Patents

Literature

78results about How to "Good scratch-resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of laminate, laminate, polarizing plate and image display device

InactiveUS20080038472A1Good scratch resistanceExcellent productivityPretreated surfacesSpecial surfacesChemical compoundChemical bond

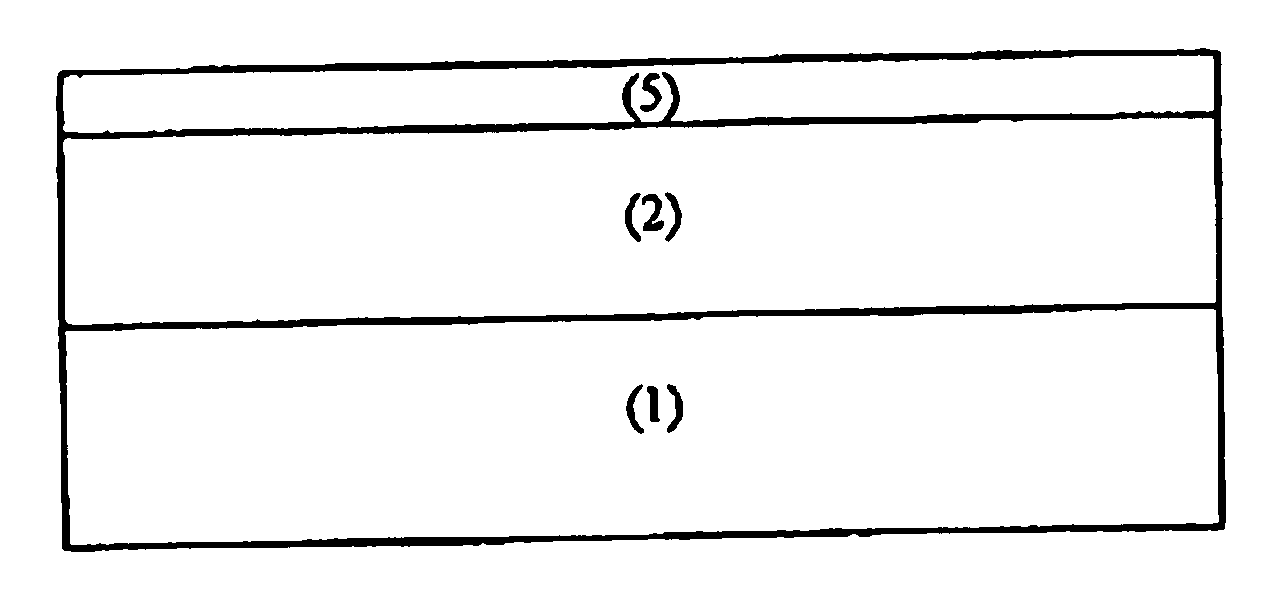

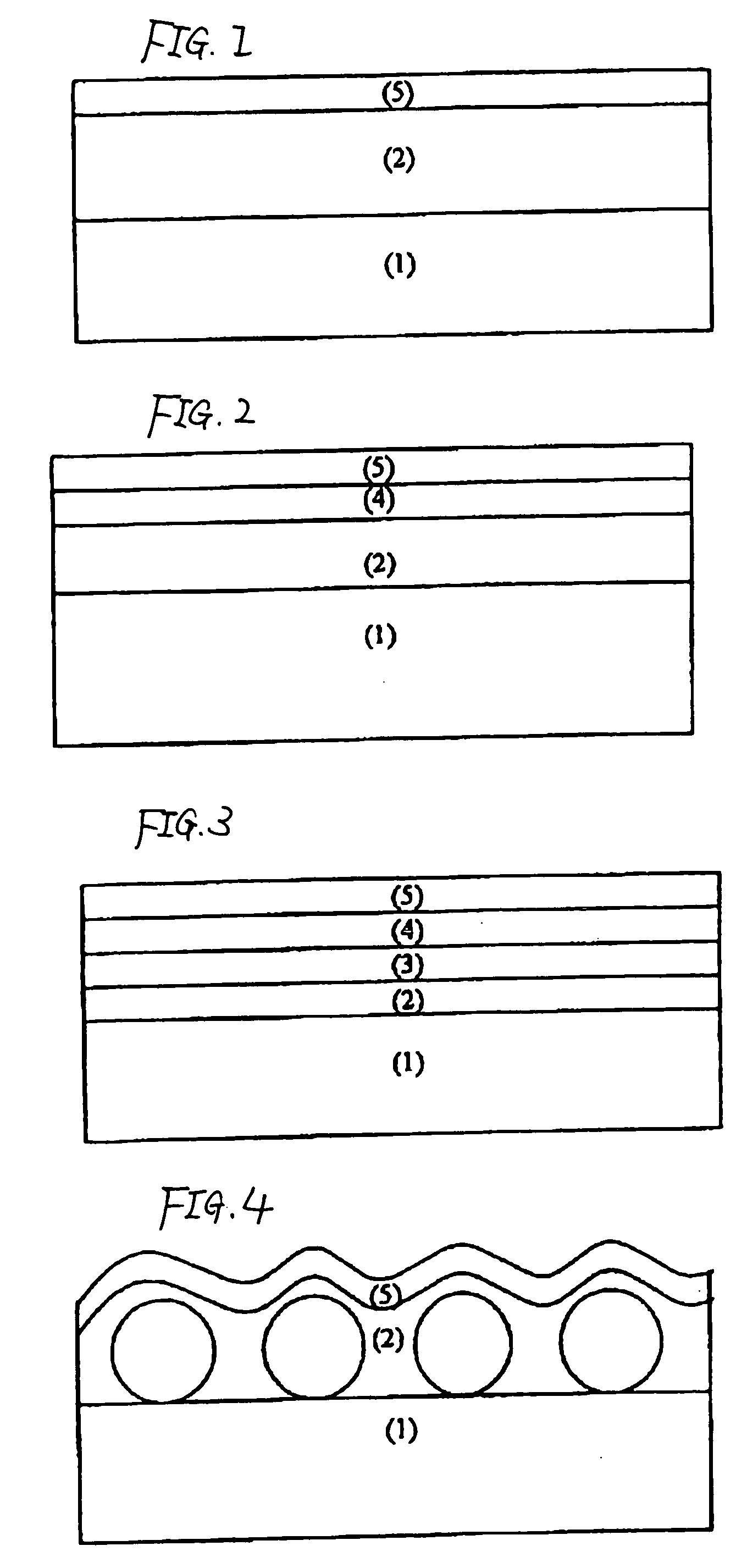

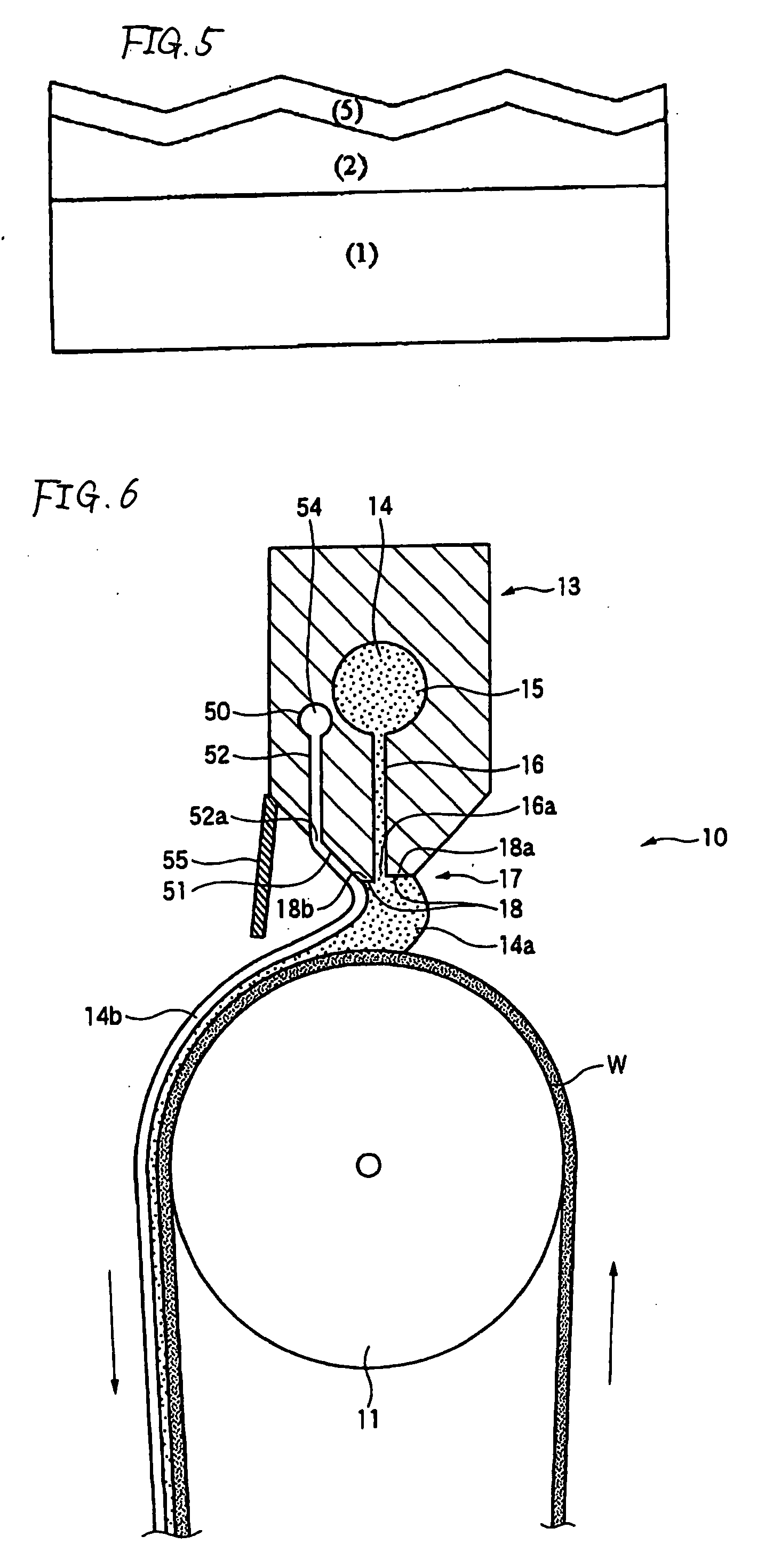

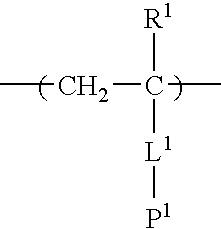

A method for producing a laminate comprising a support; and at least two layers provided by coating at least two kinds of coating compositions, respectively, the method comprising: simultaneously coating at least two kinds of coating compositions on a support; and drying the at least two kinds of coating compositions, wherein the at least two kinds of coating compositions each comprises a compound having a polymerizable functional group capable of forming a chemical bond to each other.

Owner:FUJIFILM CORP

Hard coating article, curing composition, and information recording media

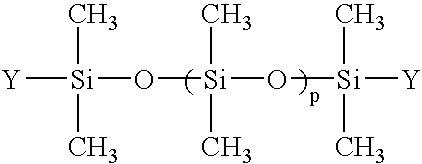

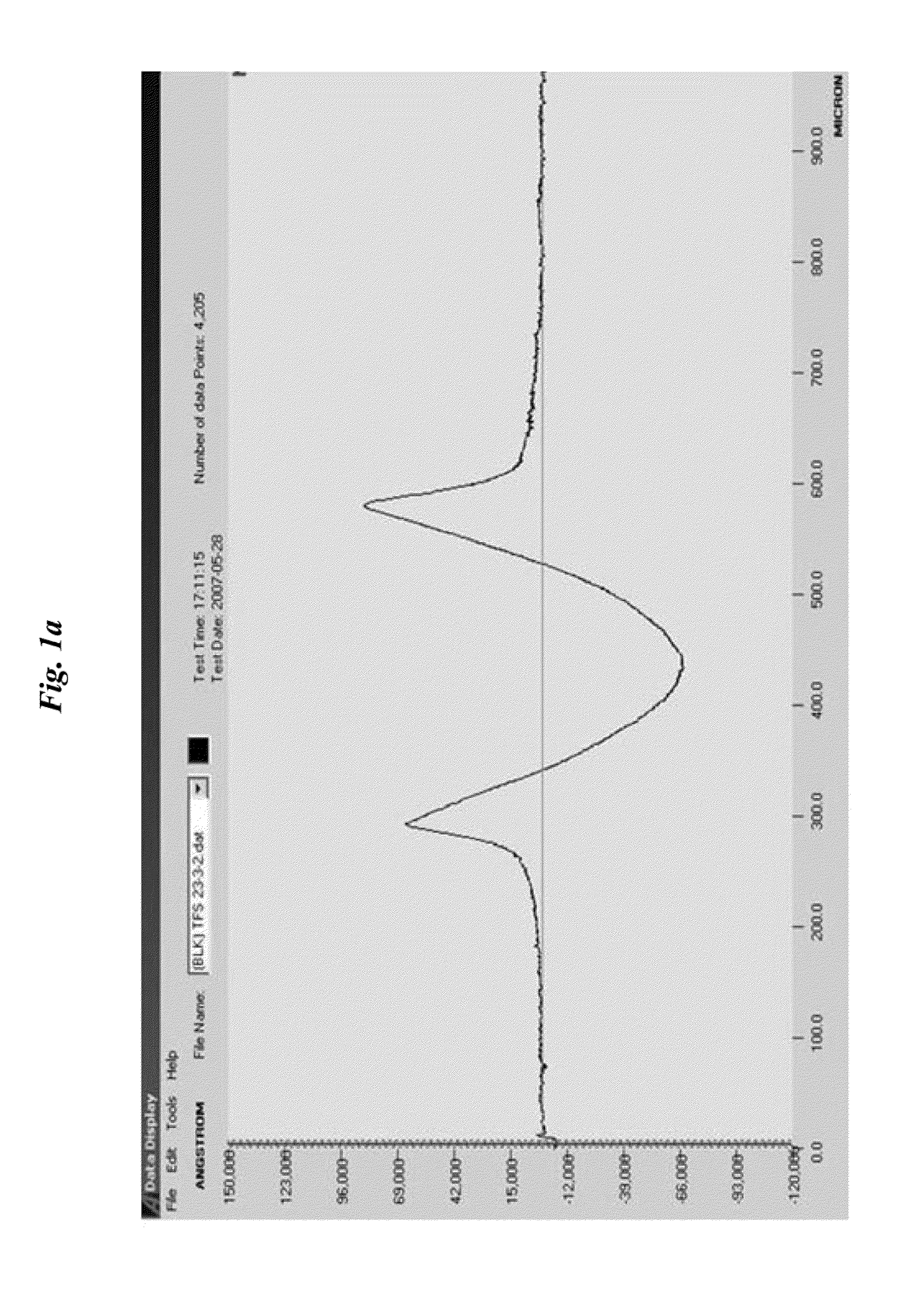

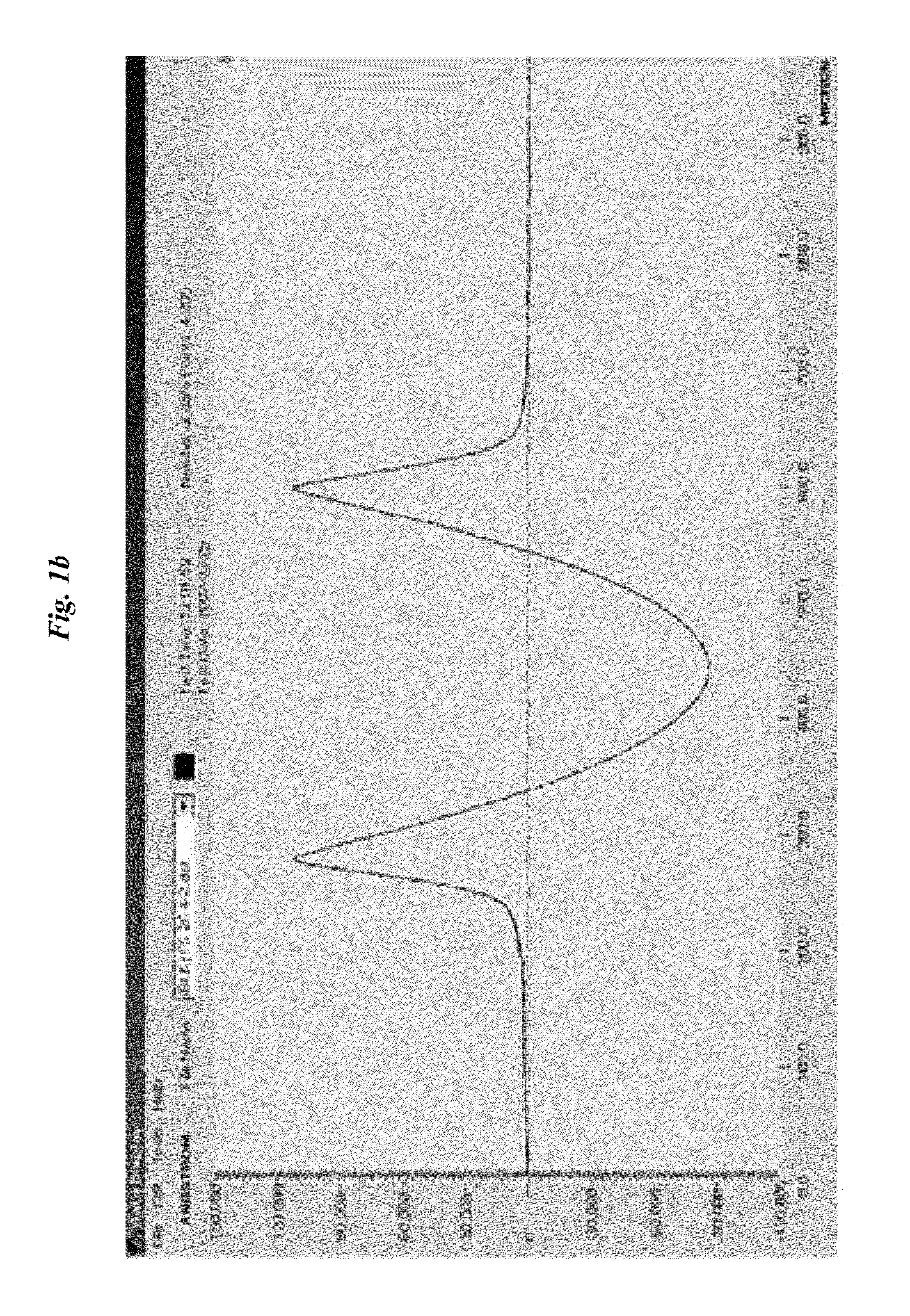

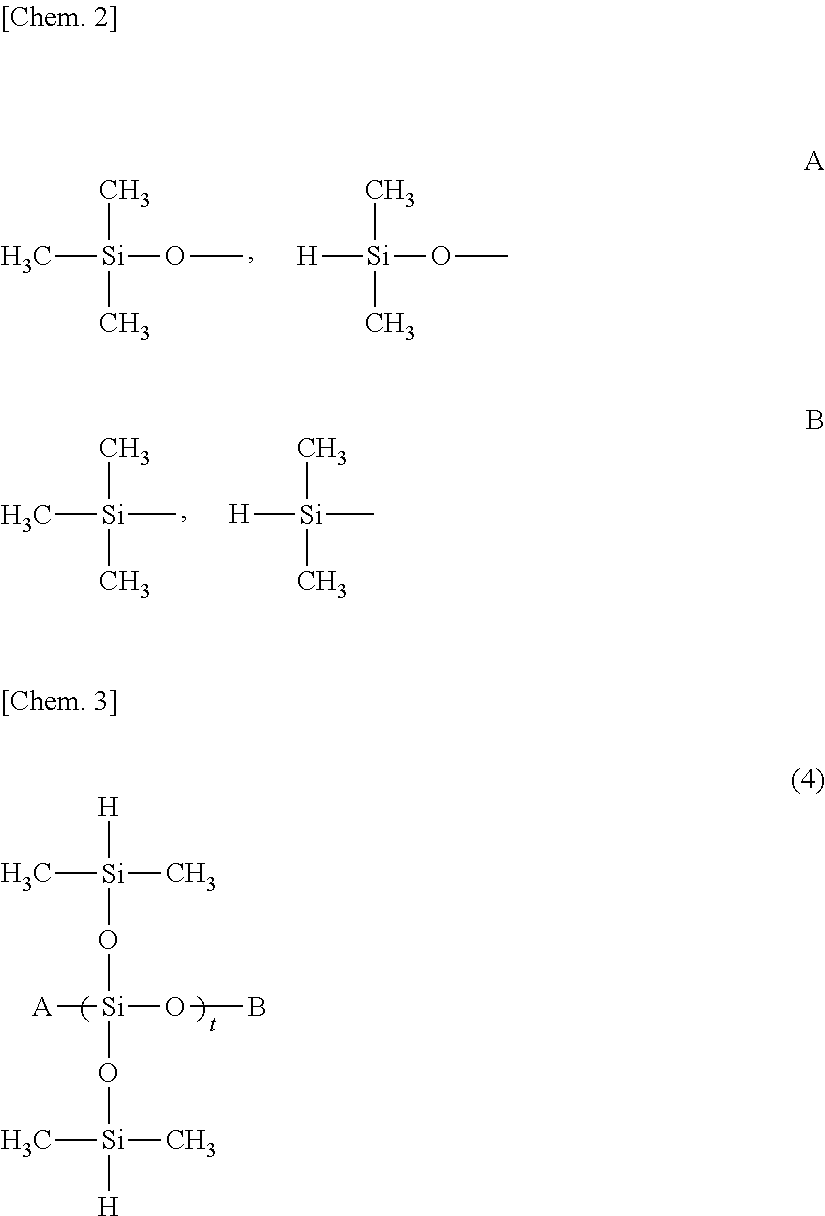

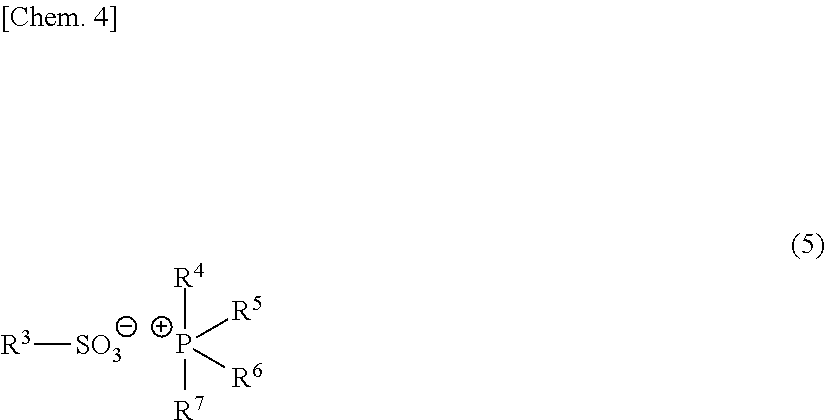

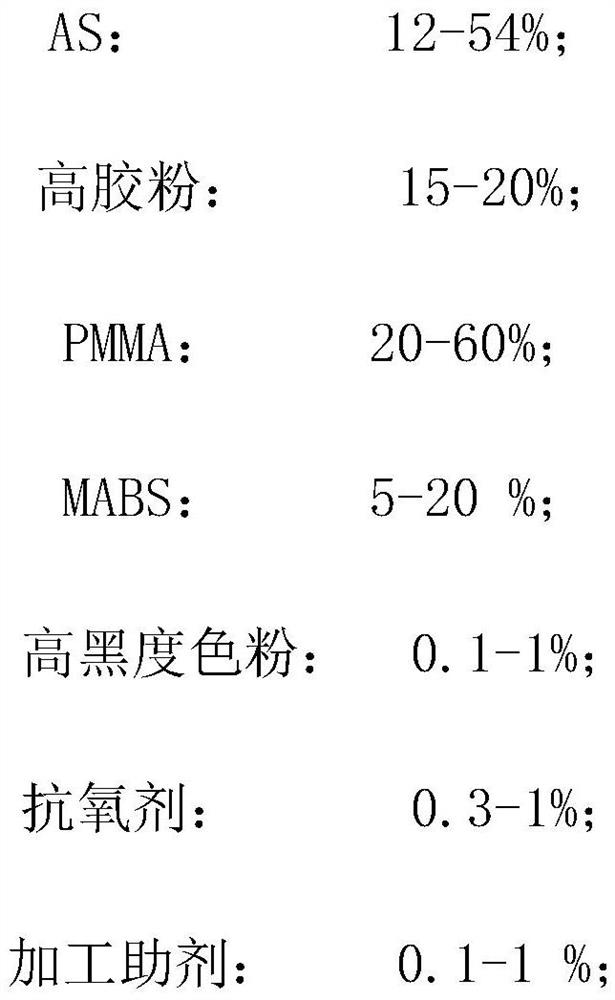

InactiveUS20070048531A1High surface hardnessGood scratch resistanceRecord carriersLayered product treatmentSilicone resinChemistry

To provide a curing composition suitable for forming an antifouling hard coat layer having high surface hardness, excellent in scratch resistance, and having an antifouling property lasting long; and to provide an optical information recording media having scratch resisting and antifouling properties, and persistent reading characteristics of records, the curing composition includes an actinic energy-curing resin, wherein the actinic energy-curing resin hass a silicone resin having a silicon content of from 23 to 32 weight %; and the optical information recording material has a light-transmitting layer formed by coating and curing the curing composition, wherein a coating amount of the silicone resin is from 0.4 to 45 mg / n2.

Owner:FUJIFILM CORP

Thermoplastic resin composition with improved compatibility

Disclosed herein is a thermoplastic resin composition that can have improved compatibility by introducing a branched acrylic copolymer to a polycarbonate resin. The thermoplastic resin composition can have good scratch resistance in addition to good colorability and appearance without requiring the addition of a compatibilizer.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Antioxidant, anti-wear and antirust lubricating oil for automobile gear and preparation method thereof

The invention discloses antioxidant, anti-wear and antirust lubricating oil for an automobile gear. The lubricating oil is characterized by being prepared from the following raw materials: base oil, a clearing agent, a dispersing agent, a preservative, an extreme-pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirust agent, a pour point depressant and an antifoaming agent, wherein in the base oil of the lubricating oil, the kinematic viscosity below 100 DEG C is 1.5-40mm<2> / s, the viscosity index is over 100, the pour point is below -25 DEG C, and the sulfur content is below 0.01% by mass. The lubricating oil for an automobile gear, disclosed by the invention, has the advantages of simple composition, low cost, relatively good viscosity index, high anti-wear property and long service life; the compatibility between the lubricating oil additive and the base oil is relatively good, and the lubricating oil is of relatively high stability; and compared with existing automobile lubricating oil, the automobile lubricating oil disclosed by the invention has high corrosion resistance, the preparation technology of the lubricating oil is simple, and the steps are simple and environment-friendly and easy to implement.

Owner:高安市超鹰科技有限公司

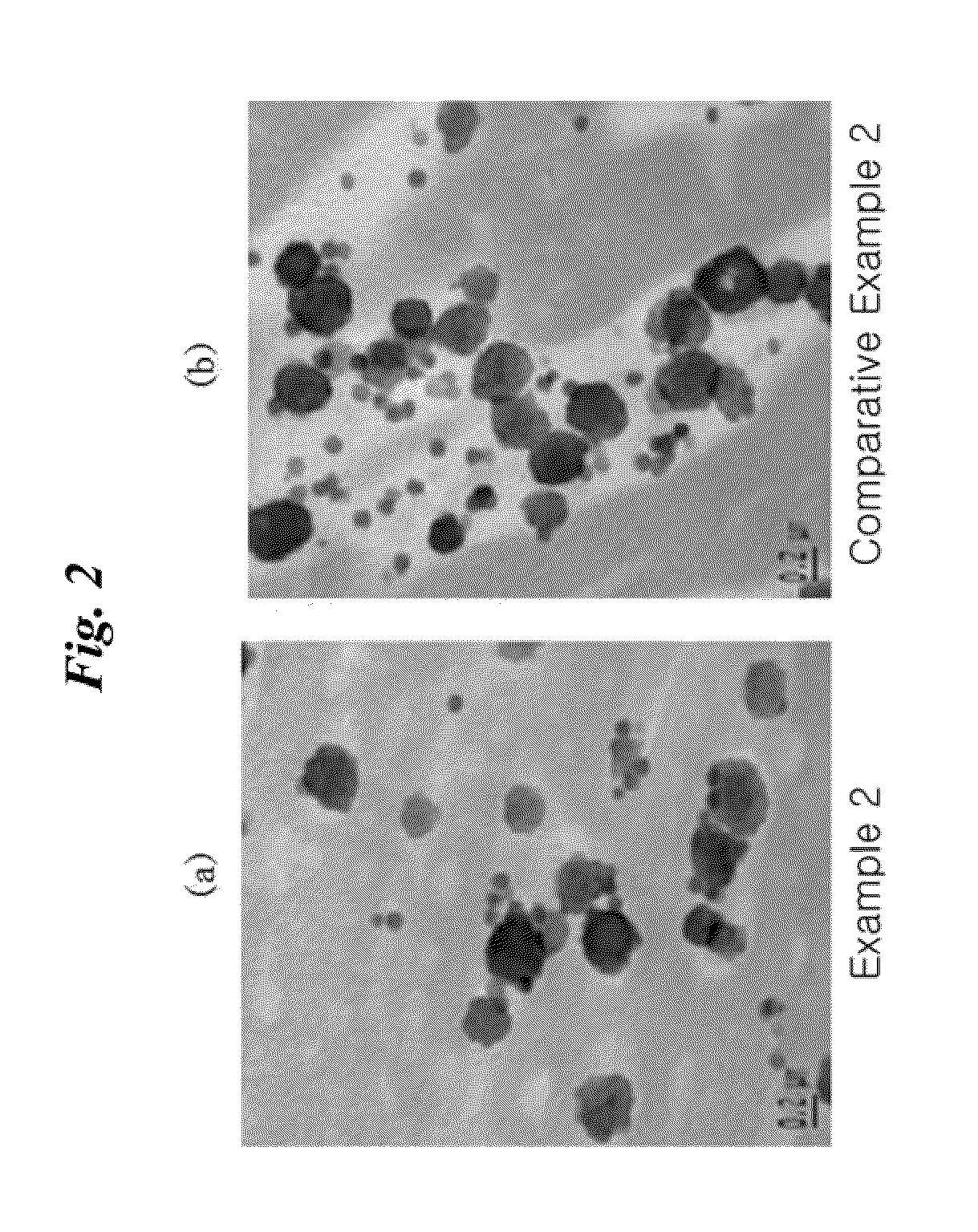

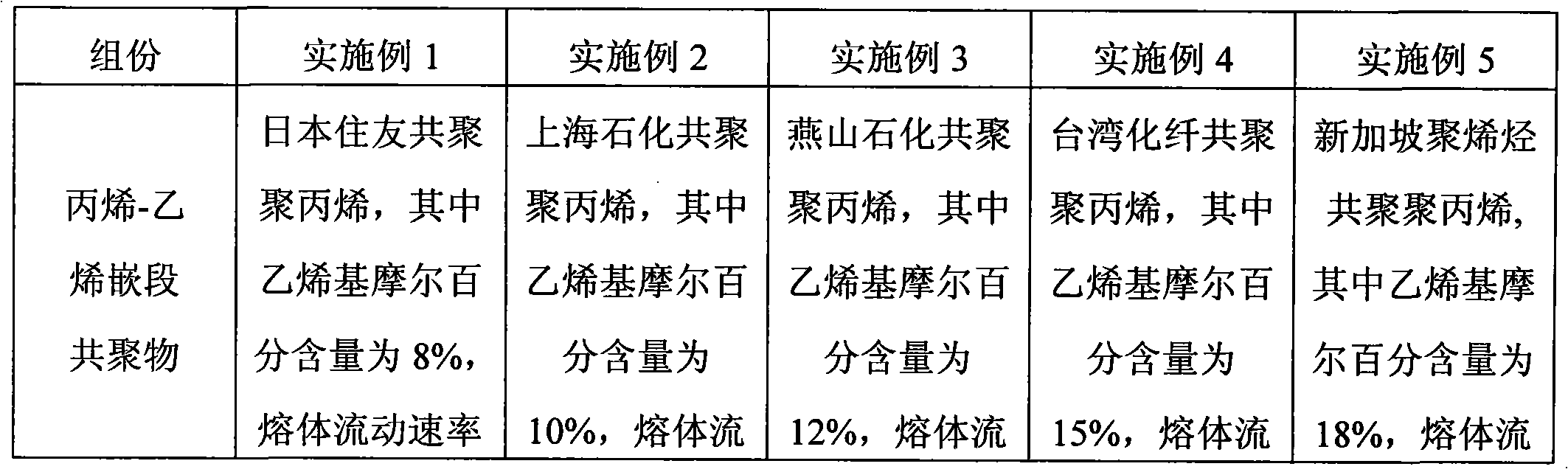

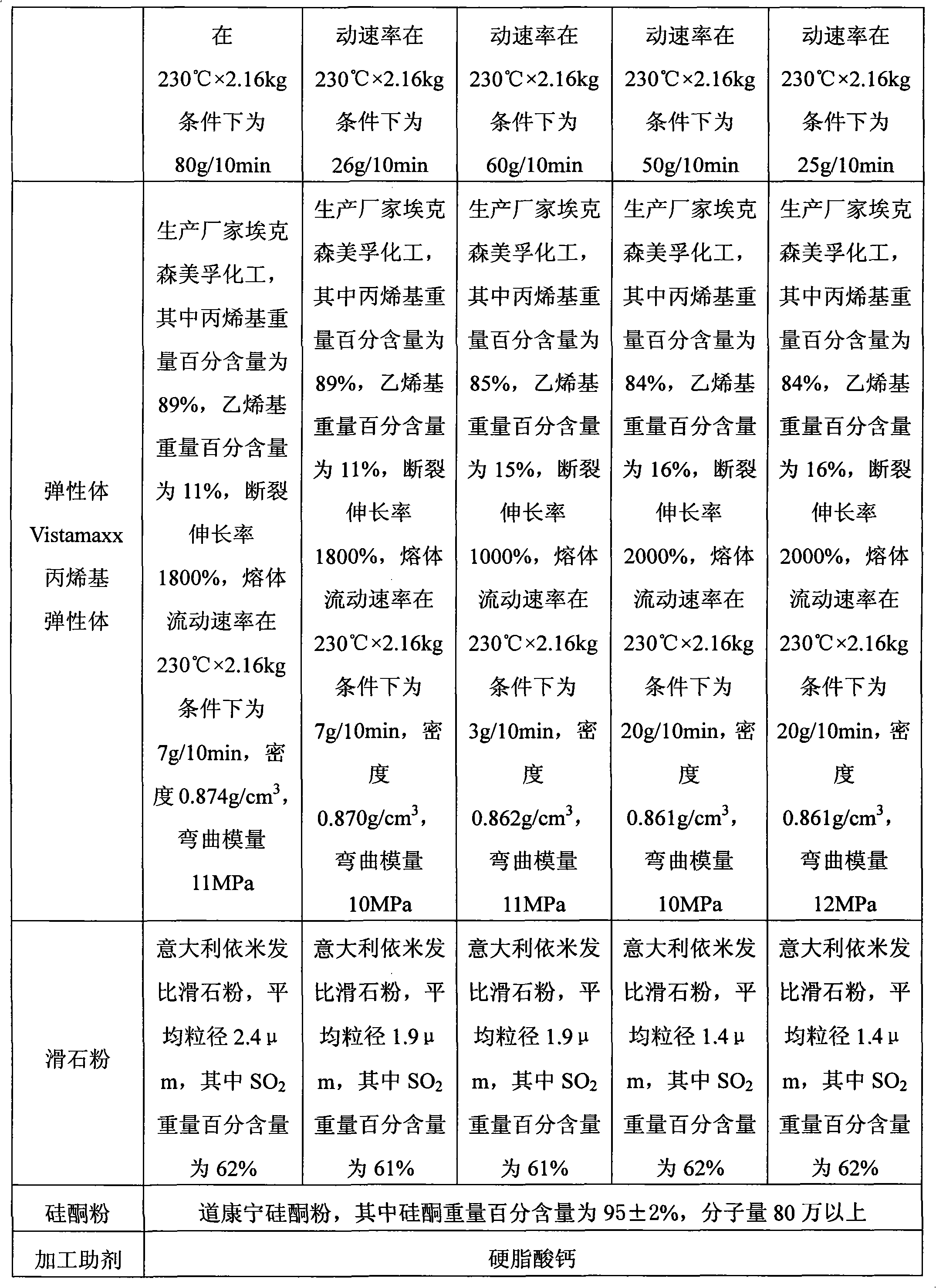

Scratch resistant and shock proof propylene-ethylene block copolymerization polypropylene modified material

The invention discloses a scratch resistant and shock proof propylene-ethylene block copolymerization polypropylene modified material, comprising the following raw materials in parts by weight: 40-90 parts of propylene-ethylene block copolymerization polypropylene, 0-30 parts of talcum powder, 5-25 parts of elastomer, 0.2-5 parts of silicone powder, 0.5-2 parts of stabilizer and 0.1-0.5 part of processing agent. The propylene-ethylene block copolymerization polypropylene modified material can show excellent scratch resistance and satisfactory shock proof performance at the same time, and especially the low-temperature shock intensity can satisfy the requirements of middle-high grade automotive upholsteries. The invention also discloses a method for preparing the propylene-ethylene block copolymerization polypropylene modified material, which has simple operation and low cost, does not need special equipment, and is suitable for industrial production.

Owner:CGN JUNER NEW MATERIALS +1

Anticorrosion epoxy powder paint used outside marine steel pipe pile

ActiveCN101724331AGood scratch resistanceImprove scratch resistanceAnti-corrosive paintsEpoxy resin coatingsWaxAluminium

The invention provides an anticorrosion epoxy powder paint used outside a marine steel pipe pile, which is characterized by comprising resin, a curing agent, an accelerant, a coupling agent, an edge covering agent, a special function auxiliary agent, a stuffing, a pigment and the like, and the formula of the anticorrosion epoxy powder paint comprises the following components in percentage by weight: 40-60 percent of phenol-modified epoxy resin, 0-20 percent of bisphenol A epoxy resin, 0-20 percent of linear phenol curing agent, 5-25 percent of phenol curing agent, 0.3-1.5 percent of 2-phenylimidazole, 0.2-1 percent of silane coupling agent, 0.2-3 percent of gas phase white carbon, 0-2 percent of hydroxy-phenyl benzotriazole ultraviolet absorbent and hindered amine light stabilizer, 0-5 percent of modified polyfluortetraethylene wax, 5-25 percent of glass powder, 5-30 percent of talcum powder, silicon powder and mica powder, 5-10 percent of aluminium triphosphate, iron red, rutile titanium pigment and cuprous oxide and 0-3 percent of pigment. The paint SEBF-6 has the advantages that the surface roughness of a coating satisfies the required built-in strength of a steel pile and the marine geological condition of the steel pile, and the paint has the characteristics of excellent scratch resistance, shock resistance, abrasion resistance, marine biological fouling resistance, ageing resistance, ultraviolet irradiation resistance and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

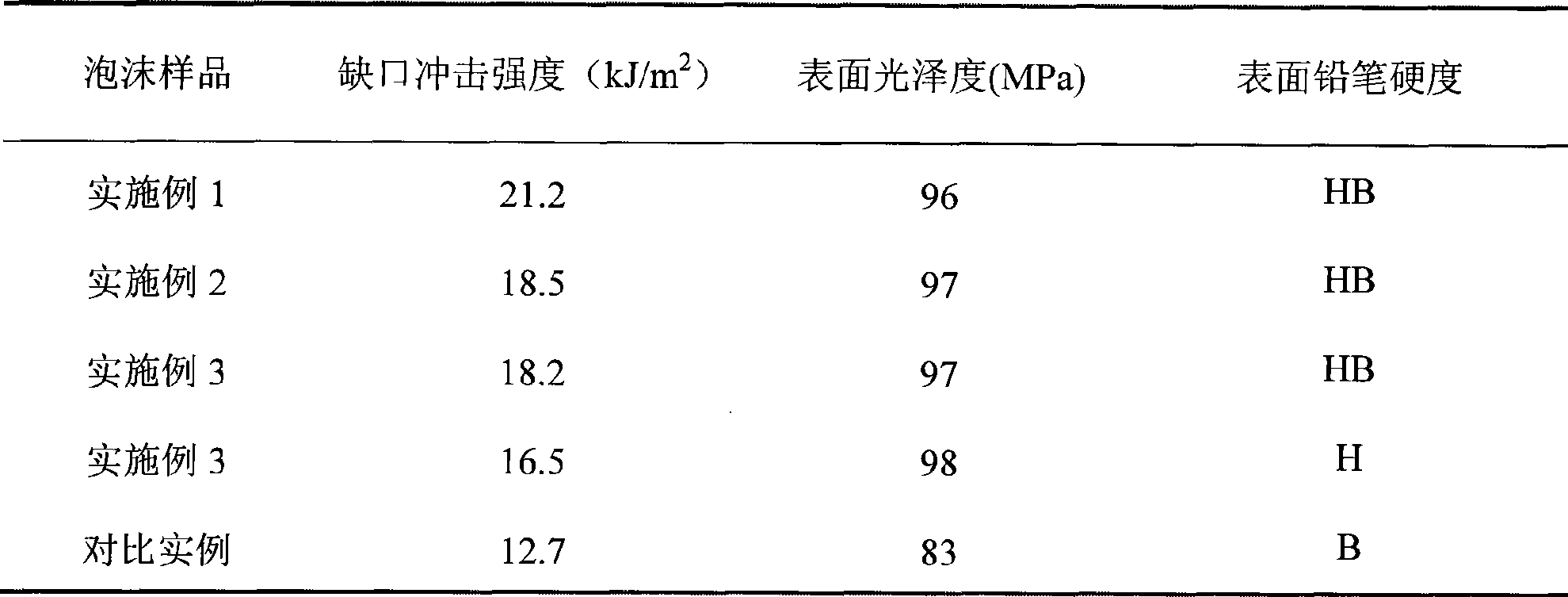

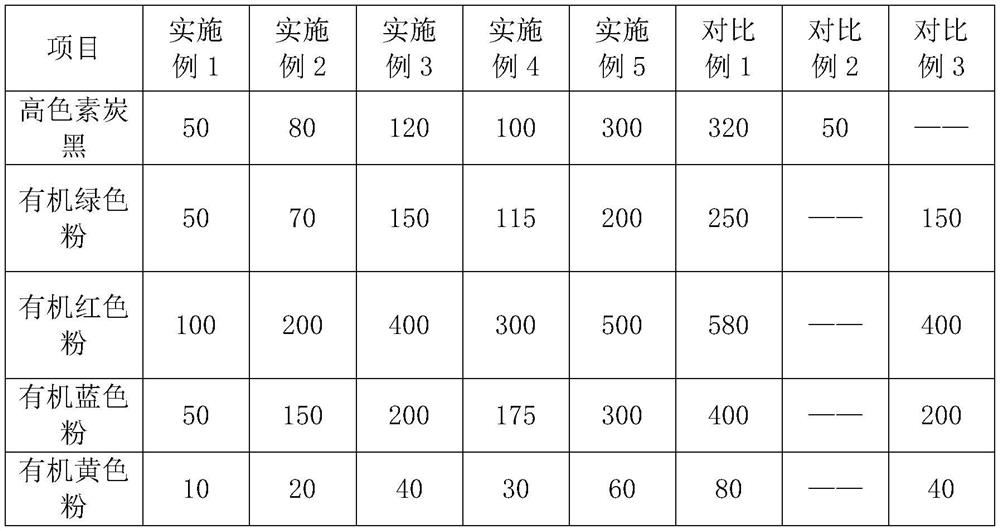

Preparation method of scratch-resistant lacquer-free ABS moulding composition with high glaze

The invention relates to a preparation method of a scratch-resistant lacquer-free ABS moulding composition with high glaze. The moulding composition comprises at least two acrylonitrile-butadiene-styrene graft copolymers with specific rubber phase grain diameter, rubber content and fusant flow characteristic, at least one of acrylonitrile-styrene copolymer with specific fusant flow characteristic, polymethylmethacrylate and polymethylmethacrylate copolymer, and black master batch made from hyperchromatic carbon black. The fusants with different flow characteristics are properly split and enriched by a moulding process such that the moulding article maintains the excellent shock-resistant toughness and has the scratch-resistant surface effect with high glaze without lacquering treatment.

Owner:四川长虹模塑科技有限公司 +1

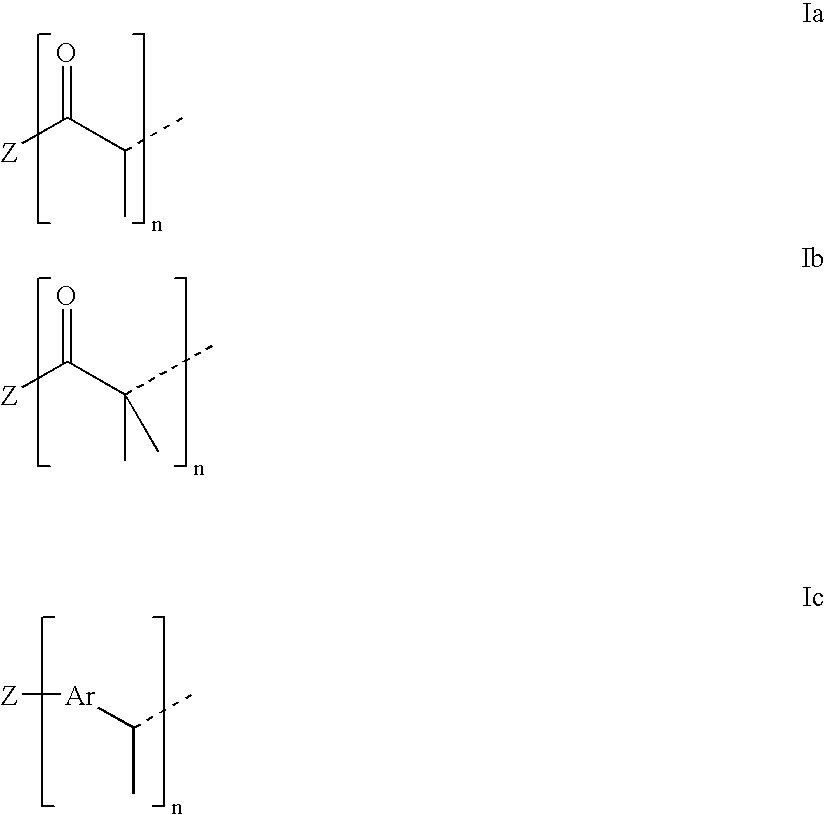

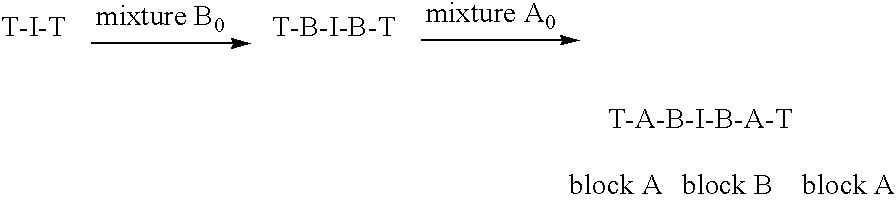

Multilayer acrylic film with improved optical and mechanical properties

InactiveUS20050233124A1Good scratch resistanceHigh transparencyGroup 5/15 element organic compoundsSynthetic resin layered productsMethyl methacrylateEmulsion

Multilayer acrylic film comprising: a layer (A) made from a thermoplastic acrylic composition comprising from 75 to 95% of a metliacrylic (co)polymer containing mostly methyl methacrylate units and from 5 to 25% of an impact modifier a layer (B) made from either a composition comprising a methacrylic (co)polymer and an impact modifying compound, or a composition prepared by sequential polymerization in aqueous emulsion of acrylate-based monomer systems, or a composition comprising, a block copolymer, and a layer (C) made from a thermoplastic acrylic composition comprising from 75 to 95% of a methacrylic (co)polymer containing mostly methyl methacrylate units and from 5 to 25% of an impact modifier. Use of the film for coating a substrate (thermoplastic resin, thermosetting resin, etc.).

Owner:ARKEMA FRANCE SA

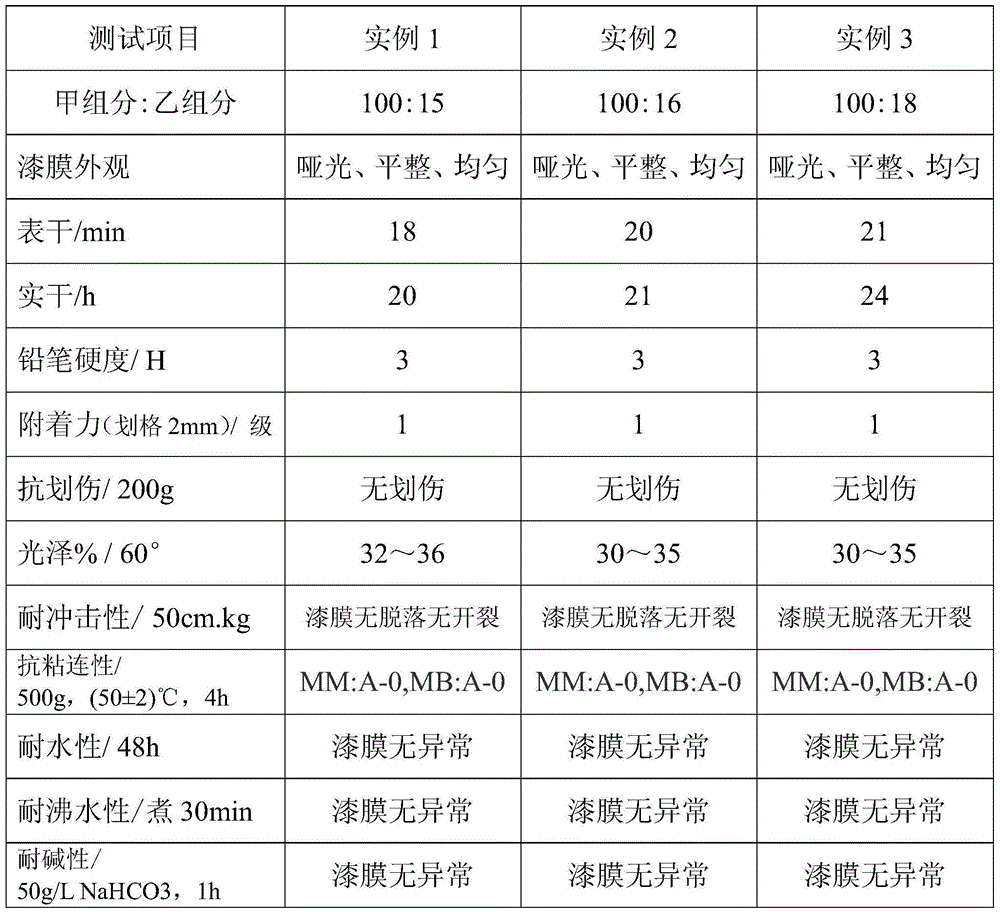

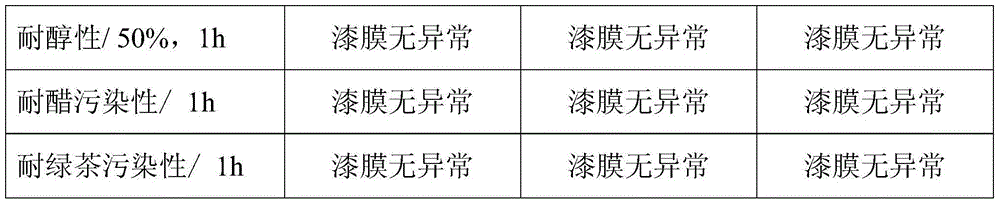

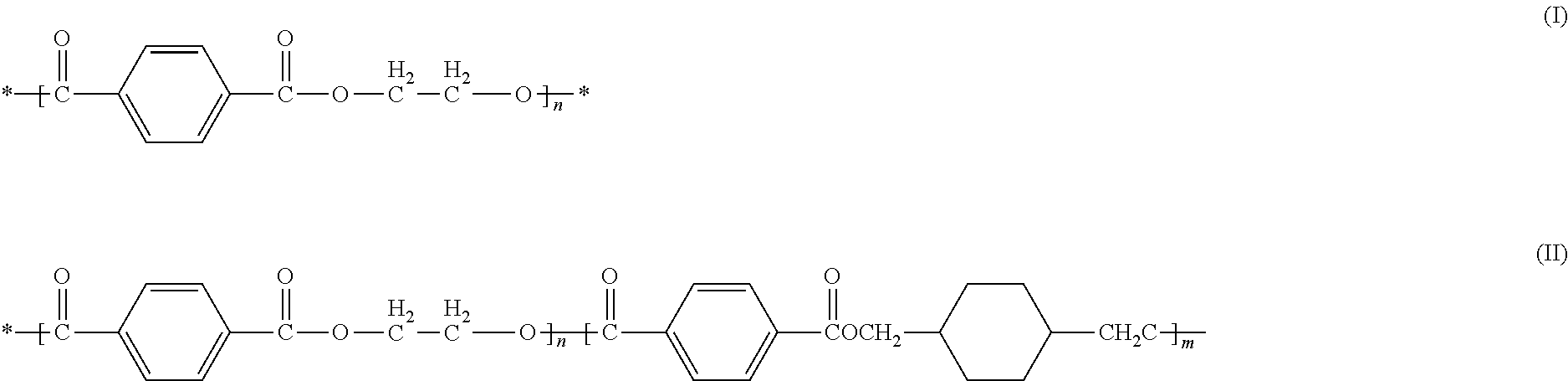

Non-ionic aqueous HDI polyurethane curing agent preparation method

ActiveCN105669947AGood scratch resistanceGood transparencyPolyurea/polyurethane coatingsSolventPolyester

The present invention relates to a non-ionic aqueous HDI polyurethane curing agent preparation method. The non-ionic aqueous HDI polyurethane curing agent mainly consists of HDI trimers, low molecular weight polyether polyols and an inert solvent. The obtained non-ionic aqueous HDI polyurethane curing agent is free of arene, glycol ethers and alkyl phenol, environmentally friendly, good in scratch resistance, good in transparency, excellent in chemical resistance, strong in pollution resistance, good in yellowing resistance, etc. A polyurethane paint prepared by an aqueous hydroxyl components is high in hardness and high in transparency, the paint film is good in scratch-resistant, and the polyurethane paint is good in flow leveling, high in fullness, good in compatibility, etc. The curing agent is a specific curing agent used for waterborne carpentry paint, waterborne industrial paint, waterborne plastic paint and various two-component waterborne polyester paint, waterborne polyurethane paint, waterborne epoxy paint, waterborne alkyd paint, waterborne polyurethane glue, etc.

Owner:UNION FOSHAN CHEM +1

Flame retarding thermoplastic alloy and its preparation method

The present invention discloses a thermoplastic flame-retardant alloy and a method for preparing it, composed of the following components by the shares and weights as below: 5-94 shares of ABS resin, 3-94 shares of polyester or co-polyester or the mixture of both, 1-50 shares of brominated flame retardant, 1-10 shares of synergistic flame-retardant, 0.001-30 shares of chlorinated polyethylene (CPE), 0.001-2 shares of anti-dripping agent and 0.1-6 shares of processing aid. Comparing with the ABS flame retardant presenting the prior art, the thermoplastic flame-retardant alloy features better glossness, scratch resistance, stronger ultraviolet radiation resistance and better mechanical property, thus making up for the disadvantage that the flame-retardant ABS is prone to become yellow on some occasions with high weatherability requirements. Furthermore, the preparation method of the thermoplastic flame-retardant alloy for the present invention is successive, stable and feasible.

Owner:KINGFA SCI & TECH CO LTD +1

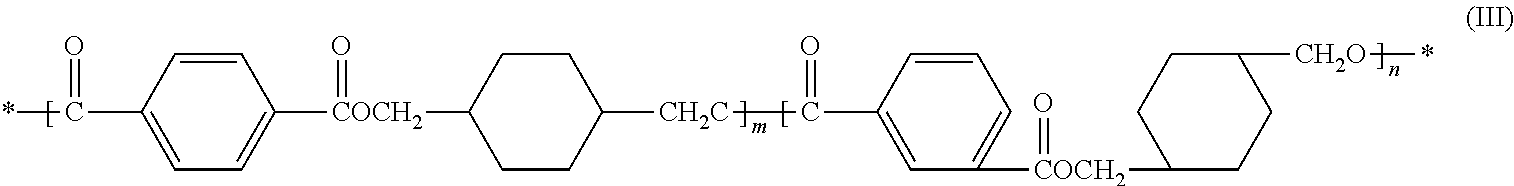

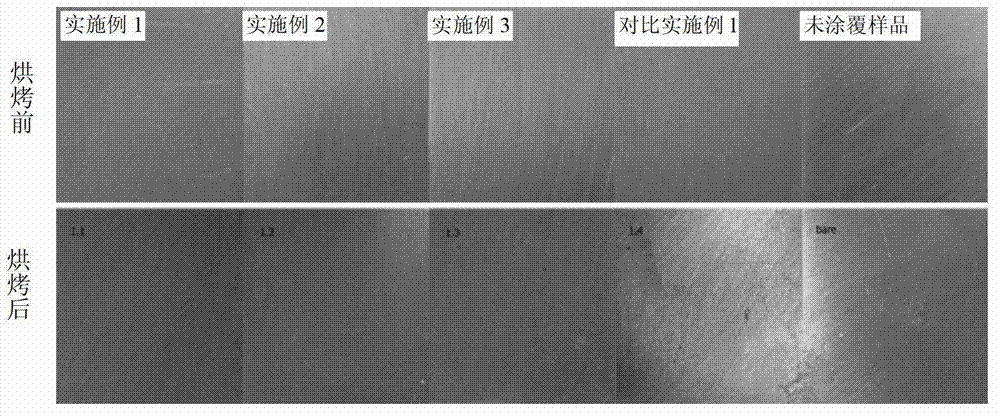

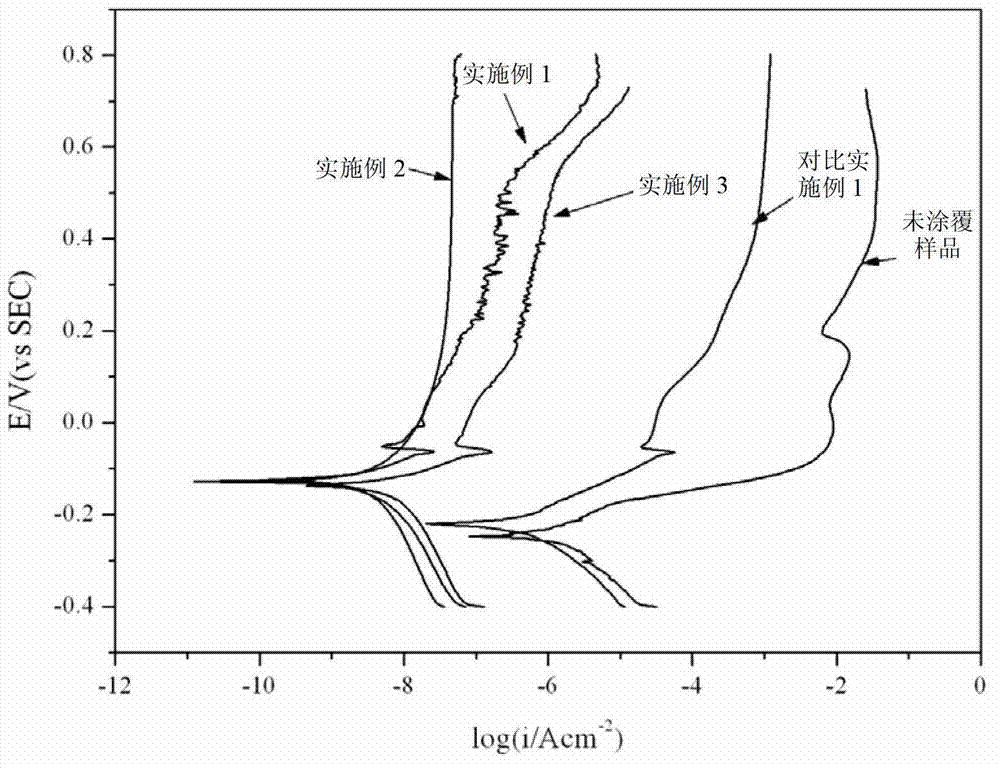

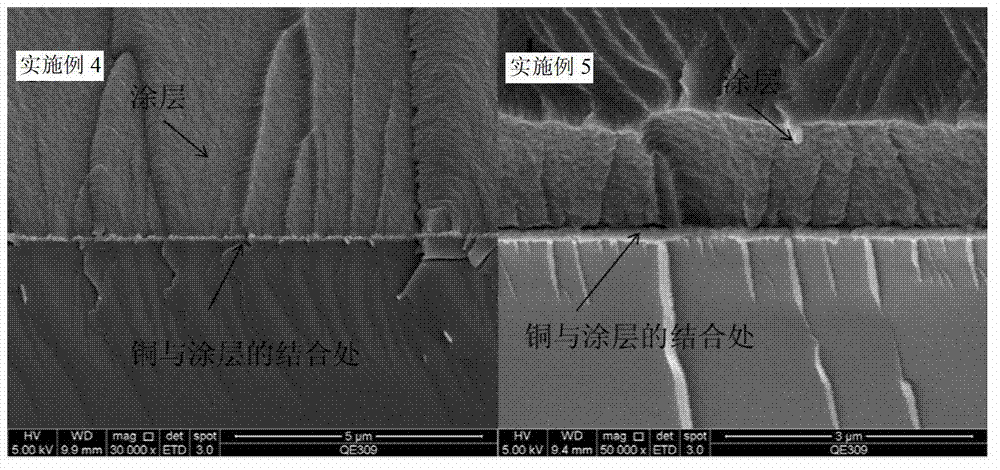

Preservative solution use for copper and copper alloy surface, preparation method and application

ActiveCN102898946AIncrease crosslink densityGood scratch resistanceAnti-corrosive paintsSilaneCatalytic effect

The invention discloses a preservative solution use for copper and a copper alloy surface, the preservative solution dissolves mercaptoalkyl alkoxy silane and alkoxy silane in an organic solvent, and a hydrolysis reaction is carried out under the catalytic effect of hydrolysis catalytic solution to obtain a hydrolysis product. Compared with the prior art, anticorrosive coatings formed by the preservative solution on copper and the copper alloy surface have good anticorrosive effect, scratch resistance performance and heat-resistant performance, and the preservative solution has excellent application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

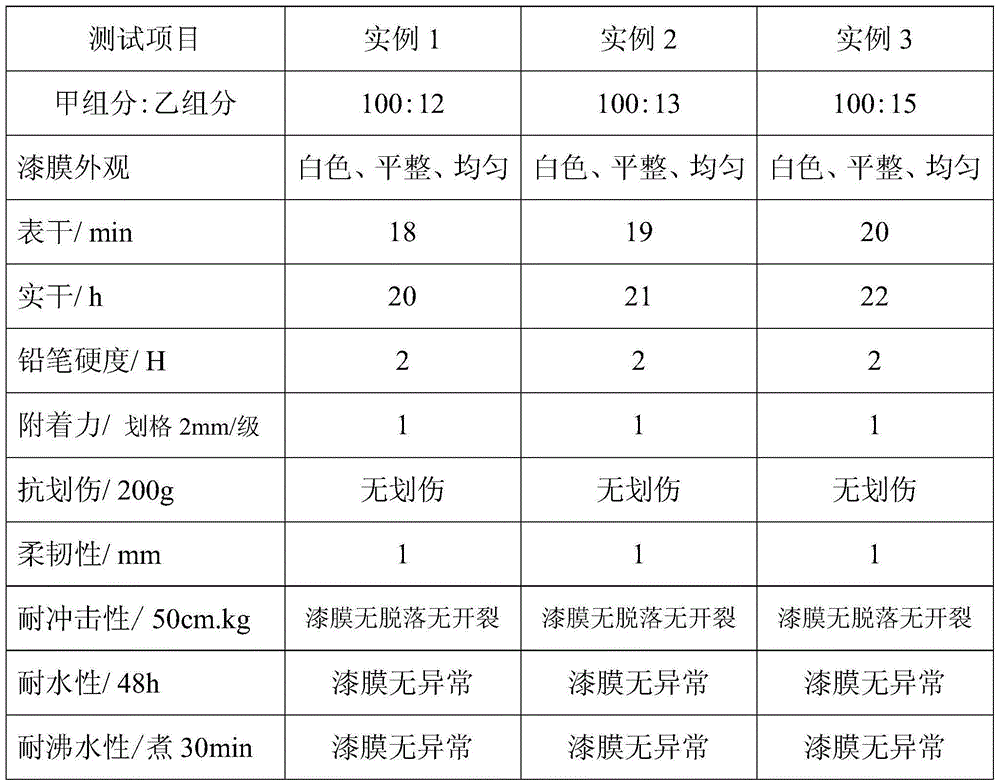

Water-based two-component floor paint and preparation method thereof

InactiveCN102925043AGood scratch resistanceImpact resistance and strong adhesionPolyurea/polyurethane coatingsWaxIon

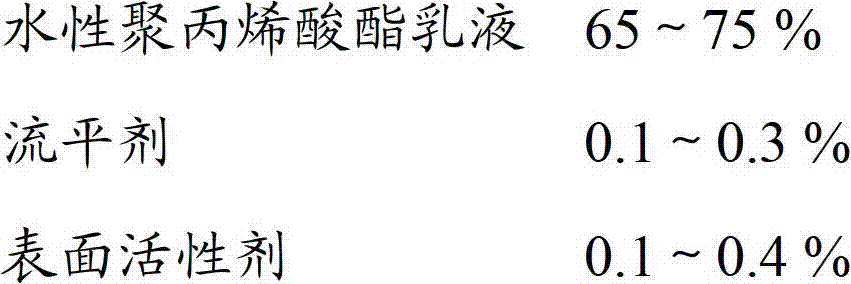

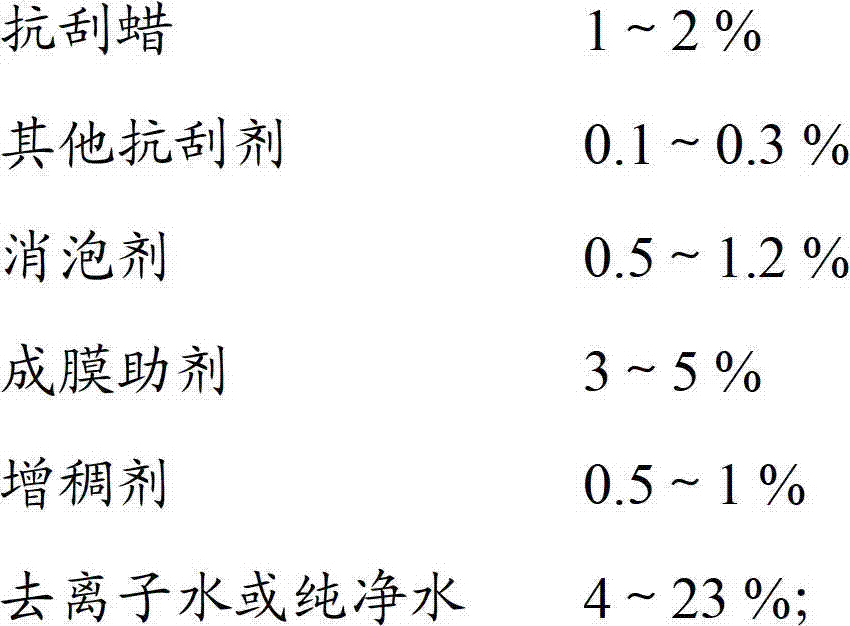

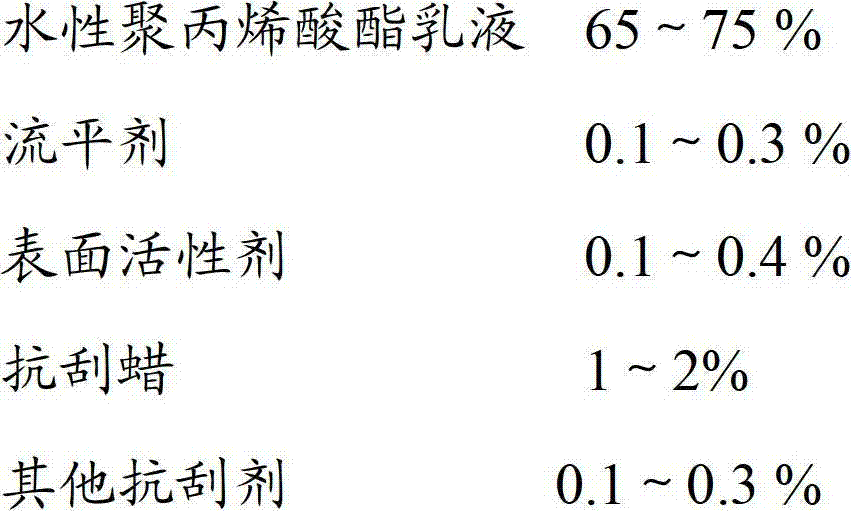

The invention discloses a water-based two-component floor paint and a preparation method thereof. The water-based two-component floor paint consists of a first component and a second component, wherein the first component comprises the following ingredients in percentage by total weight of the water-based two-component floor paint: 65 to 75 percent of water-based polyacrylate emulsion, 0.1 to 0.3 percent of leveling agent, 0.1 to 0.4 percent of surfactant, 0.1 to 0.3 percent of other scratch resistance agent, 0.5 to 1.2 percent of antifoaming agent, 3 to 5 percent of coalescing agent, 1 to 2 percent of scratch-resistant wax, 0.5 to 1 percent of thickener and 4 to 23 percent of deionized water or pure water; and the second component is water-dispersed poly diisocyanate and has the content of 8 to 10 percent by total weight of the water-based two-component floor paint. The preparation method comprises the steps of weighing the components according to a formula, preparing first, second, third and fourth mixed solutions, adding water into the fourth mixed solution and packaging.

Owner:CHINA PAINT MFG CO SHENZHEN

Flame retardant polypropylene (PP) material and its preparation method

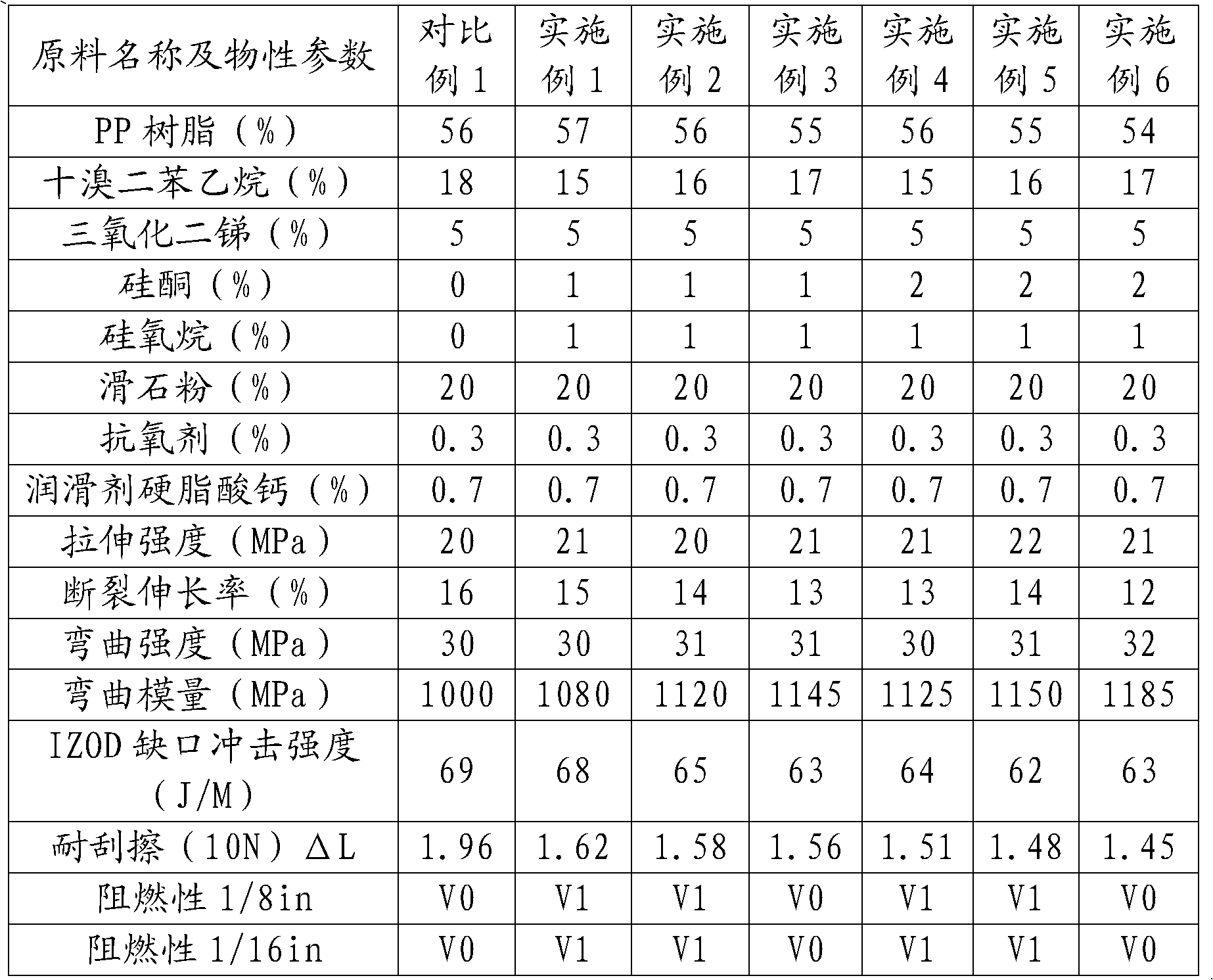

The invention discloses a flame retardant polypropylene material and its preparation method. The flame retardant polypropylene material comprises the following components by weight: 50-60% of PP resin; 20-30% of a fire retardant; 10-30% of filler; 0.2-5% of a scraping resistant agent; 0.1-0.5% of an anti-oxidant; and 0.5-1.0% of a lubricant. Specifically, the PP resin is homopolymerized PP; the fire retardant is compounded by decabromodiphenylethane and antimonony oxide; the scraping resistant agent is compounded by silicone and siloxane; and the lubricant is a stearate lubricant. The flame retardant PP material has the advantages of good scraping resistant performance on the surface, excellent mechanical performance, and environmental protection as well as flame retardation, thus being able to meeting the demands of household electrical appliances and electronic instruments on flame retardation and scraping resistant performances.

Owner:SHENZHEN KEJU NEW MATERIAL

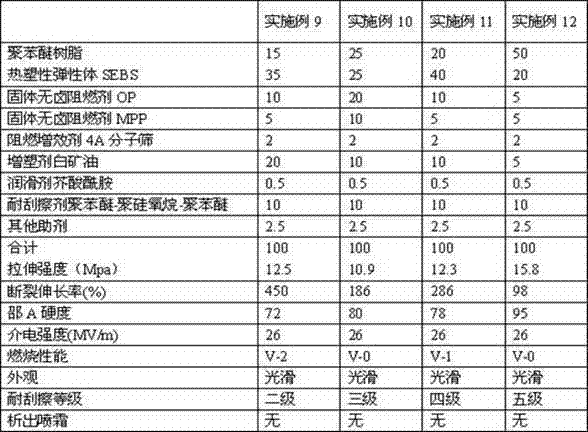

Scraping resistance halogen-free flame retardant thermoplastic elastomer composition and preparation method of composition

The invention discloses a scraping resistance halogen-free flame retardant thermoplastic elastomer composition, which comprises the following ingredients in percentage by weight: 15 to 50 percent of poly-phenylate resin, 20 to 40 percent of styrene thermoplastic elastomers, 10 to 30 percent of solid halogen-free flame retardants, 0.5 to 5 percent of flame retardant synergists, 5 to 20 percent of plasticizers and 5 to 20 percent of scraping resistance agents. The halogen-free flame retardant thermoplastic elastomer composition provided by the invention has the advantages that polysiloxane is added into the halogen-free flame retardant thermoplastic elastomer composition in a polymer form, the excellent scraping resistance is realized, the original mechanical property, the flame retardant performance, the appearance and the soft hand feeling are not damaged, on the basis, the viscosity of the composition in the extruding processing process can also be reduced, the energy consumption is reduced, and better low-carbon and environment-protection effects can be realized.

Owner:KINGFA SCI & TECH CO LTD +1

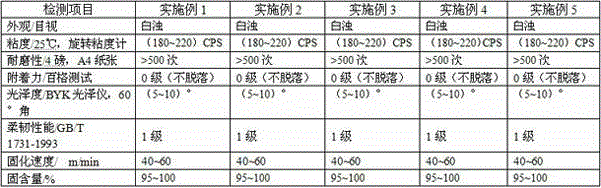

Scraping-resistant UV matt varnish applied to matt membranes and preparation method thereof

ActiveCN104130675AImprove scratch resistanceGood scratch resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceAcrylic resin

The invention relates to the field of matt varnish, and especially relates to scraping-resistant UV matt varnish applied to matt membranes and a preparation method thereof. The scraping-resistant UV matt varnish applied to matt membranes consists of, in parts by weight, 5-15 parts of epoxy acrylic resin, 20-35 parts of modified acrylic resin, 50-65 parts of an acrylic acid monomer, 10-15 parts of a photoinitiator, 5-15 parts of a matting agent, and 1-5 parts of an auxiliary agent. The preparation method comprises: a, adding the acrylic acid monomer and the matting agent into a stirring pot to pre-disperse, and mixing uniformly with stirring; b, continuing to add epoxy acrylic resin, modified acrylic resin, the acrylic acid monomer, the photoinitiator and the auxiliary agent into the stirring pot, and mixing uniformly with stirring to prepare a varnish material; and c, filtering the varnish material, so as to obtain the matt varnish. The scraping-resistant UV matt varnish has relatively good scraping resistance when applied to matt membranes, and is fine in handfeel, low in matt degree, excellent in visual effect, excellent in adhesive force and excellent in wear resistance.

Owner:东莞宏石功能材料科技有限公司

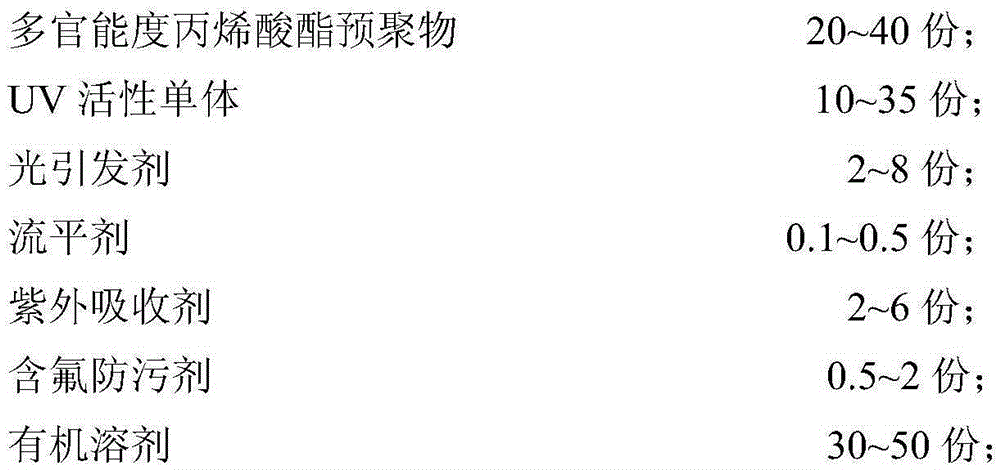

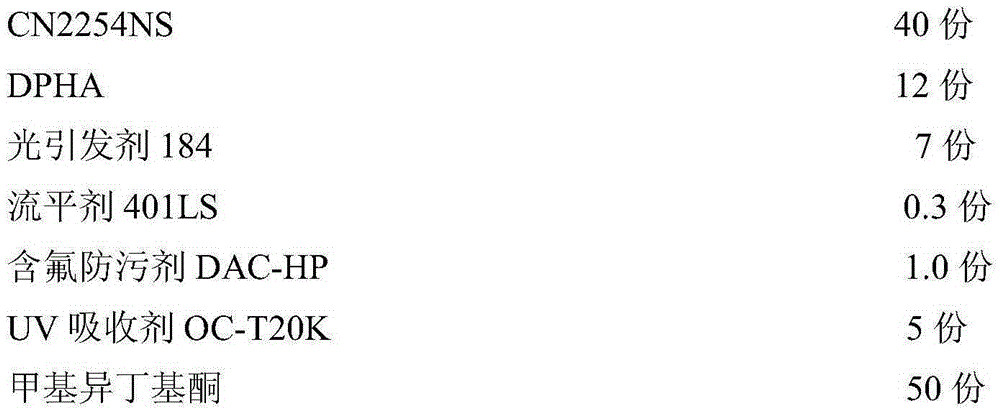

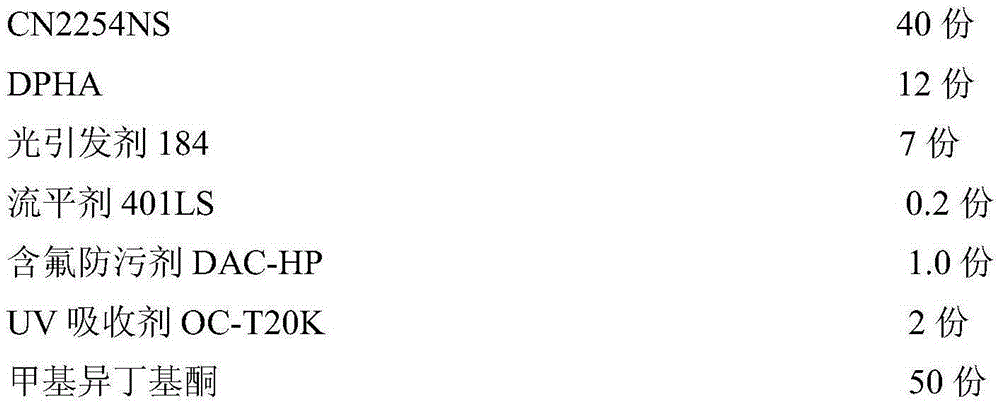

UV (ultraviolet)-blocking and antifouling coating composition, hard coating film and preparation methods

ActiveCN105273585AHydrophobic and oleophobic antifouling performance Scratch resistanceGood scratch resistanceAntifouling/underwater paintsPaints with biocidesPrepolymerUv blocking

The invention relates to UV (ultraviolet)-blocking and antifouling coating composition, a hard coating film and preparation methods. The coating composition comprises components in parts by weight as follows: 20-40 parts of a polyfunctional acrylate prepolymer, 10-35 parts of a UV active monomer, 2-8 parts of a photoinitiator, 0.1-0.5 parts of a leveling agent, 2-6 parts of a UV absorber, 0.5-2 parts of a fluorine-containing antifouling agent and 0-50 parts of an organic solvent. The UV-blocking and antifouling coating composition is applied to a substrate and heated at 60-100 DEG C for 30-100 s, then the coating is subjected to UV radiation by a high-pressure mercury lamp with the radiation strength of 150-300 w / cm and the energy of 200-400 mj / cm<2>, and the UV-blocking and antifouling hard coating film is obtained. The fluorine-containing antifouling agent and the UV absorber are added to the coating composition, so that the hard coating film prepared from the coating composition further has the UV blocking performance, hydrophobic-oleophobic antifouling performance and excellent scratch resistance besides high hardness and optical performance of a conventional hard coating film, can be widely applied to the fields of display outer screens, glass exterior walls, injection molding and the like and has the effects of UV blocking, antifouling, easiness in cleaning and scratch resistance.

Owner:NINGBO SOKEN CHEM

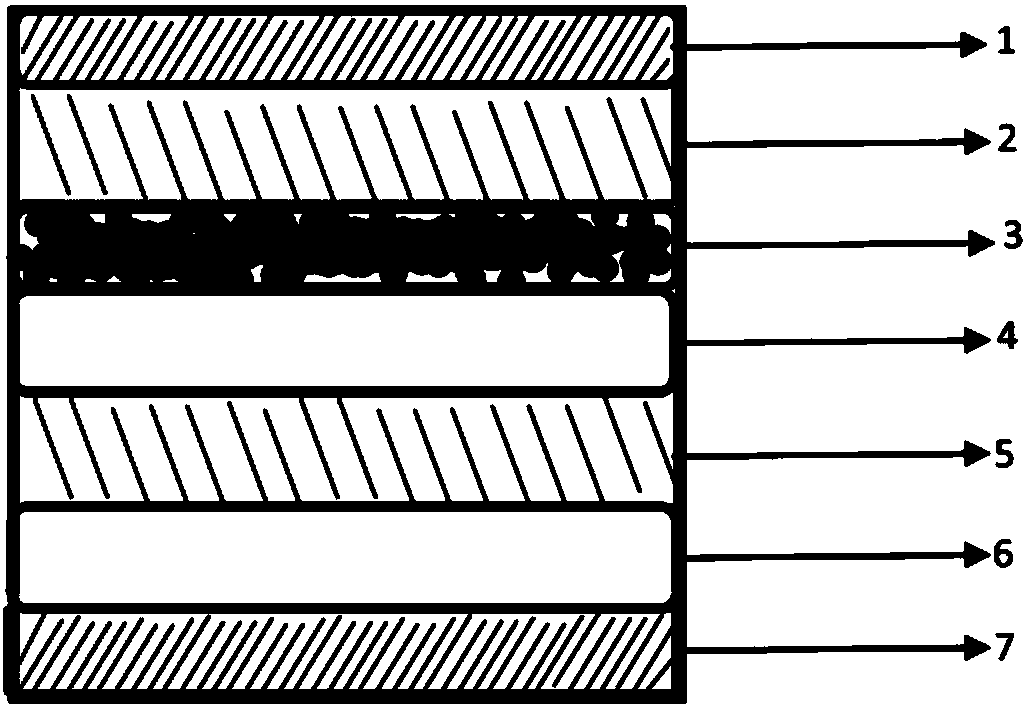

Multilayer composite protective film with high light transmittance and preparation method of multilayer composite protective film

InactiveCN108016101AHigh light transmittanceGood flexibilityLamination ancillary operationsProtective equipmentTectorial membraneWeather resistance

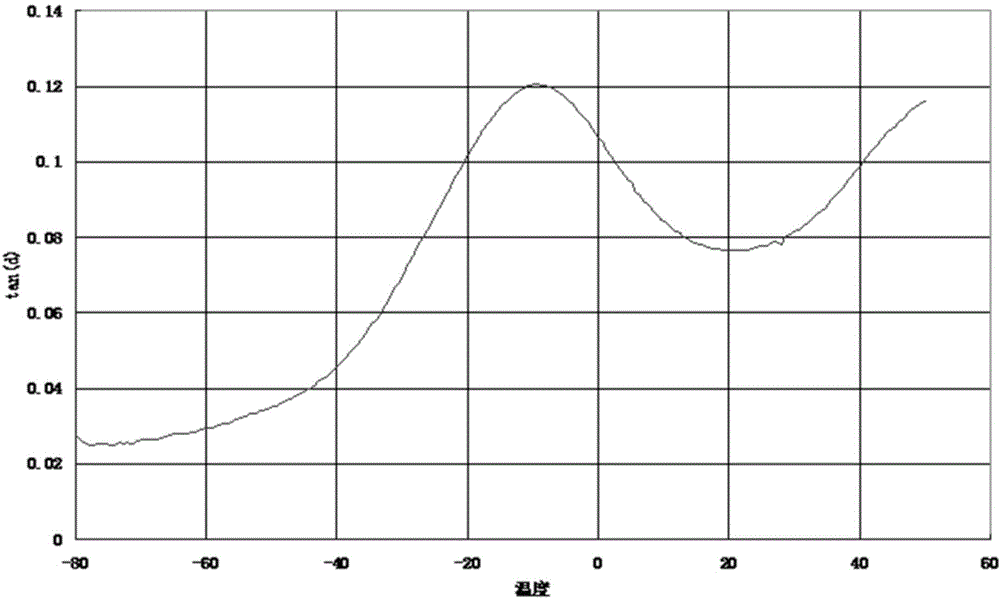

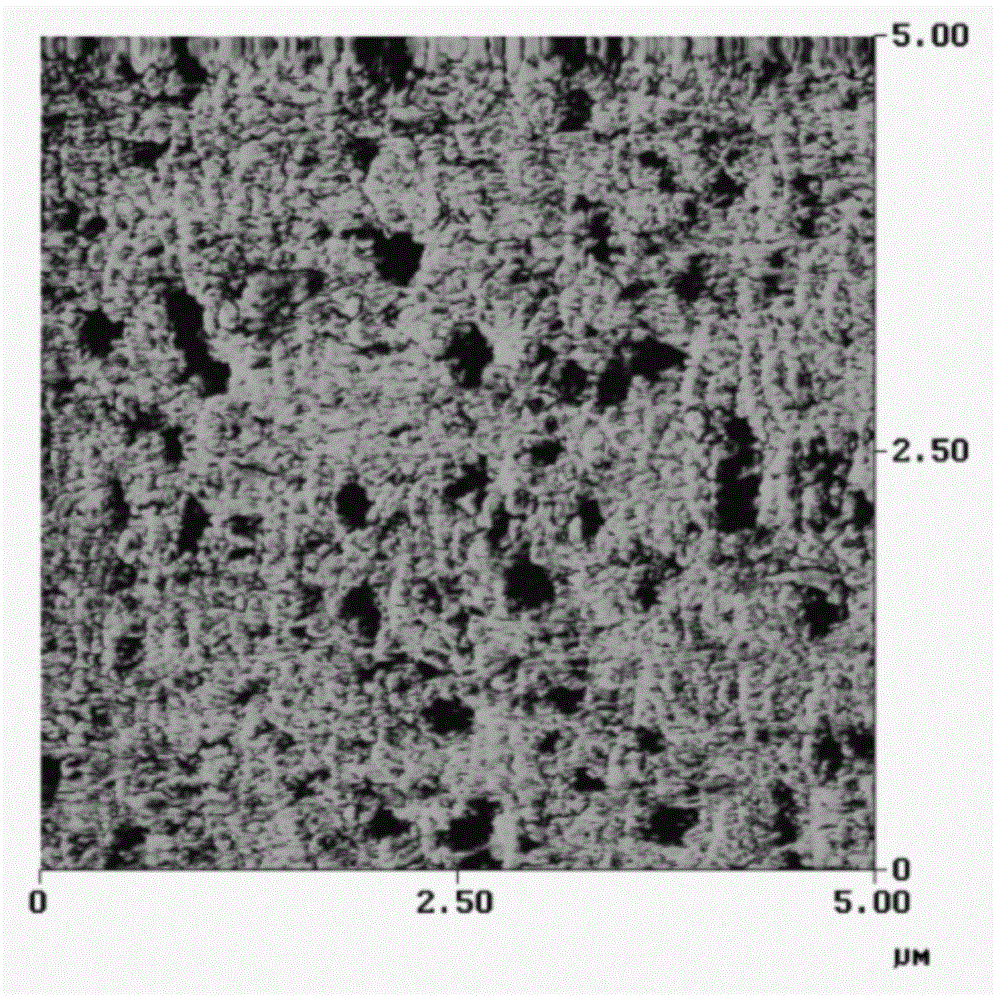

The invention relates to the technical field of package protection of integrated circuits, in particular to a multilayer composite protective film with high light transmittance and a preparation method of the multilayer composite protective film. The multilayer composite protective film with high light transmittance comprises a wear-resistant outer layer, a first substrate layer, an antireflectioncoating, an adhesive layer, a second substrate layer, a protective glue coating and a glue layer protective film layer which are distributed in sequence. The multilayer composite protective film withhigh light transmittance has the beneficial effects that flexibility and stiffness are excellent, different kinds of slitting, die cutting and the like are facilitated, and the film is stuck to various electronic product materials for protection conveniently; the protective film comprises a UV-curable optical abrasion-resistant outer layer on the non-stick surface, and excellent anti-scratch andanti-smudging effects are achieved in processes of product processing and protection; the antireflection layer material is applied between phase composite substrate layers, and the overall light transmittance is higher than 92% after addition of the antireflection layer material; the protective film is coated with a heat-curable polymer protective glue coating, the Tg (glass transition temperature) of the protective glue coating is subzero 35-subzero 65 DEG C, and weather resistance is excellent.

Owner:DONGGUAN TARRY ELECTRONICS

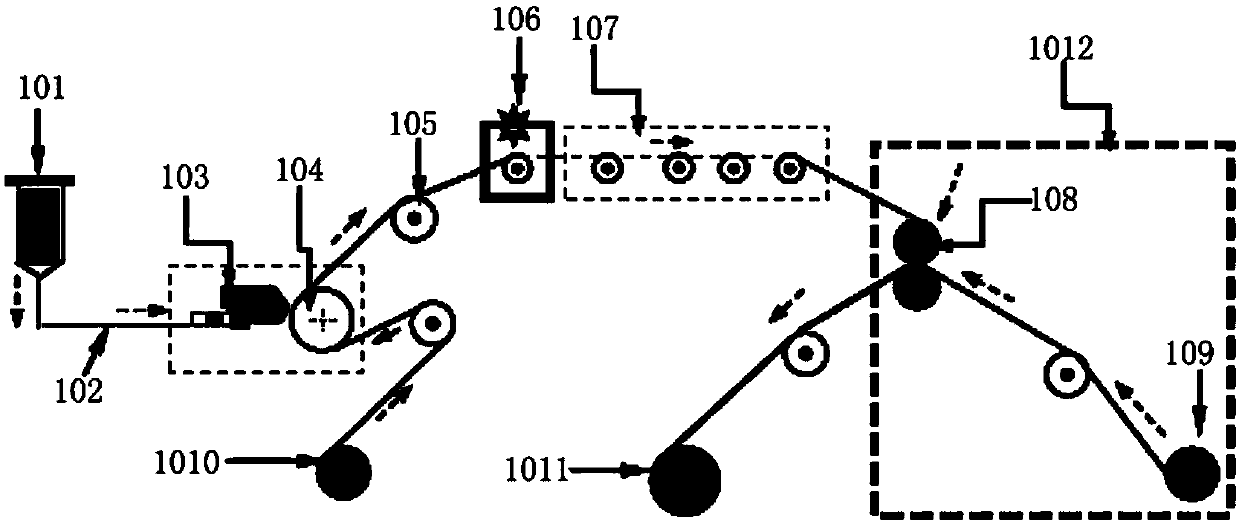

Photodiffusion agent, photodiffusion film and preparation method of photodiffusion film

ActiveCN102101971AGood levelingGood scratch resistanceDiffusing elementsPolyurea/polyurethane coatingsTransmittanceMicrometer

The invention provides a photodiffusion agent which contains polyurethane-acrylate, polymerizable monomers and organic particles, wherein the number-average molecular weight of the polyurethane-acrylate is 1000-10000, the polymerizable monomers are acrylate monomers of at least two multifunctional groups, and the average particle diameter of the organic particles is 1.8-30 micrometers. The invention also provides a photodiffusion film and a preparation method thereof. The photodiffusion film comprises a substrate and a photodiffusion layer attached to one surface of the substrate, wherein thephotodiffusion agent provided by the invention cures under the action of UV (ultraviolet) to form the photodiffusion layer. The photodiffusion layer in the photodiffusion film, which is prepared fromthe photodiffusion agent provided by the invention, has favorable mar resistance, and the photodiffusion film has favorable light transmittance and photodiffusion performance.

Owner:BYD CO LTD

Light diffusion plate for illuminated advertising board and preparation method of light diffusion plate

ActiveCN104987643AGood optical propertiesGood scratch resistanceOptical elementsTransmittanceEngineering

The invention discloses a light diffusion plate for an illuminated advertising board and a preparation method of the light diffusion plate. The light diffusion plate for the illuminated advertising board is characterized in that raw materials of the light diffusion plate comprise the following components of 100 parts of PMMA (Polymethyl Methacrylate) resin, 5 to 15 parts of SAN (Styrene Acrylonitrile) resin, 1 to 10 parts of nanosilicon dioxide, 0.1 to 1 part of octylphenyl salicylate and 0.5 to 3 parts of scratch resisting agent. The light diffusion plate for the illuminated advertising board has the advantages of scratch resistance, light transmittance, good flame retardance, no halogenated flame retardant and no secondary pollution.

Owner:上海金泛斯智能标识有限公司

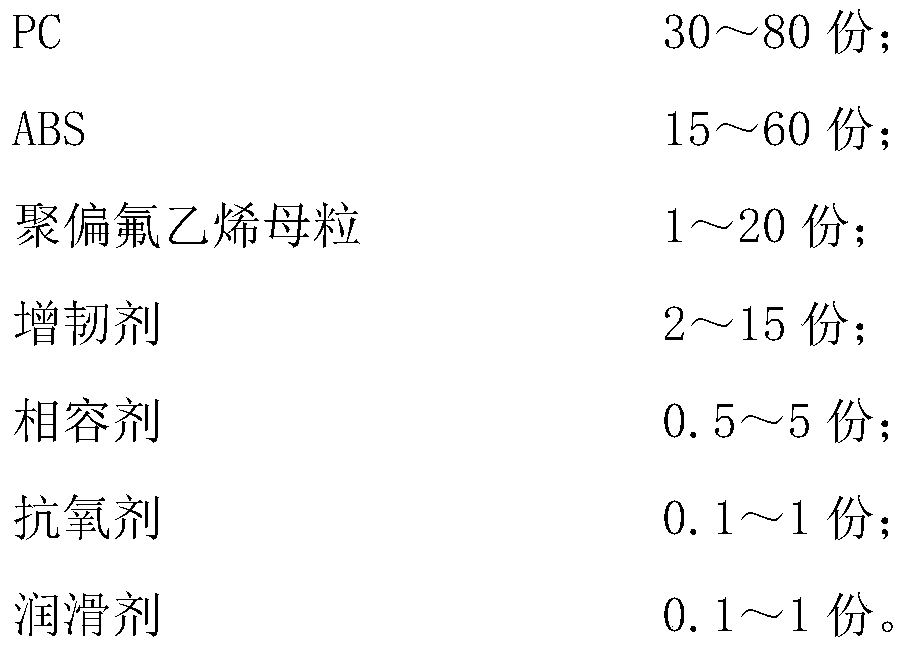

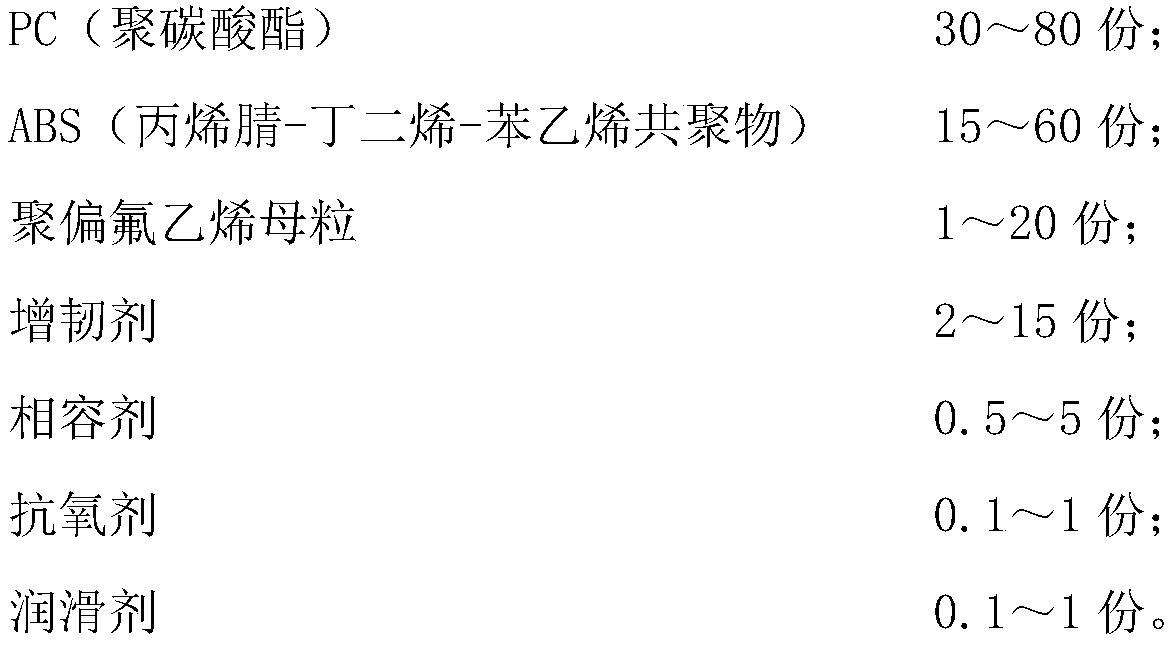

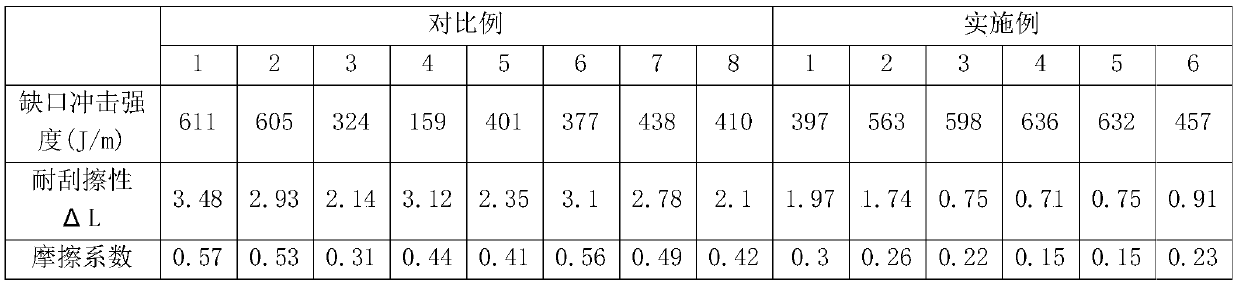

PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy with scratch resistance and preparation method thereof

The invention provides a PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy with scratch resistance and a preparation method thereof. The PC / ABS alloy comprises, by weight, 30-80 parts of PC, 15-60 parts of ABS, 1-20 parts of polyvinylidene fluoride masterbatch, 0.5-5 parts of a compatibilizer, 2-15 pats of a toughener, 0.1-1 part of an antioxidant, and 0.1-1 part of a lubricant. The preparation method comprises preparing the materials by weight, adding the materials into a medium-speed mixer except for the polyvinylidene fluoride masterbatch, mixing for 5-30 min to obtain a mixture,adding the mixture into a twin-screw extruder under controlled speed of 180-600 rpm, feeding the polyvinylidene fluoride masterbatch from the lateral side, melting and extruding, and granulating to obtain the finished PC / ABS alloy. Compared with the prior art, the PC / ABS alloy with scratch resistance provided herein has high processibility and high scratch resistance.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD

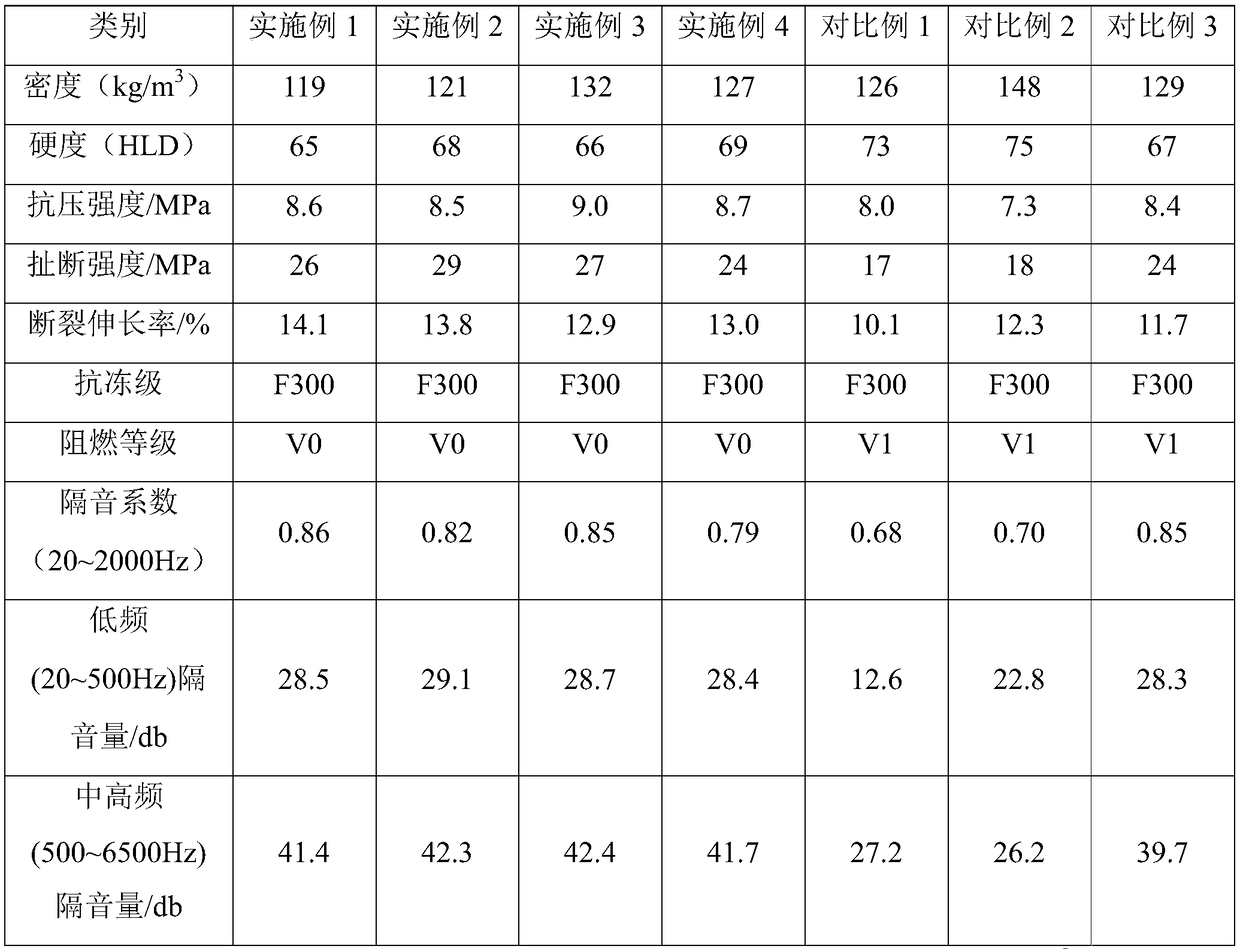

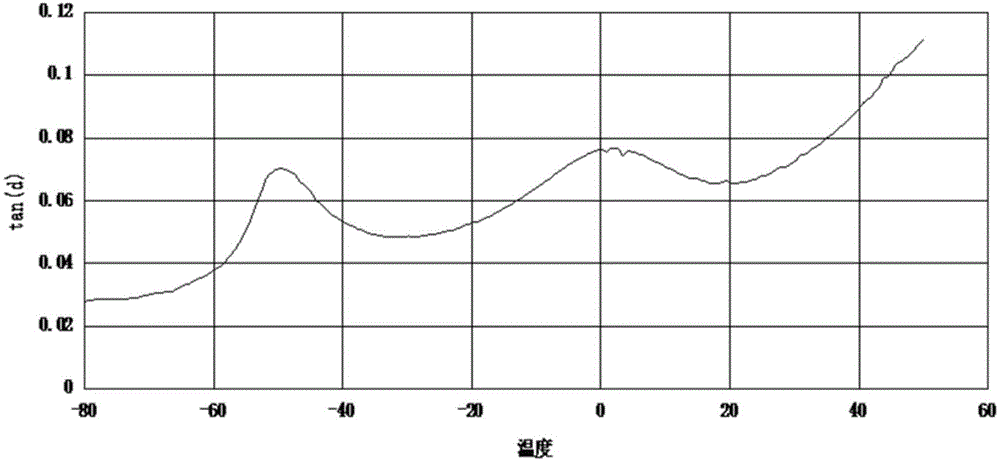

Sound insulating material and preparation method thereof

ActiveCN109054391AOvercome the disadvantages of poor sound insulationHigh impact strengthSodium stearateTurpentine

The invention discloses a sound insulating material. The sound insulating material is prepared from the following components in parts by weight: 60 to 80 parts of high damping silicone rubber, 4 to 6parts of hydroxy silicone oil, 12 to 25 parts of silica aerogel, 1 to 2 parts of dicumyl peroxide, 60 to 80 parts of PP resin, 18 to 25 parts of turpentine, 20 to 30 parts of white carbon black, 23 to38 parts of foam ceramic powder, 2 to 4 parts of barium sulfate, 0.4 to 0.9 part of sodium stearate, 0.3 to 0.5 part of active zinc oxide, 6 to 10 parts of diatomaceous earth, 3 to 7 parts of zinc borate, 5 to 8 parts of high vinyl silicone oil, 0.2 to 0.4 part of aluminate coupling agent, 3 to 5 parts of vulcanizing agent, and 1.4 to 1.9 parts of accelerator. The invention also discloses a preparation method of the sound insulating material. The sound insulating material provided by the invention has the characteristics of light weight, good mechanical performance, fire retarding, and effectively absorbing low-frequency sound waves, and has the advantages of simple preparation method, low cost and mass production.

Owner:广州凝博科技有限公司

Polypropylene composition and preparation method thereof

ActiveCN104558815AGood scratch resistanceGood anti-stress whitening propertiesWeight distributionPolypropylene

The invention relates to a polypropylene composition and a preparation method thereof. The polypropylene composition comprises polypropylene resin and a polymer composition, wherein the polymer composition comprises 40-70wt% of crystalline polypropylene A and 30-60wt% of an ethylene-propylene elastic copolymer B; both the molecular weight distribution index of the polypropylene composition and the molecular weight distribution index of the crystalline polypropylene A are greater than 4; the ratio of a melt index of the polypropylene composition to a melt index of the crystalline polypropylene A is 0.7-1.3. Products prepared by the polypropylene composition are high in scratch-resistant performance and stress-whitening-resistant performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hardened decorative film and preparation method thereof

ActiveCN111730945AHigh hardnessGood scratch resistanceLamination ancillary operationsAntifouling/underwater paintsPhotoinitiatorPhoto irradiation

The invention discloses a hardened decorative film and a preparation method thereof. The hardened decorative film comprises a base material, the base material sequentially comprises a first PET film,a PVC film and a second PET film from inside to outside, and a surface hardened film is arranged on the second PET film; the two film layers are attached through glue. The surface hardened film is prepared by coating UV hardening liquid, and the hardening liquid is prepared from the following raw material components: 43 to 57 parts of modified water-based acrylate, 40 to 60 parts of ethyl acetate,11 to 17 parts of nano silicon dioxide, 1 to 3 parts of a photoinitiator, 0.8 to 1.5 parts of a fluorine-containing stain-resistant additive and 0.5 to 1 part of a fluorine-modified acrylic acid leveling agent, wherein the modified water-based acrylate is prepared by a reaction of carboxyethyl cellulose, carbon nanotubes and water-based acrylate. A micro gravure process is adopted for coating, and after coating, the coating is cured under UV light irradiation to form a hardened decorative film with stain resistance, scratch resistance and high strength. The invention has the advantages of reasonable proportioning design and higher practicability.

Owner:JIANGSU SUNDERRAY LASER PACKAGING MATERIALS CO LTD

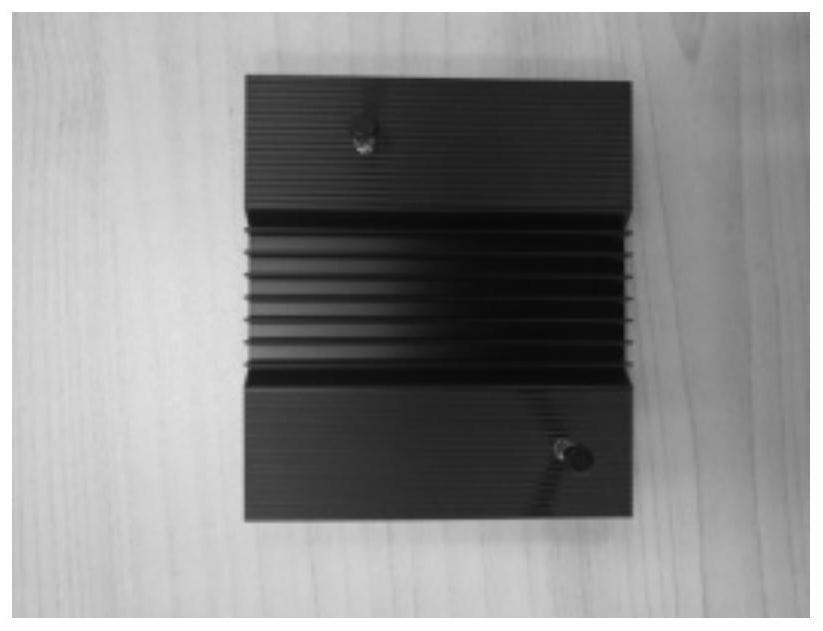

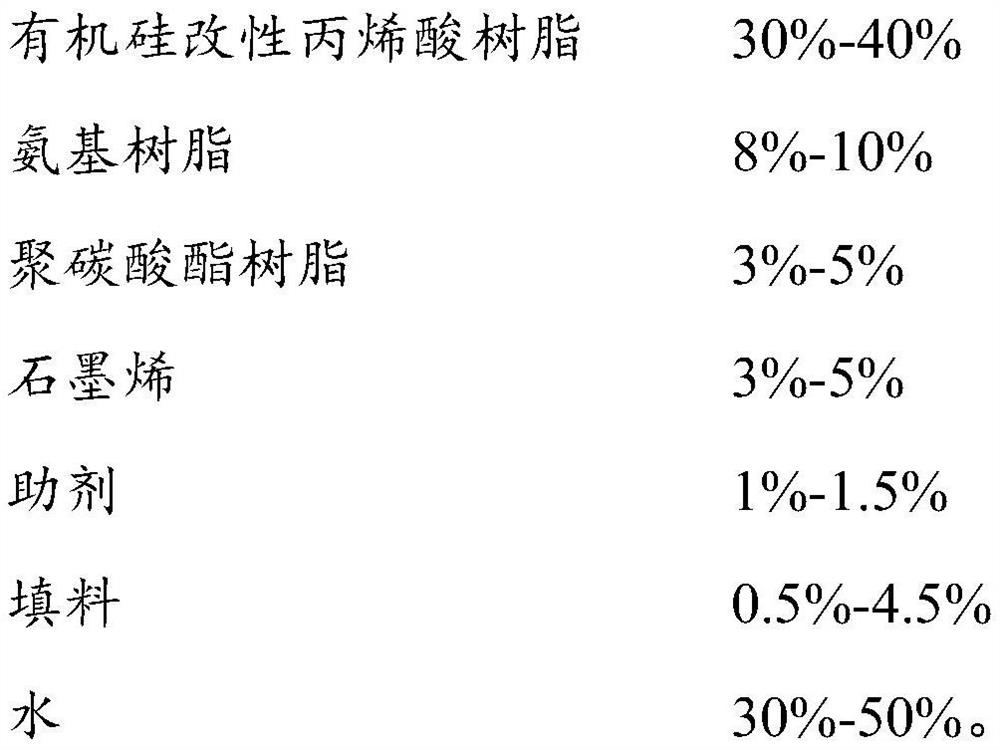

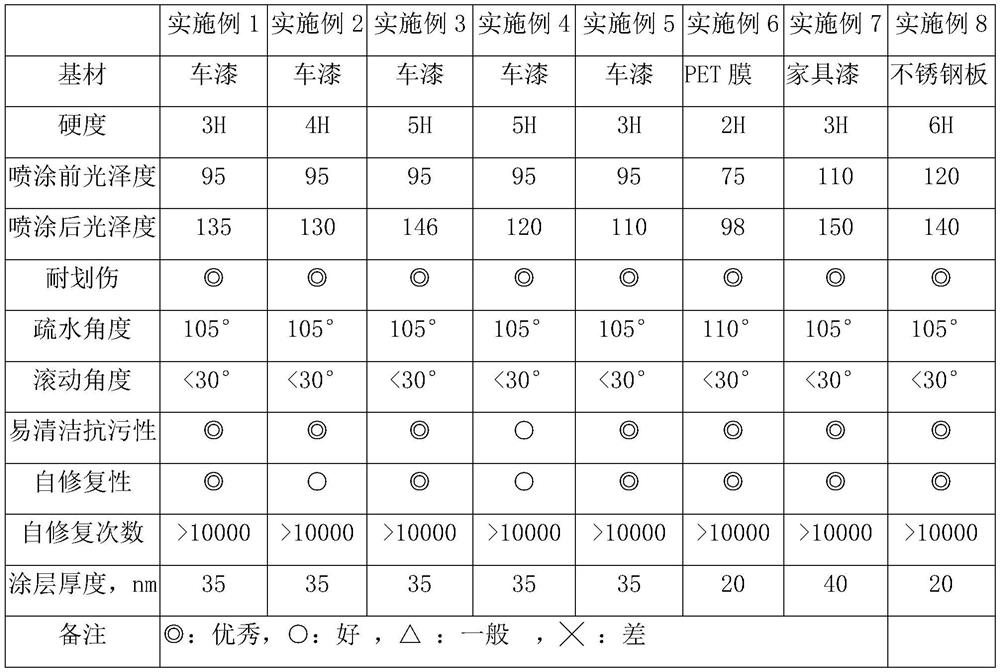

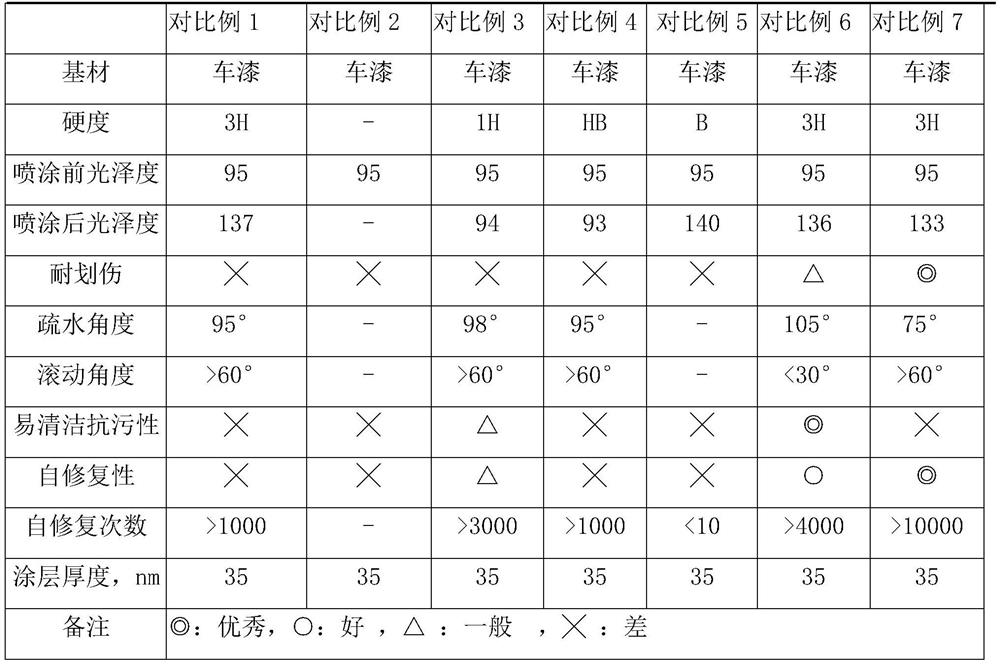

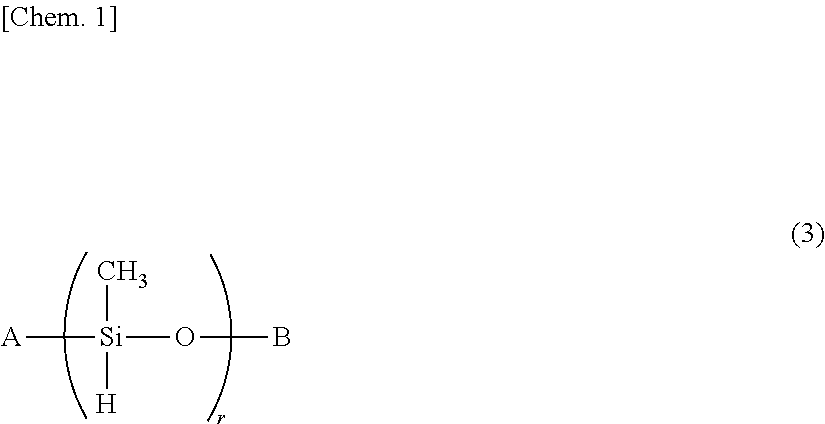

Graphene heat dissipation coating as well as preparation method and application thereof

PendingCN113025136AGood scratch resistanceEasy to prepareHeat-exchange elementsPolycarbonate coatingsPolycarbonateOrganosilicon

The invention belongs to the technical field of coatings, and particularly relates to a graphene heat dissipation coating as well as a preparation method and application thereof. The graphene heat dissipation coating comprises organic silicon modified acrylic resin, amino resin, polycarbonate resin, graphene, auxiliaries, a filler and water, has good scratch resistance, wear resistance and heat dissipation performance, and has the advantage of being environmentally friendly due to the fact that all the components are environmentally friendly. When the graphene heat dissipation coating is used for heat dissipation of an electric appliance, a relatively good heat dissipation effect can be provided for the electric appliance, the problems of paint peeling and the like caused by overlong service time of the electric appliance can be avoided, and the graphene heat dissipation coating has a good application prospect and market value.

Owner:SHENZHEN GRAPHENE LAND LEGEND TECH CO LTD

Method for implementing transfer printing by utilizing thermal-dye-sublimation transfer printing film

ActiveCN102602187AGood water resistanceGood scratch resistanceDuplicating/marking methodsEngineeringHigh pressure

The invention belongs to the technical field of thermal transfer printing films, and particularly relates to a method for implementing transfer printing by utilizing a thermal-dye-sublimation transfer printing film. The method comprises the following steps of: (1) making the thermal-dye-sublimation transfer printing film into a cylindrical pipeline with a basic film being arranged inside the cylindrical pipeline according to the size of a body to be subjected to transfer printing; (2) coating polyurethane resin on the surface of the body to be subjected to transfer printing, and then drying the body to be subjected to transfer printing for 3 to 5 minutes at the temperature of 180 to 200 DEG C; (3) inserting the coated body to be subjected to transfer printing into the cylindrical pipeline which is made of the thermal-dye-sublimation transfer printing film in (1); and (4) preheating the cylindrical pipeline holding the coated body to be subjected to transfer printing for 30 to 60 seconds at the temperature of 40 to 60 DEG C and finally heating for 3 to 5 minutes at the temperature of 160 to 180 DEG C to complete the transfer printing. The method does not need conditions such as vacuum, high temperature and high pressure, and the transfer printing can be implemented on the body to be subjected to transfer printing under a low-temperature condition, so that the loss of the basic film is not caused, mass production can be simply realized, and the efficiency of the method is 25 to 35 times of that of a traditional method.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

Intelligent self-repairing easy-to-clean anti-fouling nano coating and preparation method thereof

ActiveCN112280458AExcellent toughness and plasticityGood scratch resistanceAntifouling/underwater paintsPaints with biocidesSolventCorrosion resistant

The invention discloses an intelligent self-repairing easy-to-clean anti-fouling nano coating. A coating layer formed by the intelligent self-repairing easy-to-clean anti-fouling nano coating has thecharacteristics of corrosion resistance, aging resistance, high stain resistance, scratch resistance, self-repairing and the like. The technical scheme comprises an agent A and an agent B, wherein theagent A comprises the following components in parts by weight: 20-40 parts of self-repairing resin PU-DA, 5-10 parts of auxiliary resin, 1-3 parts of a catalyst, 2-4 parts of nano silicon dioxide, 0.2-0.4 part of a defoaming agent, 0.05-0.15 part of a base material wetting agent, 1.5-2.5 parts of a scratch-resistant auxiliary agent, 2-3 parts of an anti-fouling auxiliary agent and 40-70 parts ofa mixed solvent; the agent B comprises the following components in parts by weight: 43.5-48.5 parts of a curing agent A, 1-5 parts of a curing agent B and 0.5-1.5 parts of a diluent; the invention belongs to the technical field of coatings.

Owner:广州纳客新材料科技有限公司

Wear-resistant paint used on motor surfaces

The invention relates to a wear-resistant paint used on motor surfaces. The invention is characterized in that the wear-resistant paint is prepared from the following components in parts by weight: 40-50 parts of modified epoxy resin, 10-14 parts of modified mineral slag, 2-4 parts of titanium white, 0.5-1 part of calcium carbonate, 0.2-0.8 part of talcum powder, 1-2 parts of leveling agent, 0.5-1 part of matting agent, 2-3 parts of hand feeling agent, 12-16 parts of reinforcing fiber and 70-80 parts of dimethylbenzene. The wear-resistant paint prepared from the modified epoxy resin is easier for the fusion of the reinforcing fiber and modified mineral slag, so that the reinforcing fiber and modified mineral slag can be uniformly distributed in the paint without precipitation, and thus, the brushed paint has uniform components; and the added reinforcing fiber and modified mineral slag can enable the paint to be brushed uniformly and to have favorable wear resistance and scratch resistance.

Owner:安徽创业机电设备有限公司

Paint Composition, a Method of Paint Finishing and Painted Objects

InactiveUS20080227918A1Excellent acid resistance and resistance and water resistance and weather resistanceGood scratch resistanceCoatingsLactone CompoundStructural unit

Disclosed herein is a paint composition, comprising a hydroxyl group containing resin (A), having a hydroxyl group value of from 200 to 400 mgKOH / g, and comprising in a resin solid fraction less than 25 weight % of structural units based on a lactone compound, a hydroxyl group containing resin (B), having a hydroxyl group value of from 50 to 200 mgKOH / g, and comprising in the resin solid fraction from 25 to 75 weight % of structural units based on a lactone compound, and a crosslinking agent (C) comprising at least one functional group which reacts with hydroxyl groups, wherein the proportions by weight (A) / (B) of the hydroxyl group containing resin (A) and the hydroxyl group containing resin (B), based on the resin solid fraction, are from 90 / 10 to 10 / 90.

Owner:BASF COATINGS JAPAN

Aromatic polycarbonate resin composition and molded article formed therefrom

InactiveUS20140155548A1Good scratch resistanceImprove impact resistanceChemistryBisphenol-A-polycarbonate

To provide an aromatic polycarbonate resin composition which has an impact resistance improved by blending of an impact strength improver and which also has an excellent transparency and a good surface hardness. The aromatic polycarbonate resin composition includes, with respect to 100 parts by mass of a resin component containing 55 to 85 percent by mass of an aromatic polycarbonate resin (A) having a mass average molecular weight of 15,000 to 40,000 and 15 to 45 percent by mass of a (meth)acrylate copolymer (B) which has a mass average molecular weight of 5,000 to 30,000 and which is composed of an aromatic (meth)acrylate unit (b1) and a methyl (meth)acrylate unit (b2) at a mass ratio (b1 / b2) of 5 to 50 / 50 to 95, 1 to 20 parts by mass of an impact strength improver (C). A refractive index nab of the resin component at a wavelength of 589 nm and a refractive index nc of the impact strength improver (C) at a wavelength of 589 nm satisfy the following formula i).−0.01≦nab−nc≦+0.01 Formula i)

Owner:MITSUBISHI ENG PLASTICS CORP

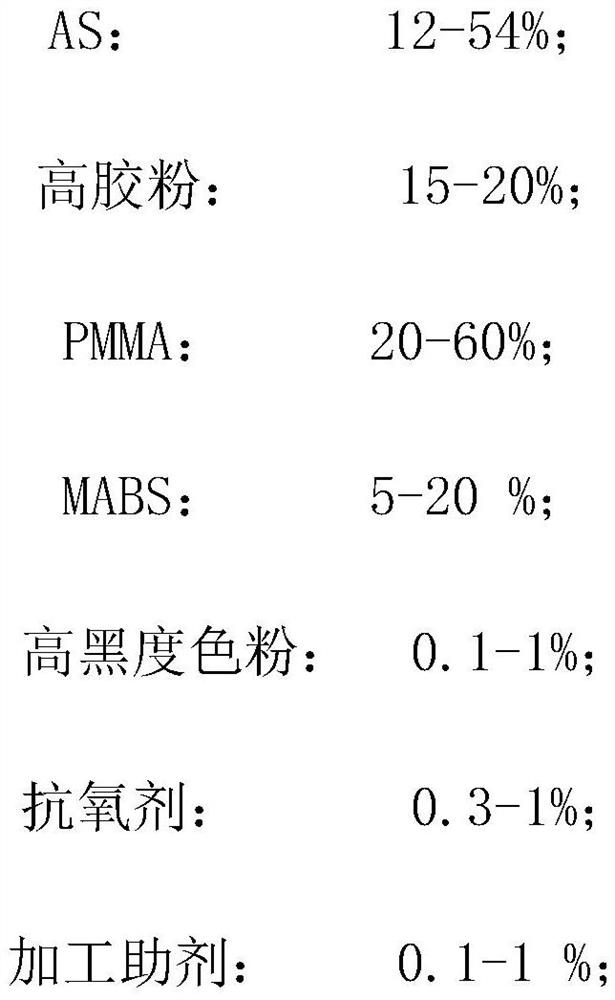

Ultra-black bright high-gloss scratch-resistant ABS compound as well as preparation method and application thereof

The invention provides an ultra-black bright high-gloss scratch-resistant ABS compound as well as a preparation method and application thereof. The ultra-black bright high-gloss scratch-resistant ABScompound comprises the following components in percentage by mass: 12-54% of AS; 15-20% of high glue powder; 20-60% of PMMA; 5-20% of MABS; 0.1-1% of a high-blackness toner; 0.3-1% of an antioxidant;and 0.1-1% of a processing aid; the high-blackness toner is a compound of inorganic black powder and organic black powder; and the mass ratio of the inorganic black powder to the organic black powderin the compound is (5-30): (21-106). The ABS compound provided by the invention has the characteristic of high blackness, and the blackness value (L value) of the material can be controlled within therange of less than 26.2.

Owner:TIANJIN KINGFA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com