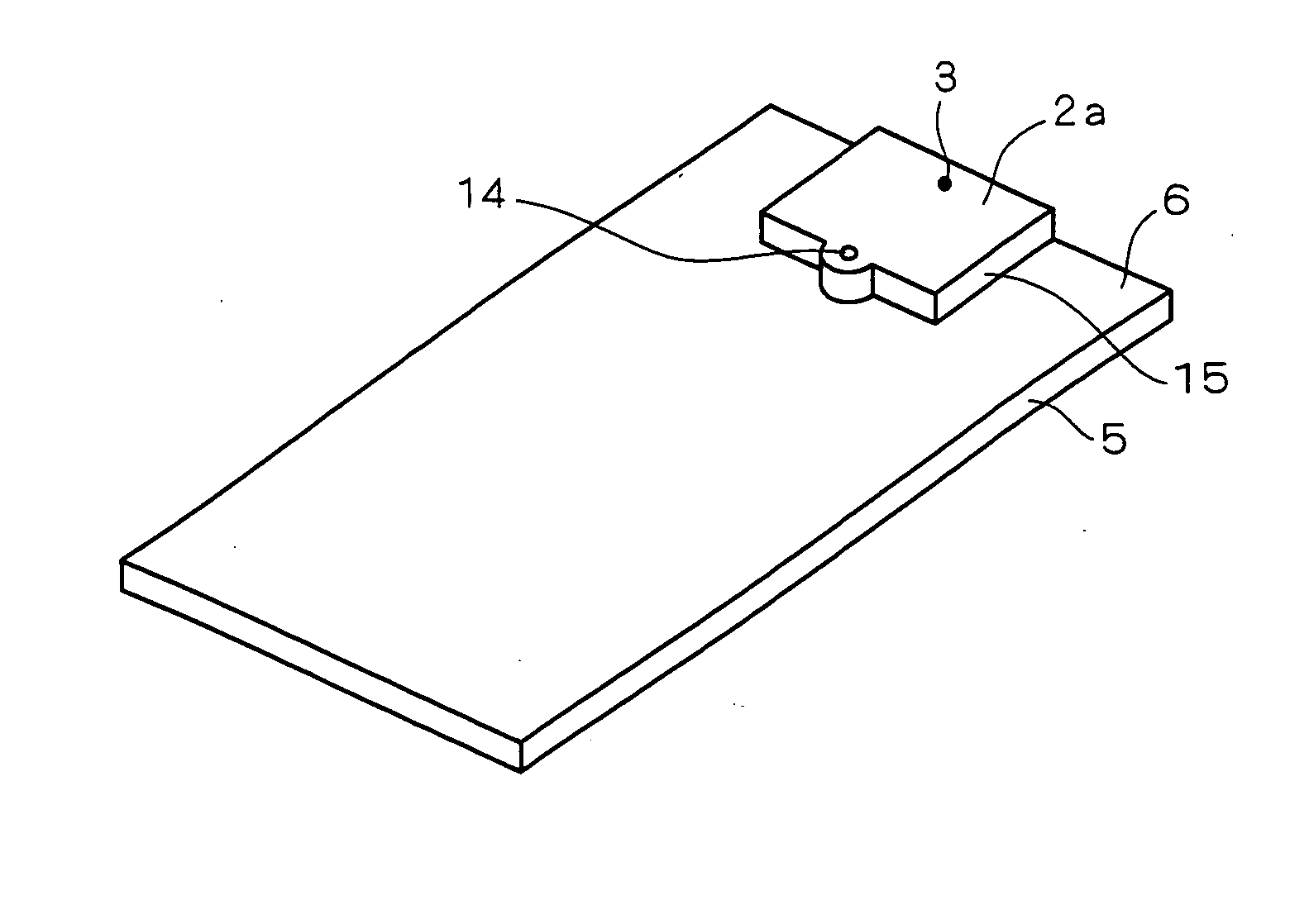

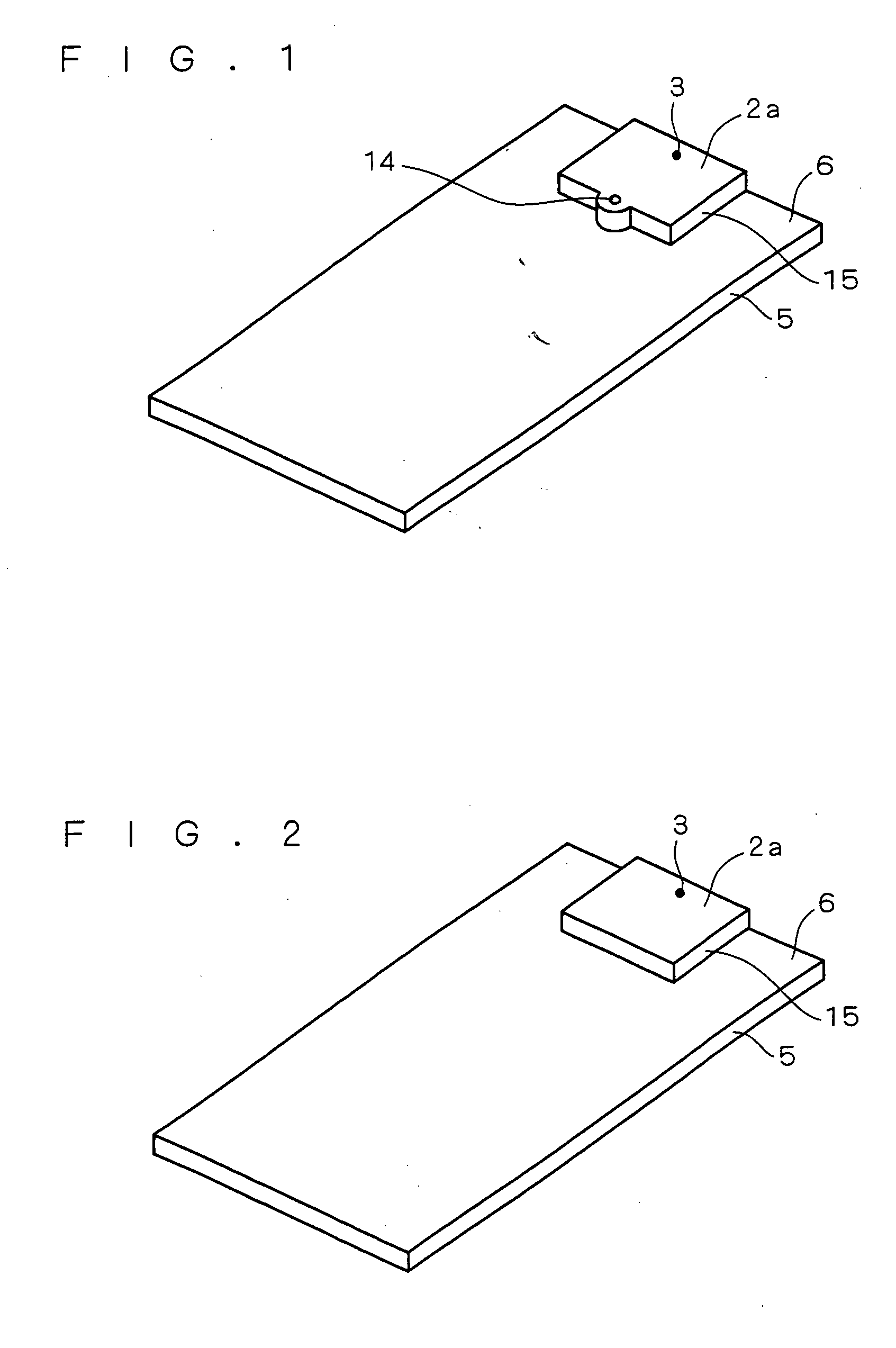

Diffractive optical relay and method for manufacturing the same

InactiveUS20080043334A1Diffraction gratingsPlanar/plate-like light guidesRefractive indexCyclo olefin polymer

An optical relay device, comprising a substrate, and at least one diffractive optical element is disclosed. The substrate is made, at least in part, of a light transmissive polymeric material characterized by a birefringence, Δn, satisfying the inequality |Δn|<ε, where ε is lower than the birefringence of polycarbonate. In a preferred embodiment, the light transmissive polymeric material comprises a cycloolefin polymer or a cycloolefin copolymer.

Owner:MIRAGE INNOVATIONS

Polyolefin film containing cycloolefin polymer, process for the production thereof, and the use thereof

InactiveUS6068936AHigh strength valueGood barrier effectFlexible coversWrappersPolymer sciencePolyolefin

A polyolefin film which includes at least one layer containing polyolefin and cycloolefin polymer (COP), where the cycloolefin polymer is amorphous and has a mean molecular weight Mw in the range from 200 to 100,000, and this mean molecular weight Mw of the cycloolefin polymer is at most 50% of the mean molecular weight Mw of the polyolefin, and the cycloolefin polymer is a homopolymer or a copolymer containing at most 20% by weight of comonomer.

Owner:TICONA GMBH

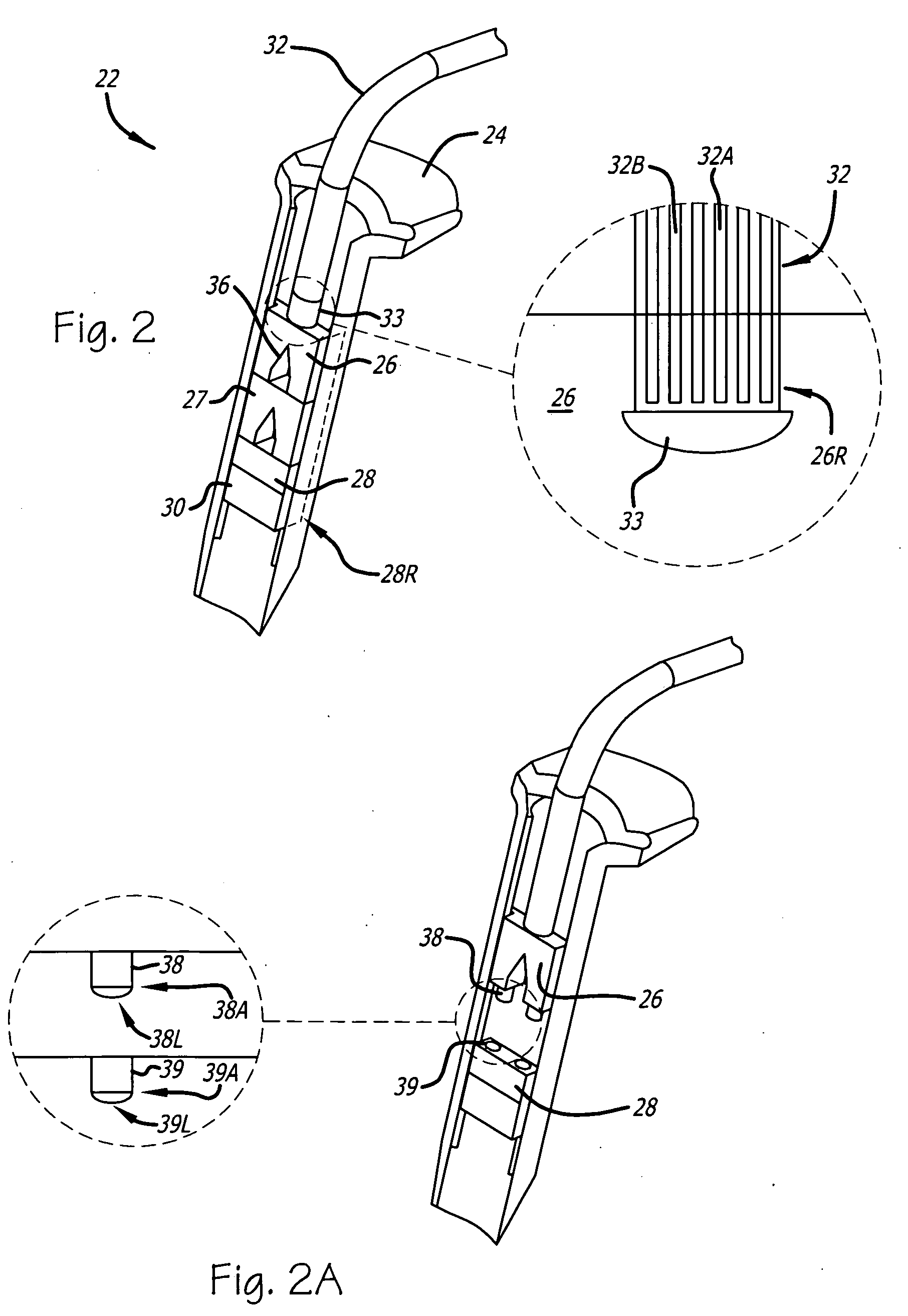

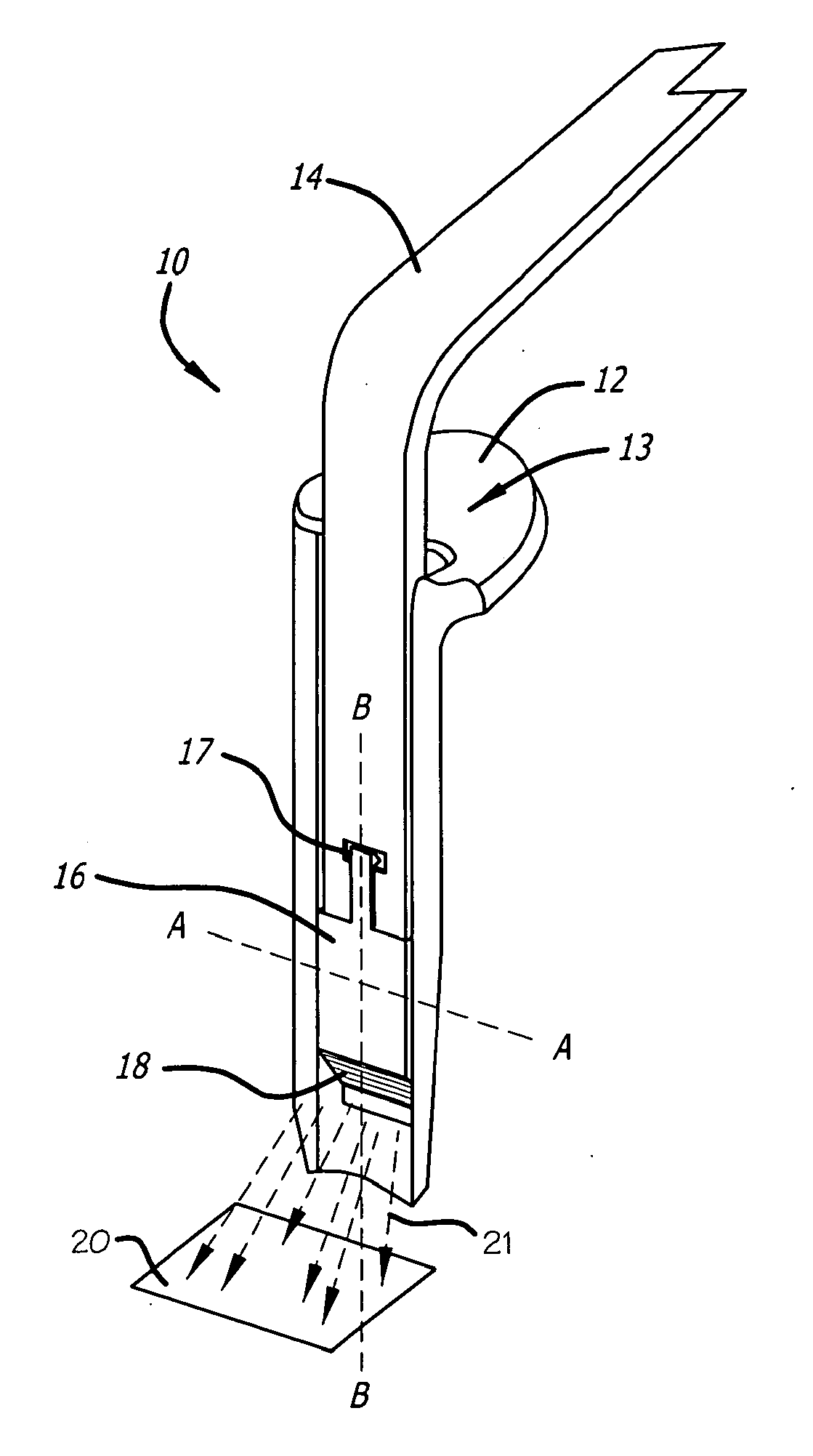

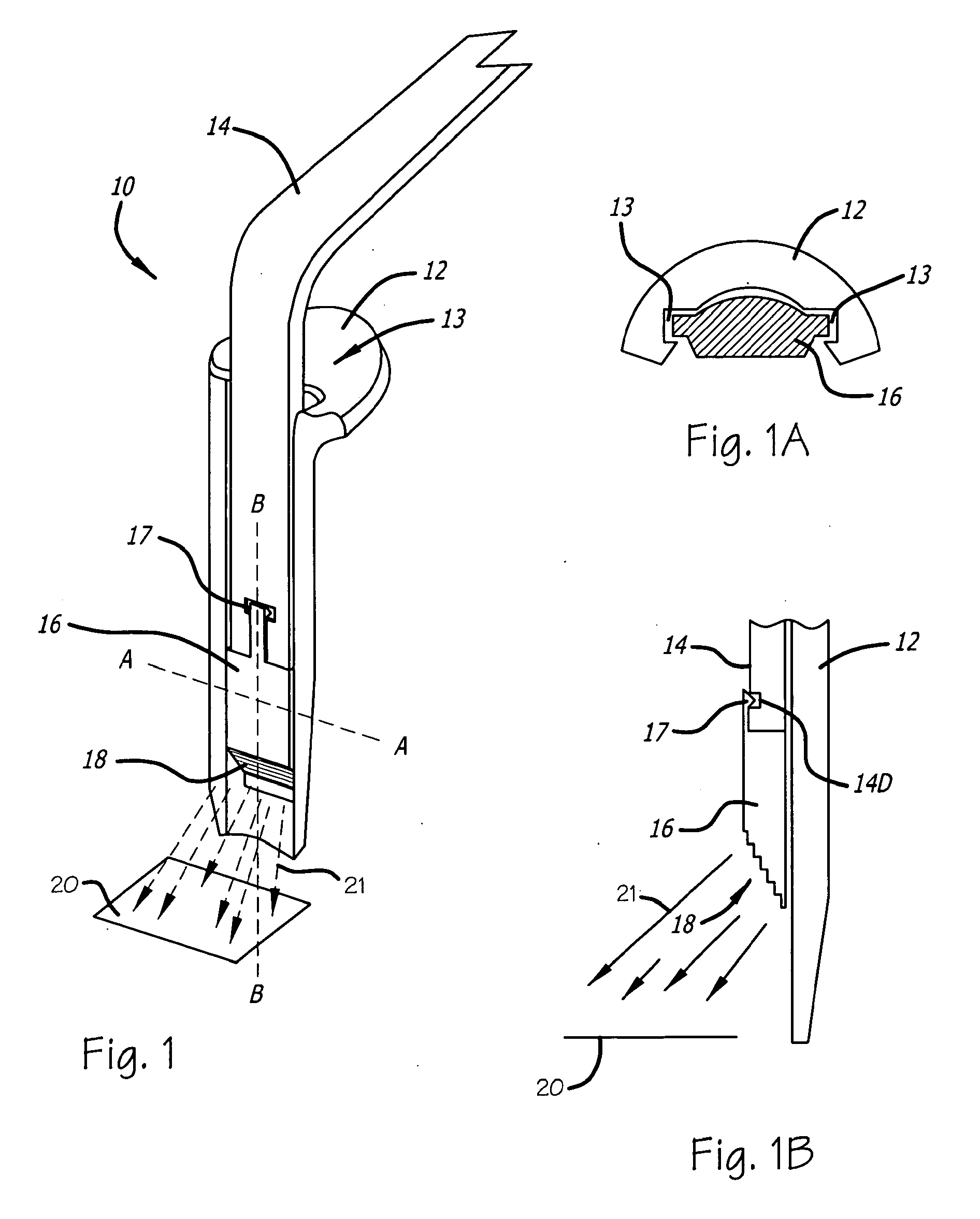

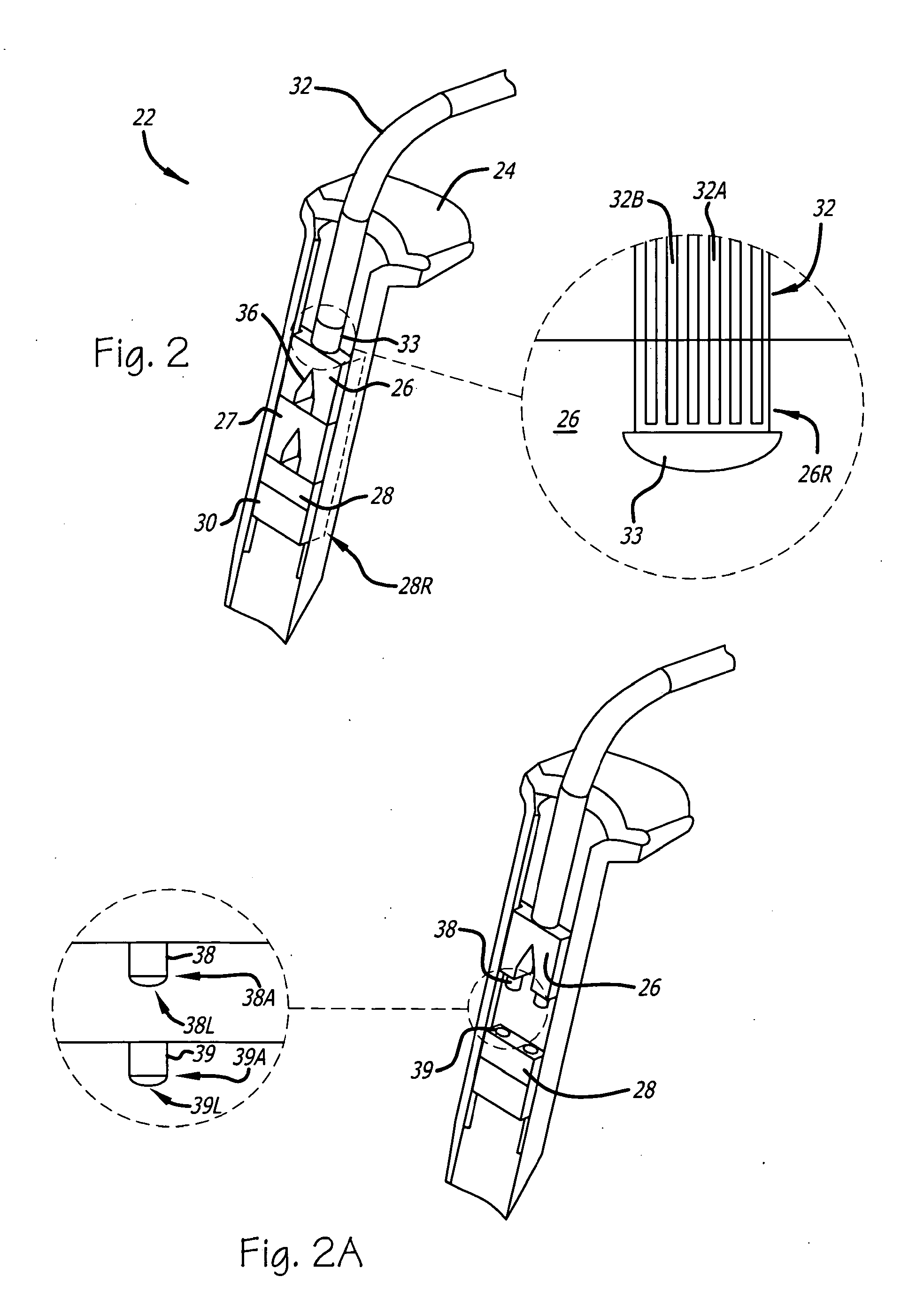

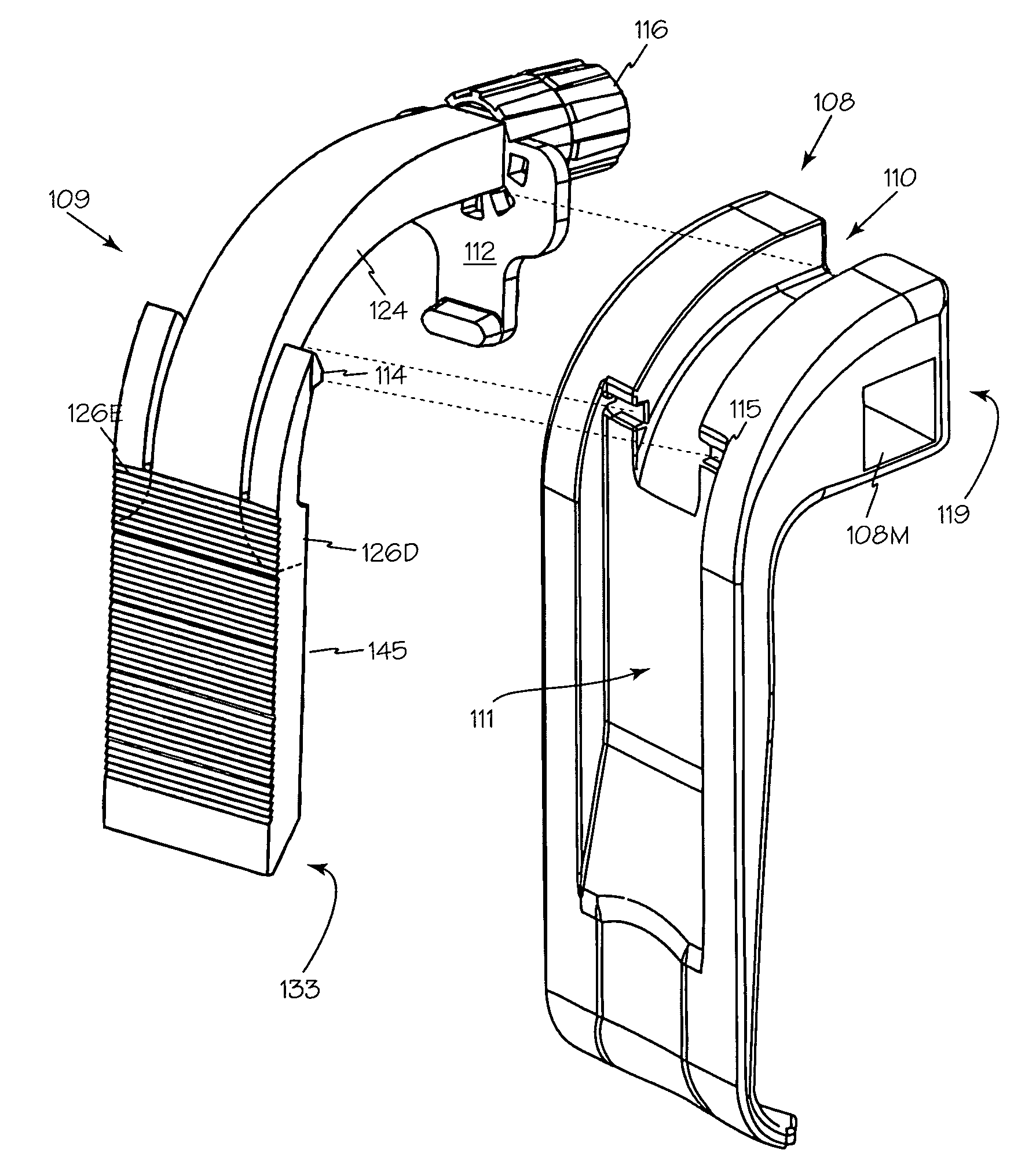

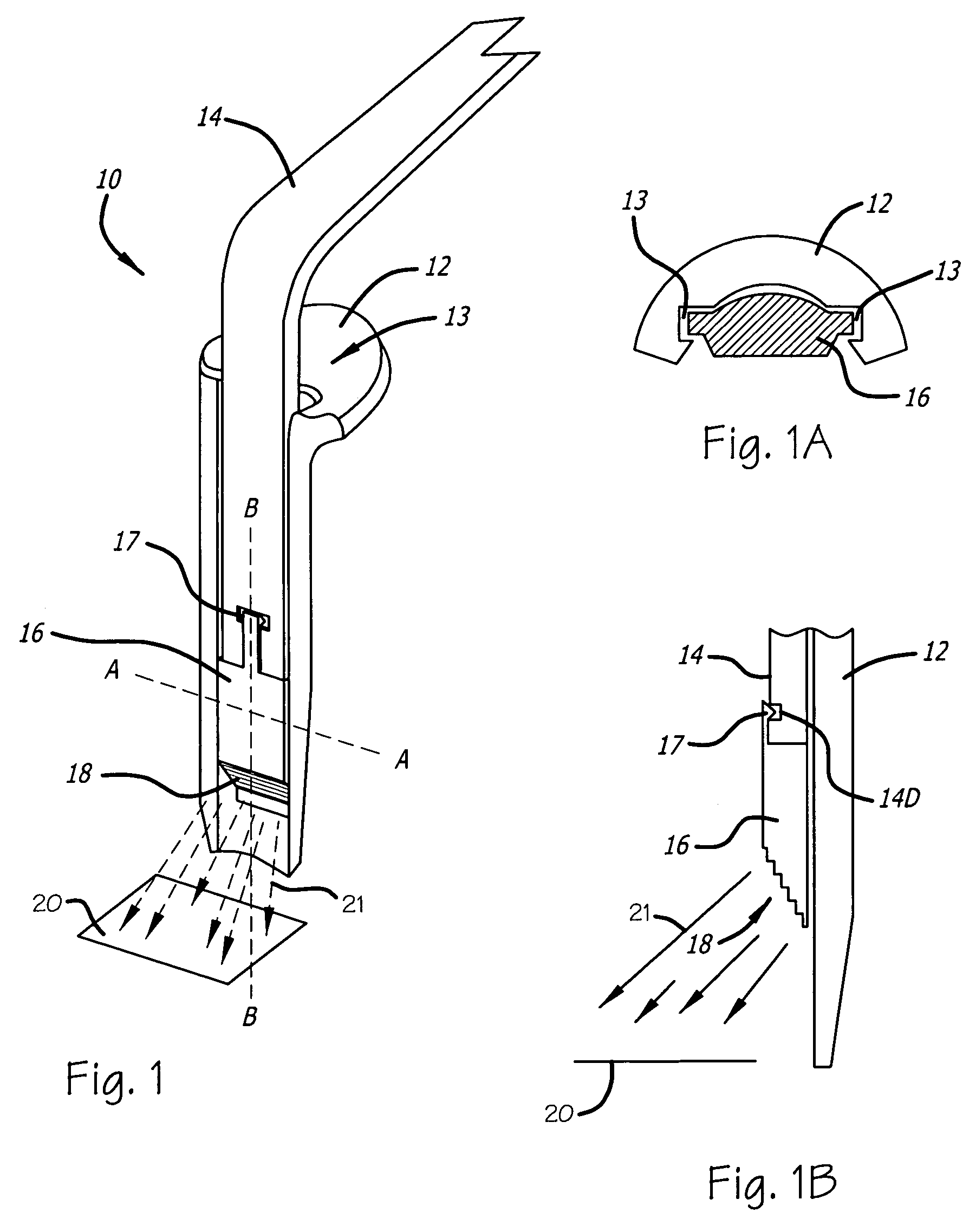

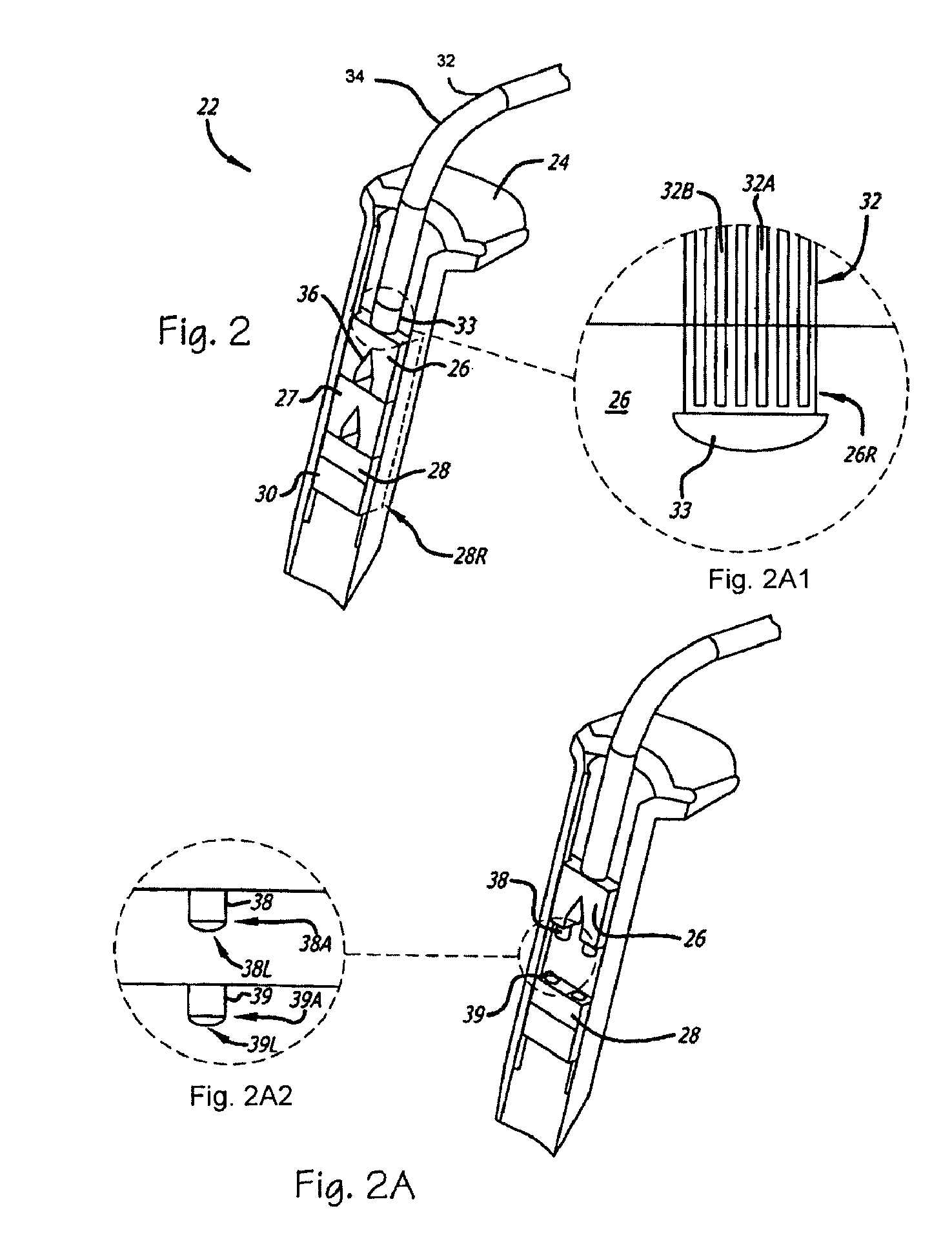

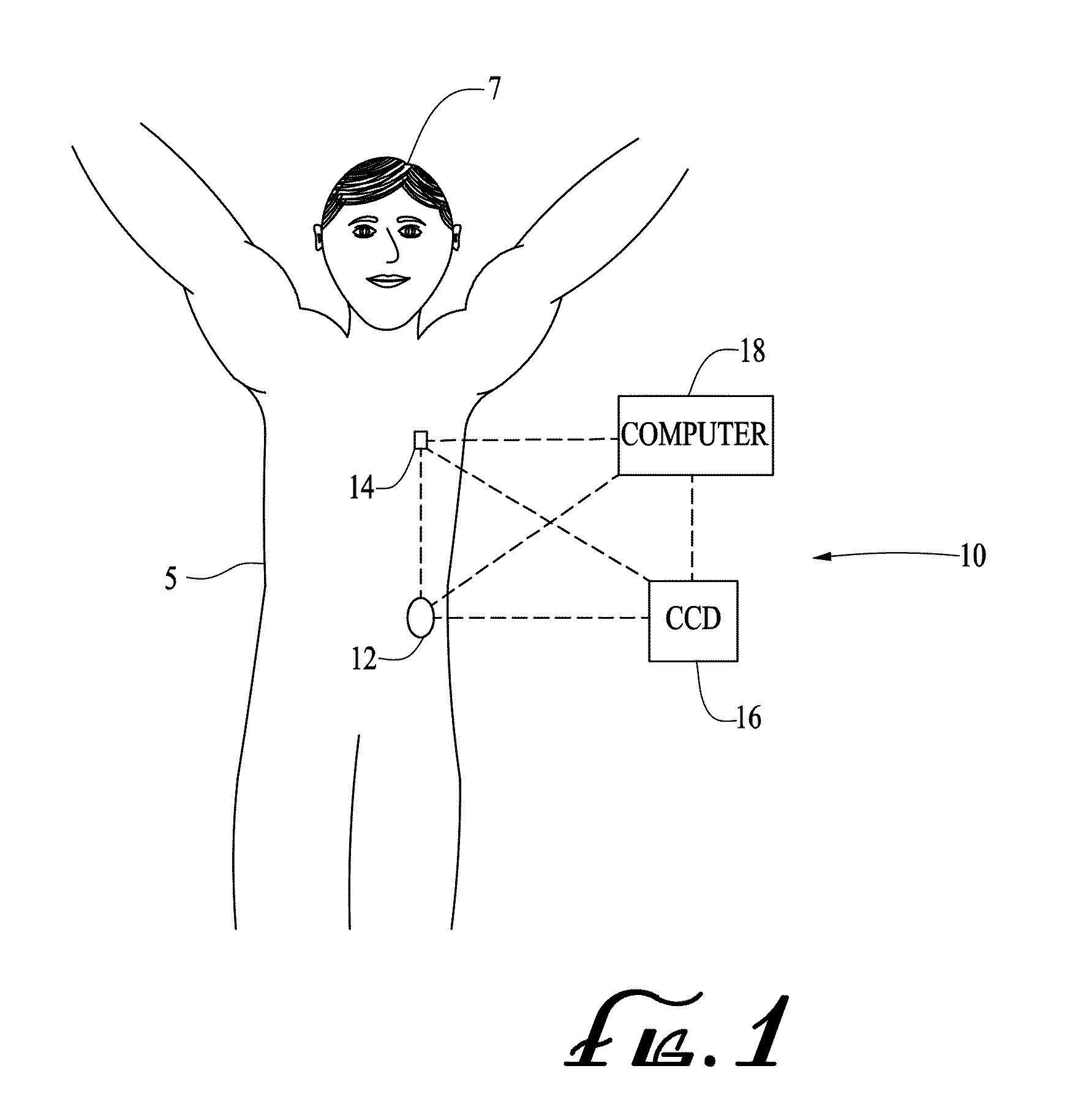

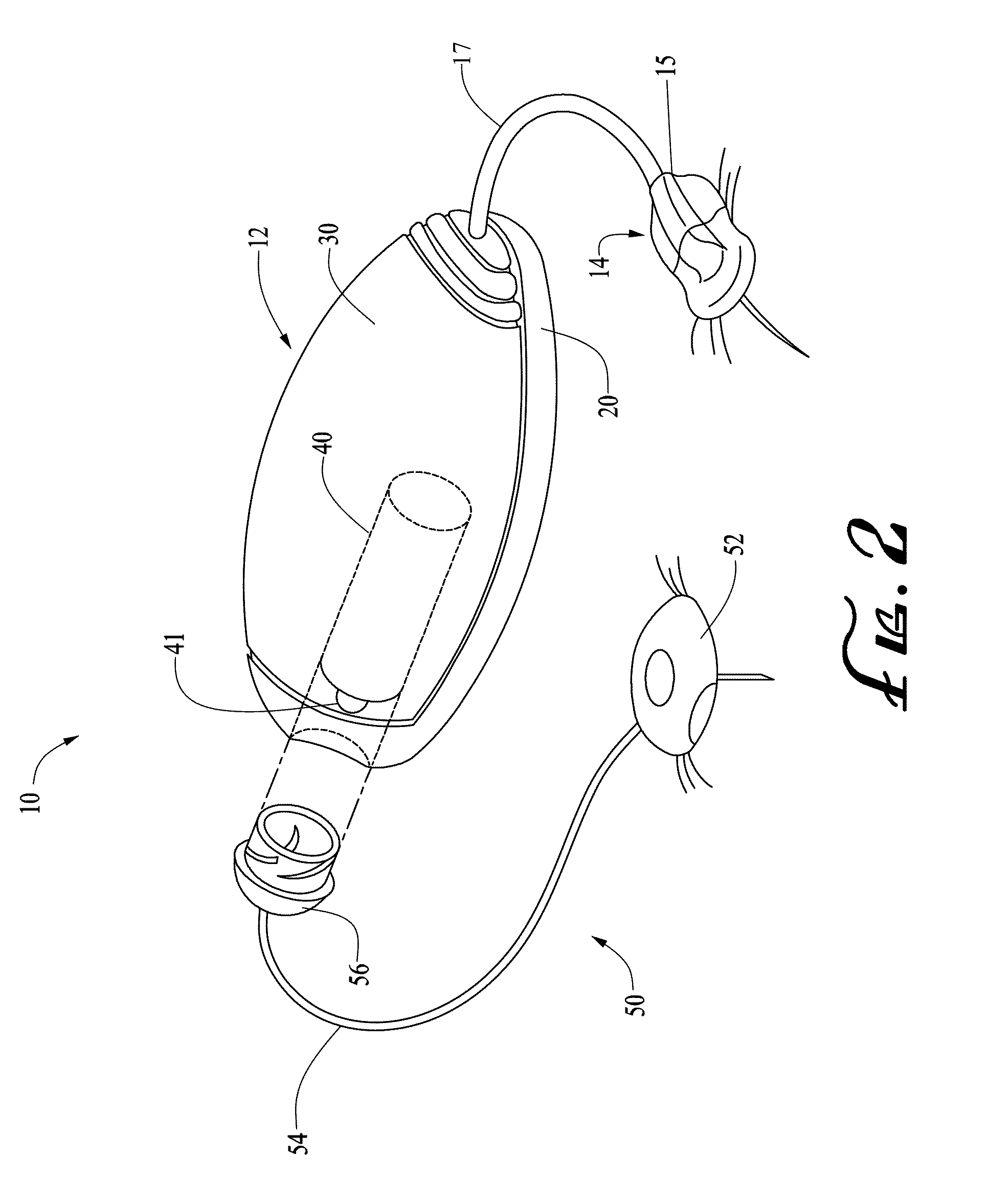

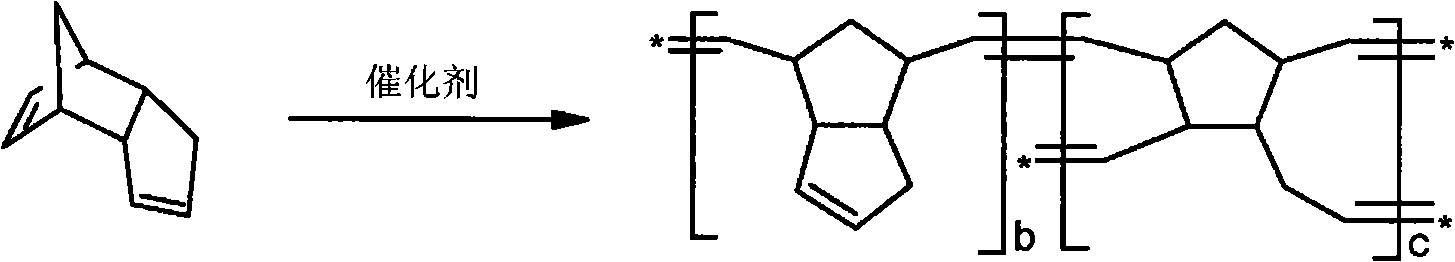

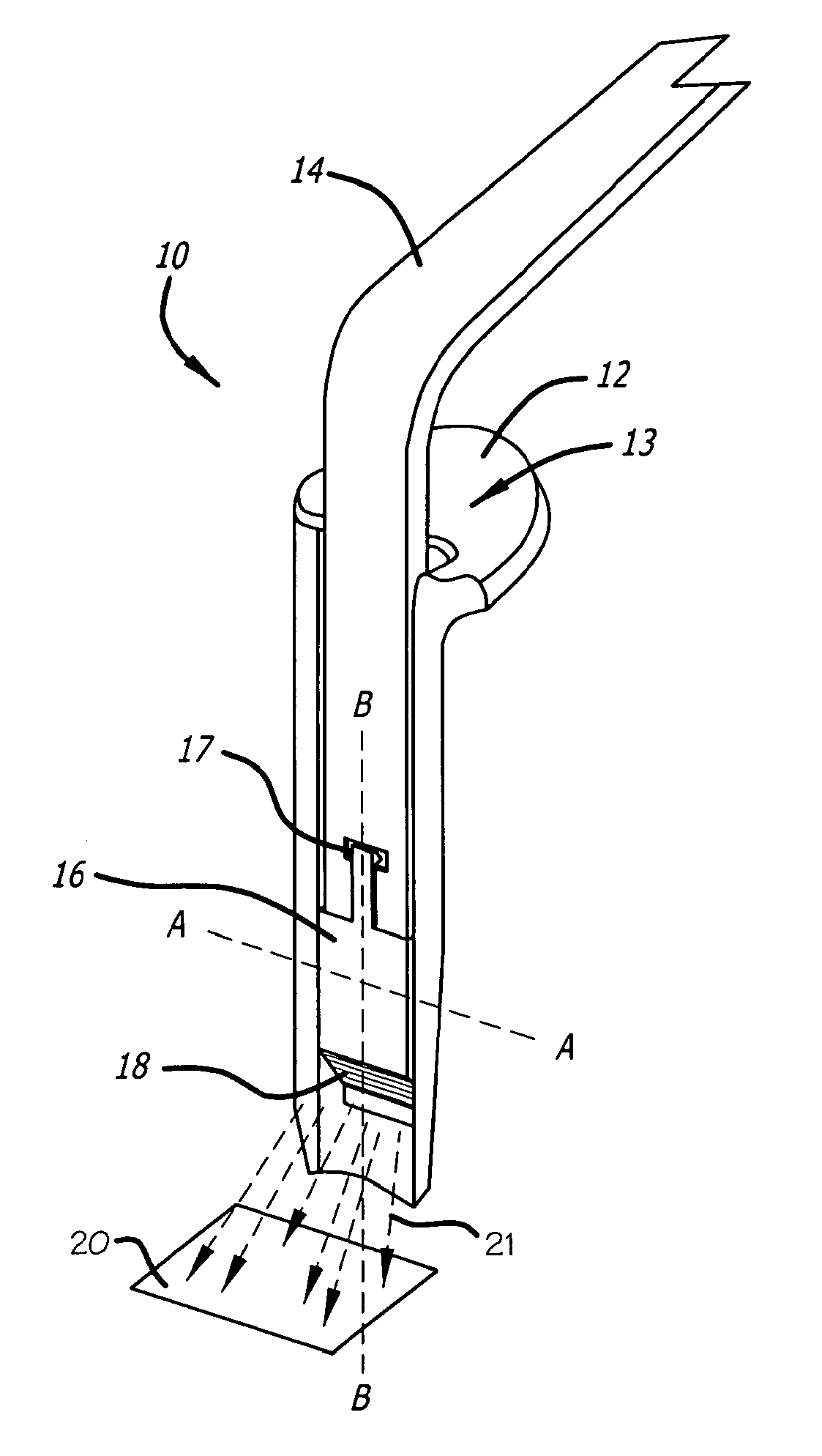

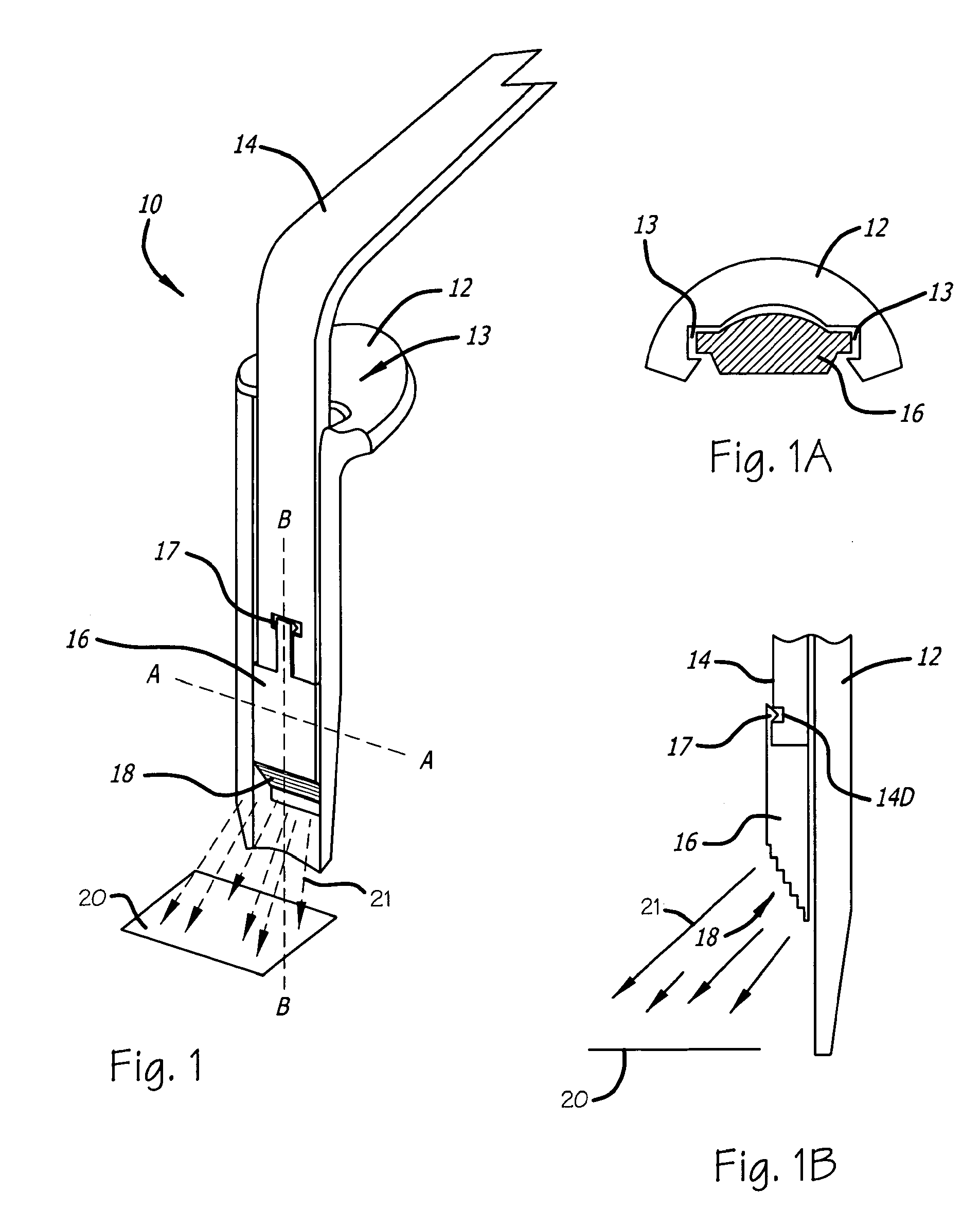

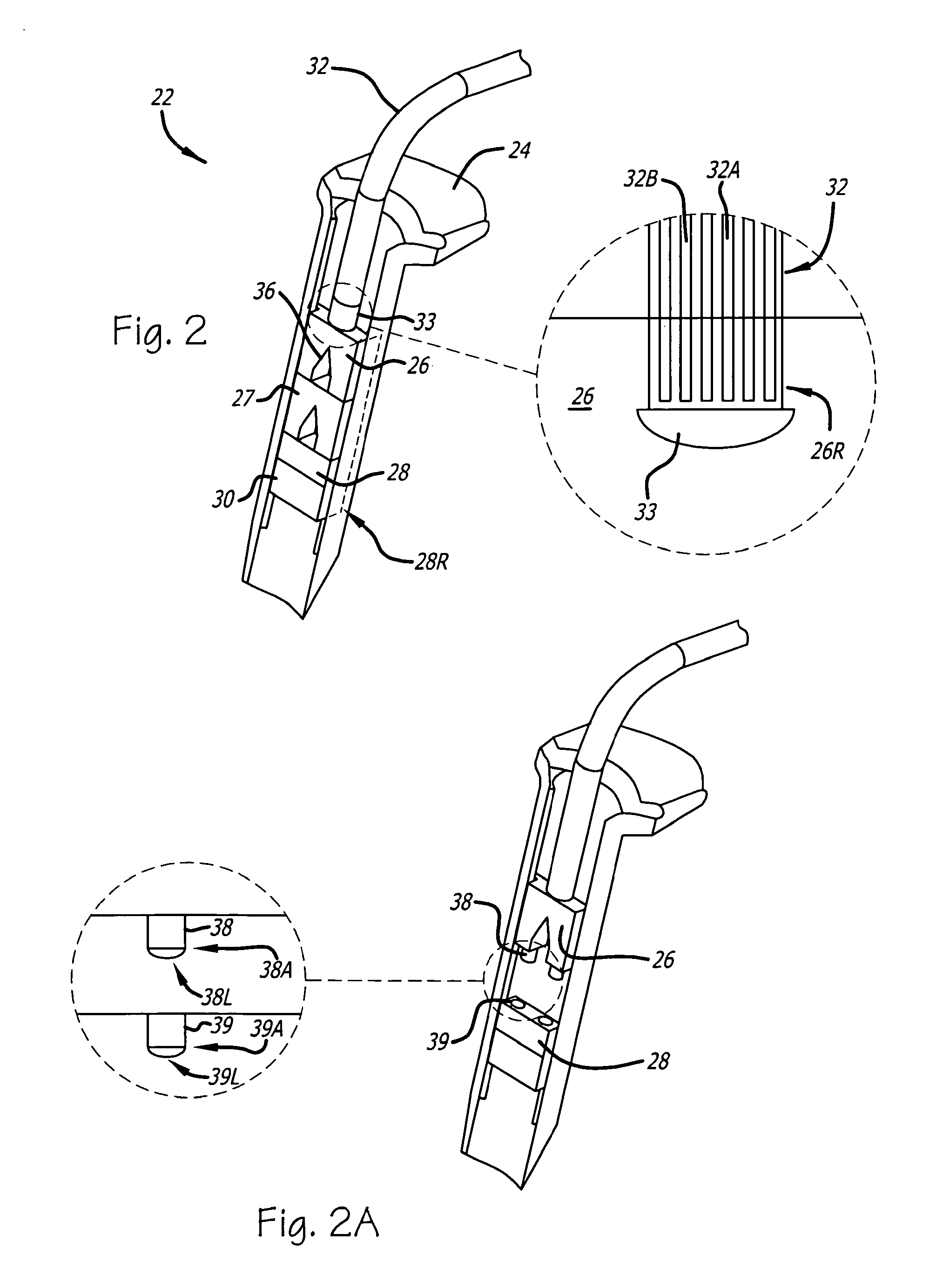

Cyclo Olefin Polymer and Copolymer Medical Devices

Owner:INVUITY

Cyclo olefin polymer and copolymer medical devices

ActiveUS20120041268A1Different performanceBronchoscopesLaryngoscopesDistal portionCyclo olefin polymer

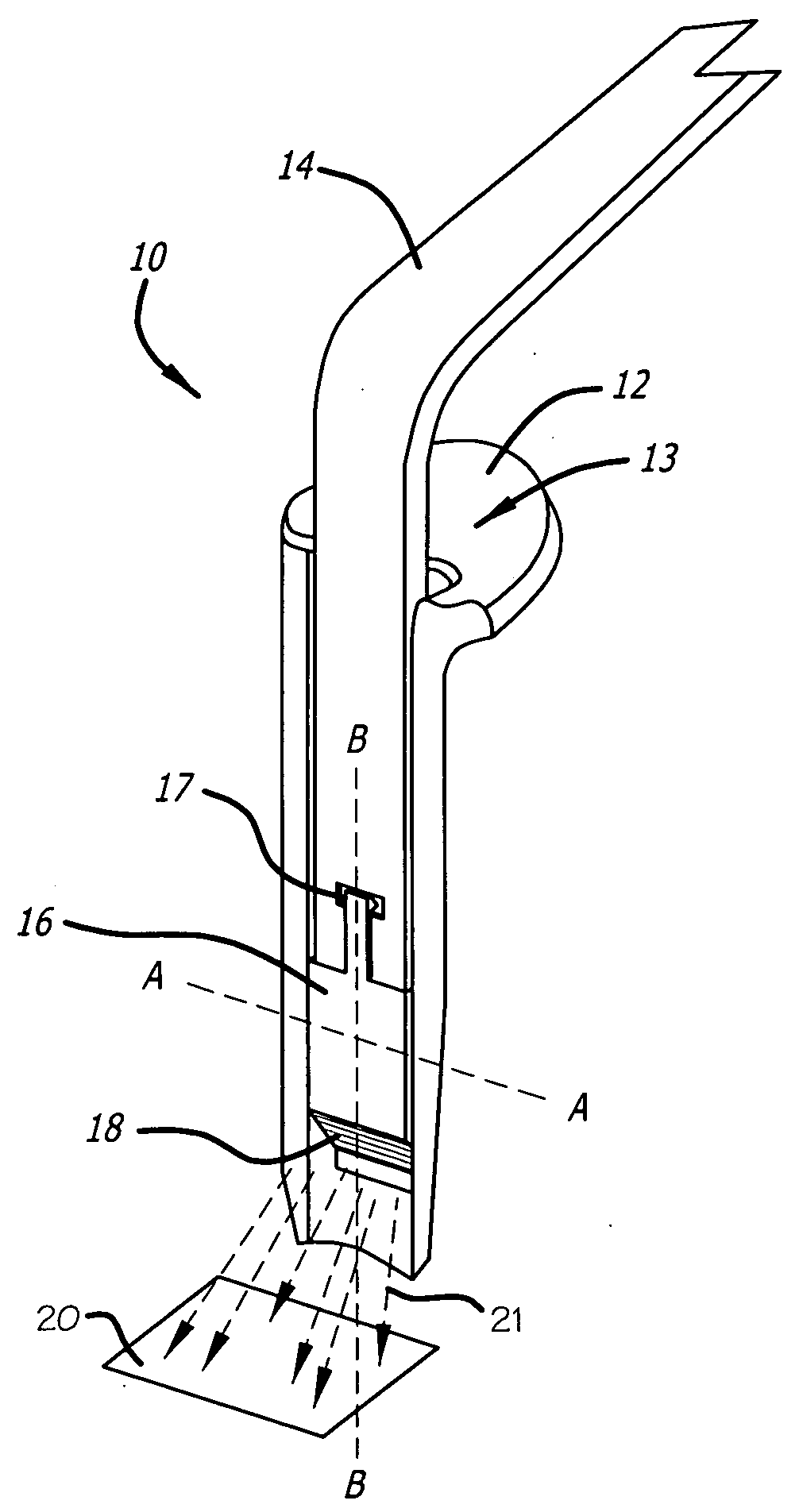

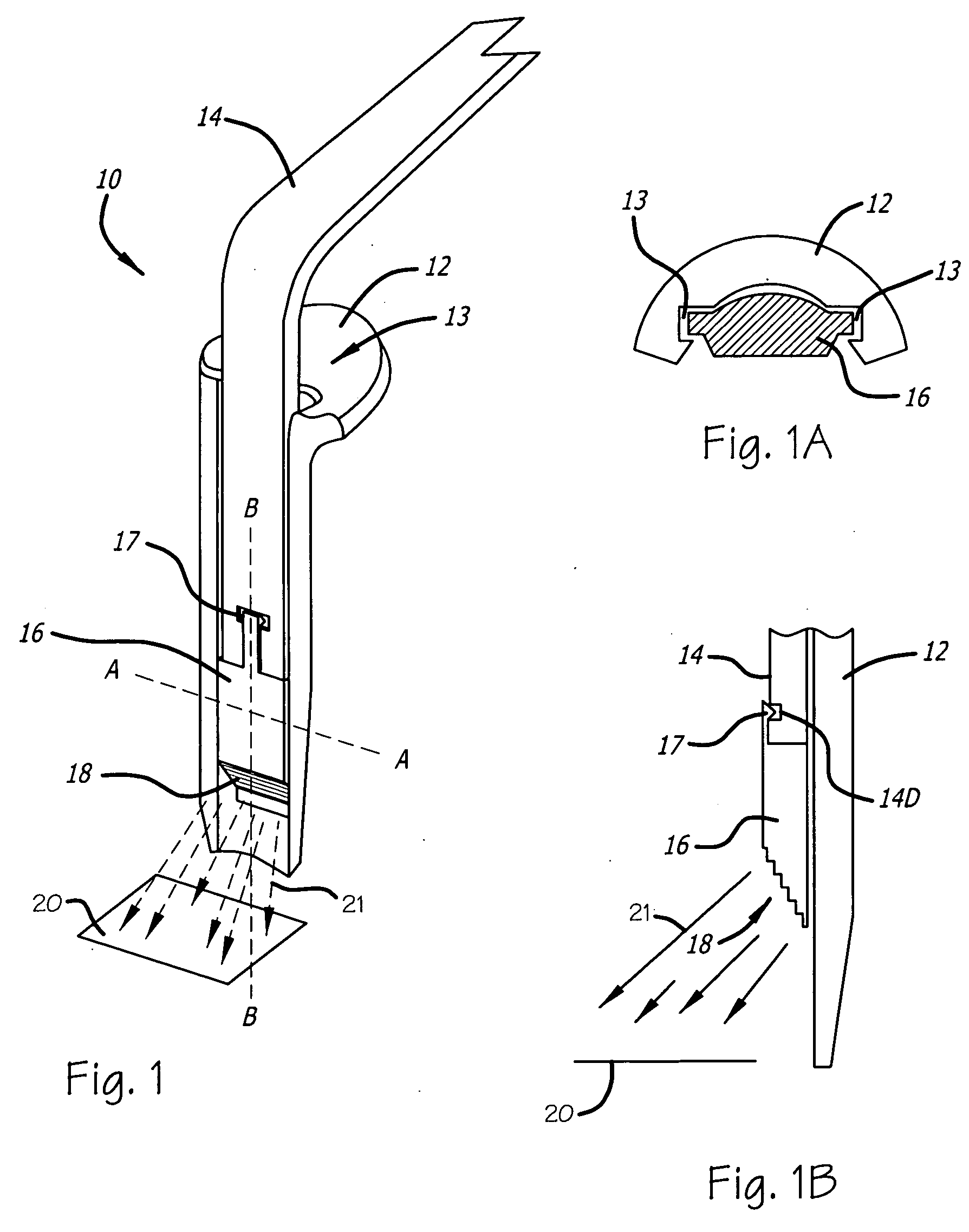

An illuminated medical system comprises a medical instrument and a light transmitting waveguide. The waveguide projects lights from a distal portion of the waveguide toward a target area. The waveguide is formed primarily of a cyclic olefin copolymer or a cyclic olefin polymer.

Owner:INVUITY

Cyclo olefin polymer and copolymer medical devices

Owner:INVUITY

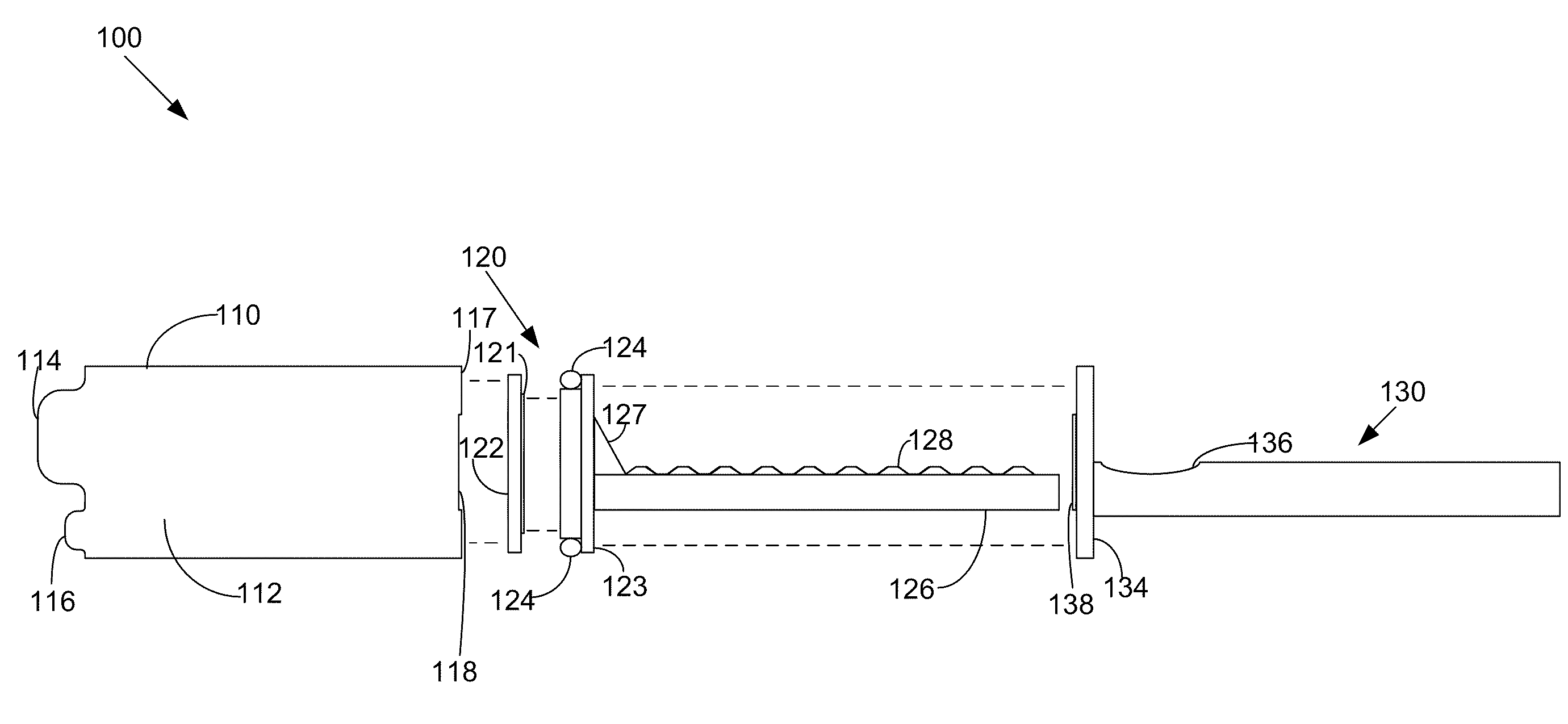

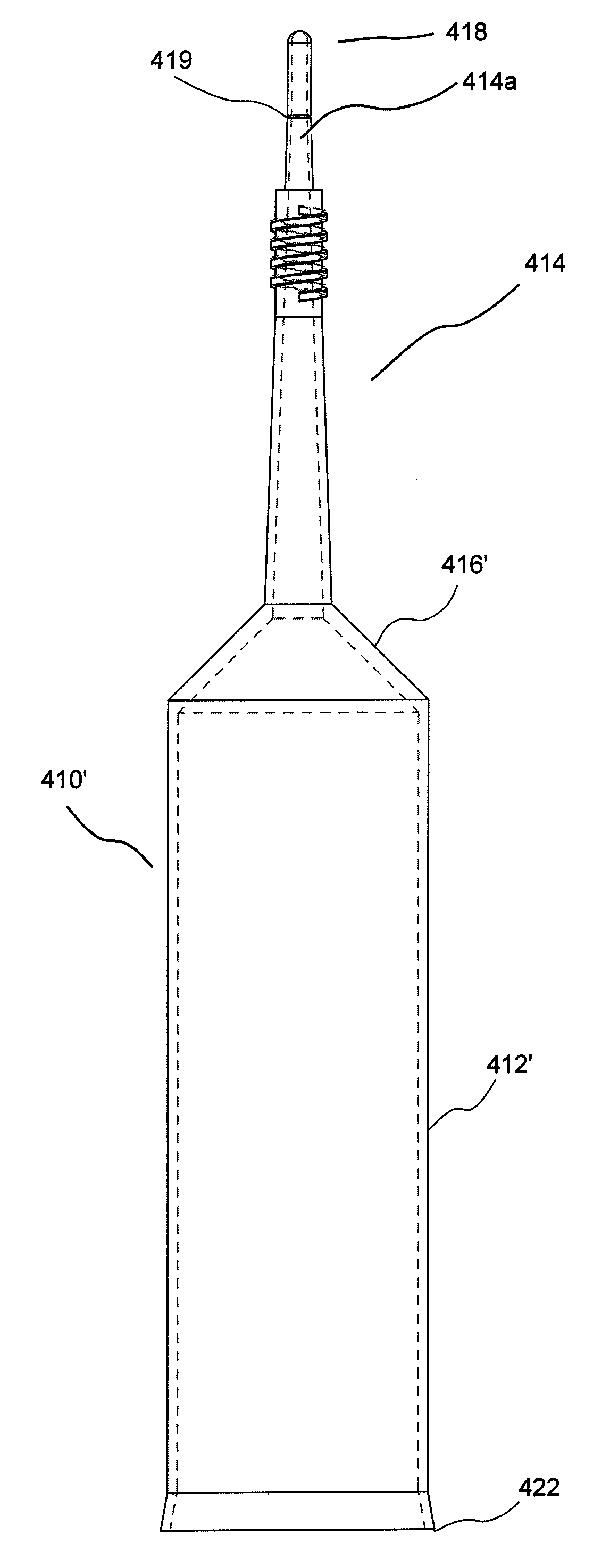

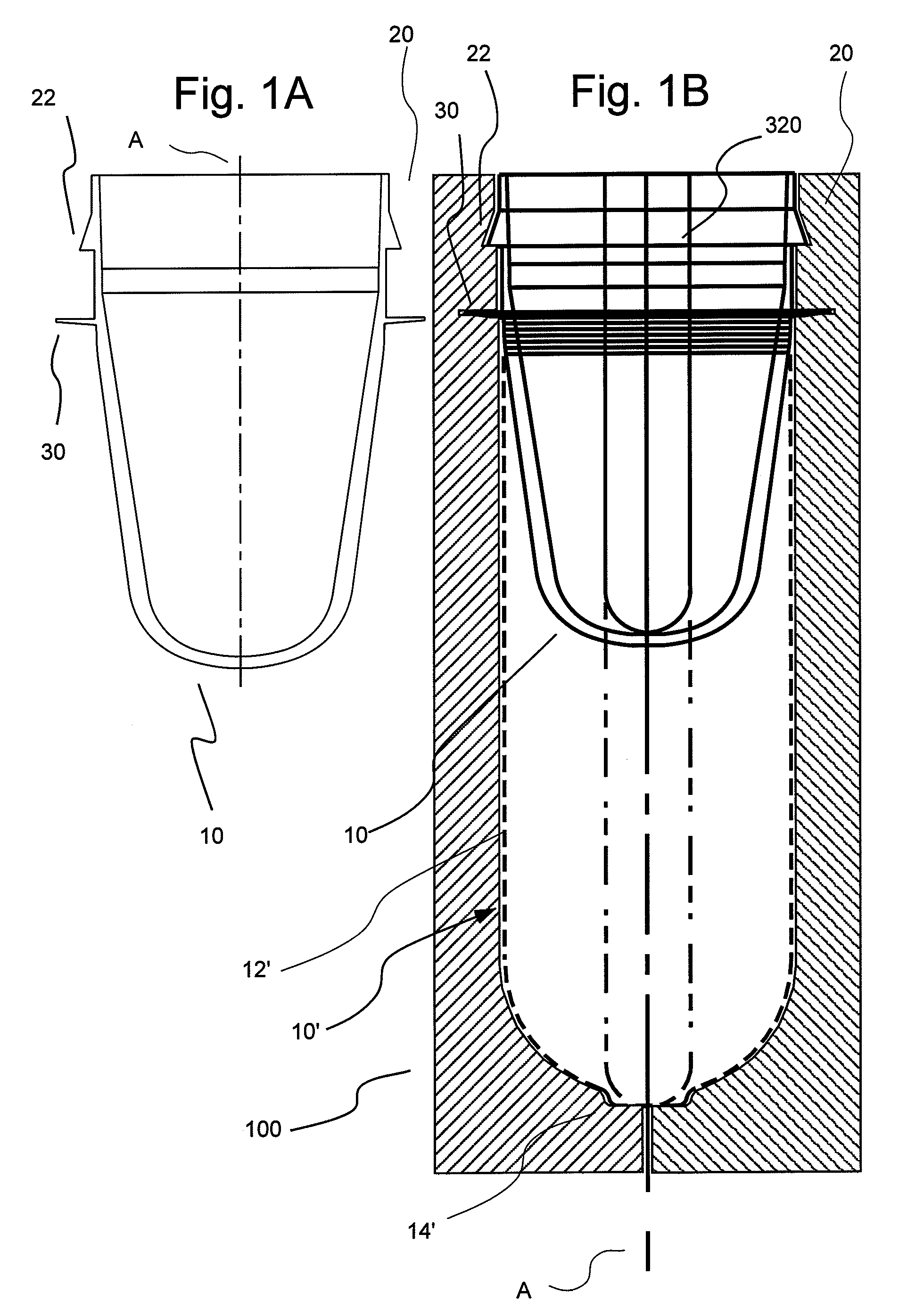

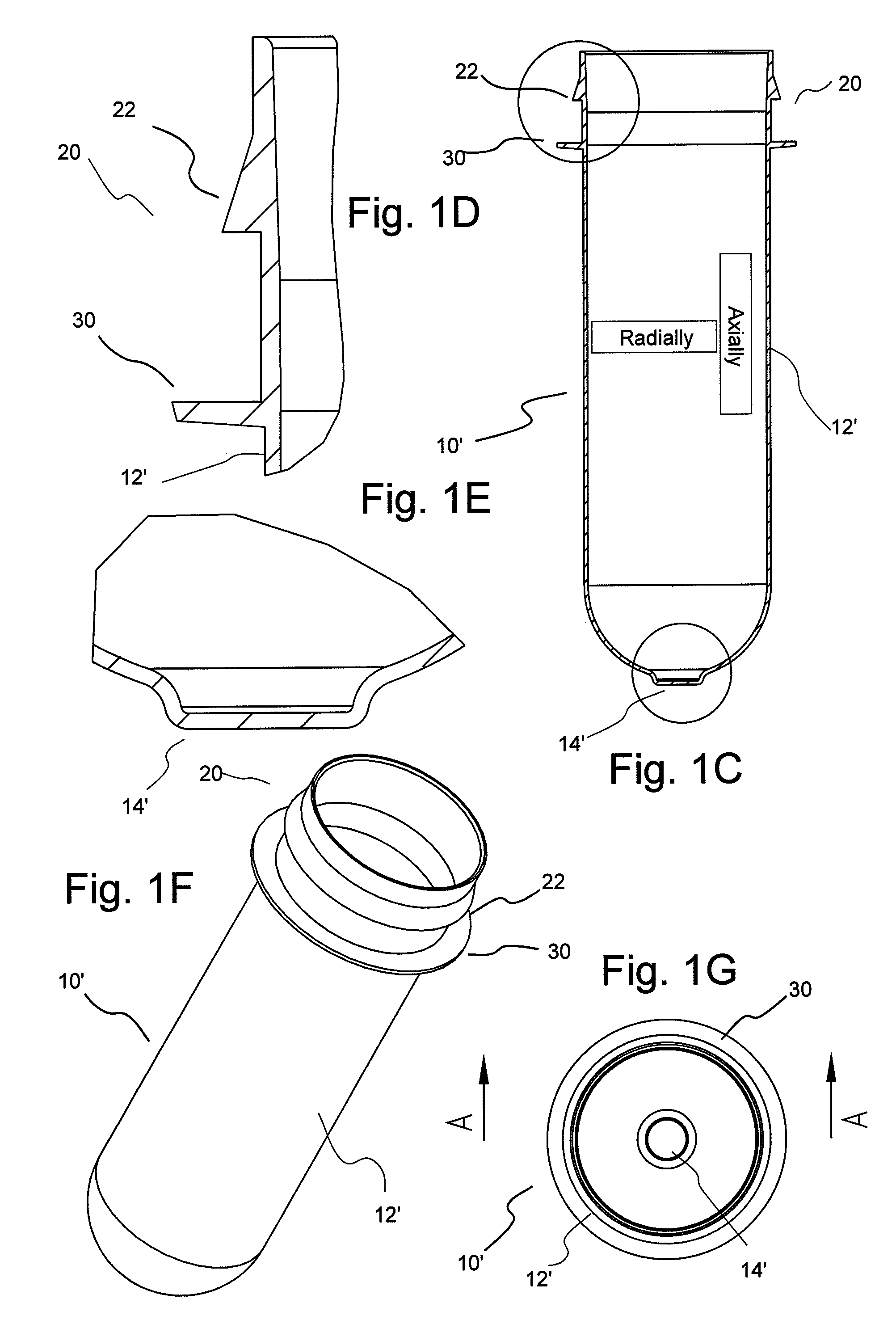

Reservoir plunger head systems and methods

A plunger head moveable in an axial direction within a reservoir having an interior volume for containing fluidic media may have a first portion in contact with fluidic media when fluidic media is in the interior volume of the reservoir, the first portion comprising a first material compatible with fluidic media in the interior volume of the reservoir, a second portion located on an opposite side of the plunger head from the interior volume of the reservoir, the second portion connectable to a plunger arm, and a third portion located between the first portion and the second portion of the plunger head, at least one of the first portion, second portion, and the third portion is made of a material that comprises one of a cyclic olefin copolymer and a cyclic olefin polymer.

Owner:MEDTRONIC MIMIMED INC

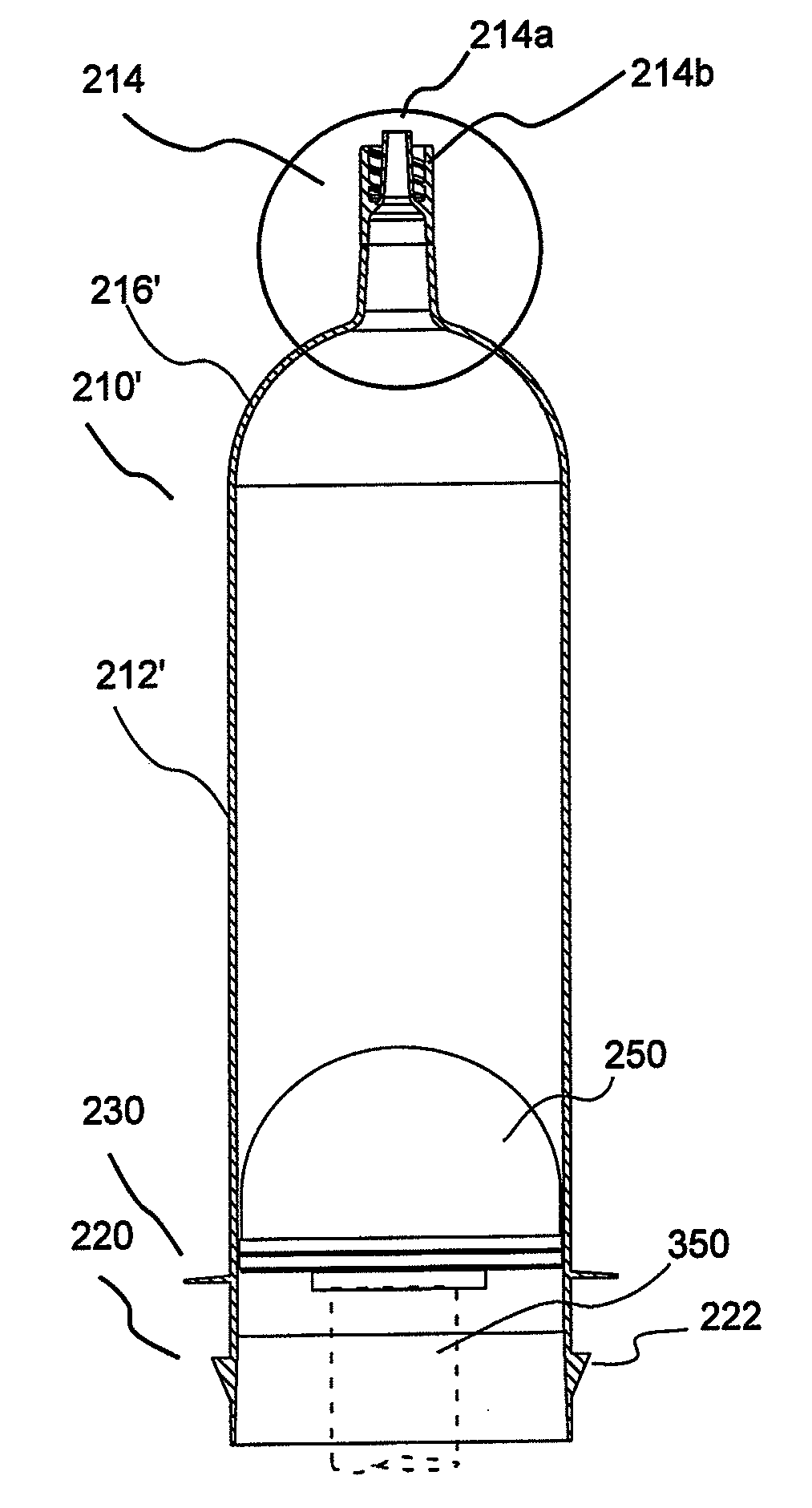

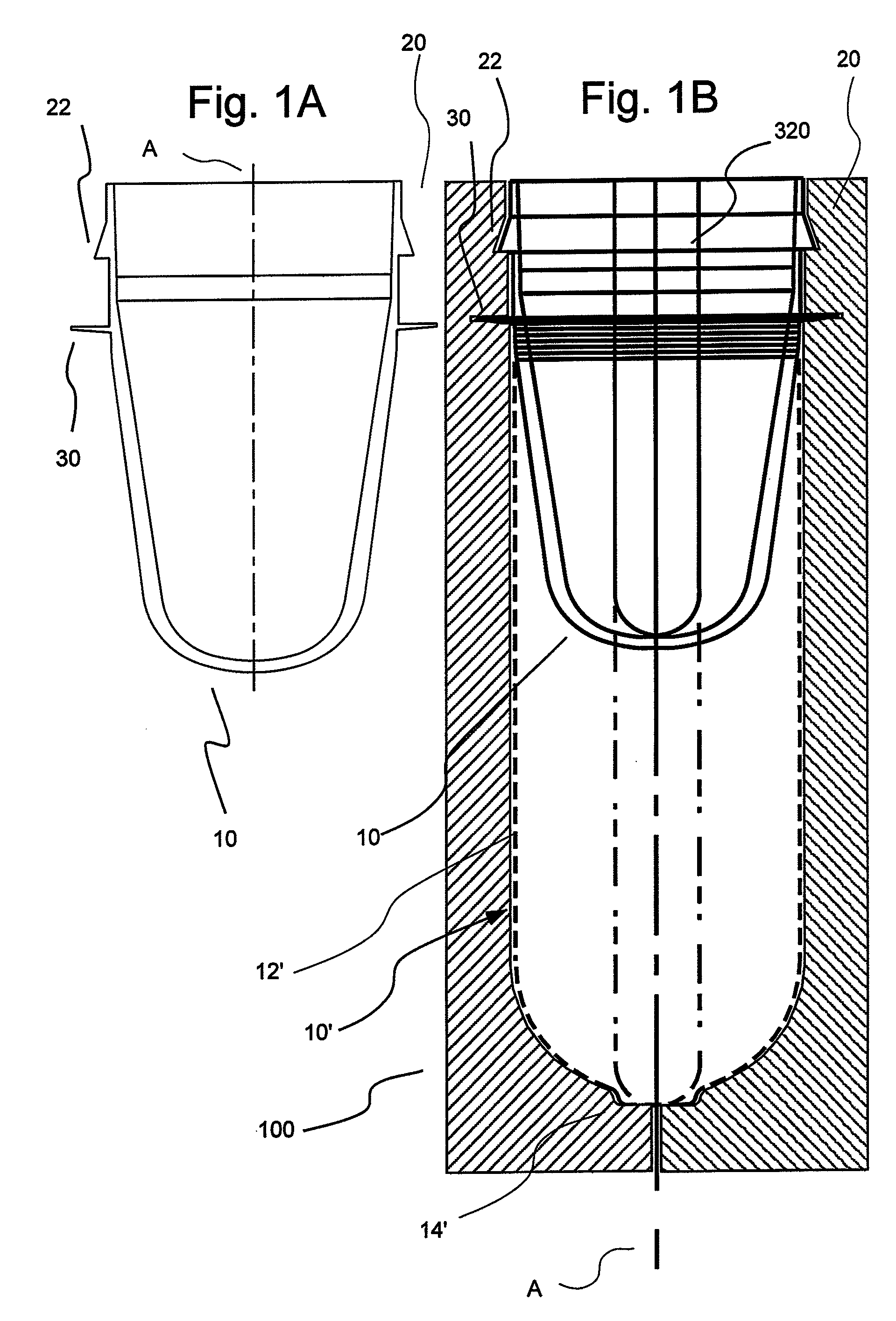

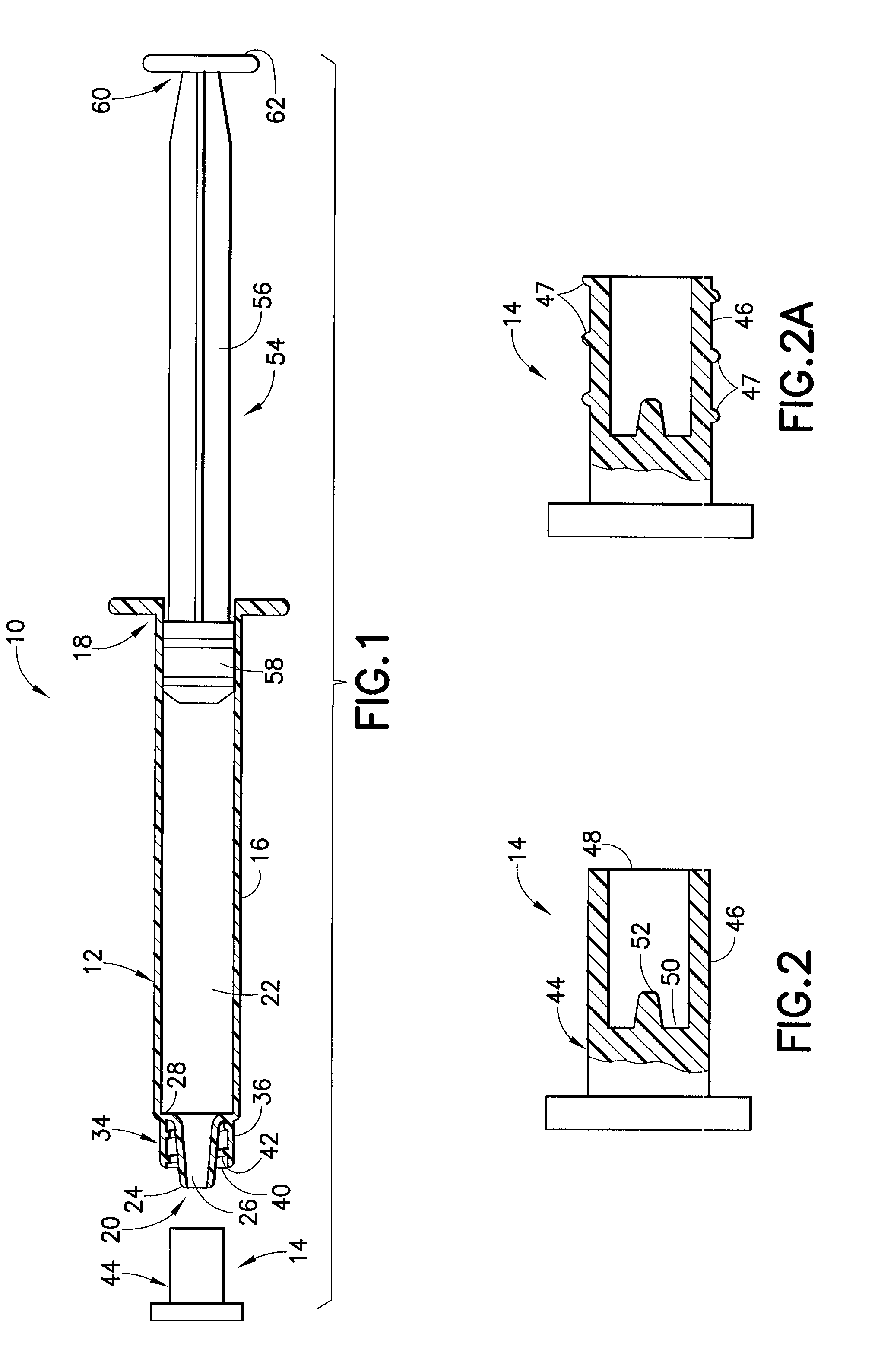

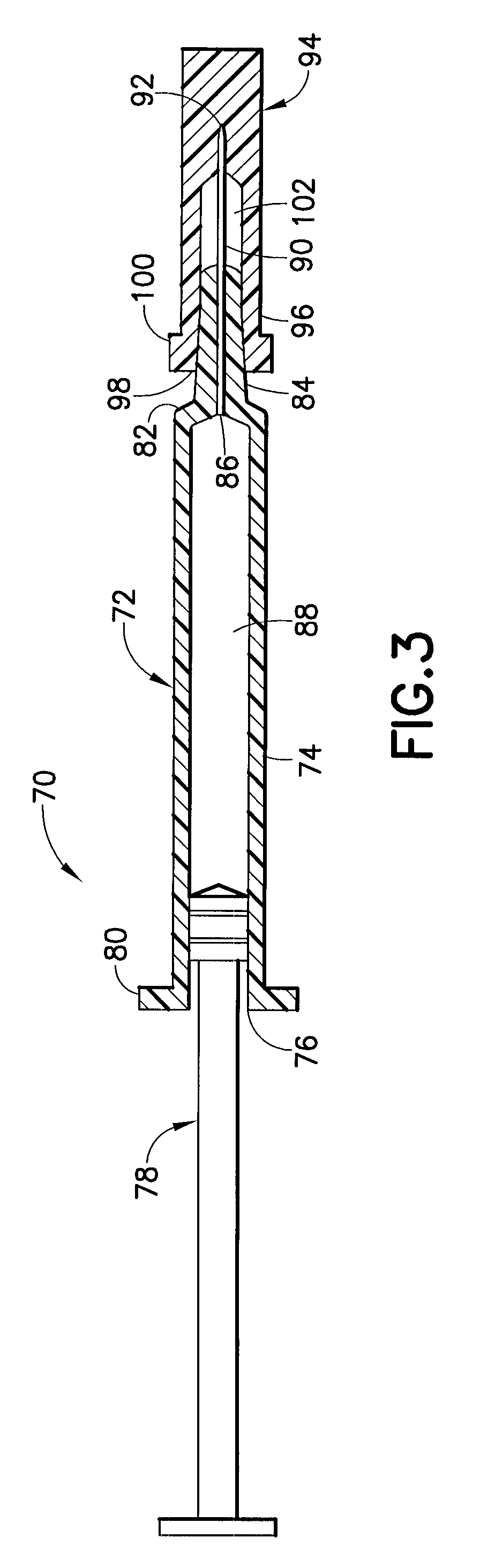

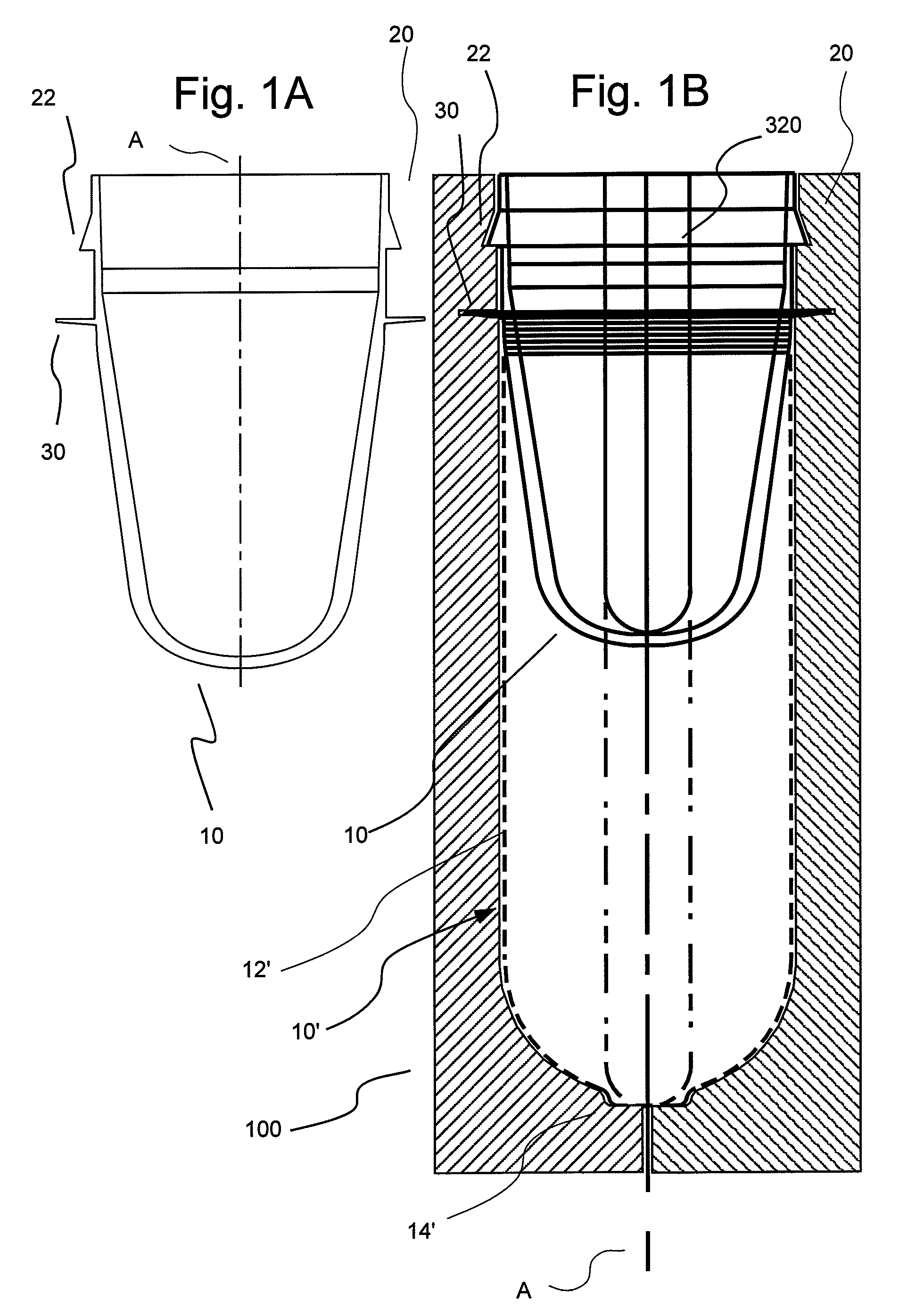

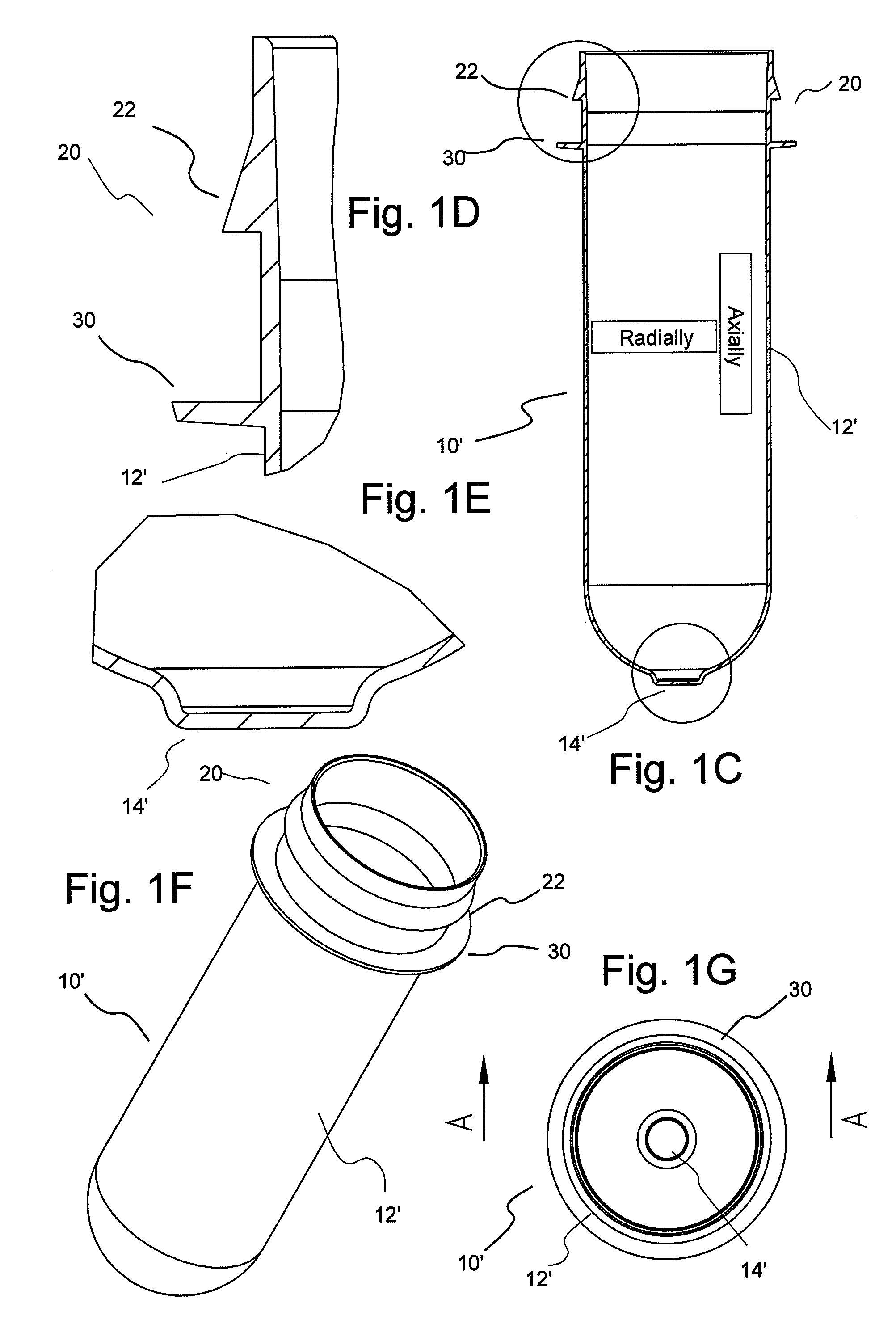

Syringe for use with injectors and methods of manufacturing syringes and other devices

ActiveUS20080033367A1Reduce thicknessInfusion syringesMedical devicesPolystyreneCyclo olefin polymer

A syringe for use in a pressurized injection of a fluid includes a syringe barrel including a polymeric material having undergone expansion via blow molding. An inner diameter of the syringe barrel can, for example, be sufficiently constant (over at least a portion of the axial length of the syringe) that a plunger slidably positioned within the syringe barrel and in generally sealing contact with an inner wall of the syringe barrel can be used within the syringe barrel to generate a pressure of at least 1 psi within the syringe barrel. In several embodiment, the inner diameter of the syringe barrel is sufficiently constant to generate a pressure of at least 100 psi, at least 300 psi, or even at least 500 psi within the syringe barrel. A method of forming a syringe includes the steps of: injection molding at least one polymeric material to form a preform; placing the preform into an blow mold die; and expanding at least a portion of the preform while heating the preform within the die to form a barrel of the syringe. The syringes can be formed to withstand relatively high pressures as described above. The at least one polymeric material can, for example, be polyethyleneterephthalate, cyclic olefin polymer, polypropylene, polystyrene, polyvinylidene chloride, polyethylene napthalate and / or nylon.

Owner:BAYER HEALTHCARE LLC

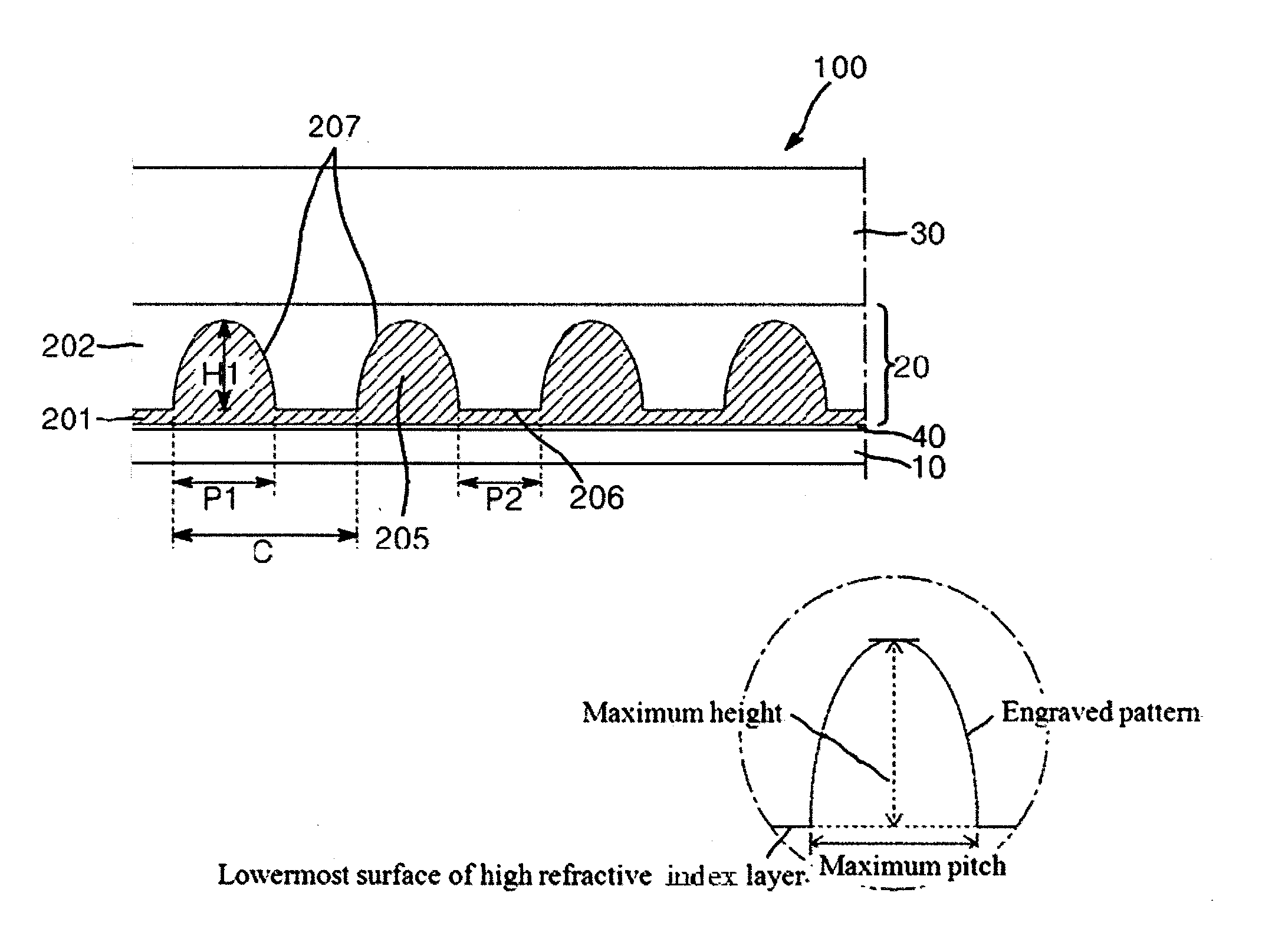

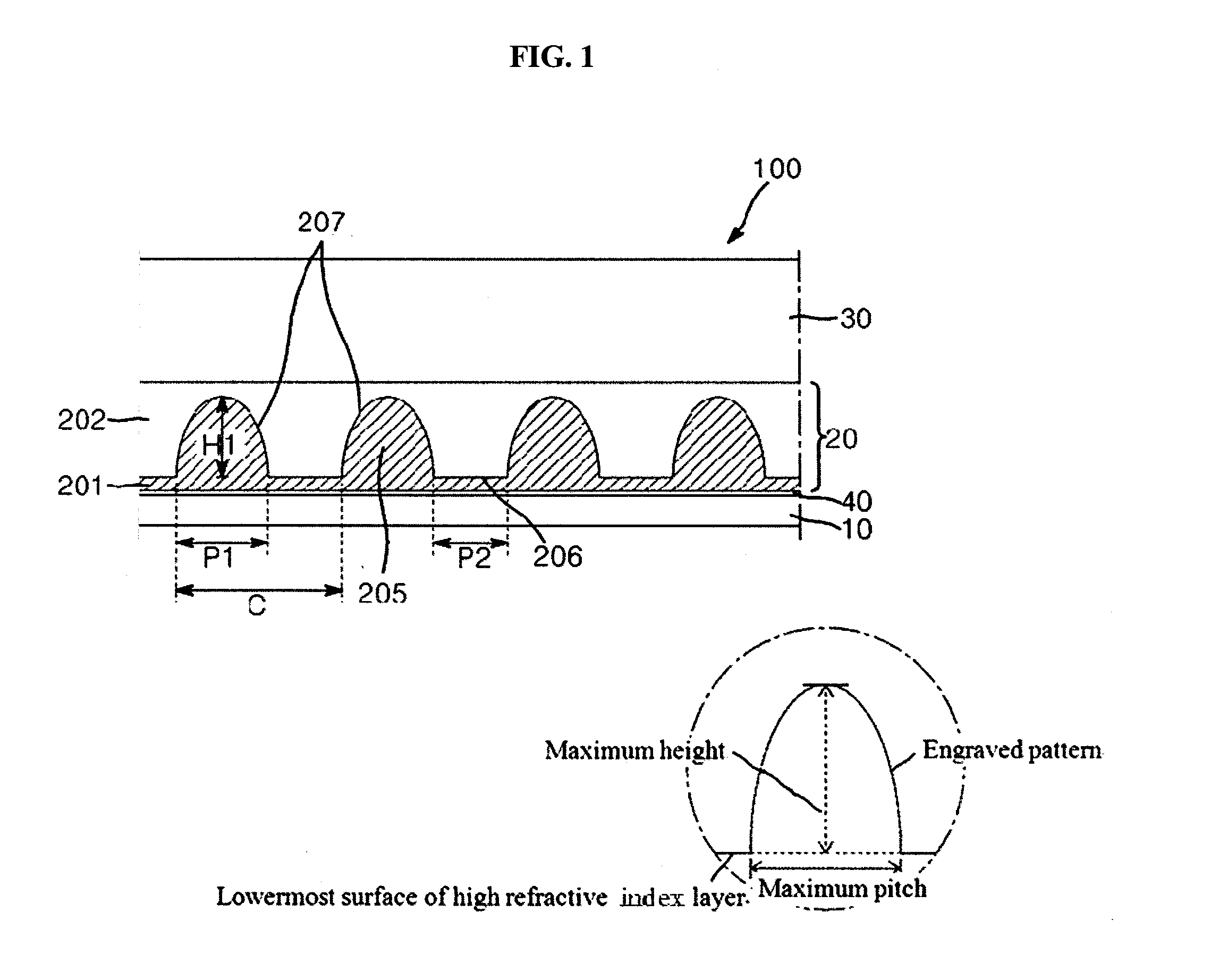

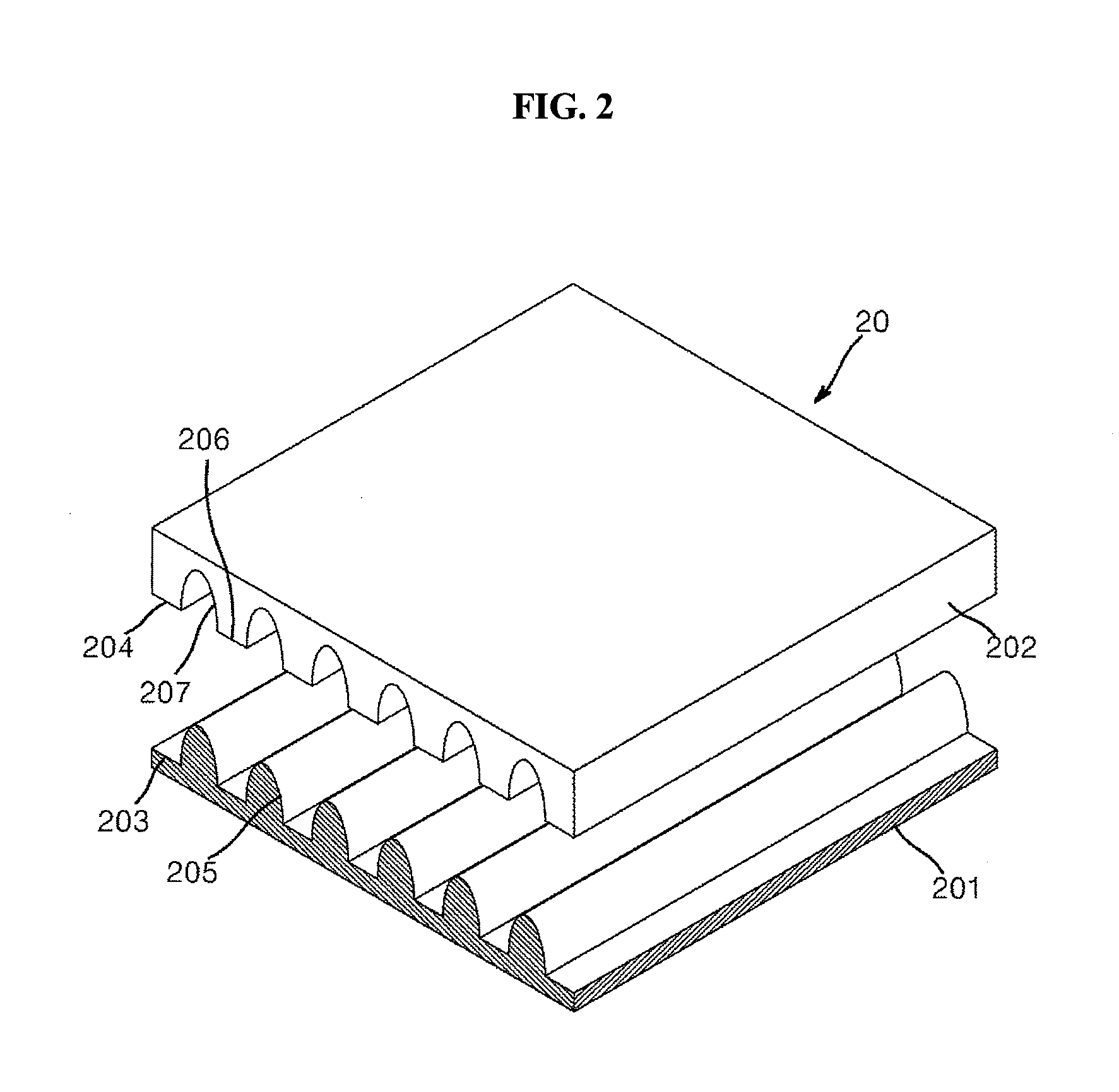

Polarizing plate and liquid crystal display comprising the same

ActiveUS20160252665A1High refractive indexPolarising elementsNon-linear opticsLiquid-crystal displayPolyethylene terephthalate

A polarizing plate includes: a polarizer; a pattern layer on one surface of the polarizer, the pattern layer including a first refractive index layer having at least one engraved pattern and a second refractive index layer having a filling pattern filling at least a portion of the engraved pattern, the first refractive index layer having a higher refractive index than the second refractive index layer; and a first protective layer. The polarizing plate has a structure in which the polarizer, the second refractive index layer, the first refractive index layer and the first protective layer are sequentially stacked in that order, or in which the polarizer, the first protective layer, the second refractive index layer and the first refractive index layer are sequentially stacked in that order. The first protective layer includes a base film including at least one resin of triacetylcellulose, polyethylene terephthalate, cyclic olefin polymer, and acrylic resins.

Owner:SAMSUNG SDI CO LTD

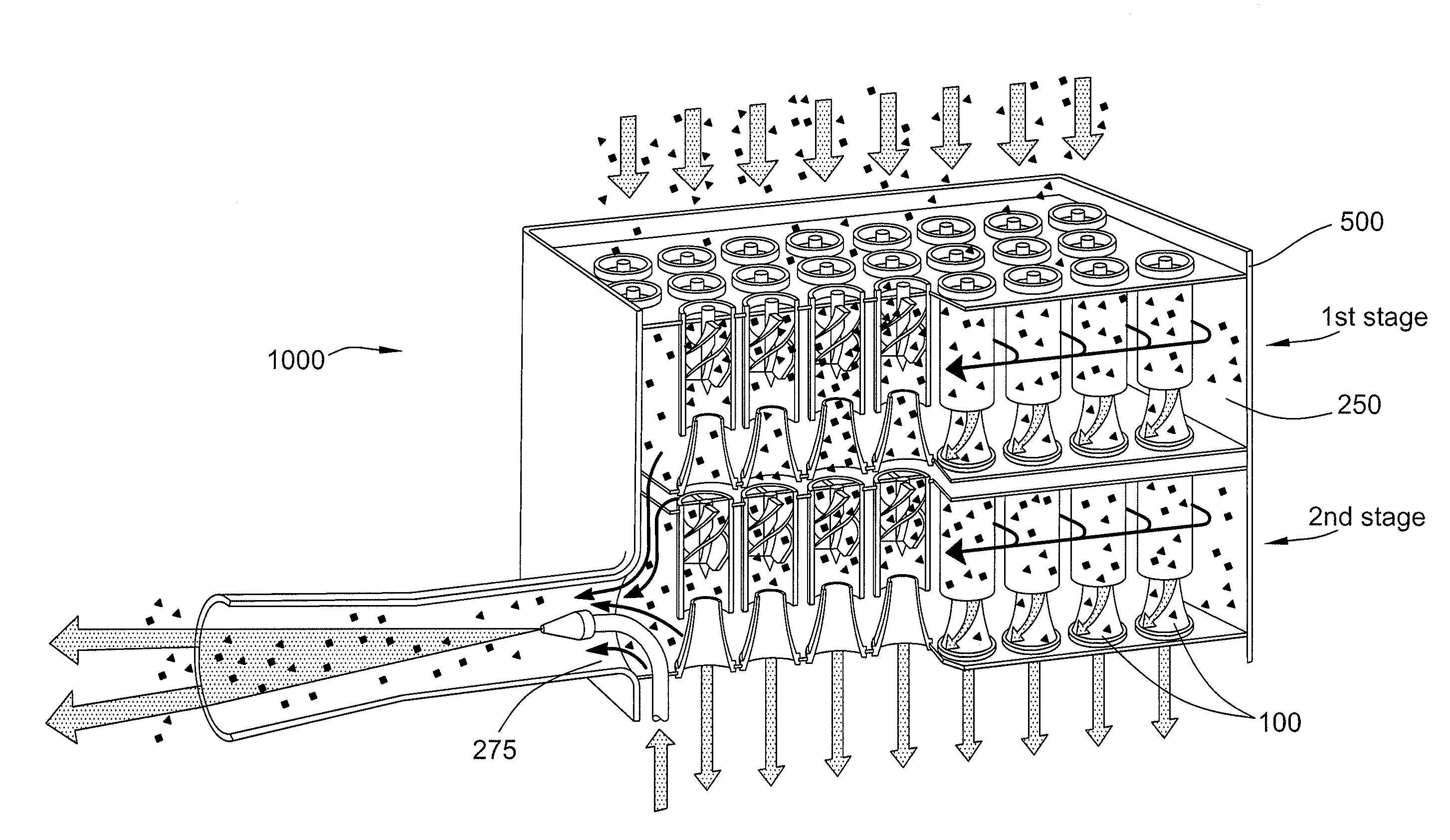

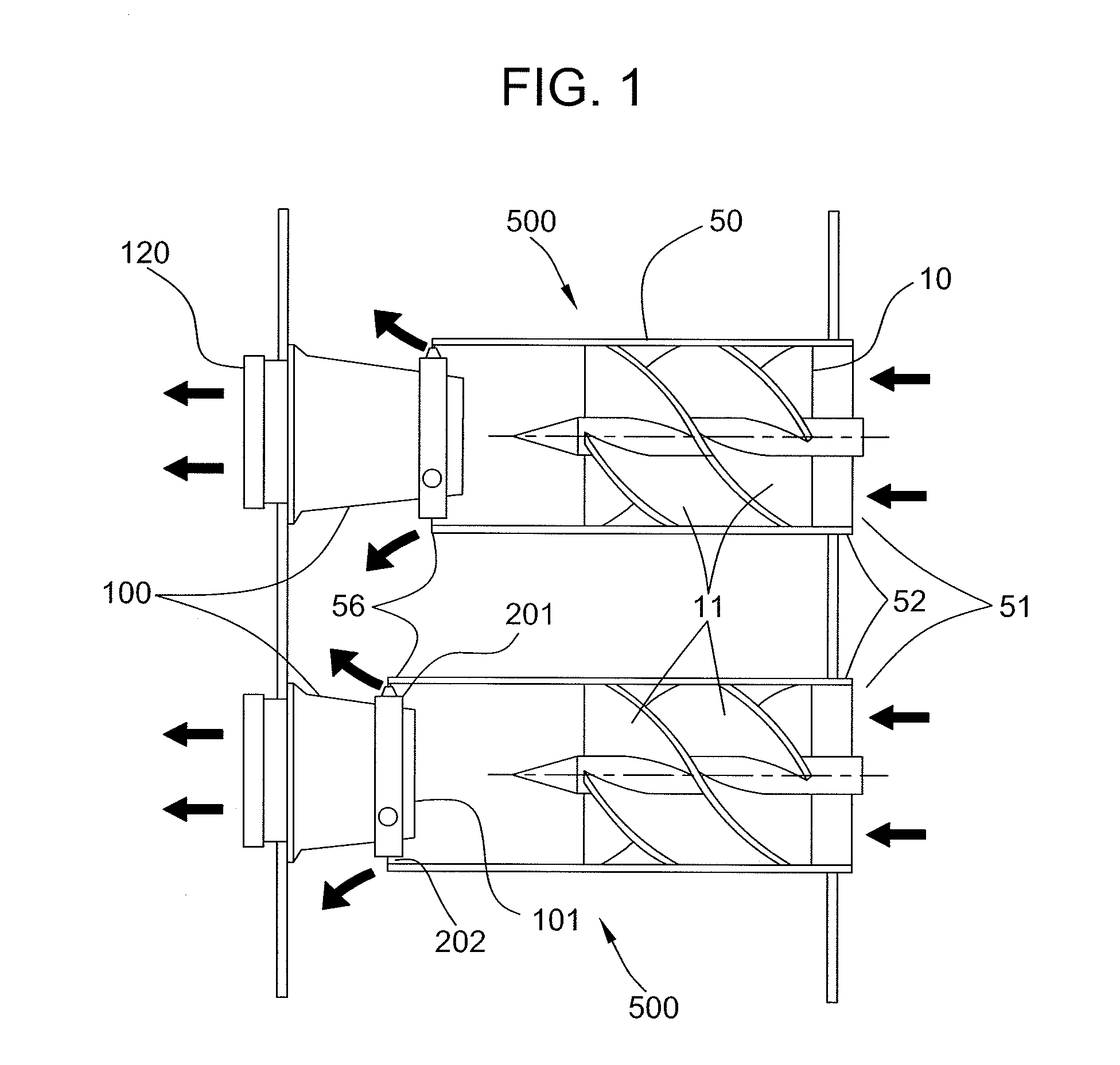

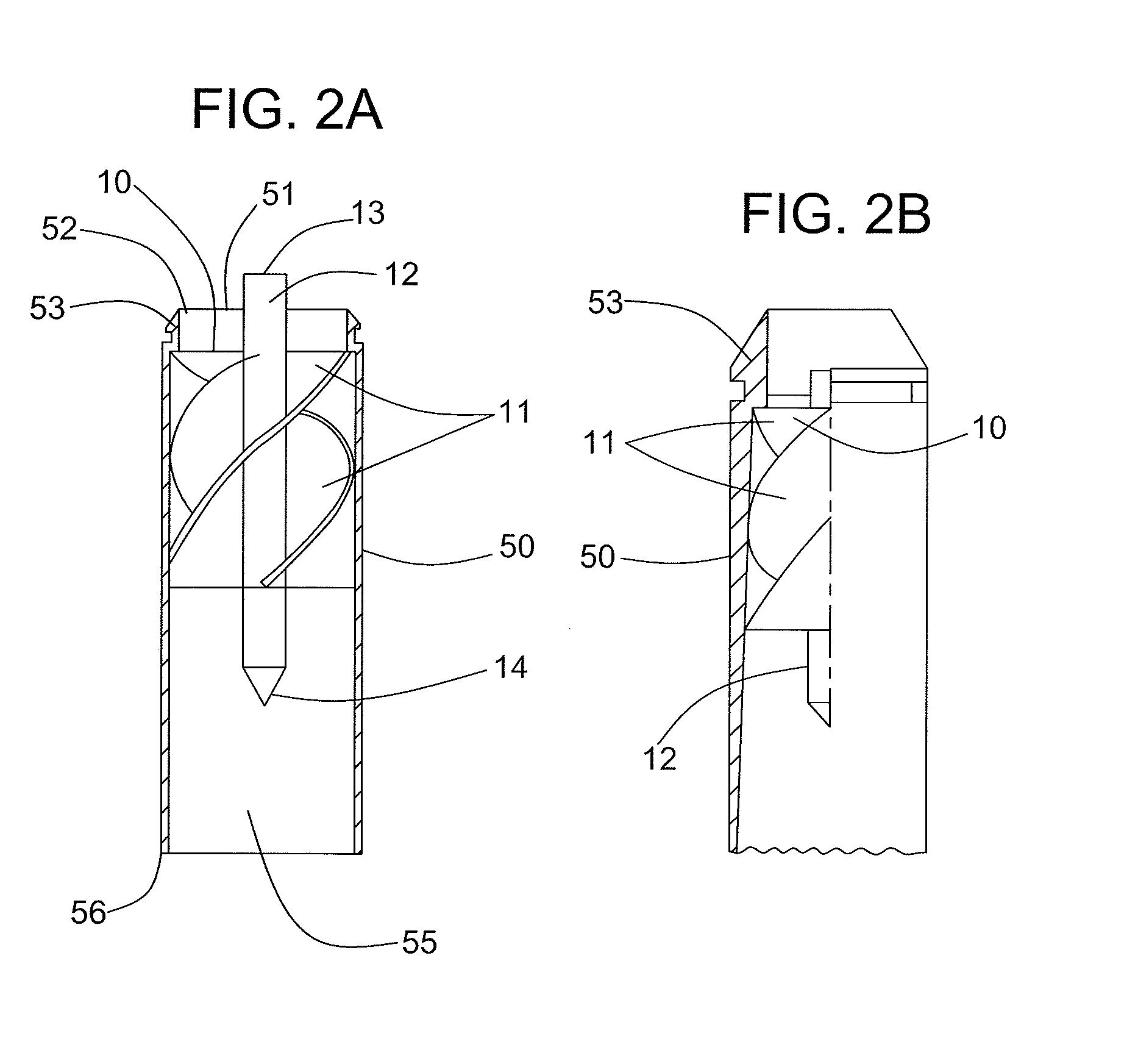

Inertial separator

An inertial separator comprising a tubular body, the tubular body comprises a composition comprising a polymer selected from the group consisting of a cyclic olefin polymer and a cyclic olefin copolymer, and, a polyhedral oligomeric silsesquioxane and / or a flame retardant and / or an anti-static additive, is disclosed.

Owner:PALL CORP

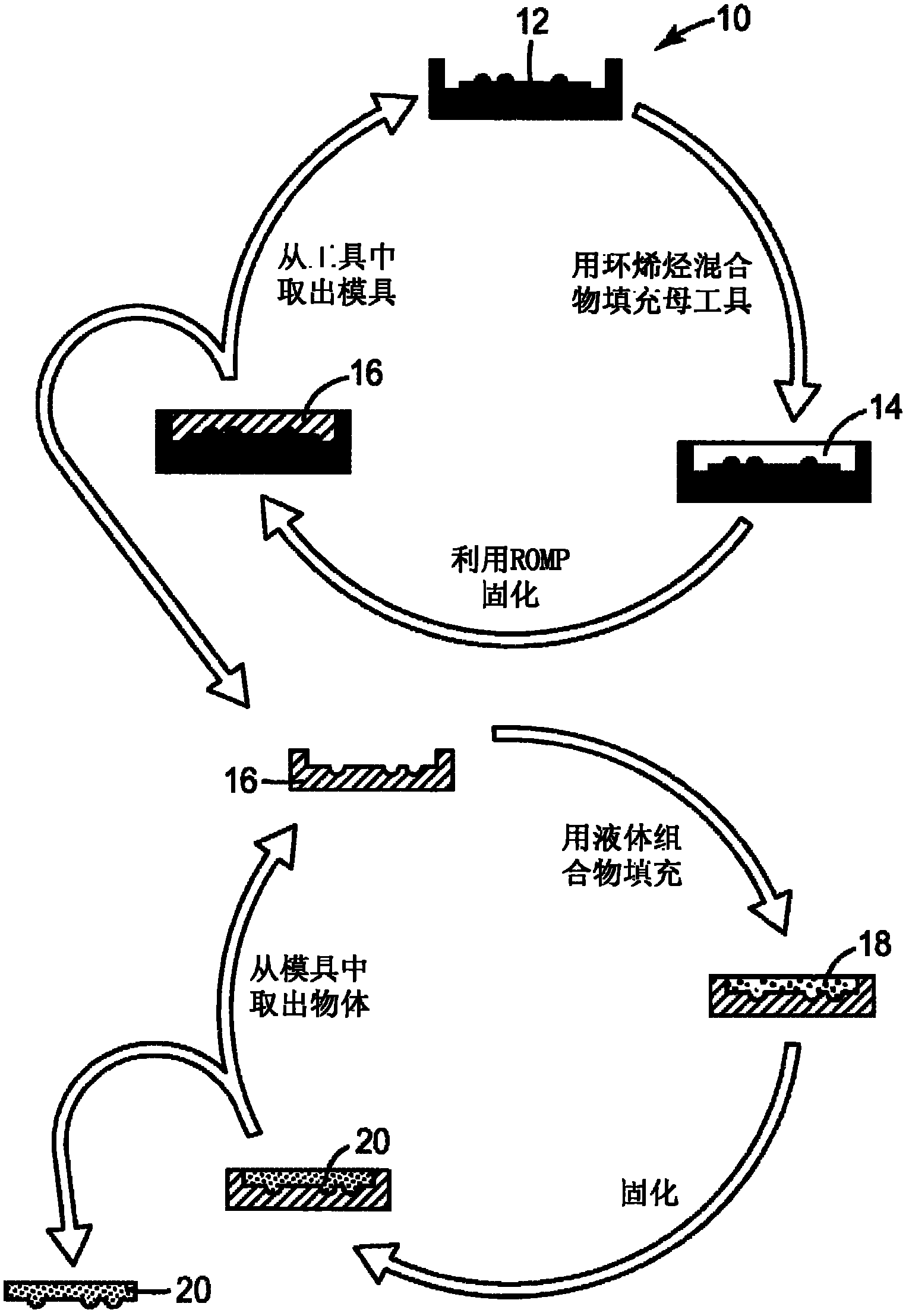

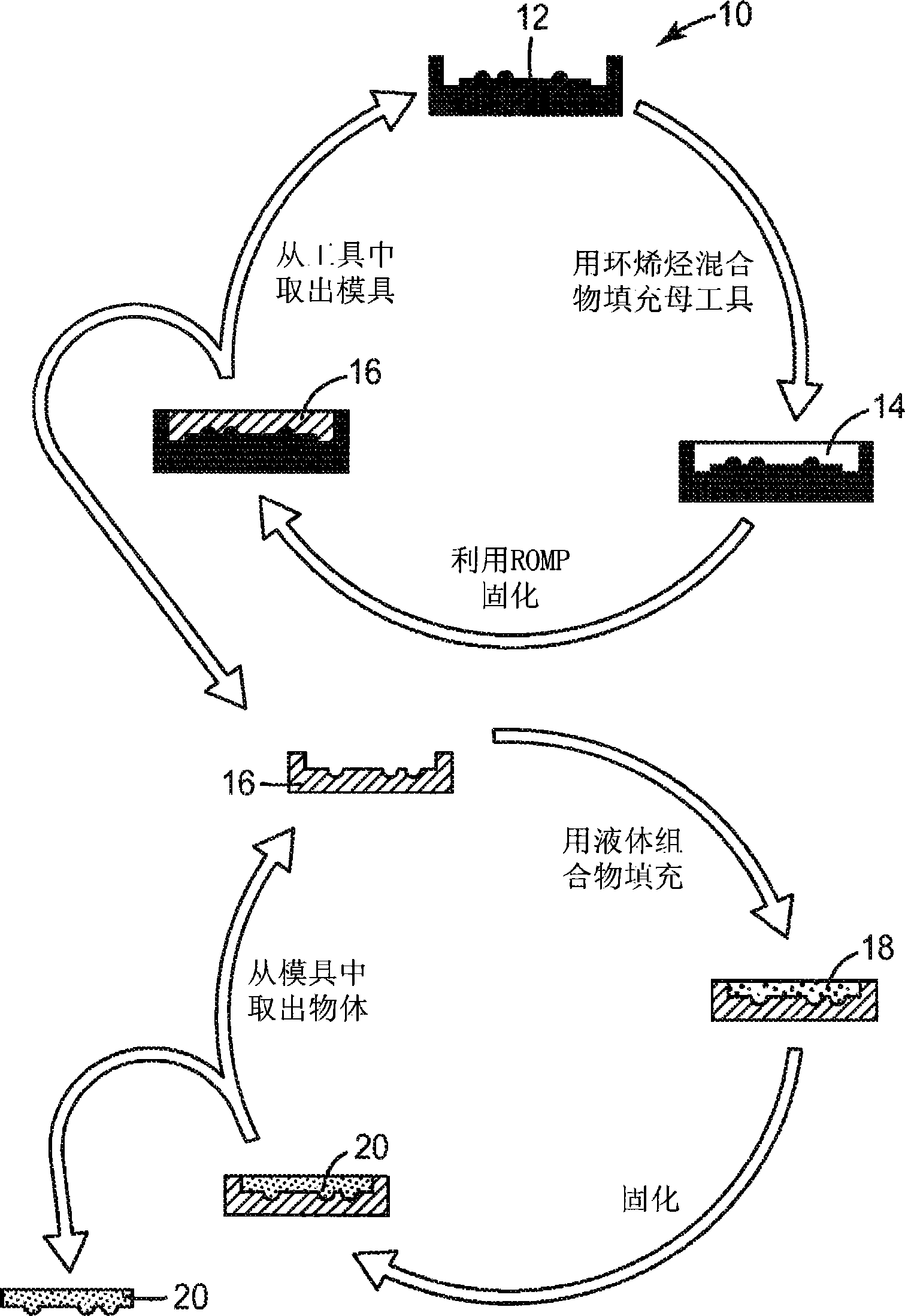

Polymeric molds and articles made therefrom

Disclosed herein are polymeric molds that can be used to make molded articles. The polymeric molds are made from cyclic olefin polymers that may be formed by ring opening metathesis polymerization (ROMP) of a polycyclic monomer having two or more reactive double bonds and a cyclic monomer comprising one reactive double bond. Fluorinated monomers may be used. The polymeric molds may be structured molds in that they have at least one microstructured feature having a dimension of less than about 2 mm, or less than about 500 um. The polymeric molds may also have a plurality of such microstructured features. Also disclosed herein are methods of making the polymeric molds, methods of making molded articles therefrom, and the molded articles.

Owner:3M INNOVATIVE PROPERTIES CO

Cyclo olefin polymer and copolymer medical devices

An illuminated medical system comprises a medical instrument and a light transmitting waveguide. The waveguide projects lights from a distal portion of the waveguide toward a target area. The waveguide is formed primarily of a cyclic olefin copolymer or a cyclic olefin polymer.

Owner:INVUITY

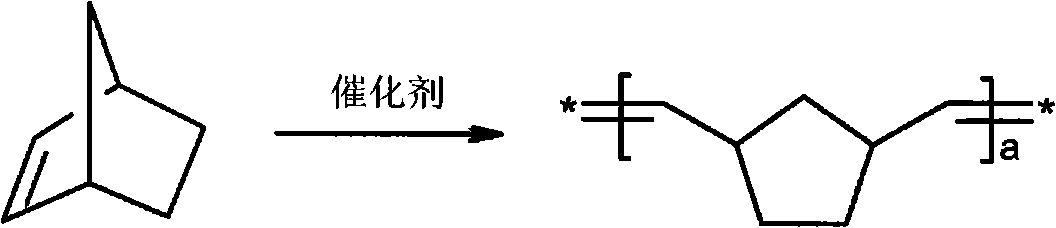

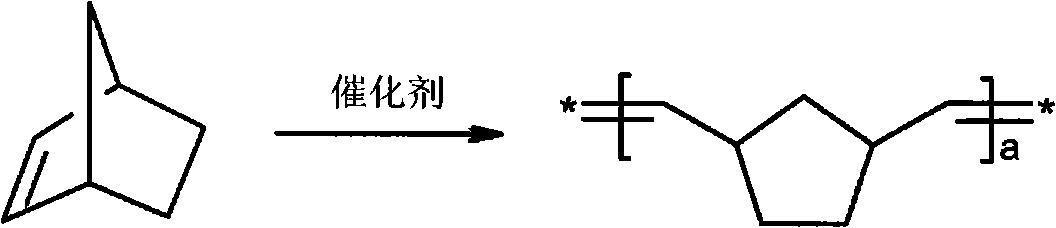

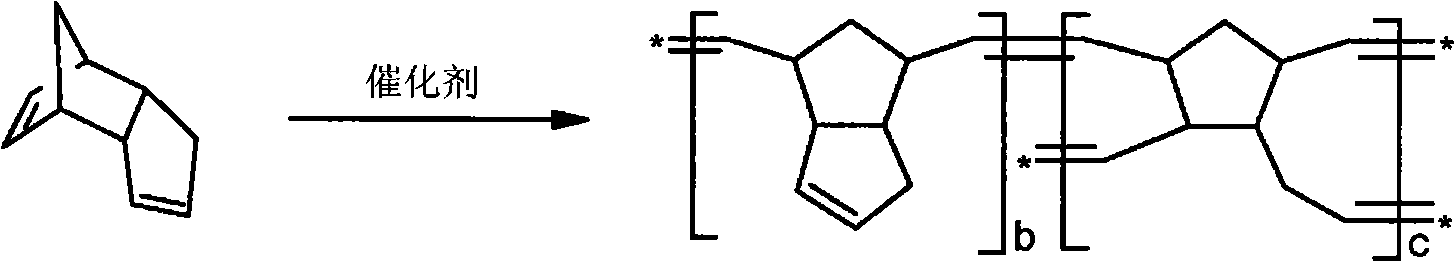

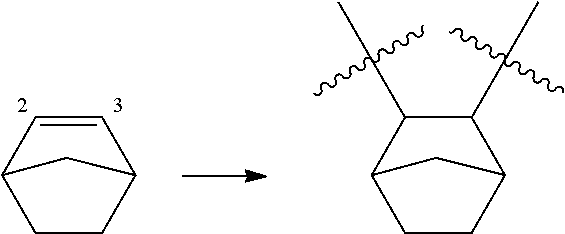

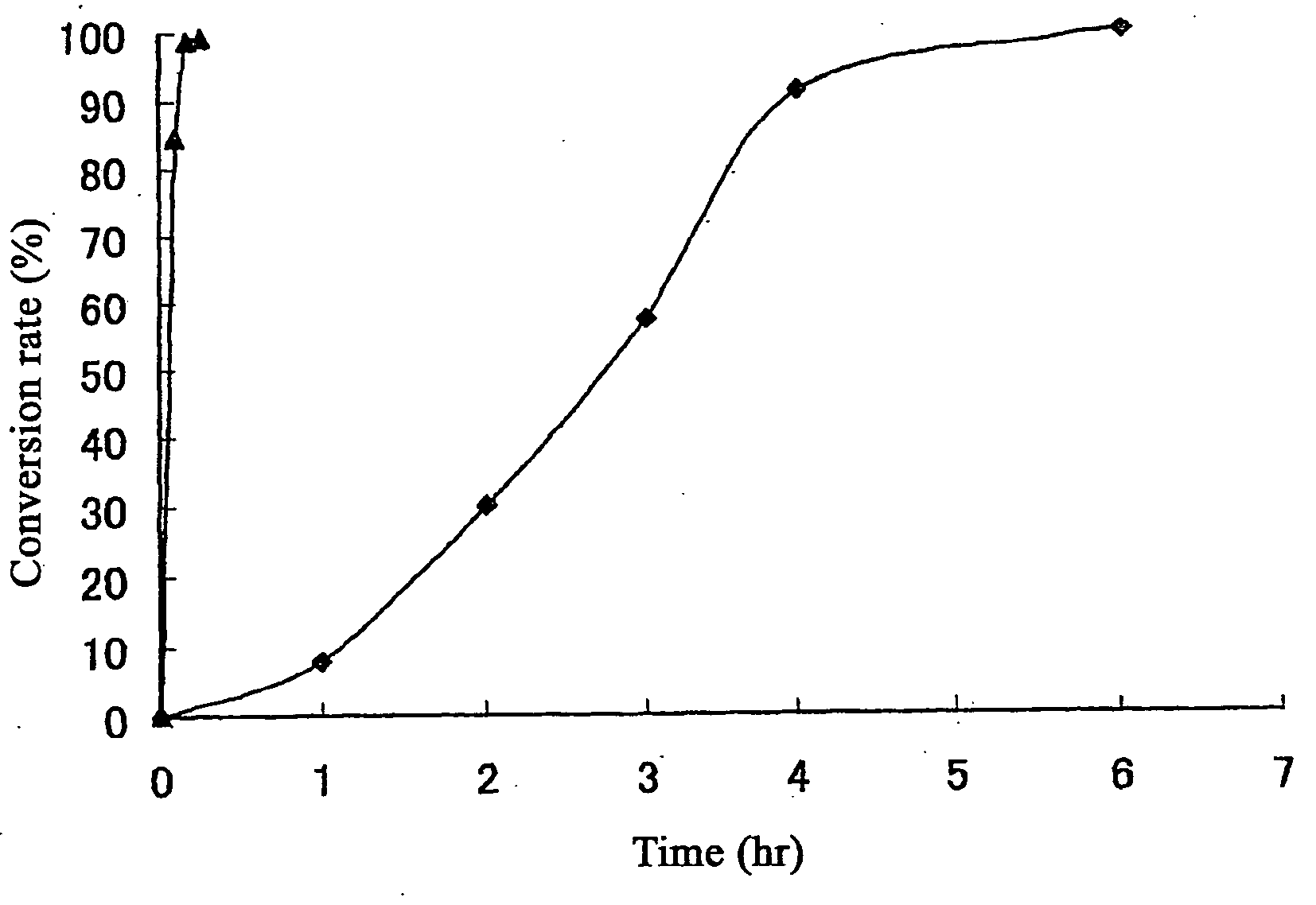

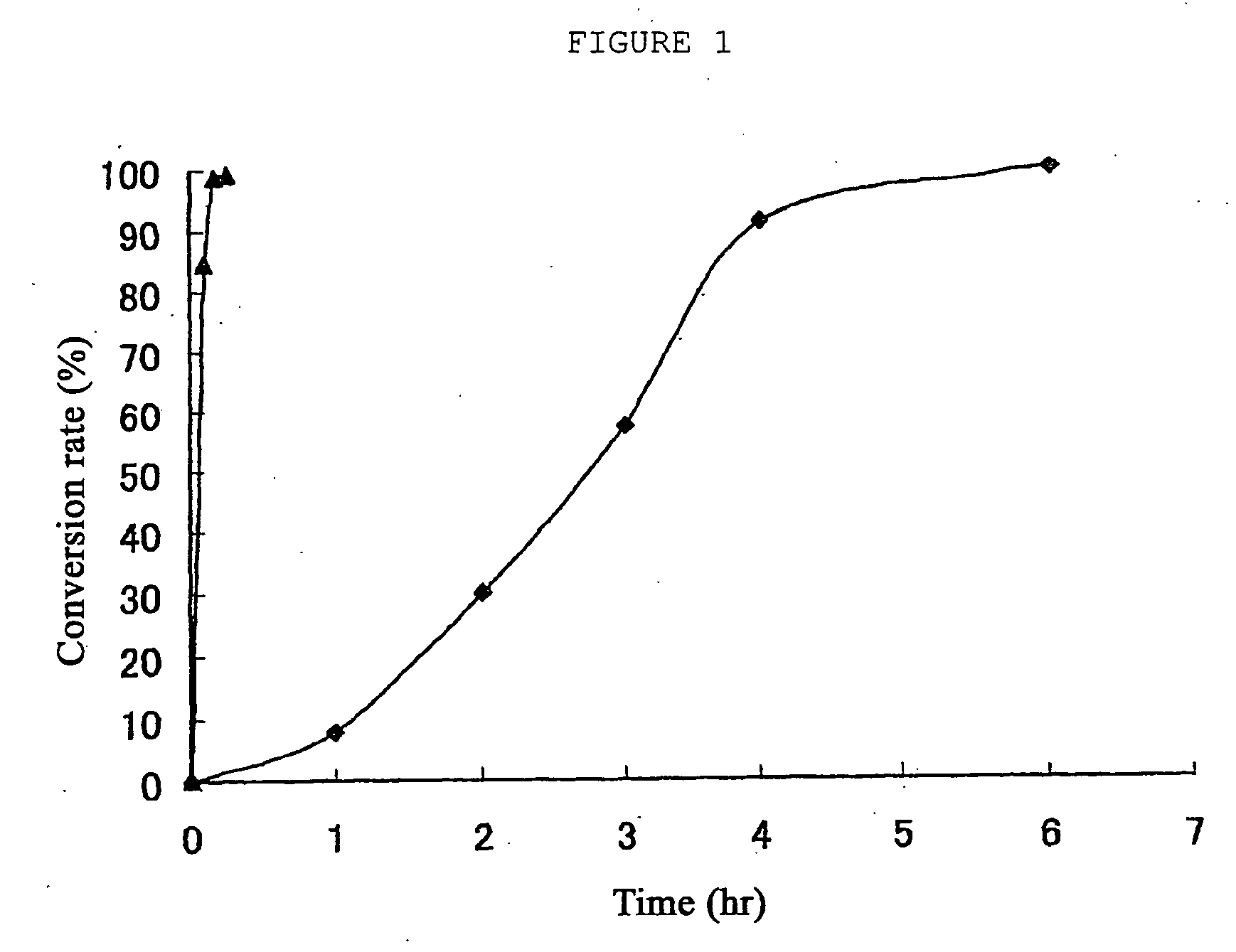

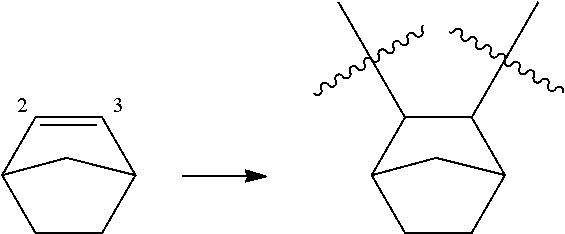

Process for producing hydrogenated product of cyclic olefin polymer prepared through ring-opening polymerization

A process for producing a hydrogenated product of a polymer prepared through ring-opening polymerization which comprises a polymerization step of polymerizing a cyclic olefin through ring-opening polymerization in the presence of a polymerization catalyst comprising an organoruthenium compound or an organoosmium compound to prepare a polymer, and a hydrogenation step of adding a hydrogenation catalyst and hydrogen into a polymerization system resulting from the polymerization step to hydrogenate the carbon-carbon double bonds of the polymer prepared through the ring-opening polymerization. When the organoruthenium compound- or organoosmium compound-containing catalyst further comprises a carbene compound, the catalyst exhibits a higher activity for the ring-opening polymerization.

Owner:ZEON CORP

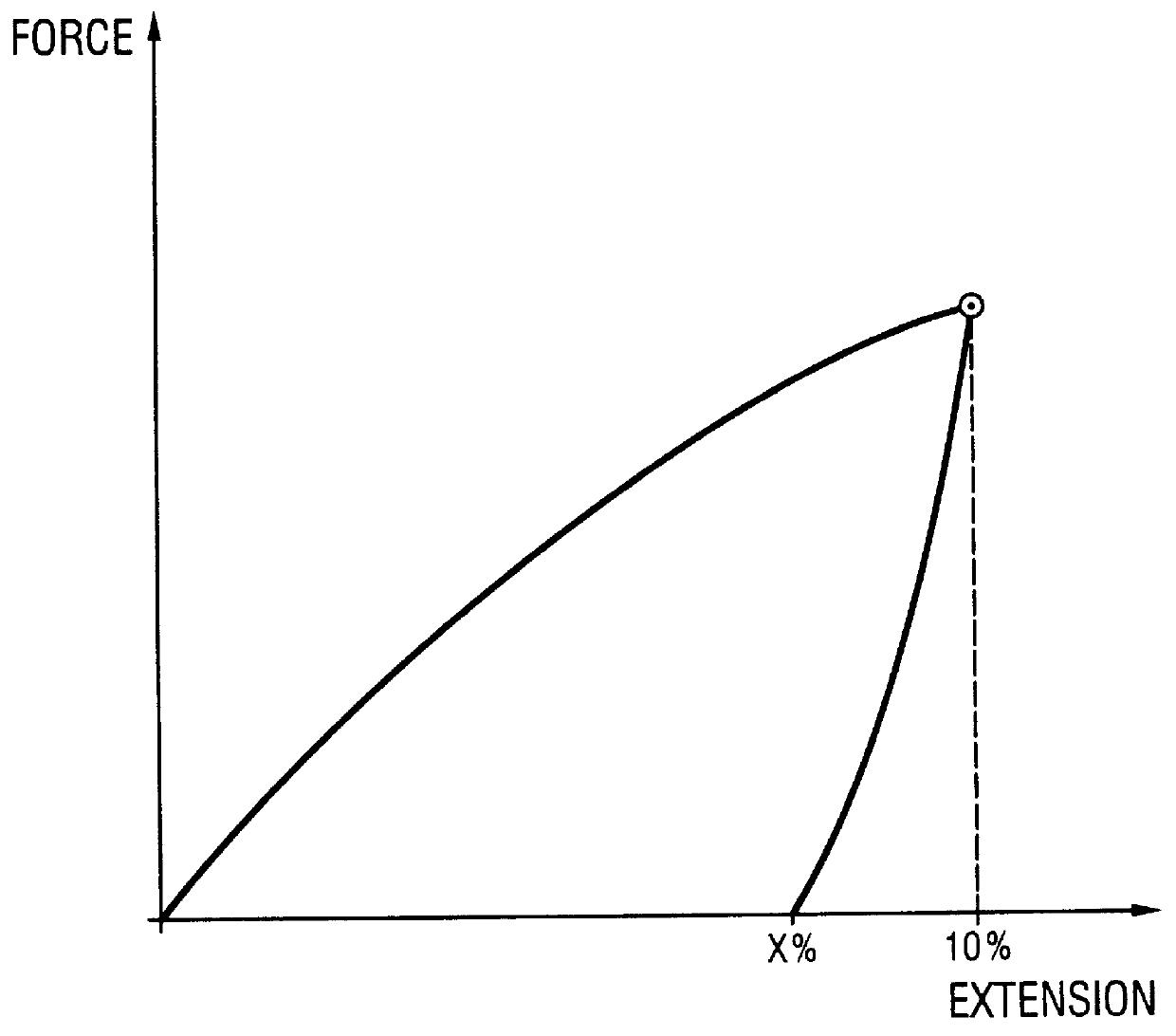

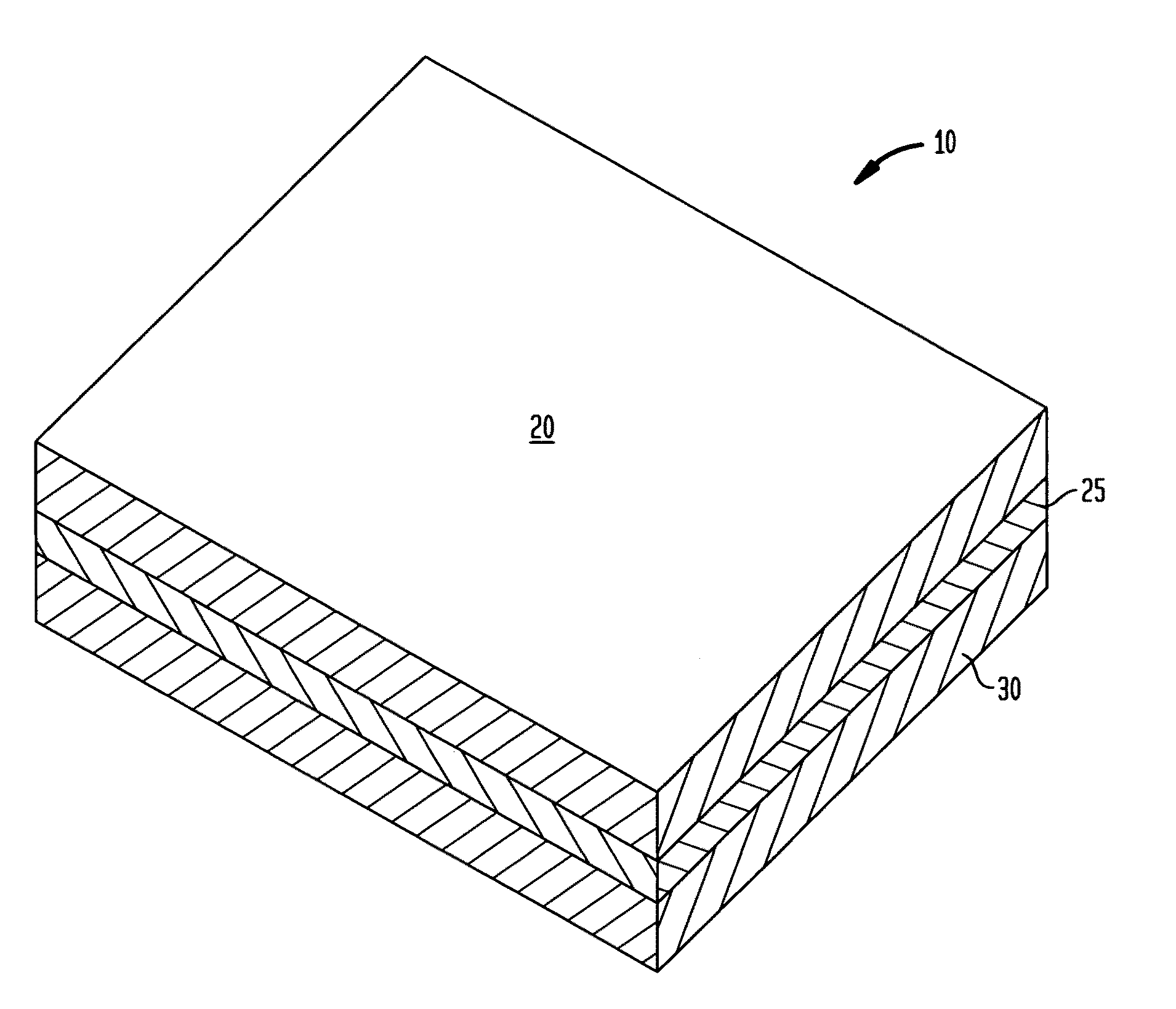

Melt blends of amorphous cycloolefin polymers and partially crystalline cycloolefin elastomers with improved toughness

ActiveUS20110256373A1Simple compositionImprove toughnessSynthetic resin layered productsThin material handlingElastomerCyclo olefin polymer

A melt-blend resin composition prepared by melt-blending includes from 60 parts to 99 parts per hundred weight resin in the blend of an amorphous cycloolefin polymer composition exhibiting a glass transition temperature in the range of from 30° C. to 200° C.; and from 40 parts to 1 part per hundred weight resin in the blend of a partially crystalline, cycloolefin elastomer of norbornene and ethylene preferably having a glass transition temperature in the range of from −10° C. to 15° C. and a crystalline melting temperature in the range of from 60° C. to 125° C. and a % crystallinity by weight in the range of from 5% to 40%. The partially crystalline, cycloolefin elastomer optionally has a second glass transition temperature at less than −90° C.

Owner:TOPAS ADVANCED POLYMERS

Method of manufacturing syringes and other devices

Owner:BAYER HEALTHCARE LLC

Low extractable, thermoplastic syringe and tip cap

InactiveUS20090149816A1Low extractable levelWithout loss of flexible and resilient propertyAmpoule syringesLavatory sanitoryThermoplastic elastomerCyclo olefin polymer

A prefilled syringe and syringe assembly having a syringe and a tip cap are produced from materials that do not interfere with the substance contained in the syringe and enable long term storage. The tip cap is made from a blend of a cyclic olefin polymer or copolymer and a thermoplastic elastomer. The thermoplastic elastomer is blended with the cyclic olefin copolymer in an amount so that the normally stiff and hard cyclic olefin copolymer is flexible and resilient to effectively seal and couple to the tip of a prefilled syringe.

Owner:BECTON DICKINSON & CO

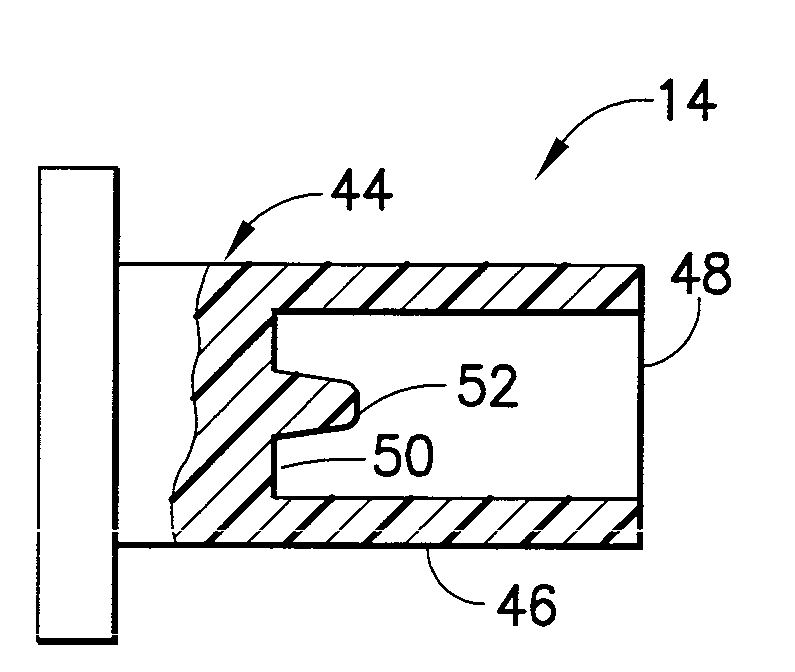

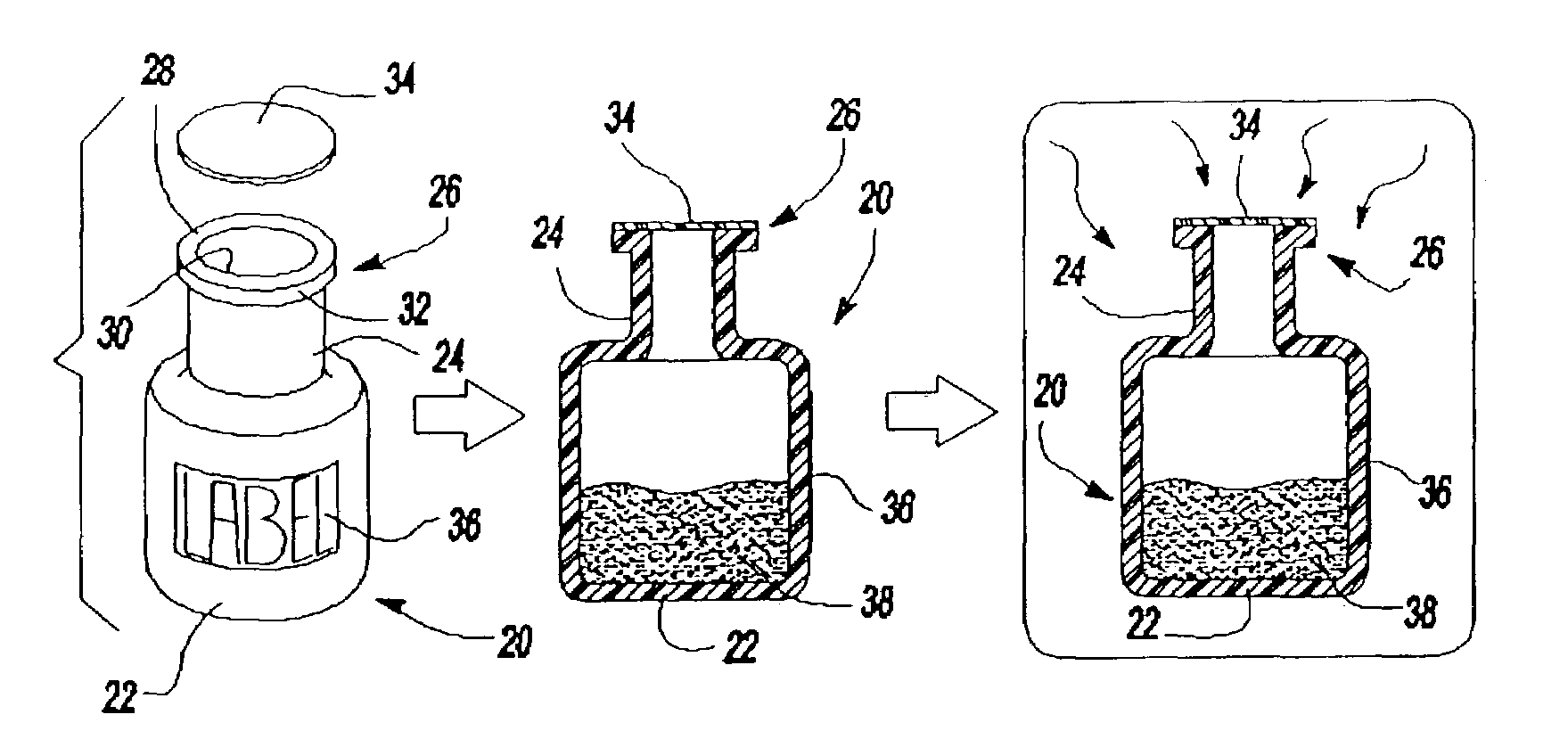

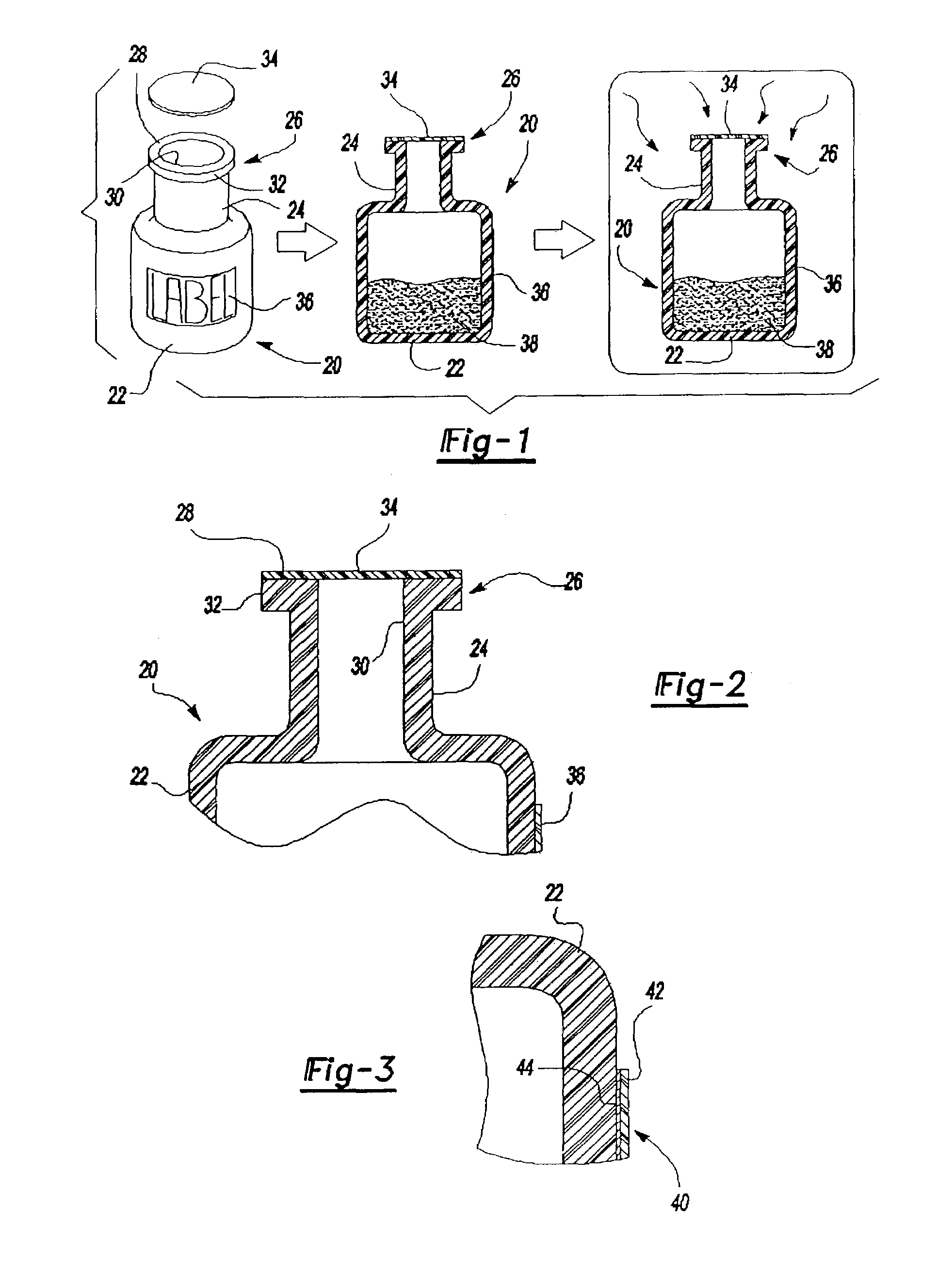

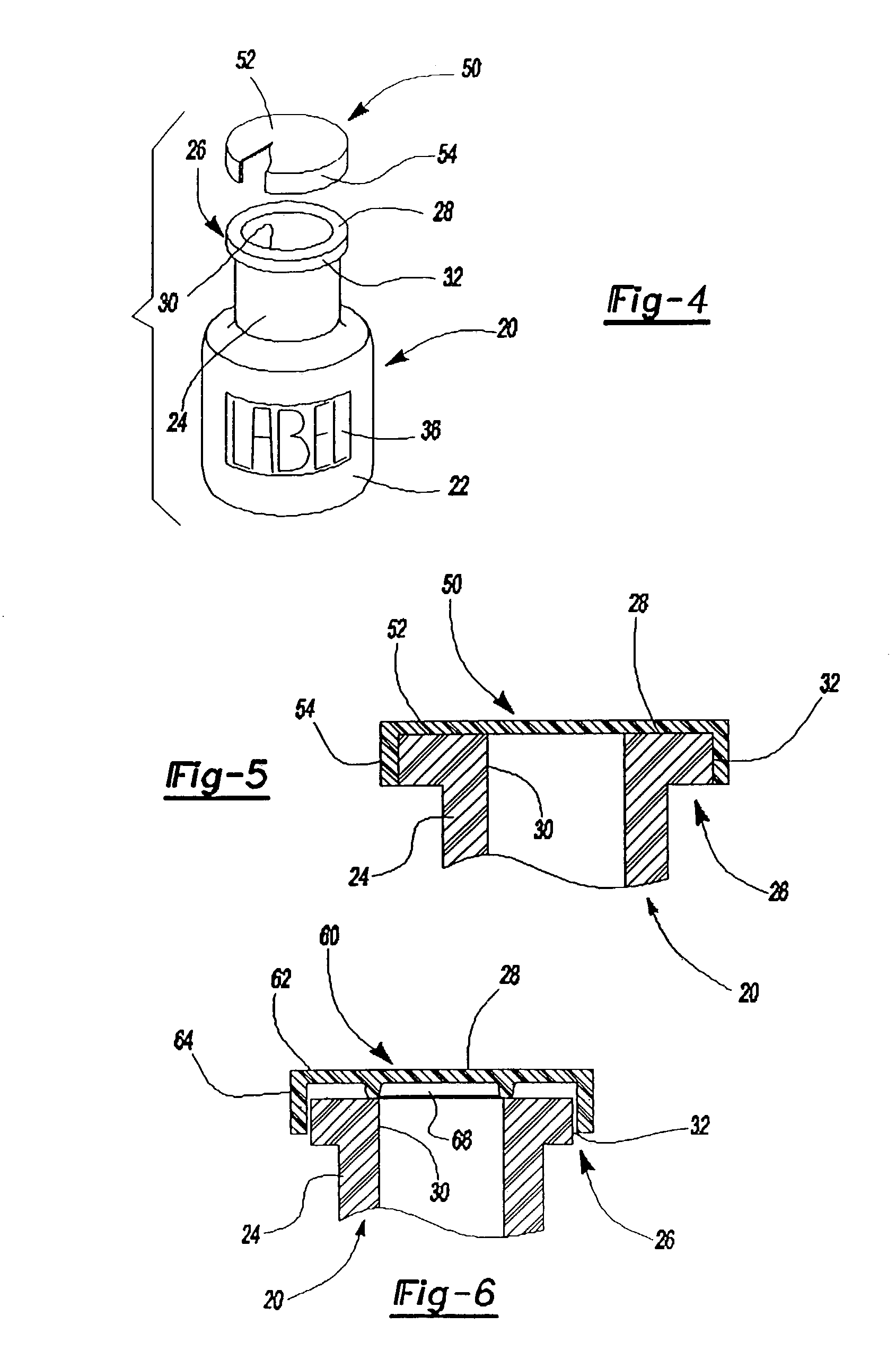

Method of fusing a component to a medical storage or transfer device and container assembly

InactiveUS7297216B2Eliminates crimping of metal or plastic closuresCapsClosure using stoppersPolymer scienceRelative energy

A method of fusing a component to a sterilized storage or delivery device formed of a cyclic olefin polymer which includes forming the storage or delivery device from a cyclic olefin polymer, forming a second member or component having at least a surface layer formed of the second polymer, wherein the Hansen relative energy distance Ra / Ro of the second polymer relative to the cyclic olefin polymer is equal to or less than 0.7, applying the second member to the storage or delivery device, and heating the assembly to the sterilization temperature, thereby causing the second polymer to chemically interact with the cyclic olefin polymer, fusing the second component to the storage or delivery device. The preferred embodiment of the invention is a medical container, such as a vial, wherein the vial is formed of a cyclic olefin polymer and the cap, closure or collar is formed of a second polymer heat fused to the vial or container.

Owner:BECTON DICKINSON & CO

Polymeric molds and articles made therefrom

Disclosed herein are polymeric molds that can be used to make molded articles. The polymer mold is made of a cyclic olefin polymer that can be formed from a polycyclic monomer having two or more reactive double bonds and a cyclic monomer containing one reactive double bond. Ring metathesis polymerization (ROMP) formation. Fluorinated monomers can be used. The polymeric molds may be structured molds in that they have microstructured features with at least one dimension less than about 2 mm or less than about 500 μm. The polymer mold can also have many of these microstructured features. Also disclosed herein are methods of making polymeric molds, methods of making molded articles therefrom, and molded articles.

Owner:3M INNOVATIVE PROPERTIES CO

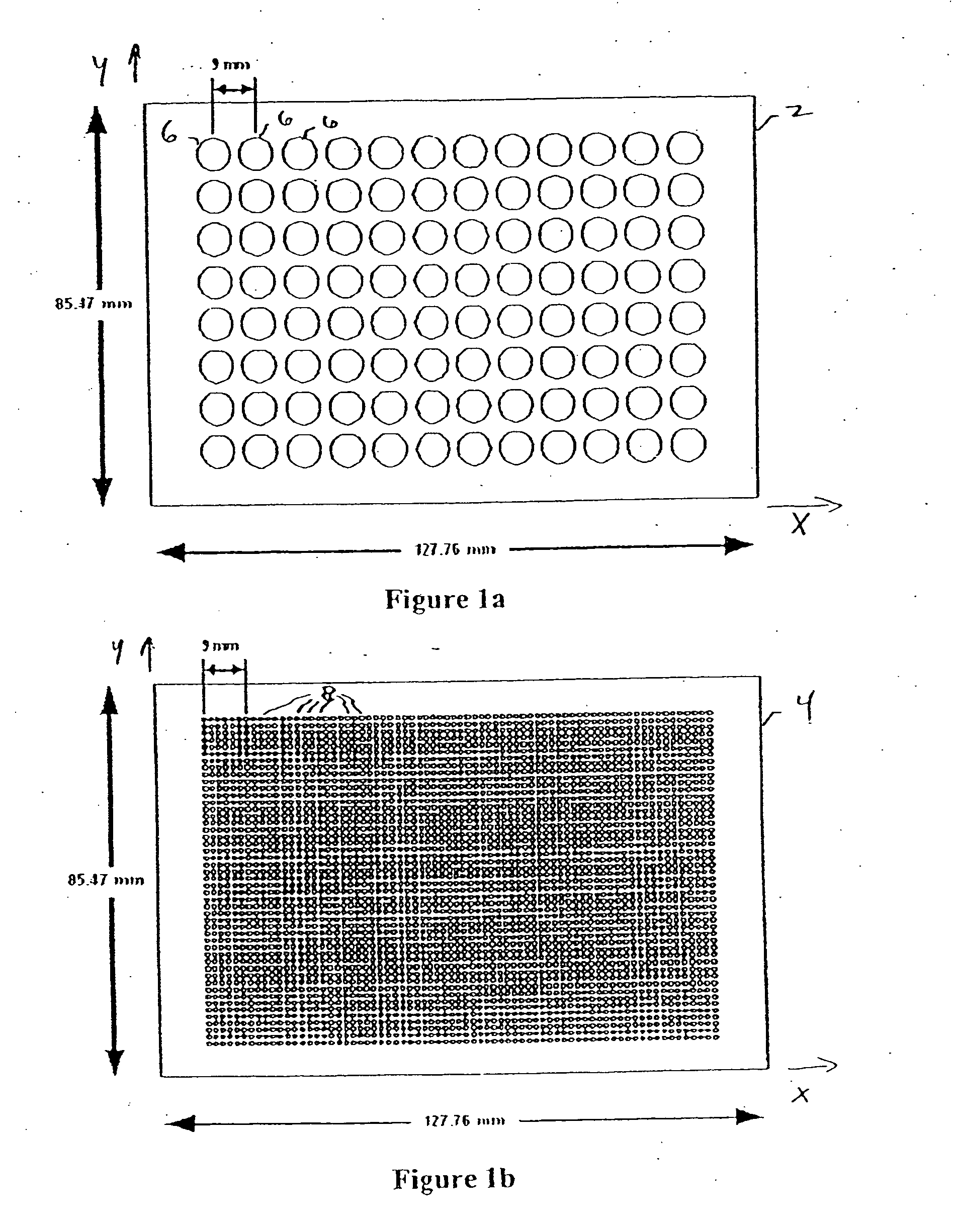

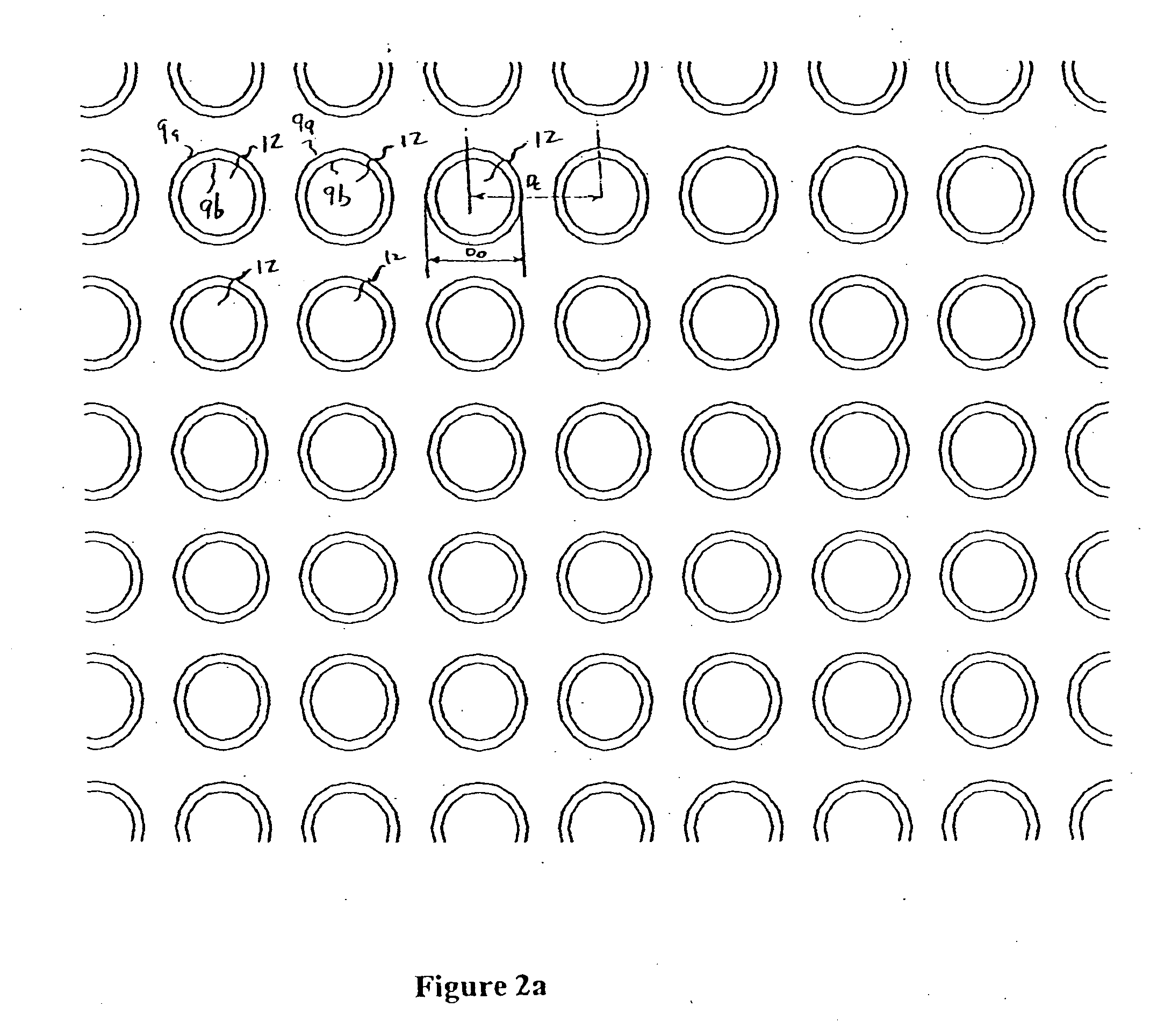

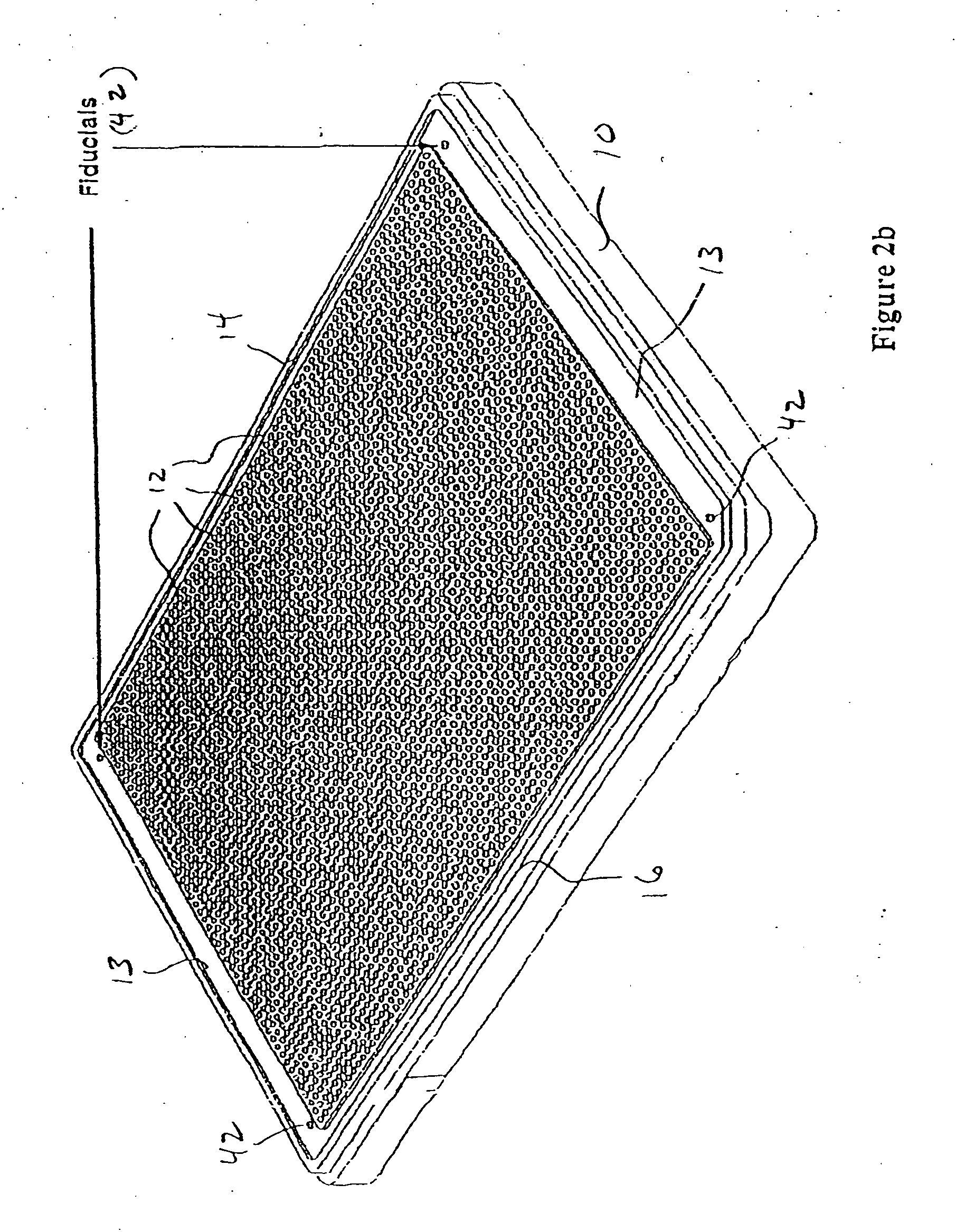

Multi-well plate providing a high-density storage and assay platform

ActiveUS20050048575A1Reduced autofluorescenceBioreactor/fermenter combinationsBiological substance pretreatmentsHigh densityEvaporation

A dual-use, high density plate for storage and assays includes a frame including a matrix of wells. The matrix includes preferably 3456 wells with top portions being arranged preferably approximately flush with a plane of the frame. A solvent-resistant material such as cyclo-olefin polymer forms at least the bottom portions of the wells, and preferably the same solvent resistant material forms the frame, although varying from the bottoms of the wells by being rendered opaque. Evaporation control wells are preferably included at the periphery of the matrix for reducing effects of evaporation on edge wells.

Owner:NEXUS BIOSYSTEMS INC

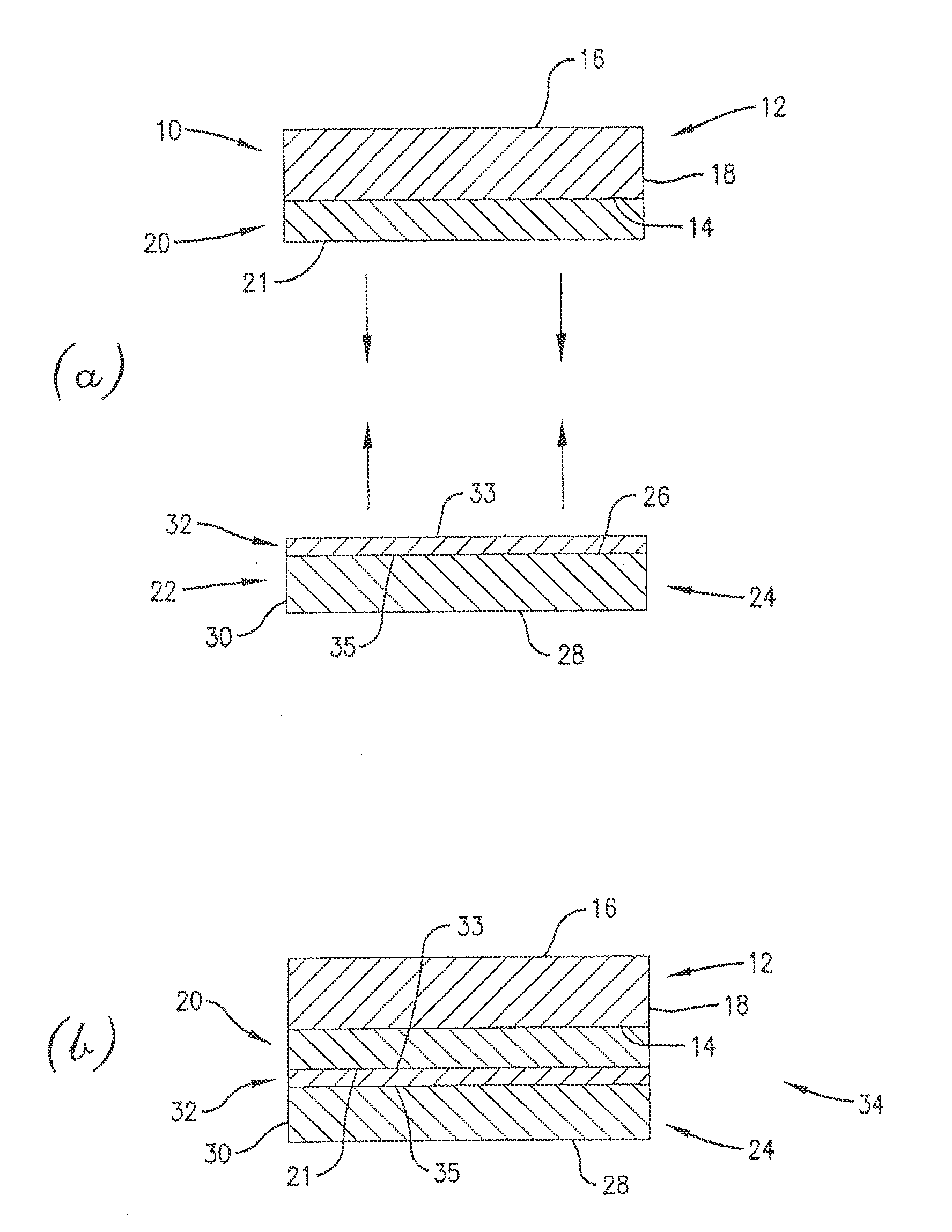

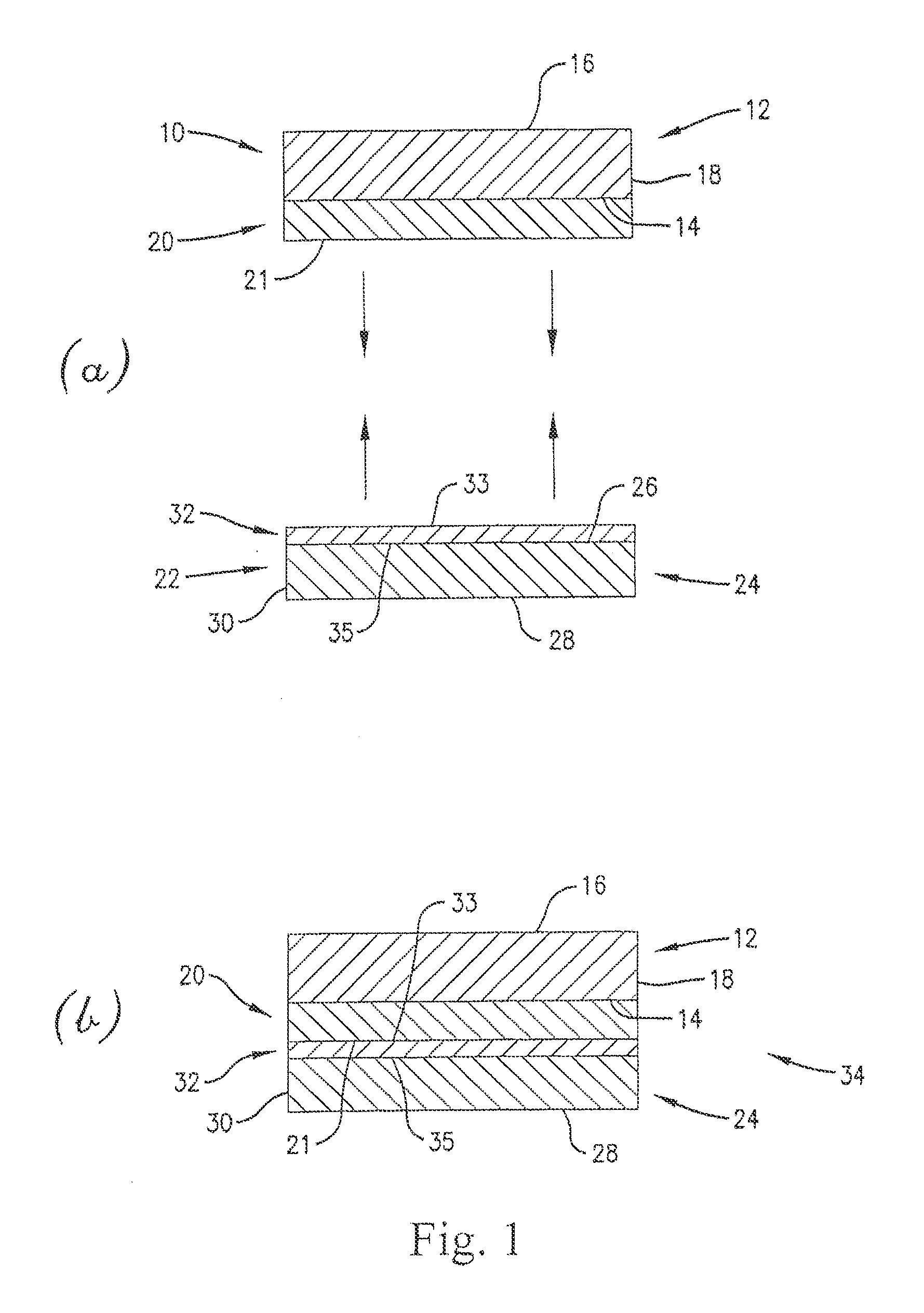

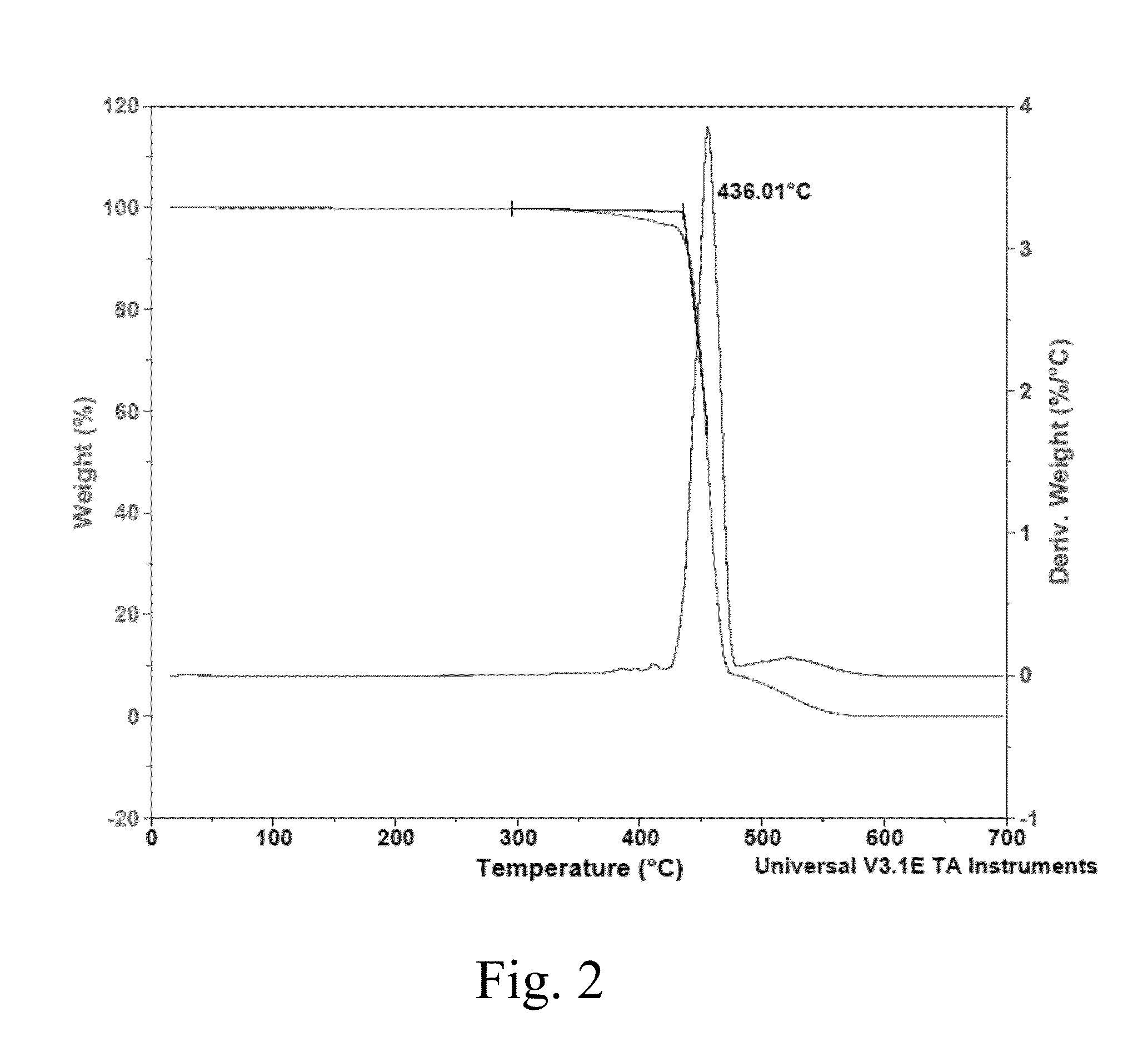

Cyclic olefin polymer compositions and polysiloxane release layers for use in temporary wafer bonding processes

ActiveUS20150194331A1Semiconductor/solid-state device detailsSynthetic resin layered productsCyclo olefin polymerWafer bonding

The invention broadly relates to cyclic olefin polymer bonding compositions and release compositions, to be used independently or together, that enable thin wafer handling during microelectronics manufacturing, especially during a full-wafer mechanical debonding process. The release compositions comprise compositions made from siloxane polymers and copolymers blended in a polar solvent, and that are stable at room temperature for longer than one month. The cyclic olefin polymer bonding compositions provide high thermal stability, can be bonded to fully-treated carrier wafers, can be mechanically or laser debonded after high-temperature heat treatment, and are easily removed with an industrially-acceptable solvent. Wafers bonded according to the invention demonstrate lower overall post-grind stack TTV compared to other commercial bonding materials and can survive 200° C. PECVD processing.

Owner:BREWER SCI

Telechelic olefin metathesis polymers from renewable feedstocks

Olefin metathesis polymerization reactions are disclosed, and more particularly ring-opening metathesis polymerization of cyclic olefins with olefinic compounds, such as are derived from seed oils and the like, to form telechelic polymers. In one aspect, a method is provided for carrying out a catalytic ring-opening metathesis polymerization reaction, comprising contacting at least one olefinic compound with at least one cyclic olefin, in the presence of a ruthenium alkylidene olefin metathesis catalyst under conditions effective to allow ring-opening metathesis polymerization of the cyclic olefin, whereby the cyclic olefin polymer formed is terminated with the olefinic compound. The invention has utility in the fields of catalysis, organic synthesis, polymer chemistry, and industrial chemistry.

Owner:MATERIA

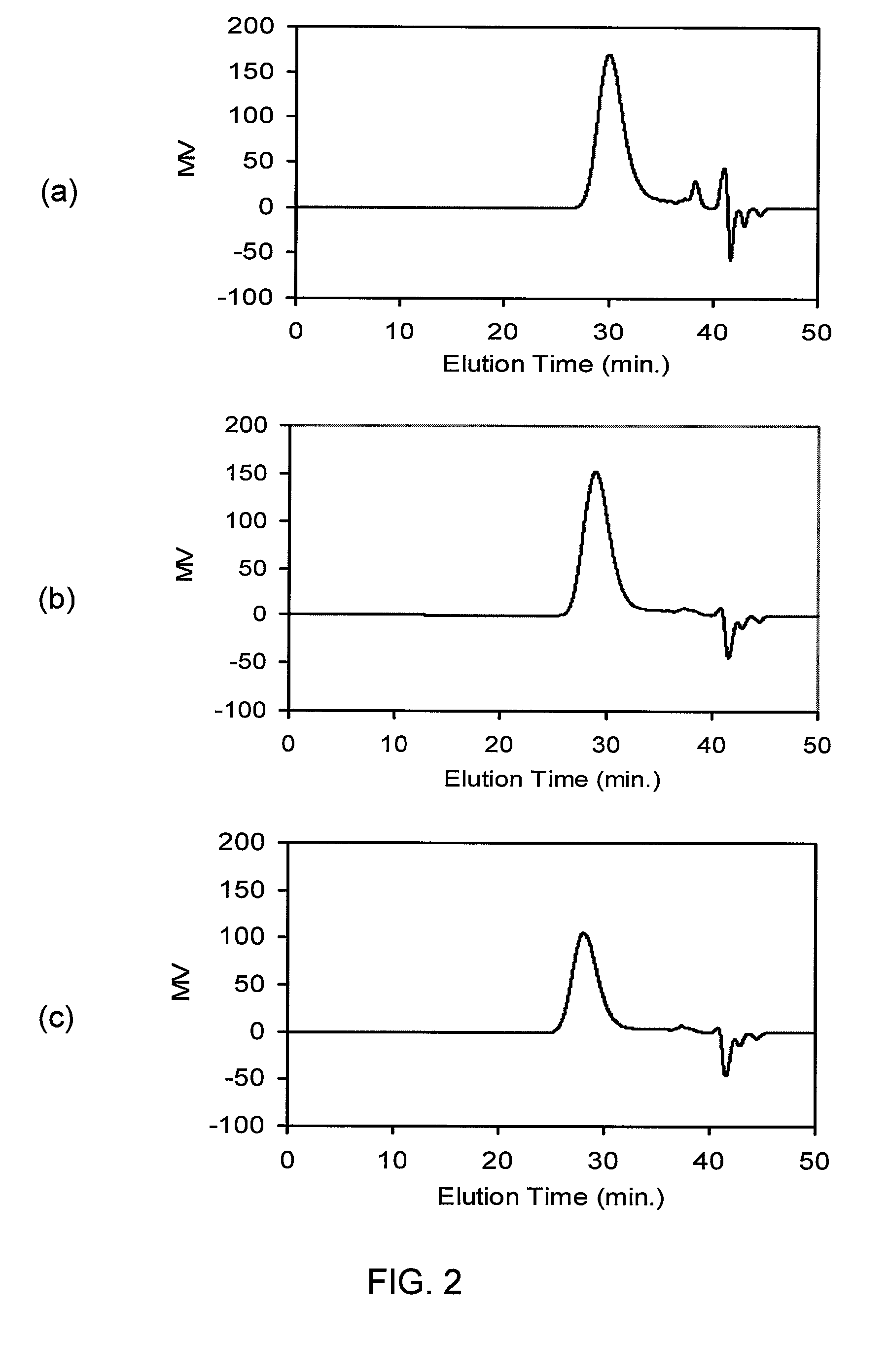

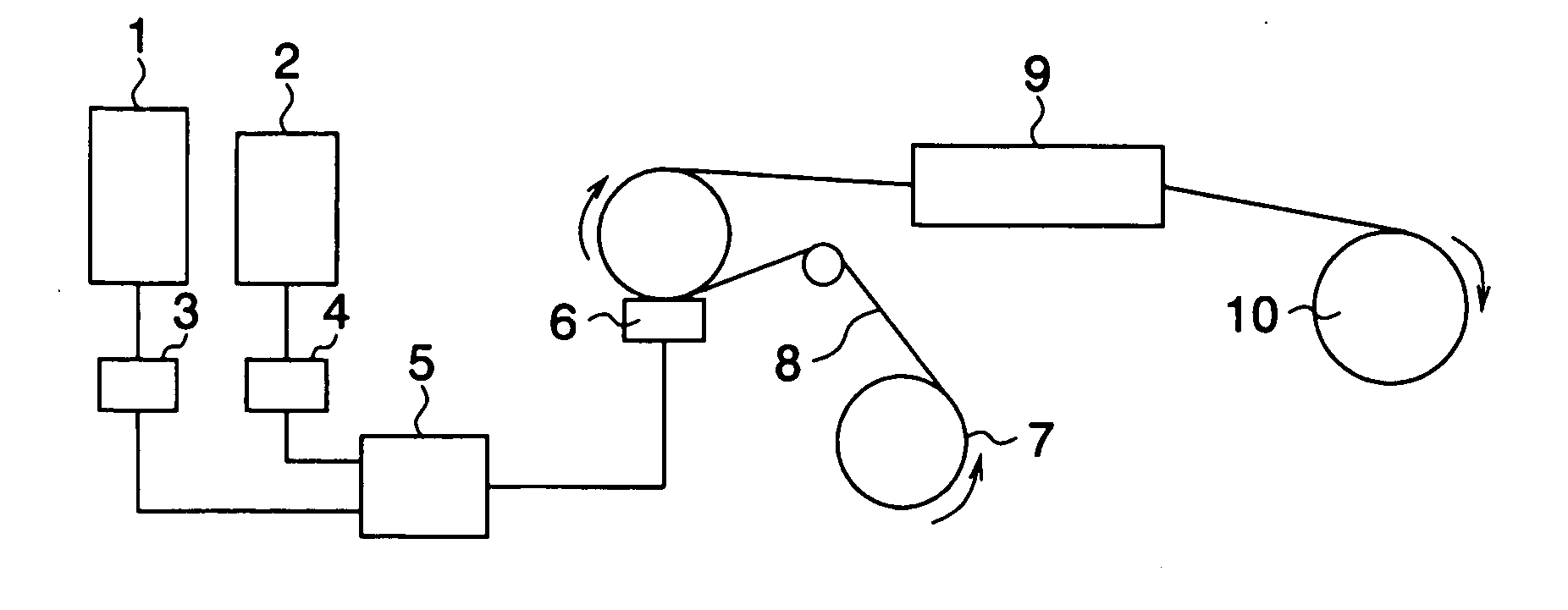

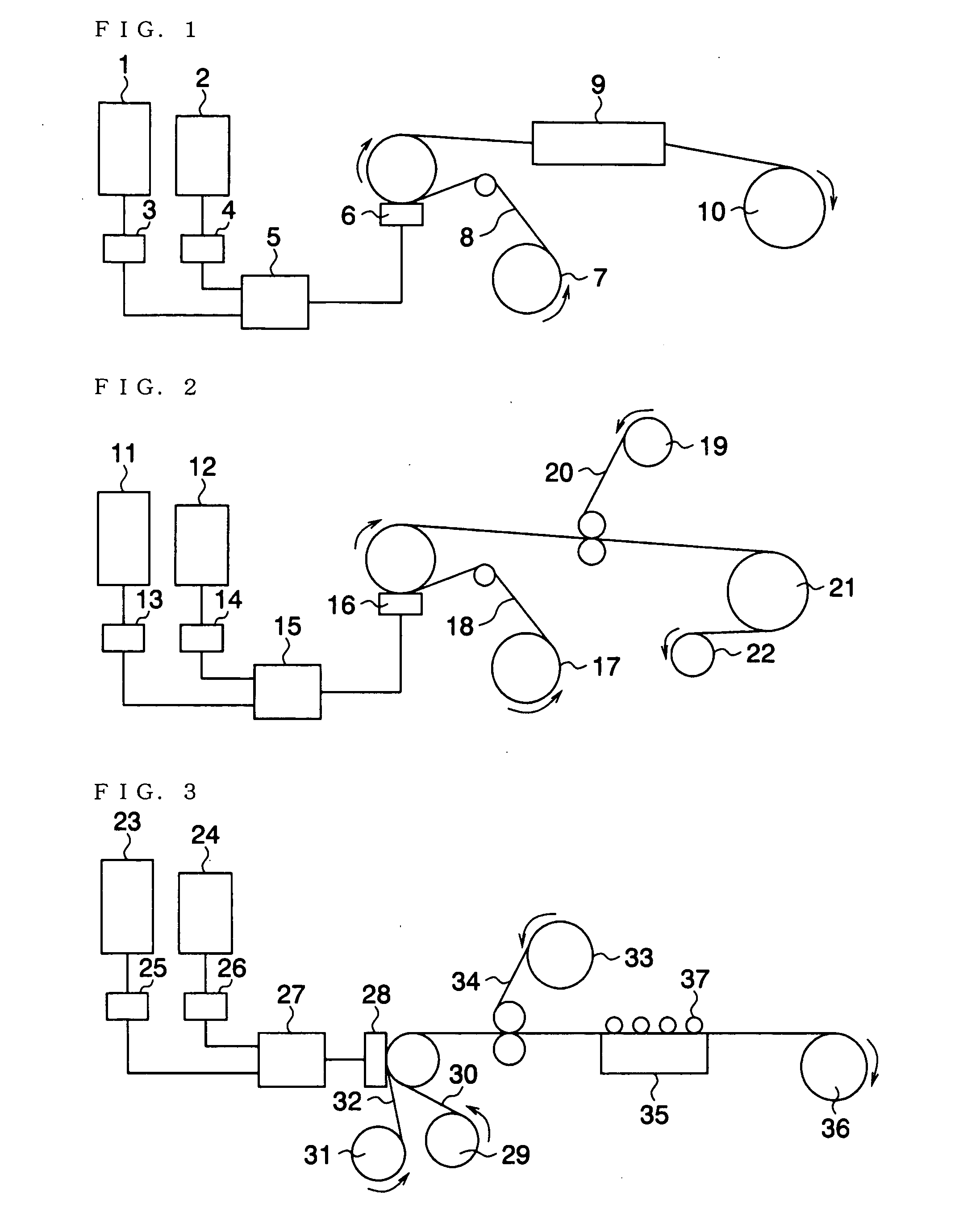

Process for producing cycloolefin resin film and process for producing cycloolefin polymer sheet or film

InactiveUS20070037946A1Improve production efficiencyImprove adhesionThin material handlingBulk polymerizationRuthenium

A process (1) for producing a cycloolefin resin film comprising the steps of: the step (I) of mixing a cycloolefin monomer and a metathesis polymerization catalyst to prepare a polymerizable composition (A); the step (II) of coating or impregnating the supporting body with the polymerizable composition (A) at once after the step (I), and the step (III) of polymerizing the polymerizable composition (A) by polymerization; and a process (2) for producing a cycloolefin polymer sheet or film with the thickness of 1 mm or less comprising polymerizing a reactive solution containing a ruthenium complex catalyst, having a hetero atom-containing carbene compound as a ligand, and a cycloolefin monomer by ring-opening metathesis bulk polymerization, wherein the polymerization of the cycloolefin monomer is completed by heating the reactive solution to 100° C. or higher at the heating rate of 20° C. / min or more. Thus, a cycloolefin resin film having excellent adhesion to other materials and a cycloolefin polymer sheet or film having a thickness of 1 mm or can be efficiently produced.

Owner:ZEON CORP

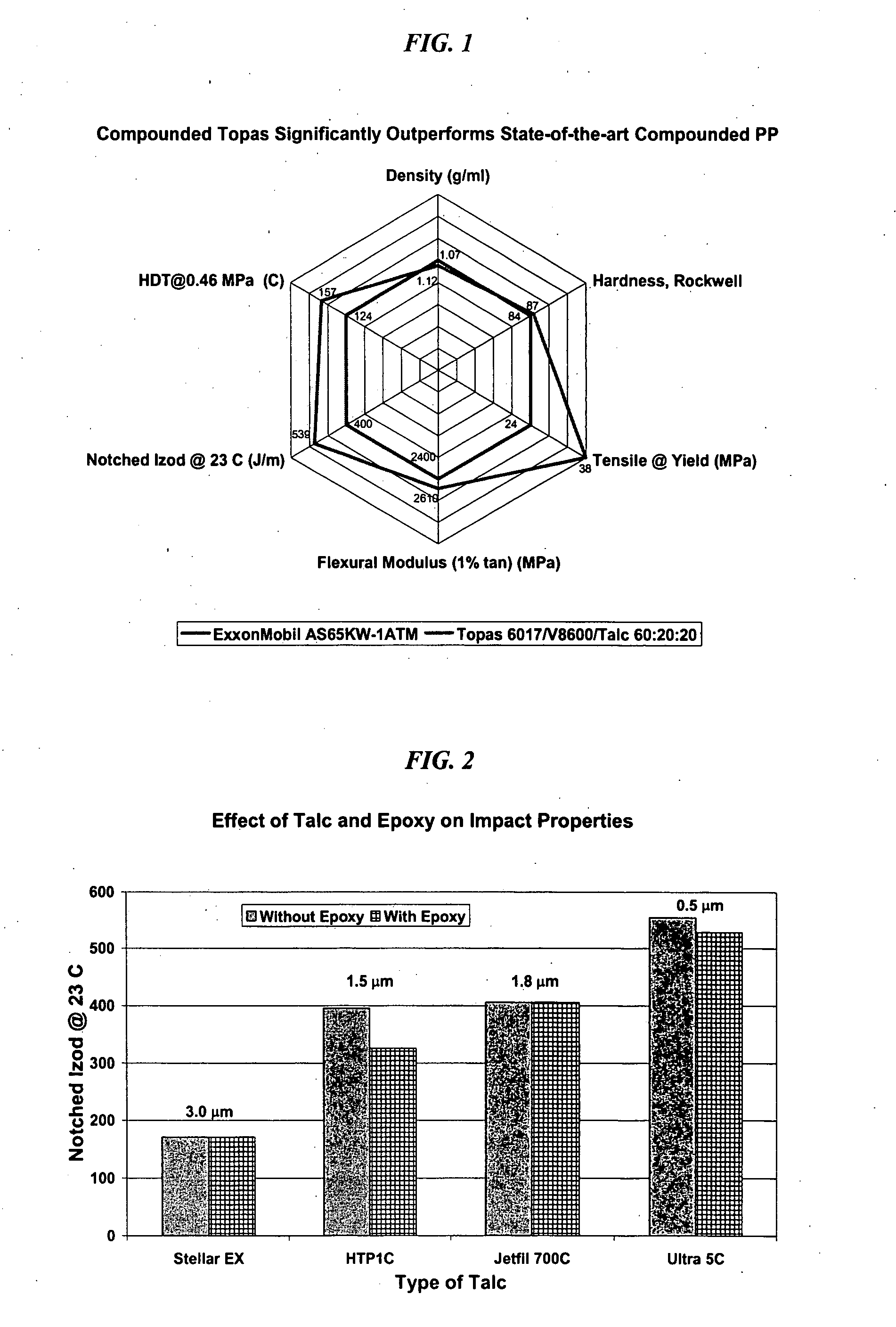

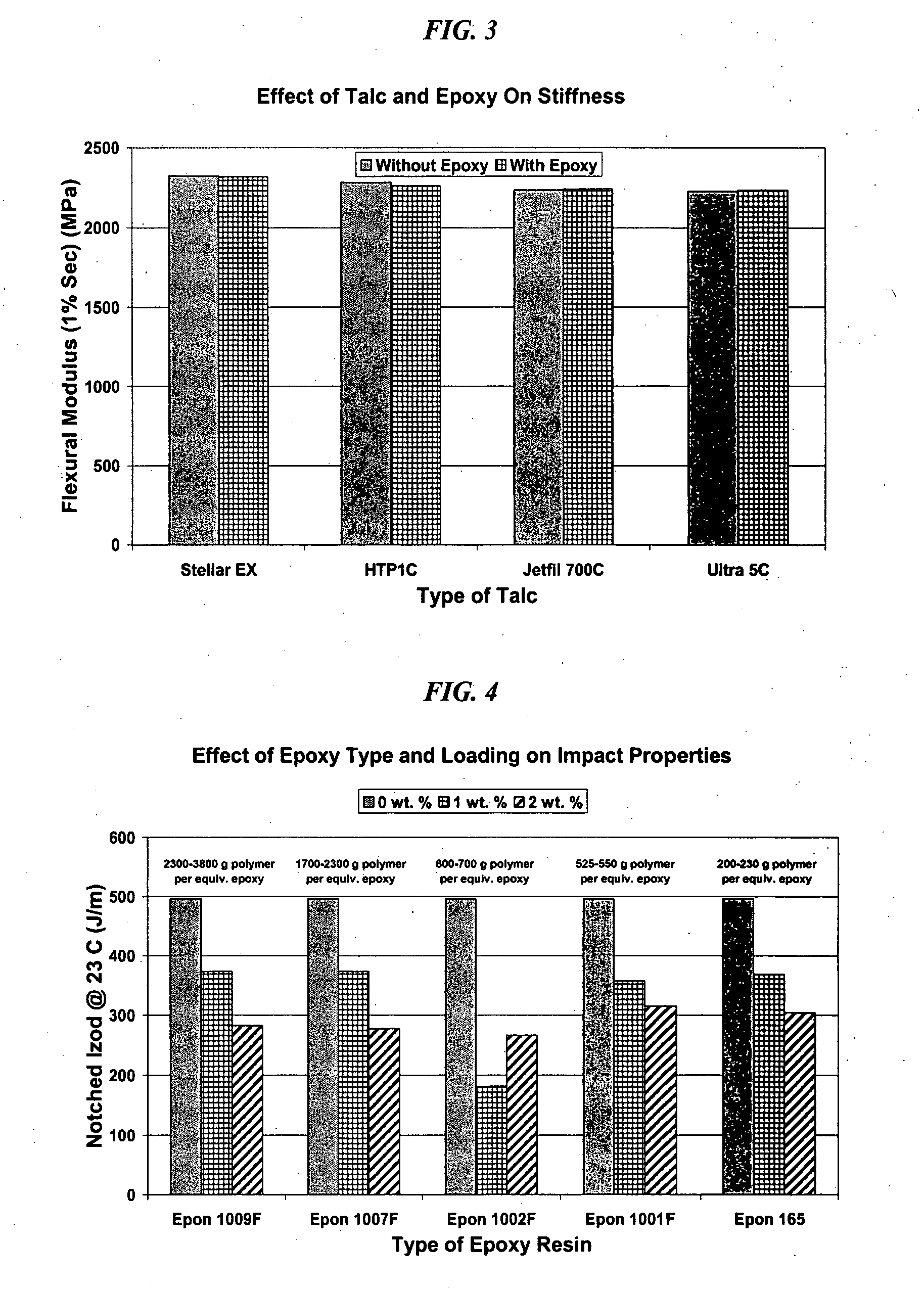

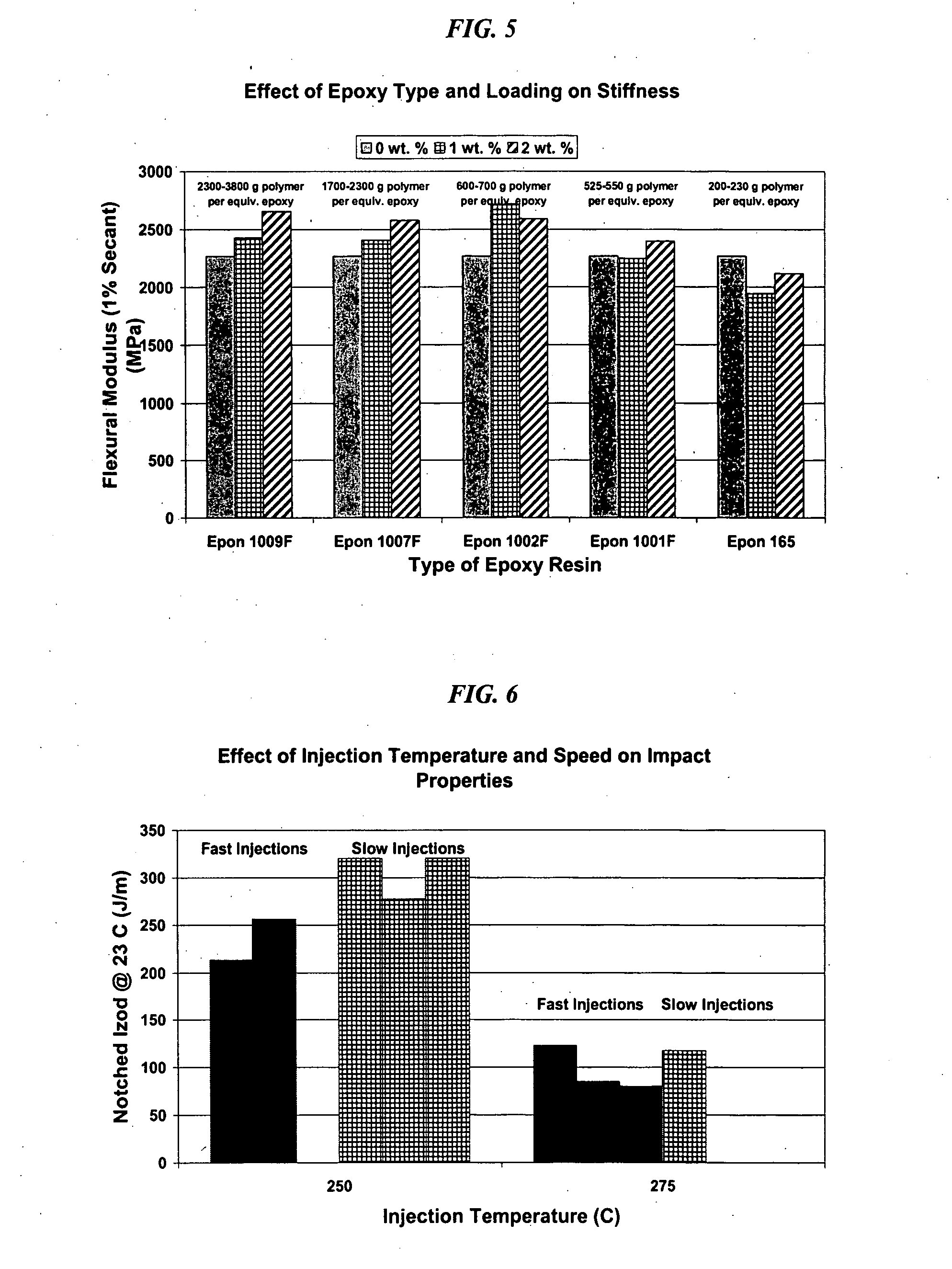

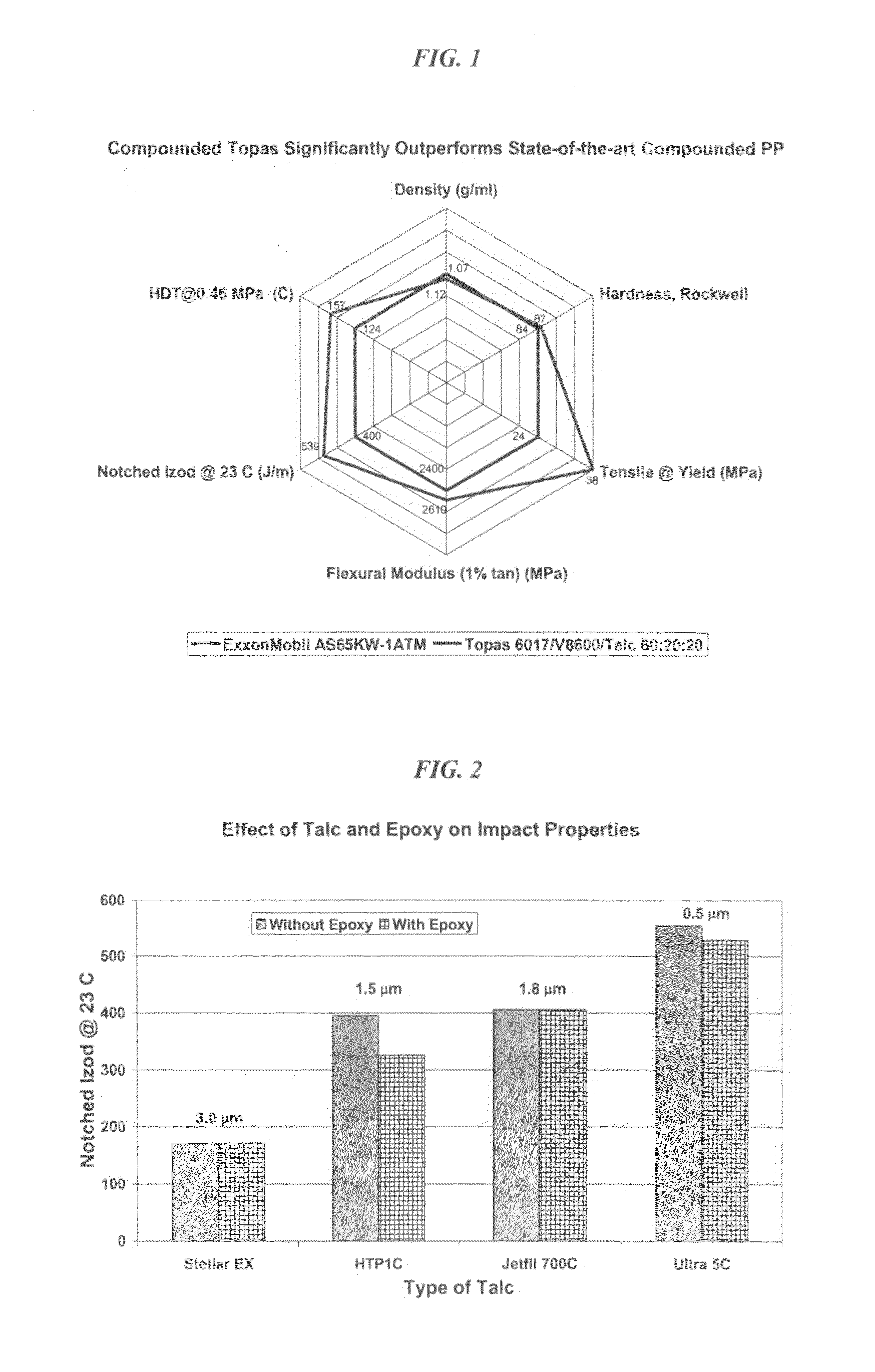

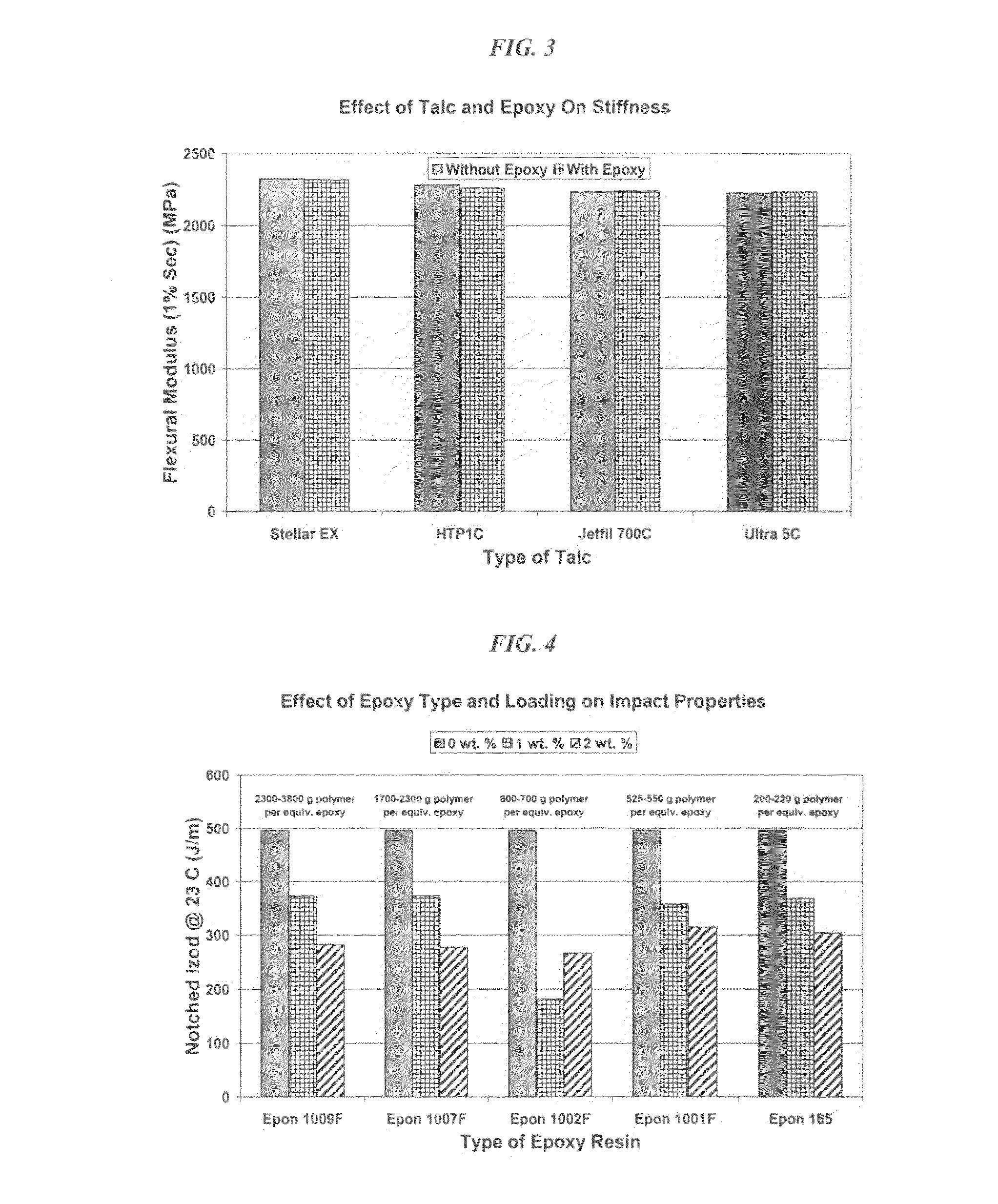

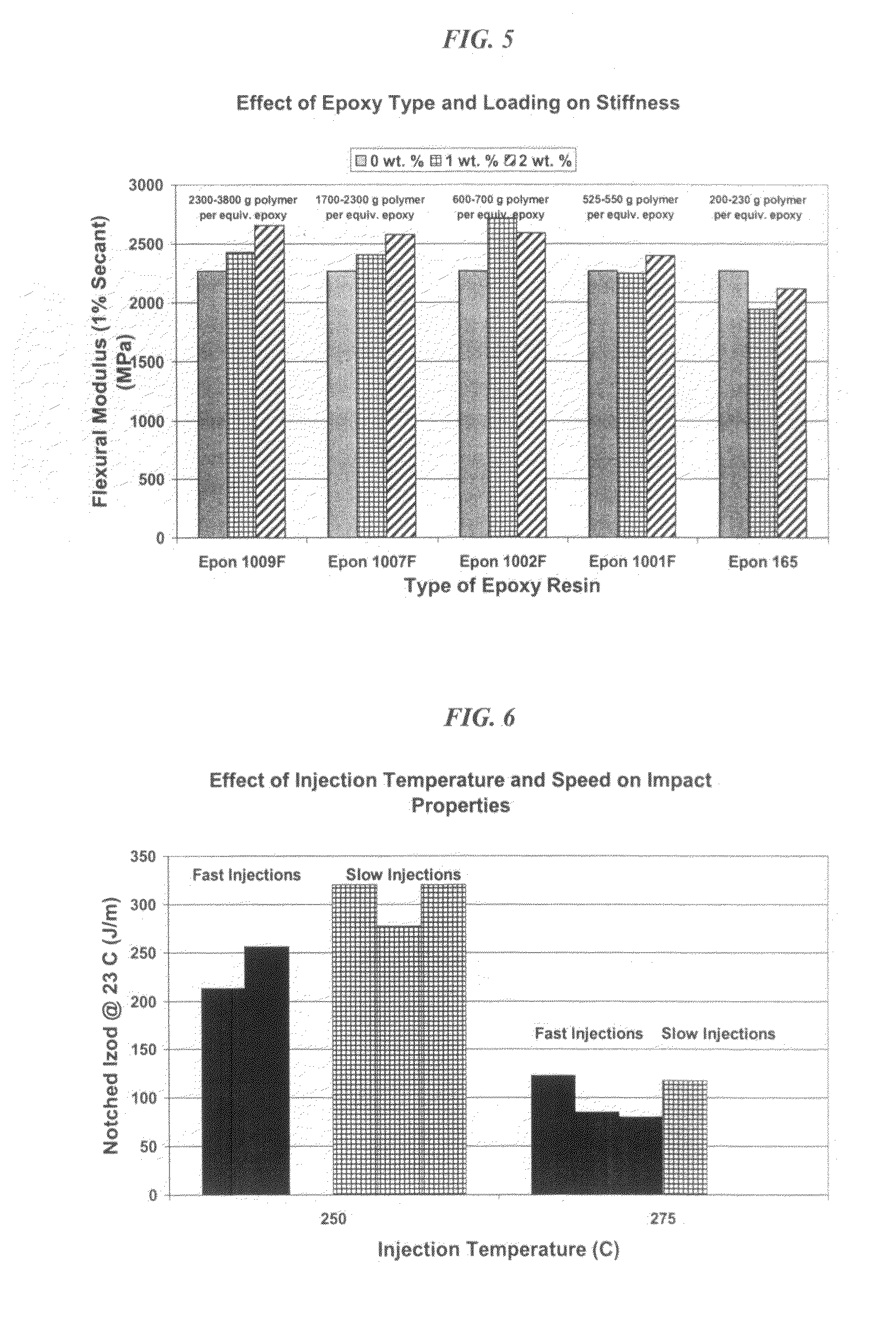

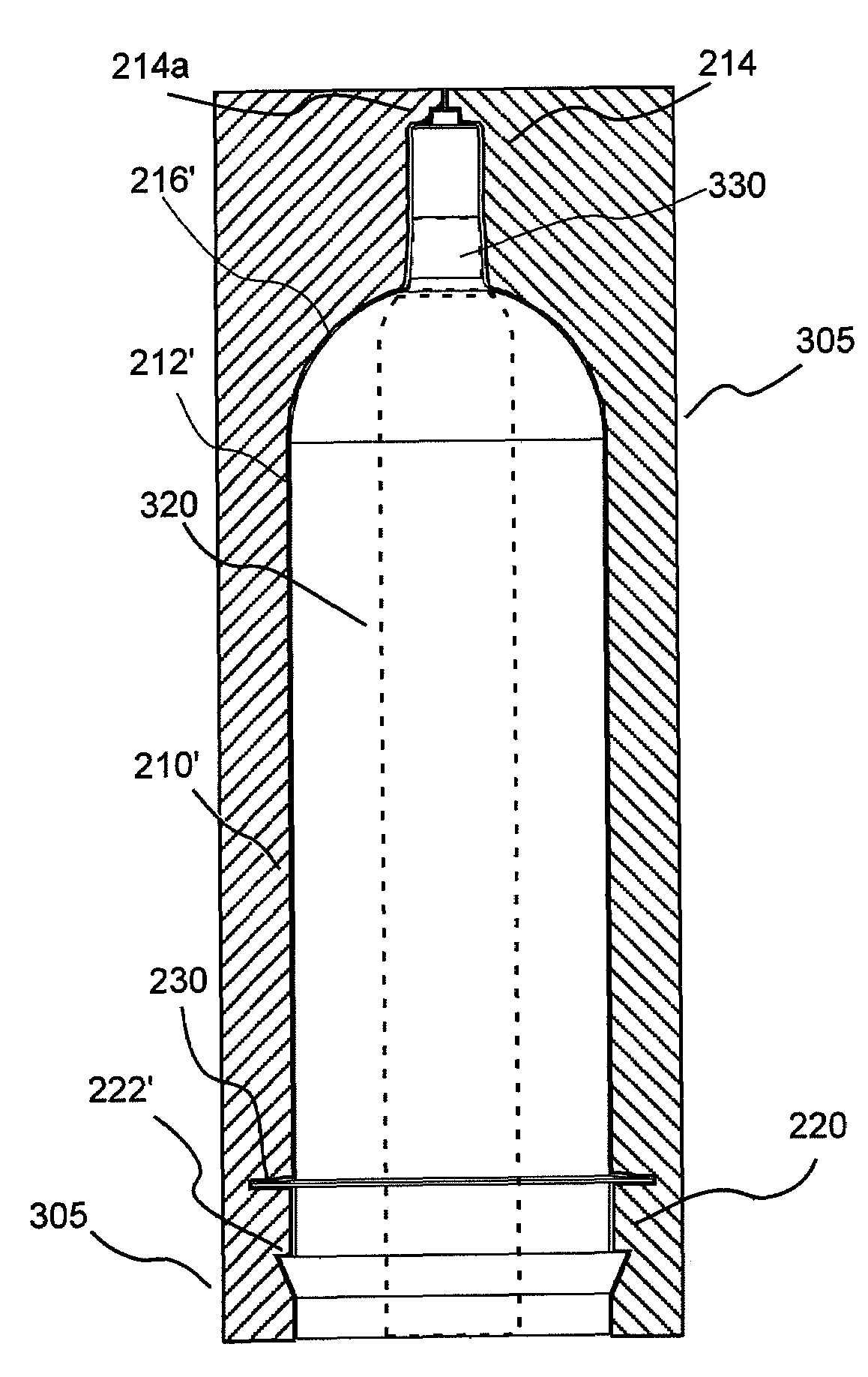

Polymer compositions comprising cyclic olefin polymers, polyolefin modifiers, and fillers

A polymer composition comprises (a) least 40 wt % (based upon the weight of the composition) of a cyclic olefin polymer comprising at least one acyclic olefin and at least 20 wt % of one or more cyclic olefins (based upon the weight of the cyclic olefin polymer), wherein at least a portion of the cyclic olefin polymer has a glass transition temperature of greater than 100° C.; (b) an acyclic olefin polymer modifier in an amount up to 40 wt % (based upon the weight of the composition); and (c) at least 10 wt % (based upon the weight of the composition) of one of more fillers. The polymer composition has a notched Izod impact resistance measured at 23° C. of greater than 100 J / m and a flexural modulus (1% secant method) of greater than 1400 MPa.

Owner:EXXONMOBIL CHEM PAT INC

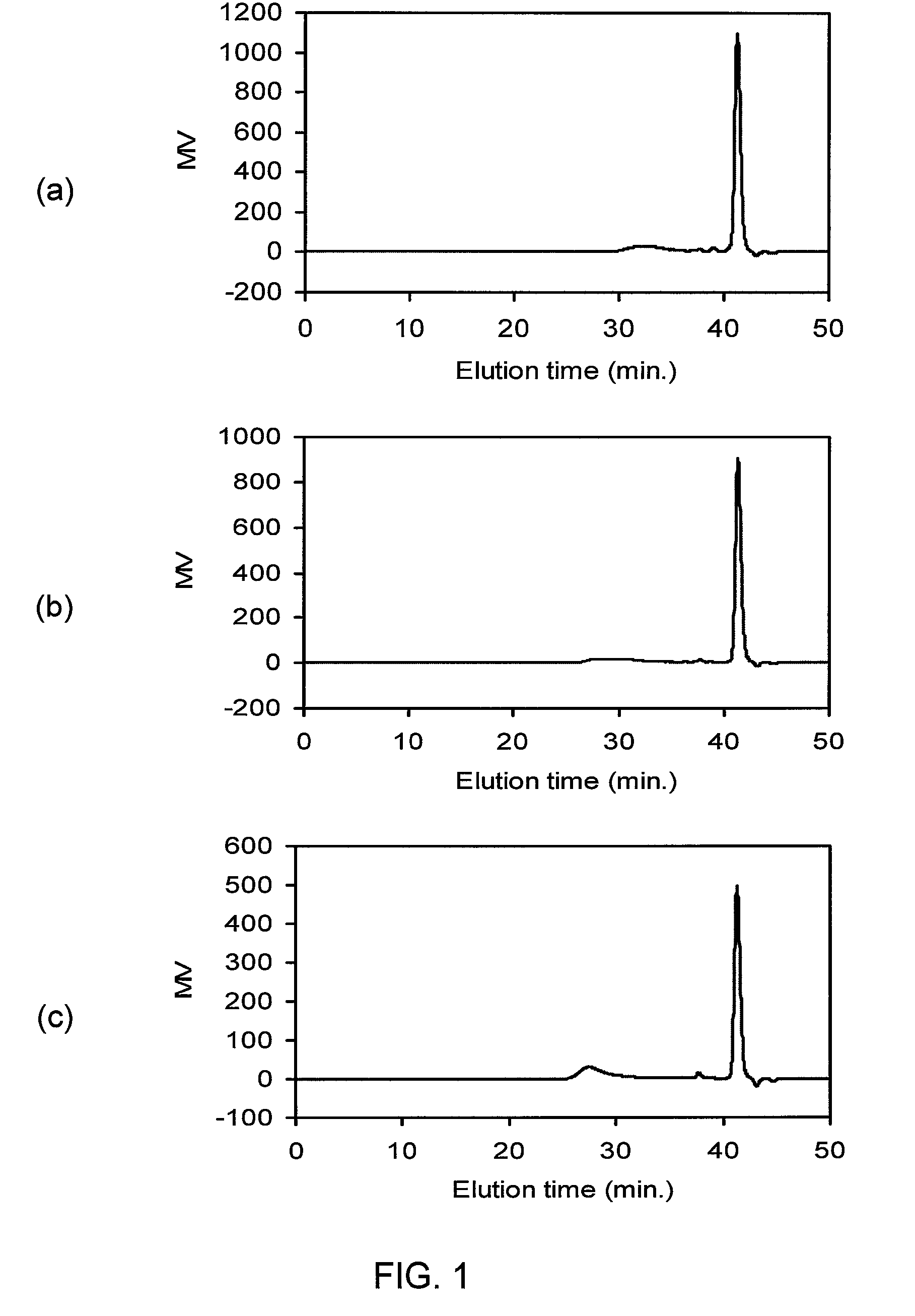

Polycycloolefin polymer compositions as optical materials

ActiveUS20170058145A1High colorless optical transparencyGood uniform levelingPolyester coatingsOptical elementsRefractive indexCyclo olefin polymer

Embodiments in accordance with the present invention encompass compositions encompassing components A and B which respectively contain a procatalyst and an activator along with one or more monomers which undergo vinyl addition polymerization when both components are mixed together to form a substantially transparent film. The monomers employed therein have a range of refractive index from 1.4 to 1.8 and thus these compositions can be tailored to form transparent films of varied refractive indices. Accordingly, compositions of this invention are useful in various opto-electronic applications, including as coatings, encapsulants, fillers, leveling agents, among others.

Owner:SUMITOMO BAKELITE CO LTD

Polymer compositions comprising cyclic olefin polymers, polyolefin modifiers, and fillers

A polymer composition comprises (a) least 40 wt % (based upon the weight of the composition) of a cyclic olefin polymer comprising at least one acyclic olefin and at least 20 wt % of one or more cyclic olefins (based upon the weight of the cyclic olefin polymer), wherein at least a portion of the cyclic olefin polymer has a glass transition temperature of greater than 100° C.; (b) an acyclic olefin polymer modifier in an amount up to 40 wt % (based upon the weight of the composition); and (c) at least 10 wt % (based upon the weight of the composition) of one of more fillers. The polymer composition has a notched Izod impact resistance measured at 23° C. of greater than 100 J / m and a flexural modulus (1% secant method) of greater than 1400 MPa.

Owner:EXXONMOBIL CHEM PAT INC

Method of molding a syringe

A syringe for use in a pressurized injection of a fluid includes a syringe barrel including a polymeric material having undergone expansion via blow molding. An inner diameter of the syringe barrel can, for example, be sufficiently constant (over at least a portion of the axial length of the syringe) that a plunger slidably positioned within the syringe barrel and in generally sealing contact with an inner wall of the syringe barrel can be used within the syringe barrel to generate a pressure of at least 1 psi within the syringe barrel. In several embodiment, the inner diameter of the syringe barrel is sufficiently constant to generate a pressure of at least 100 psi, at least 300 psi, or even at least 500 psi within the syringe barrel. A method of forming a syringe includes the steps of: injection molding at least one polymeric material to form a preform; placing the preform into an blow mold die; and expanding at least a portion of the preform while heating the preform within the die to form a barrel of the syringe. The syringes can be formed to withstand relatively high pressures as described above. The at least one polymeric material can, for example, be polyethyleneterephthalate, cyclic olefin polymer, polypropylene, polystyrene, polyvinylidene chloride, polyethylene napthalate and / or nylon.

Owner:BAYER HEALTHCARE LLC

Protein stabilization in solution

InactiveUS20060160720A1Increase chanceSmall article dispensingPeptide/protein ingredientsCyclo olefin polymerSilicon dioxide

Provided are storage containers for proteinaceous pharmaceutical compositions which are characterized in, among other things, comprising (i) a wall portion, wherein an inner wall material thereof is selected from silica-coated glass, silicone-coated glass, polymers of non-cyclic olefins, cycloolefin polymers and cycloolefin / linear olefin copolymers and (ii) one or more closure portions not constituting part of the wall portion, and which contains a formulation of a protein. Also provided are new methods of storing proteinaceous compositions. In one aspect, the stored protein is characterized as having an amino-terminal γ-carboxyglutamic acid (Gla) domain with 9-12 Gla residues.

Owner:NOVO NORDISK AS

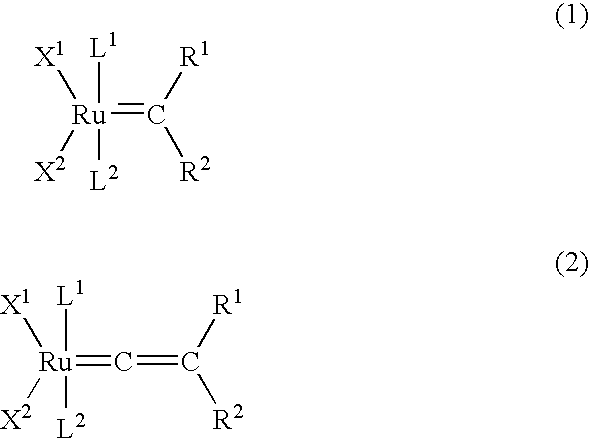

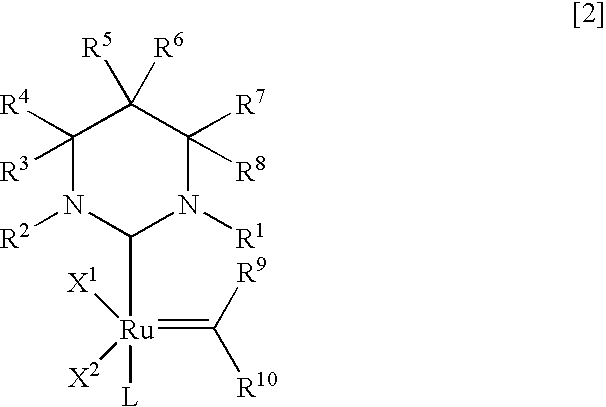

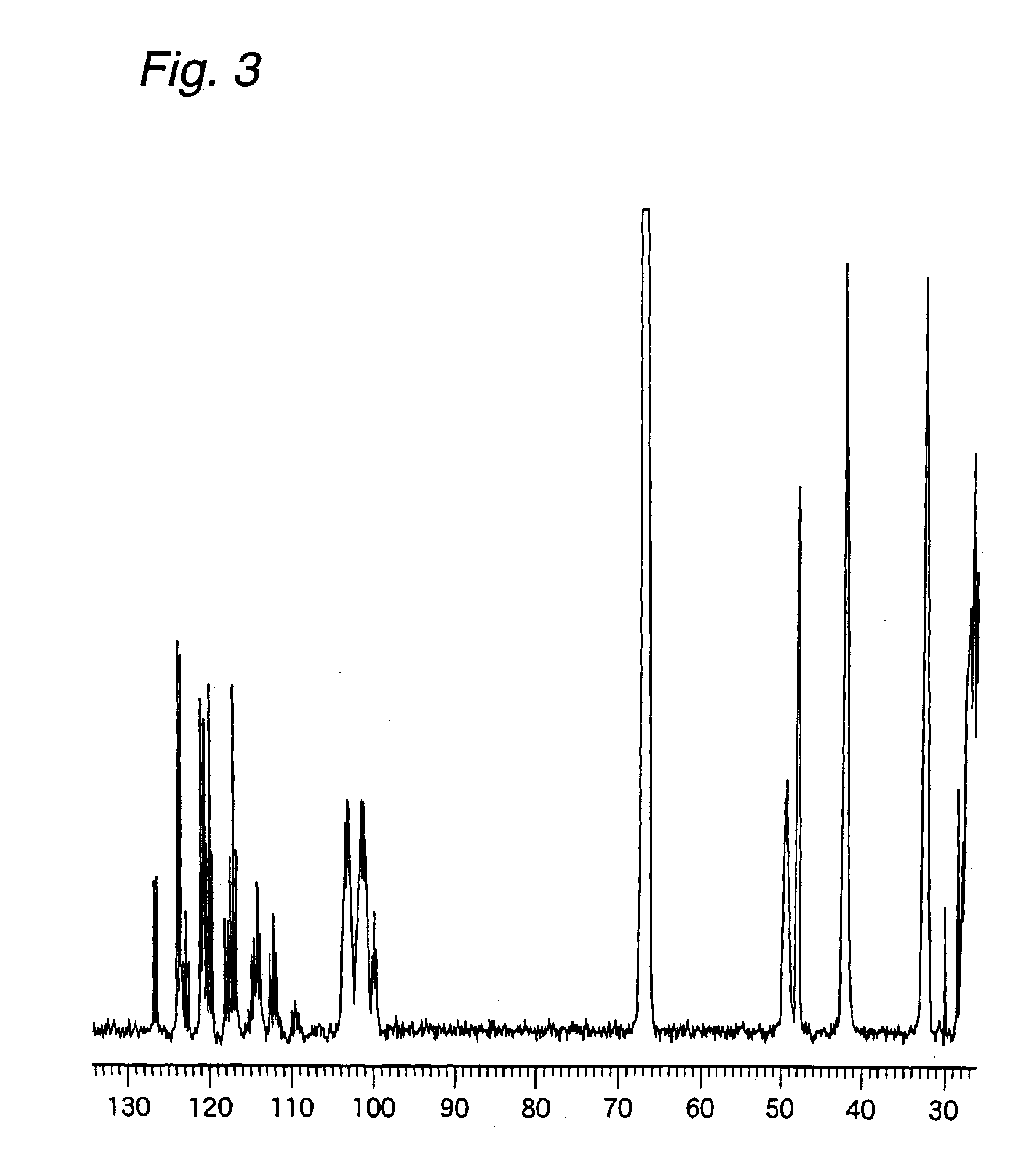

Ruthenium complexes, process for preparation thereof, and processes for producing open-ring polymer of cycloolefins and hydrogenation products thereof by using the complex as catalyst

InactiveUS20050014916A1Improve heat resistanceGroup 4/14 element organic compoundsRuthenium organic compoundsHeat resistanceHeteroatom

The present invention relates to ruthenium complex compound wherein a heteroatom-containing carbene compound having a six-membered ring structure is bonded to ruthenium and a process for the preparation thereof; a process for producing ring-opened cyclic olefin polymer by subjecting a cyclic olefin to ring-opening metathesis polymerization in the presence of such a ruthenium complex compound; and a process for producing hydrogenated product of ring-opened cyclic olefin polymers by hydrogenating the carbon-carbon double bonds of the above ring-opened polymers. The invention gives hydrogenated product of ring-opened cyclic olefin polymers having physical properties different from those of hydrogenated product of ring-opened polymers of the prior art. Particularly, the use of dicyclopentadiene can give a hydrogenated product of ring-opened cyclic olefin polymer excellent in heat resistance, and this product can be advantageously used as parts or formed products for medical appliances or electrical components.

Owner:ZEON CORP

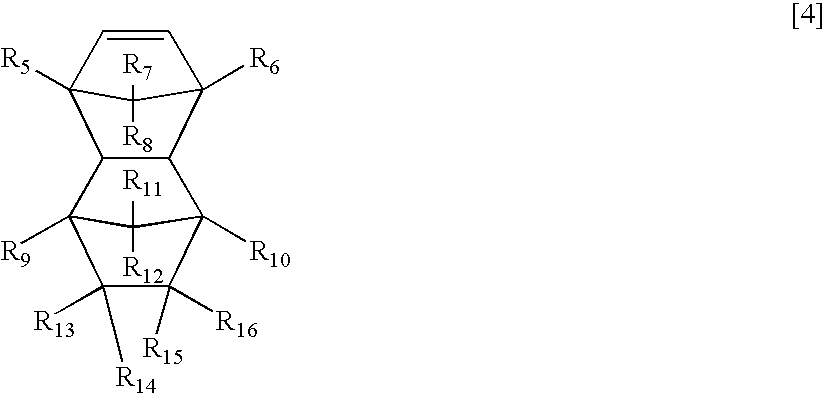

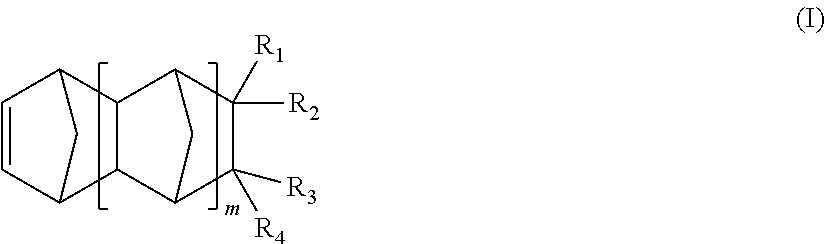

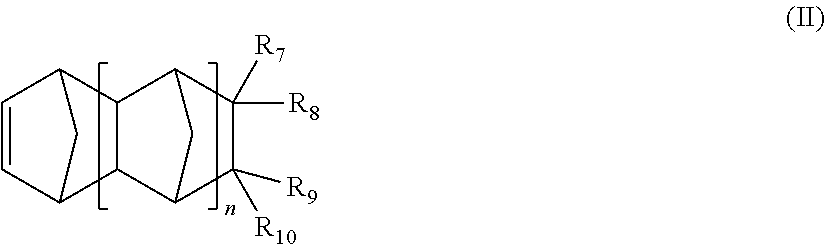

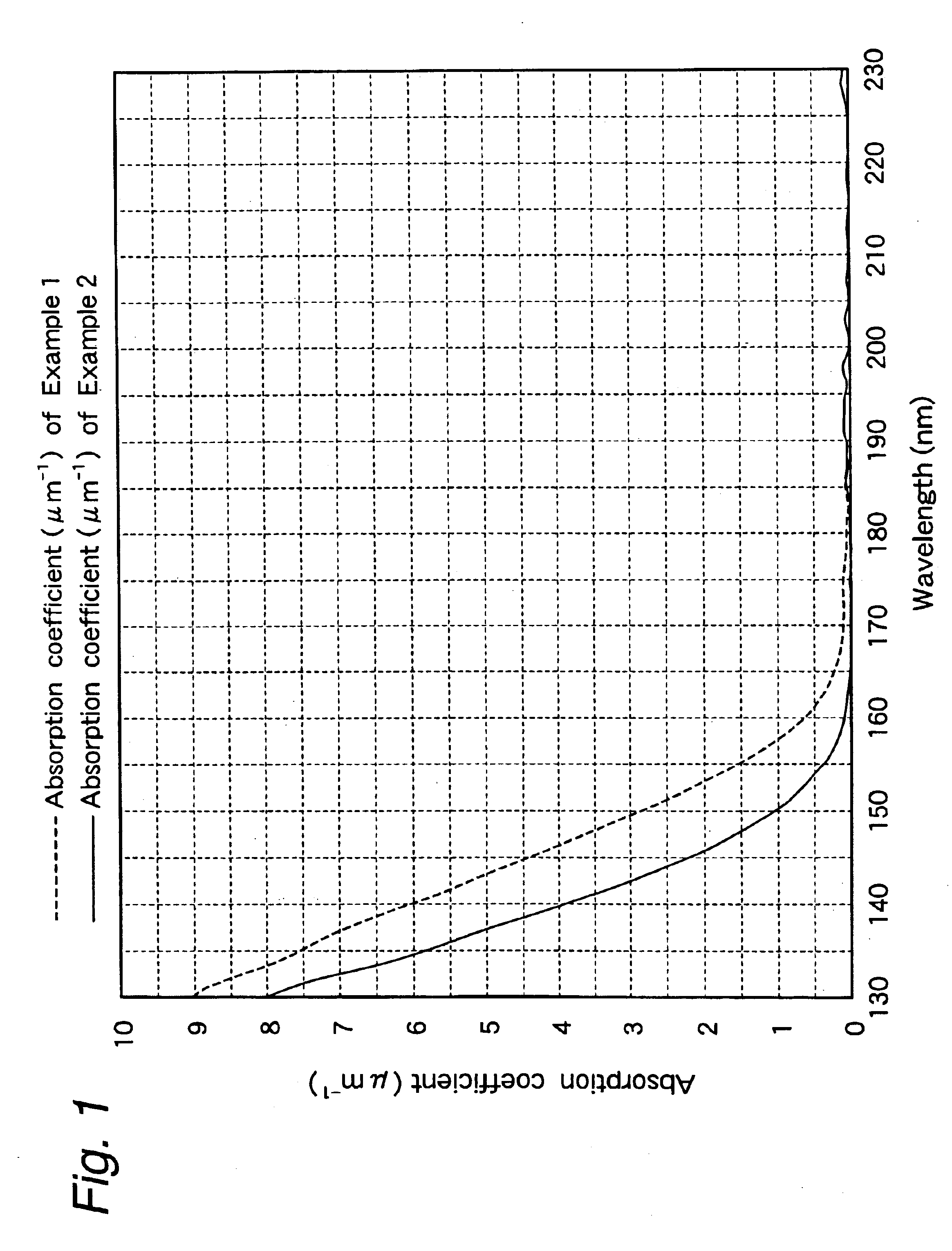

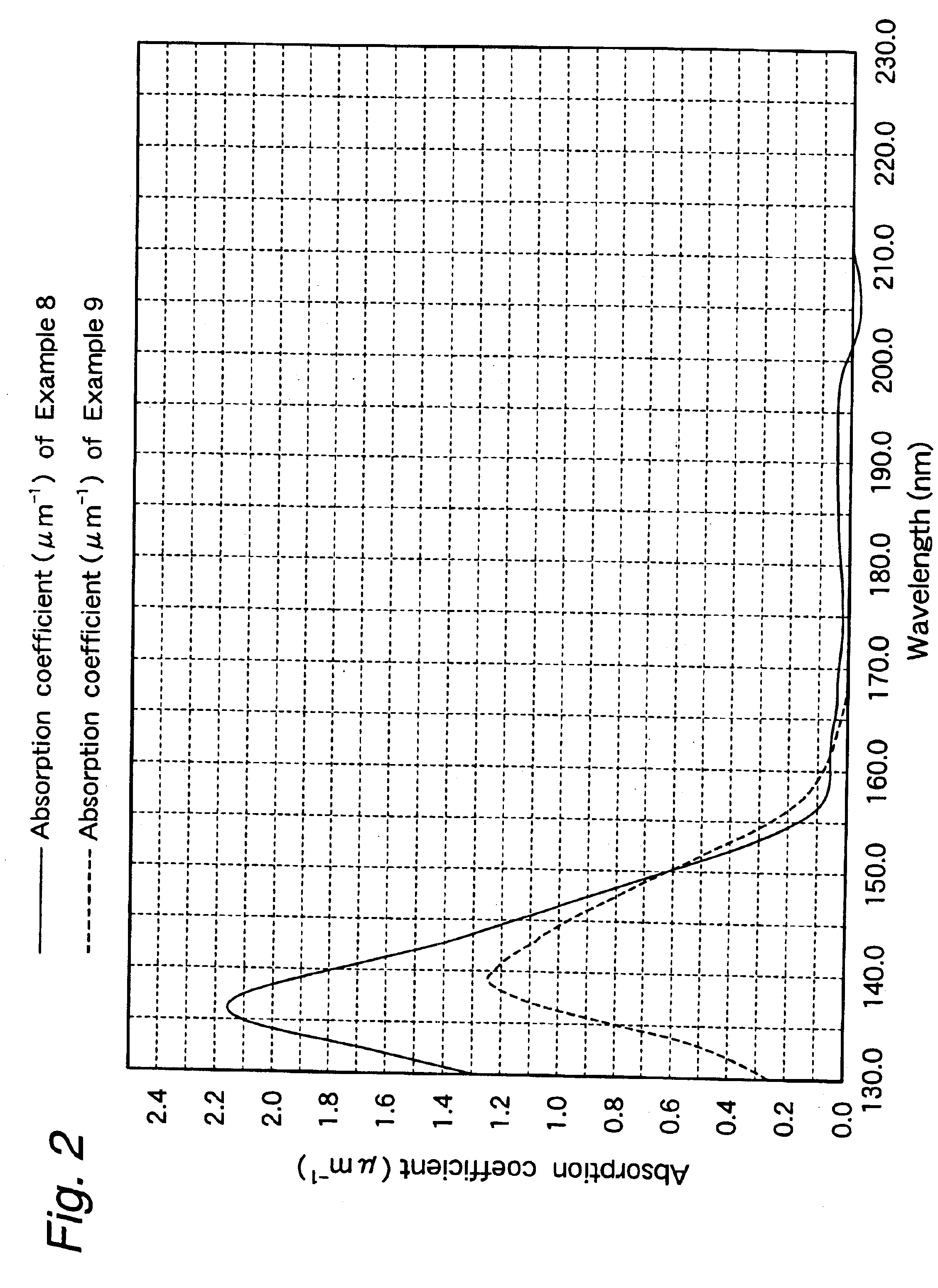

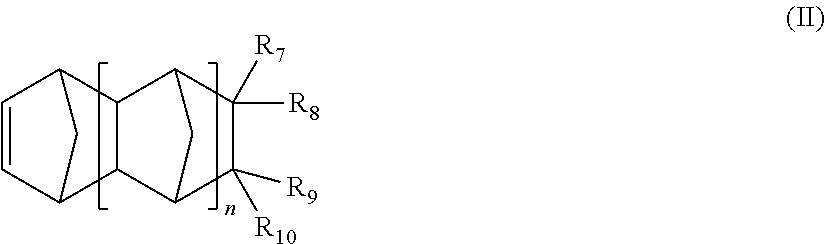

Fluorinated cycloolefin polymers, processes for preparation of fluorinated cycloofefin monomers and polymers thereof, and use of the same

InactiveUS6875819B2Satisfactory light transmissionOriginals for photomechanical treatmentPolymer scienceHydrogen

The present invention is to provide a fluorine-containing polymer having excellent light transmission in the vacuum ultraviolet region of not more than 193 nm, a monomer favorably used for preparing the fluorine-containing polymer, a process for preparing the fluorine-containing polymer, and uses of the fluorine-containing polymer. The fluorine-containing polymer has at least a repeated unit structure represented by the following formula (1) and has an absorption coefficient of not more than 3.0 μm−1 at 157 nm of ultraviolet rays. wherein R1 to R12 are each fluorine, a fluorine-containing alkyl group of 1 to 20 carbon atoms, or the like; X1 is —CRaRb—, —NRa— or —PRa— (Ra and Rb are each fluorine, a fluorine-containing alkyl group of 1 to 20 carbon atoms, hydrogen, —O—, —S—, an alkyl group of 1 to 20 carbon atoms, or the like); at least one of R1 to R12 and X1 is fluorine or a fluorine-containing group; and n is 0 or an integer of 1 to 3.

Owner:MITSUI CHEM INC

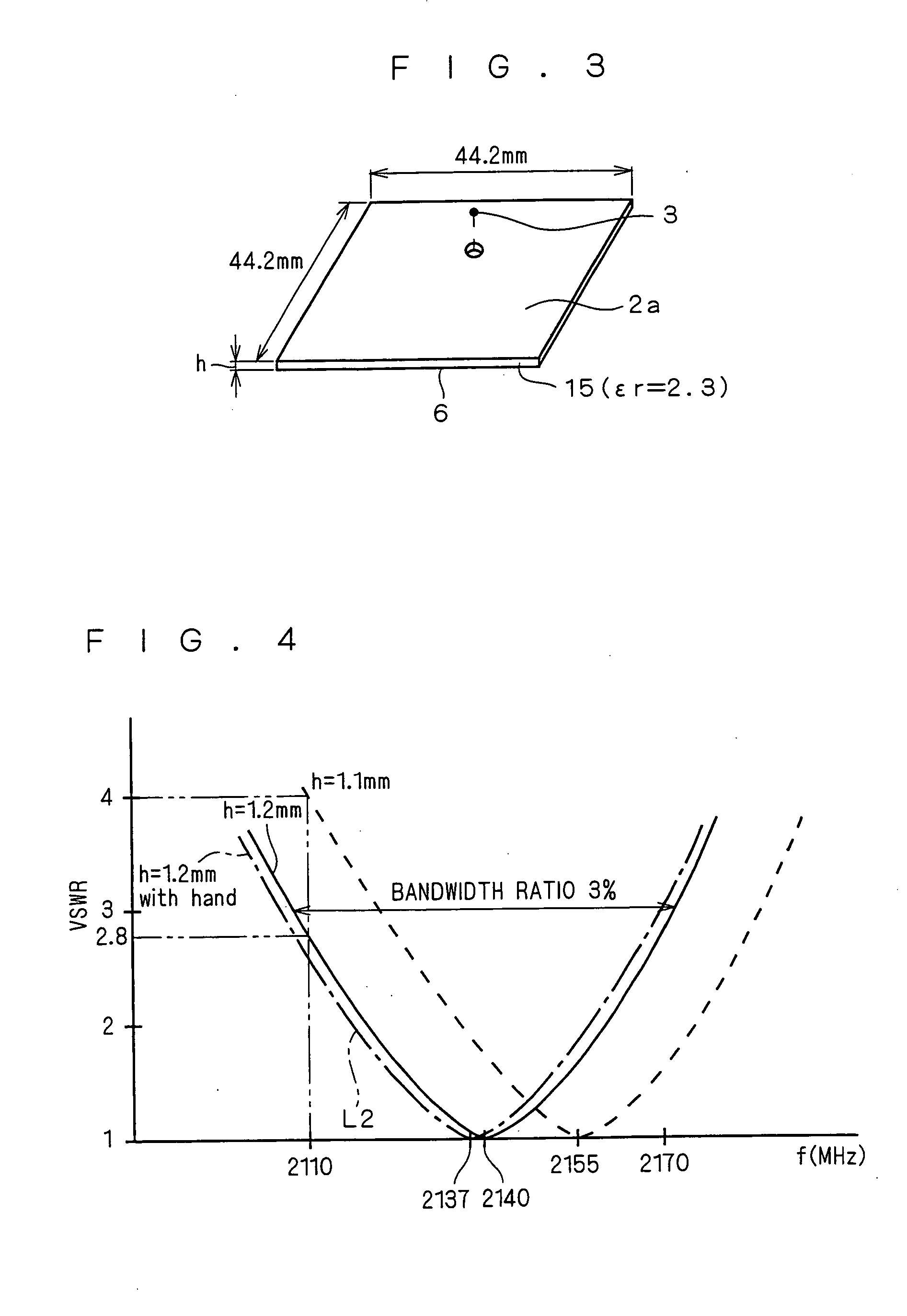

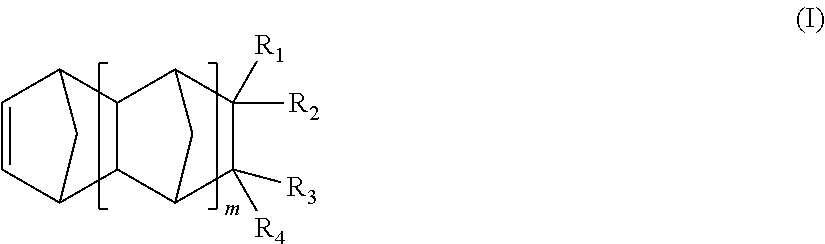

Cell phone and built-in antenna thereof

InactiveUS20050079903A1Reduce physical sizeReduce weightAntenna supports/mountingsRadiating elements structural formsDielectricElastomer

A cell phone including a built-in antenna, the cell phone having a reduced physical size of an antenna element, a decreased weight and satisfying an impact resistance, and suppressing a variation in a dimension caused by mass production and considering an actual use state in which a hand or the like approaches. A dielectric between an antenna element and a ground is a support member of a cyclo-olefin polymer in a plating grade having an impact resistance which is obtained by blending styrene type rubber, polyolefin type rubber (elastomer) or both of them, and the antenna element is constituted by a plating formed on a main surface of the dielectric.

Owner:MITSUBISHI ELECTRIC CORP

Polycycloolefin polymer compositions as optical materials

ActiveUS9944818B2Improve the level ofLow viscosityPolyester coatingsOptical elementsRefractive indexCyclo olefin polymer

Embodiments in accordance with the present invention encompass compositions encompassing components A and B which respectively contain a procatalyst and an activator along with one or more monomers which undergo vinyl addition polymerization when both components are mixed together to form a substantially transparent film. The monomers employed therein have a range of refractive index from 1.4 to 1.8 and thus these compositions can be tailored to form transparent films of varied refractive indices. Accordingly, compositions of this invention are useful in various opto-electronic applications, including as coatings, encapsulants, fillers, leveling agents, among others.

Owner:SUMITOMO BAKELITE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com