Preparation method of scratch-resistant lacquer-free ABS moulding composition with high glaze

A molding composition and anti-scratch technology, which is applied in the field of preparation of high-gloss anti-scratch paint-free ABS molding composition, which can solve the problems of low application flexibility, limited surface gloss improvement, material surface gloss, hardness research, etc. problem, to achieve the effect of low cost, good surface gloss and good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

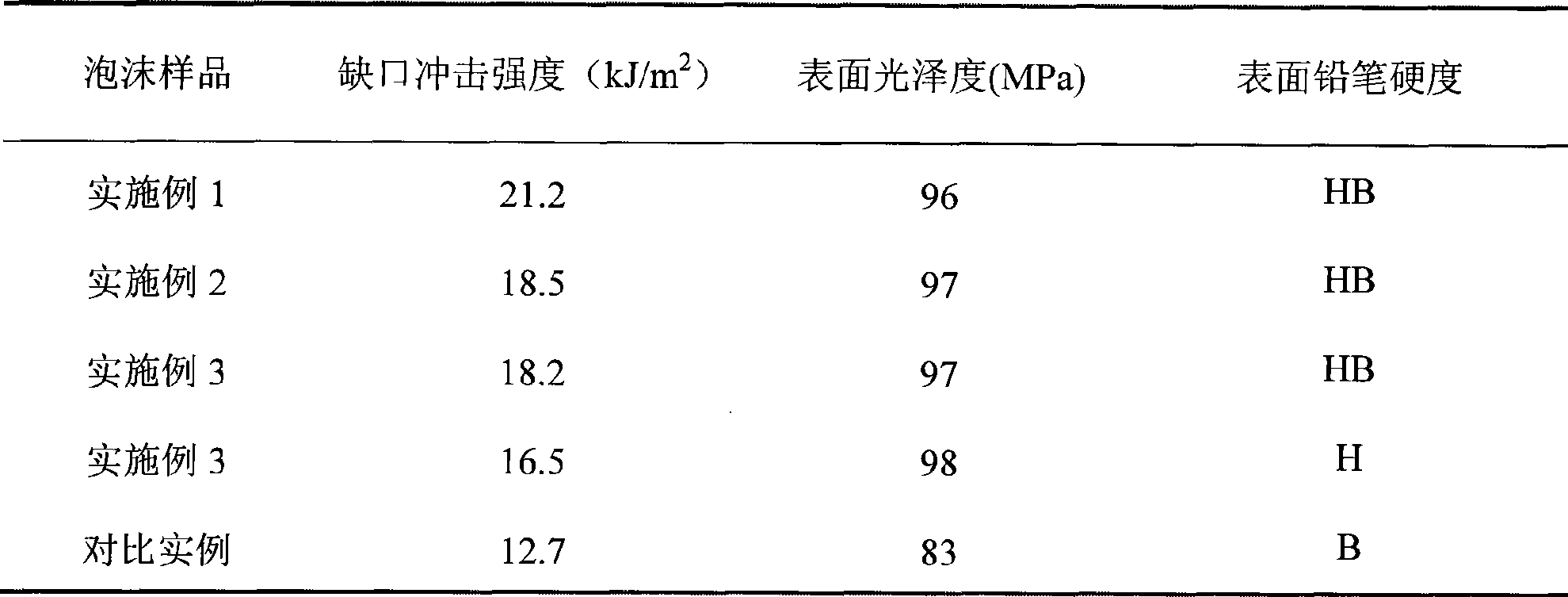

Examples

Embodiment 1

[0025] Example 1: 40 parts of ABS with a rubber phase content of 25%, an average rubber phase particle size of 150 nm, and a melt index of 1.8, and 40 parts of ABS with a rubber phase content of 35%, an average rubber phase particle size of 450 nm, and a melt index of 1.2 ABS, 20 parts of SAN with a melt index of 4.2, 4 parts of high-pigment carbon black masterbatch and 0.1 part of antioxidant are mixed, melted and extruded into pellets by twin-screw extruder, and the extruded pellets are made by injection molding Samples for relevant performance tests.

Embodiment 2

[0026] Example 2: 30 parts of ABS with a rubber phase content of 20%, an average rubber phase particle size of 130 nm, and a melt index of 2.5, and 50 parts of ABS with a rubber phase content of 35%, an average rubber phase particle size of 400 nm, and a melt index of 1.2 ABS, 20 parts of PMMA with a melt index of 3.6, 4 parts of high-pigment carbon black masterbatch and 0.5 parts of antioxidant are mixed, melted and extruded into pellets by twin-screw extruder, and the extruded pellets are made by injection molding Samples for relevant performance tests.

Embodiment 3

[0027] Example 3: 30 parts of ABS with a rubber phase content of 20%, an average rubber phase particle size of 130 nm, and a melt index of 2.5, and 30 parts of ABS with a rubber phase content of 35%, an average rubber phase particle size of 450 nm, and a melt index of 1.2 ABS, 40 parts of SAN with a melt index of 3.6, 5 parts of medium pigment carbon black masterbatch and 0.3 parts of antioxidant are mixed, melted and extruded to pelletize by twin-screw extruder, and the extruded pellets are made by injection molding Samples for relevant performance tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com