Ultra-black bright high-gloss scratch-resistant ABS compound as well as preparation method and application thereof

A high-gloss, composite technology, applied in the field of ABS materials, can solve problems such as environmental pollution, high cost, and increased VOC release, and achieve the effects of reducing environmental hazards, excellent scratch resistance, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

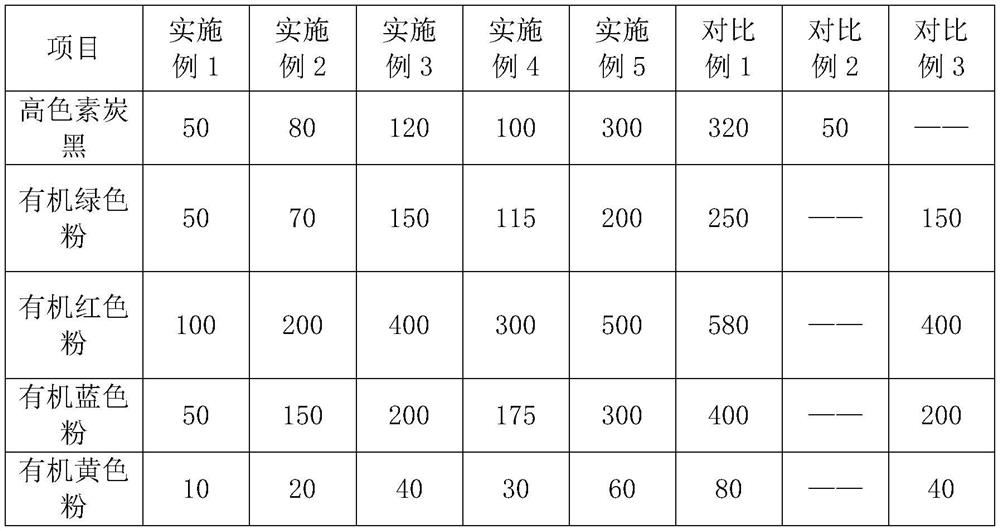

Examples

Embodiment 1

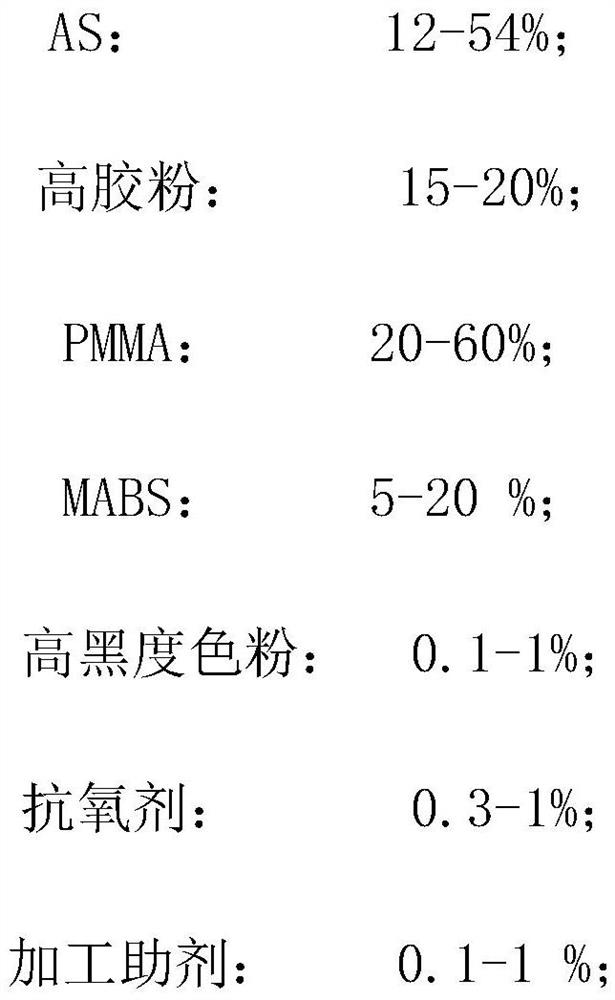

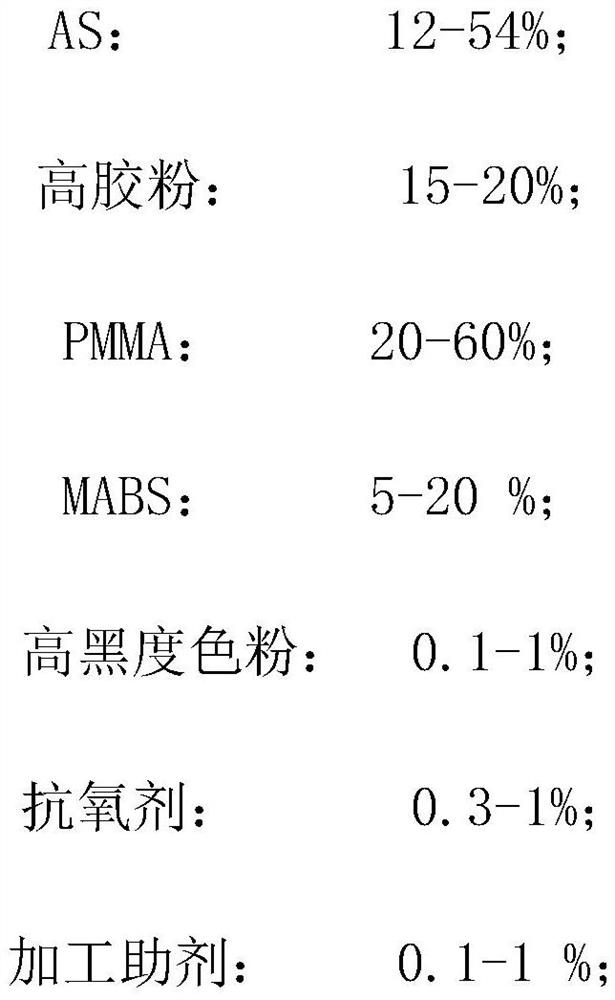

[0037] Embodiment 1: the preparation of a kind of good mechanical property, ultra-black, high-gloss, anti-scratch ABS compound, comprises the following steps:

[0038] The PMMA of 20wt%, the AS of 54wt%, the high rubber powder of 15wt%, the MABS of 10wt%, the high blackness toner of 0.2wt%, the antioxidant 1010 of 0.1wt%, the antioxidant 168 of 0.2wt% Add 0.5wt% processing aid (EBS) into the high-speed mixer and mix evenly, and feed it into the extruder through the feeder, kneading, melt extrusion, stranding, cooling, and pelletizing to obtain good mechanical properties. Ultra black, high gloss, scratch resistant ABS compound.

[0039] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the first zone is 150-200°C, the temperature of the second zone is 190-240°C, the temperature of the third zone is 190-240°C, the temperature of the fourth zone is 190-240°C, and the temperature of the fifth zone is 190-250°C , the temperature in the...

Embodiment 2

[0040] Embodiment 2: the preparation of a kind of good mechanical property, ultra-black, high-gloss, anti-scratch ABS compound, comprises the following steps:

[0041] The PMMA of 30wt%, the AS of 42wt%, the high rubber powder of 17wt%, the MABS of 10wt%, the high blackness toner of 0.2wt%, the antioxidant 1010 of 0.1wt%, the antioxidant 168 of 0.2wt% Add 0.5wt% processing aid (EBS) into the high-speed mixer and mix evenly, and feed it into the extruder through the feeder, kneading, melt extrusion, stranding, cooling, and pelletizing to obtain good mechanical properties. Ultra black, high gloss, scratch resistant ABS compound.

[0042] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the first zone is 150-200°C, the temperature of the second zone is 190-240°C, the temperature of the third zone is 190-240°C, the temperature of the fourth zone is 190-240°C, and the temperature of the fifth zone is 190-250°C , the temperature in the...

Embodiment 3

[0043] Embodiment 3: the preparation of a kind of good mechanical property, ultra-black, high-gloss, anti-scratch ABS compound, comprises the following steps:

[0044]The PMMA of 45wt%, the AS of 24wt%, the high rubber powder of 20wt%, the MABS of 10wt%, the high blackness toner of 0.2wt%, the antioxidant 1010 of 0.1wt%, the antioxidant 168 of 0.2wt% Add 0.5wt% processing aid (EBS) into the high-speed mixer and mix evenly, and feed it into the extruder through the feeder, kneading, melt extrusion, stranding, cooling, and pelletizing to obtain good mechanical properties. Ultra black, high gloss, scratch resistant ABS compound.

[0045] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the first zone is 150-200°C, the temperature of the second zone is 190-240°C, the temperature of the third zone is 190-240°C, the temperature of the fourth zone is 190-240°C, and the temperature of the fifth zone is 190-250°C , the temperature in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com