Patents

Literature

50results about How to "Good antistatic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antistatic polypropylene composite material and method for preparing same

The invention discloses an antistatic polypropylene composite material and a method for preparing the same and belongs to the technical field of modifying and processing polymers. The antistatic polypropylene composite material is prepared from the following raw materials in percentage by weight: 50 to 98 percent of polypropylene, 0 to 30 percent of inorganic filler, 0 to 20 percent of flexibilizer POE, 1 to 5 percent of antistatic agent, 0.1 to 1 percent of antioxidant and 0 to 1 percent of other auxiliary agents. The composite material and the method have the advantages that: 1, a proper amount of tin oxide is added in the composite material system, so that the prepared polypropylene composite material has better antistatic property; 2, under a condition of guaranteeing the antistatic property, the physical mechanical properties of the prepared polypropylene composite material are hardly affected; and 3, the method for improving the antistatic property of the polypropylene composite material is simple in preparation process and low in production cost.

Owner:SHANGHAI PRET COMPOSITES

Mother stock of polyvinyl carbon nanotube anti-static composite material and anti-static composite material based on mother stock

InactiveCN1670070AGood antistatic propertiesComprehensive mechanical propertiesAntistatic MaterialsMaleic anhydride

The invention relates to an anti-static modified material with carbon nanotubes (CNTs) predominantly and a process which is a thermal oxidation treatment with acid together with a ball grinding surface treatment to CNTs and comprises: adding maleic anhydride grafted polyethylene, coupling agents and EPT rubber to prepare the high concentration masterbatch of CNTs / PE anti-static composite material by solution blending and melt blending methods, mixturing the said masterbatch with common PE in a finite proportion to melt blend and prill, then getting the final CNTs / PE anti-static composite material. The electrical surface resistivity and volume resistivity can reach the operating requirements of the anti-static material when the content of CNTs is only 0.3 wt % in the CNTs / PE anti-static composite material in the invention.

Owner:EAST CHINA UNIV OF SCI & TECH

Anti-static poly(ethylene terephthalate) material and preparation method thereof

InactiveCN101230186AGood antistatic propertiesEasy to prepareOther chemical processesWater soluble polymersWater soluble

The invention discloses an antistatic polyethylene glycol terephthalate and a preparation method thereof. The antistatic polyethylene glycol terephthalate calculated according to the parts by weight comprises 96.8-89.5 parts of polyethylene glycol terephthalate, 3-10 parts of antistatic agent, and 0.2-0.5 part of antioxidant. The antioxidant is composed of [Beta-(3,5-di-tert-butyl-4-hydroxy-phenyl) methyl acetic acid] pentaerythritol ester and tri dimethylphenyl phosphate (2,4-di-tert-butyl-benzyl) according to the mol ratio of 1:2. The antistatic agent comprises water-soluble polymer sodium polystyrene sulfonate and nano-silver colloid with equal molar, and the preparation method comprises the following steps: the water-soluble polymer sodium polystyrene sulfonate and the nano-silver colloid with equal molar flow back in water for 5-6 hours, the coordination reaction happens between the molar water-soluble polymer sodium polystyrene sulfonate and the nano-silver colloid to cause the molar water-soluble polymer sodium polystyrene sulfonate and the nano-silver colloid to be combined together, and then the composition is dried and ground. The antistatic polyethylene glycol terephthalate has good antistatic performance, the preparation process is simple, and the preparation method is convenient and easy to be operated.

Owner:合诚技术股份有限公司

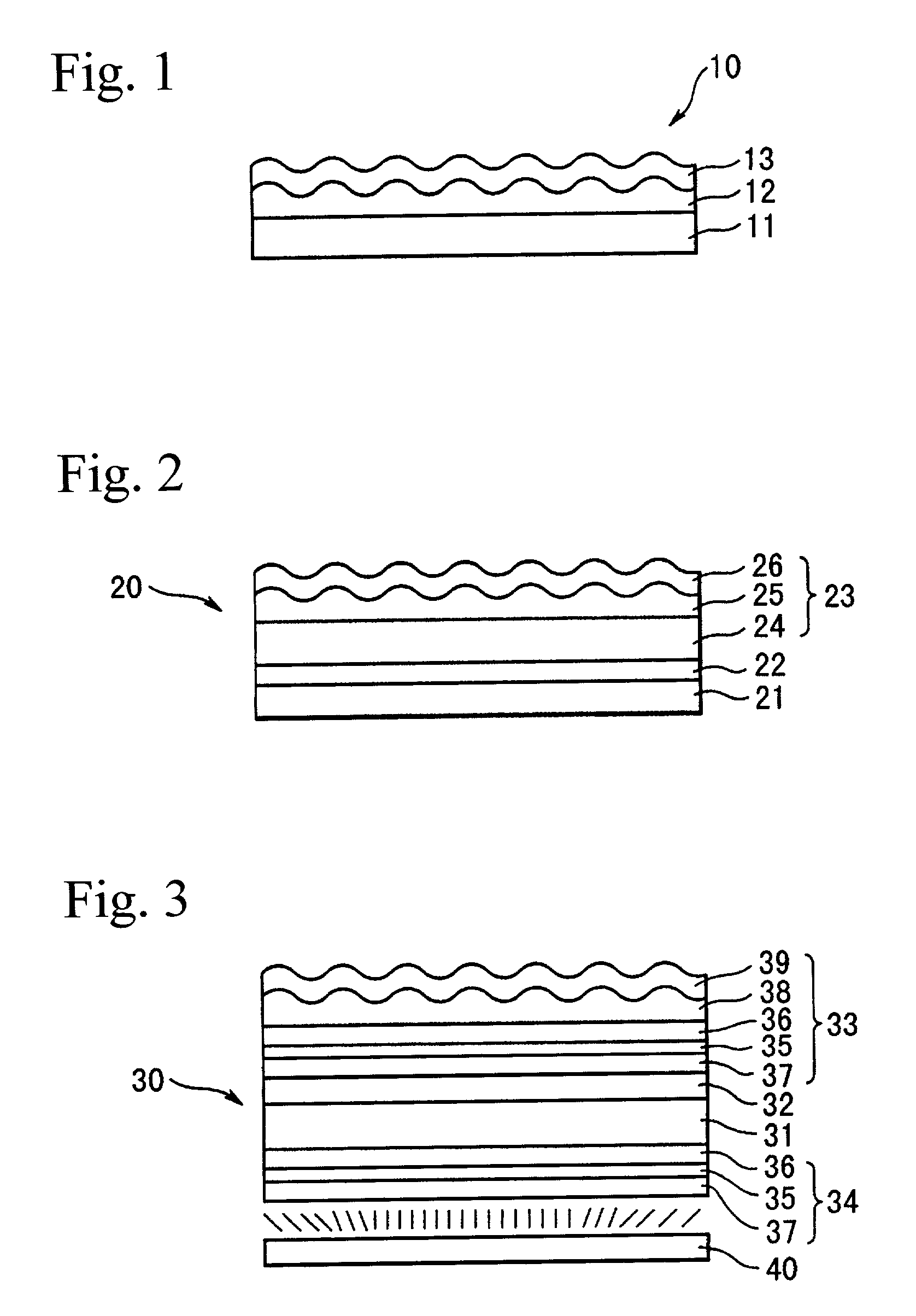

Anti-static anti-reflective film

InactiveUS20020058147A1Superior optical property and physical propertyGood antistatic propertiesSynthetic resin layered productsCoatingsChemistryDisplay device

The present invention provides an anti-static anti-reflective film which exhibits not only superior optical properties and physical properties, but also superior anti-static properties, and which is suitable for use in displays. A low reflective layer is provided by coating a silicon compound containing at least a cation-modified silicon compound on the surface of a transparent substrate directly or via another layer and by curing, and therefore an anti-static anti-reflective film is produced.

Owner:TOMOEGAWA PAPER CO LTD

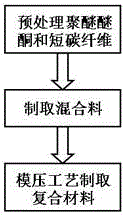

Polyether-ether-ketone heat conduction composite material and preparation method thereof

InactiveCN105778407AGood thermal conductivityGood antistatic propertiesPre treatmentPoly ether ether ketone

The invention provides a polyether-ether-ketone heat conduction composite material and a preparation method thereof. The polyether-ether-ketone heat conduction composite material comprises raw material components of polyether-ether-ketone resin, copper powder and short carbon fiber. The preparation method comprises the following steps: a) pretreating the polyether-ether-ketone resin and the short carbon fiber; b) preparing a mixed material; c) performing a mold pressing process, thereby obtaining the composite material. The invention discloses the polyether-ether-ketone heat conduction composite material and the preparation method thereof, the composite material is prepared by a mold pressing method, has excellent heat conduction properties and relatively good anti-static functions, and is very wide in market prospect.

Owner:SUZHOU YAKE PLASTIC RUBBER CO LTD

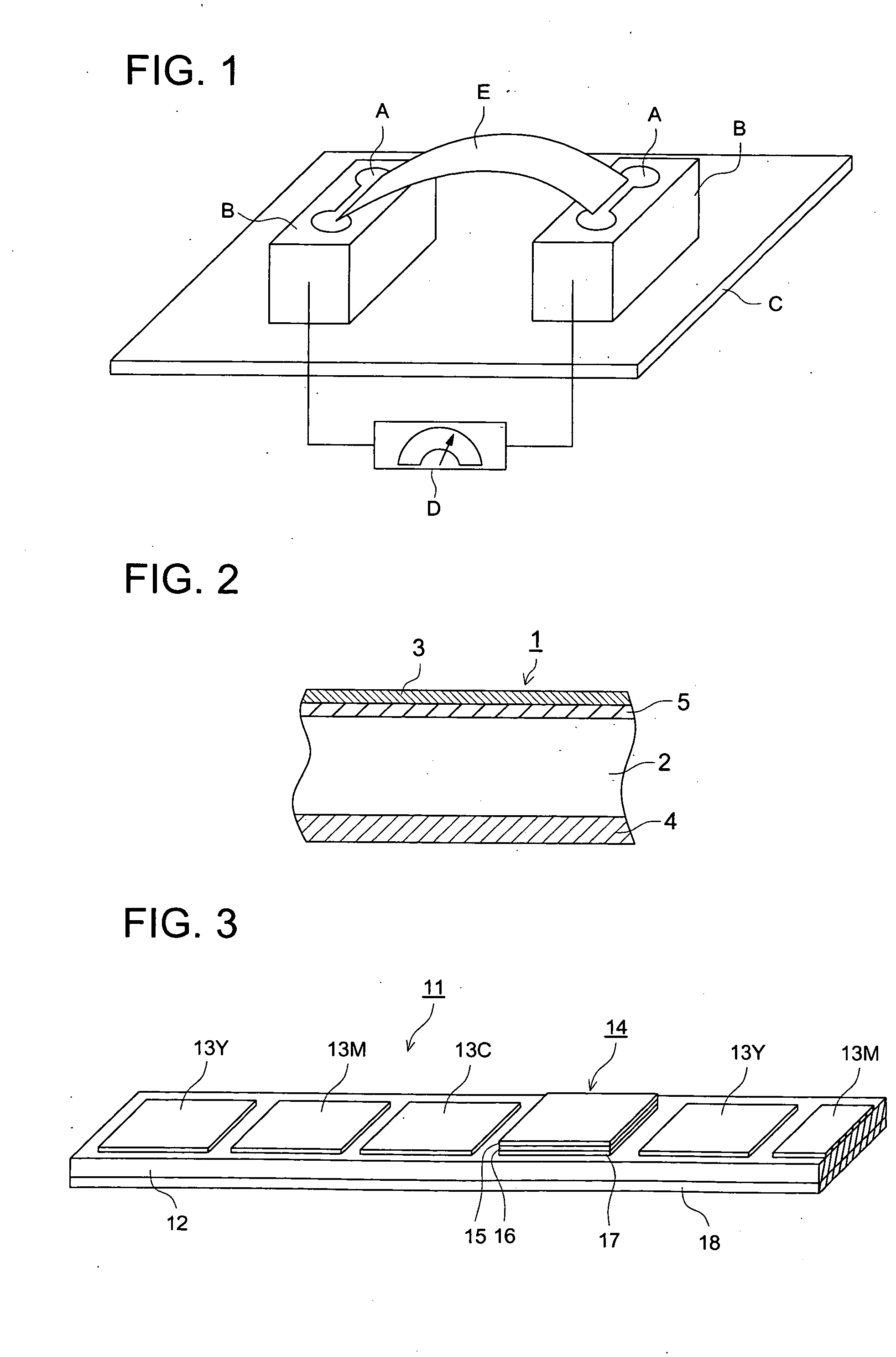

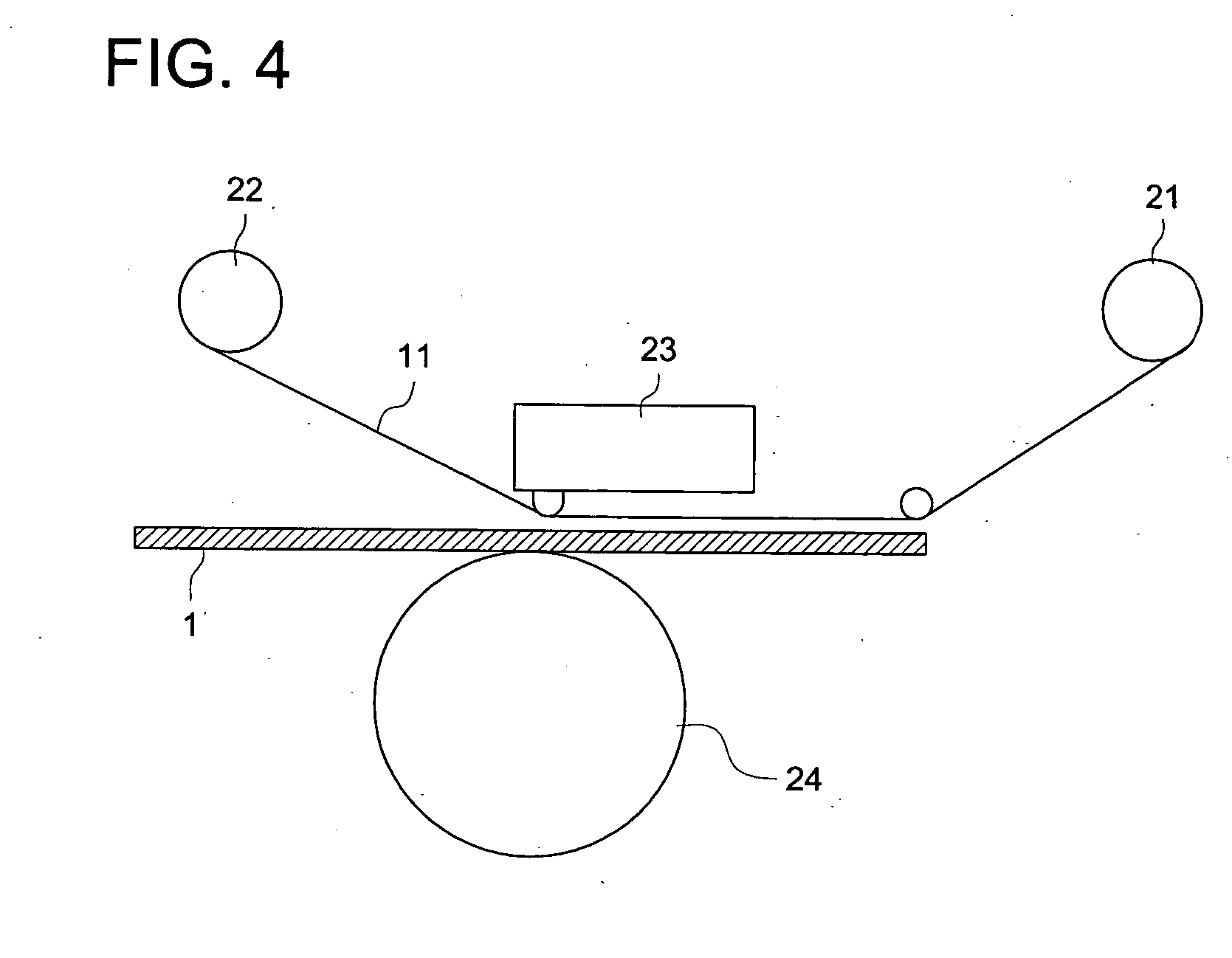

Thermal transfer image receiving sheet and image forming method using the same

InactiveUS20050068406A1Good antistatic propertiesExcellent handling propertyRecording apparatusThermographySalt bridgeOhm

A thermal transfer image receiving sheet comprising a support having an image receiving layer on one surface of the support and a backing layer on the other surface of the support, wherein, (a) a first electrical resistance of the thermal transfer image receiving sheet is in a range of 1×108-1×1012 ohms per square before the transferable protection layer is transferred; and (b) a second electrical resistance of the thermal transfer image receiving sheet is in a range of 1×108-1×1012 ohms per square after the transferable protection layer is transferred and after the backing layer is removed, the first and second electrical resistances being measured by a salt bridge method.

Owner:KONICA MINOLTA PHOTO IMAGING

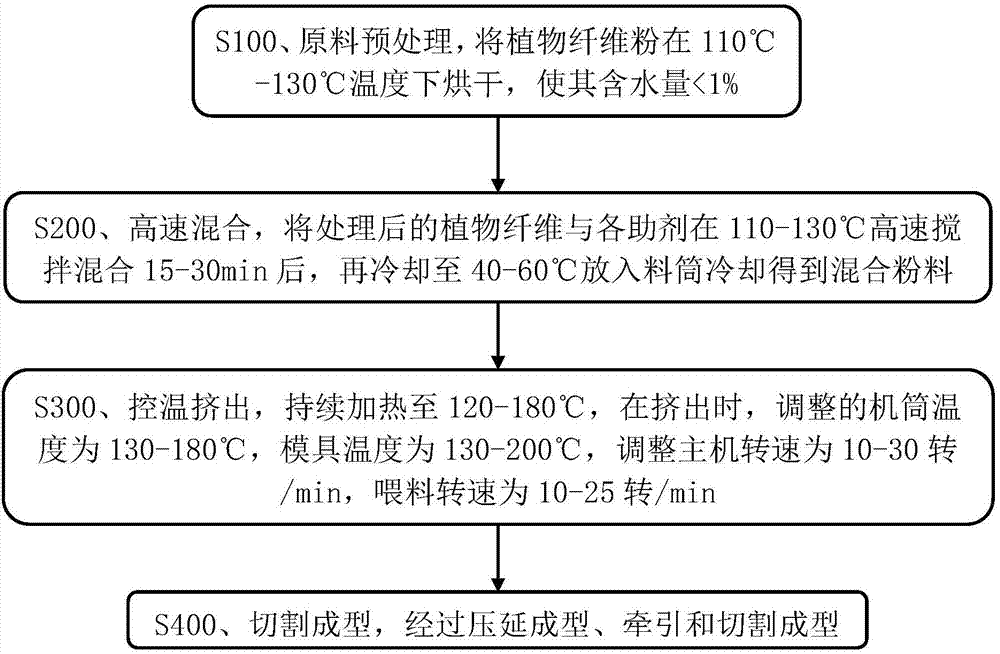

Antistatic wood-plastic composite material and preparation method thereof

InactiveCN107880448AGood mechanical propertiesGood antistatic propertiesLayered structureWater content

The invention discloses an antistatic wood-plastic composite material and a preparation method thereof. The antistatic wood-plastic composite material is prepared from the following raw materials in parts by weight: 30 to 60 parts of PVC resin powder, 10 to 30 parts of calcium filling agent, 15 to 25 parts of plant fiber powder, 1 to 5 parts of plasticizing adjusting agent, 1 to 3 parts of processing additives, 2 to 6 parts of environment-friendly stabilizer, 1 to 3 parts of lubricating agent, 1 to 5 parts of toughening agent, and 10 to 20 parts of antistatic agent. The preparation method comprises the following steps: drying at a high temperature, enabling the water content to be less than 1 percent, stirring and mixing at high speed at the temperature of 110 to 130 DEG C, adding the treated mixed powder into an extruder, extruding at the high temperature, calendaring molding, drawing and cutting and molding, wherein graphene powder of a layered structure is uniformly distributed in PVC and forms a netted structure with the PVC, so that the wood-plastic composite material prepared by the invention is excellent in various mechanical performance and good in antistatic performance, wherein the antistatic performance (specific resistance) can reach the order magnitude of 106 ohm / sq; and moreover, the whole production process is simple and stable and suitable for industrialized production.

Owner:SHANDONG XIAGUANG INDAL +1

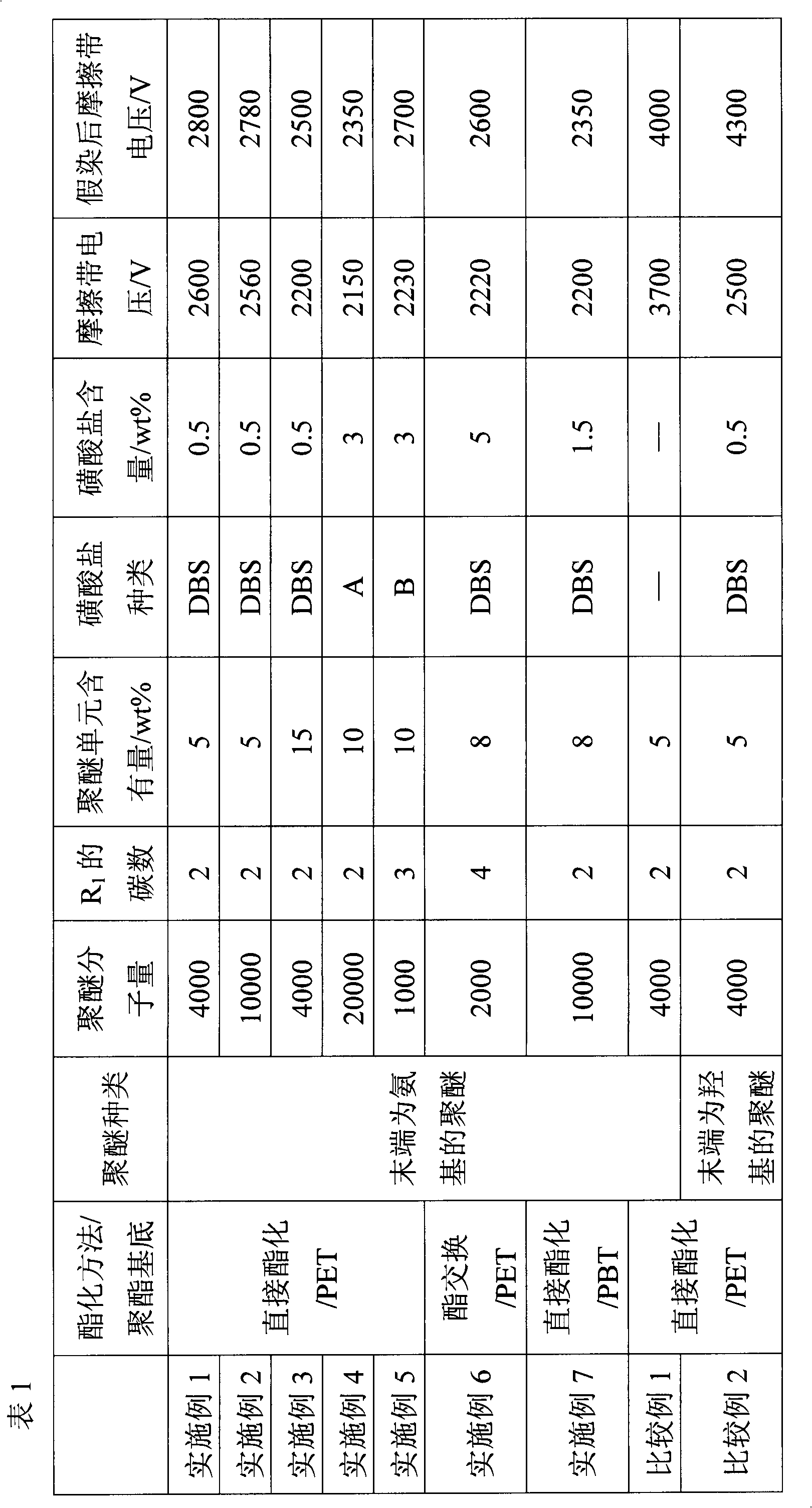

Antistatic polyester, preparation method and application of antistatic polyester

InactiveCN103122058AReduce churnGood antistatic propertiesMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses antistatic polyester, a preparation method and application of the antistatic polyester. The antistatic polyester comprises polyether with amino end groups and sulphonate. The polyether with the amino end groups overcomes the defect of easy hydrolyzation of polyether with hydroxyl end groups, so that the antistatic performance can be still maintained after the antistatic polyester is dyed or reduced. By aid of the sulphonate, the additive amount of the polyether with the amino end groups is reduced to guarantee the spinnability of the antistatic polyester. The antistatic polyester can be widely applied to fibers.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Long-lasting antistatic polyester random copolymer and preparation method and use thereof

PendingCN106866949AThe synthesis process is simpleGood antistatic propertiesPolyester coatingsFunctional monomerLong lasting

The invention discloses a long-lasting antistatic polyester random copolymer. The long-lasting antistatic polyester random copolymer is prepared from terephthalic acid, ethylene glycol and an antistatic functional monomer. Through use of the terephthalic acid, ethylene glycol and antistatic functional monomer, the long-lasting antistatic polyester random copolymer obtained by copolymerization has good antistatic performances. Through mixing of the long-lasting antistatic polyester random copolymer and a PET material, the long-lasting antistatic polyester random copolymer can move to the surface of PET so that antistatic properties of the PET surface are greatly improved and the problem that the existing production technology produces accumulation of static electricity on the surface of PET plastic or fiber products is solved. The long-lasting antistatic polyester random copolymer realizes a low cost and is prepared through simple processes. The random copolymer has a PET chain section and thus the random copolymer has good adhesion with the substrate PET, has good antistatic durability, has excellent mechanical properties and high temperature stability and has a great application prospect and market value.

Owner:SHANTOU UNIV

Production process of antistatic kitted fabric

InactiveCN105463677AGood antistatic propertiesFeel plumpWeft knittingBleaching apparatusCotton fibreSizing

The invention provides a production process of an antistatic kitted fabric, and belongs to the technical field of multifunctional knitted fabrics. The production process of the antistatic kitting fabric comprises the specific steps that firstly, antistatic fibers and cotton fibers are woven into a knitted gray fabric on a circular knitting machine according to blended yarn of different proportions, then the knitted gray fabric is sequentially subjected to a refining and bleaching process, a dyeing process, an antistatic functional afterfinish process and a sizing process, and the functional knitted fabric with the good antistatic function and excellent comfort is produced. The knitted fabric produced through knitting, refining and bleaching, dyeing, finishing, sizing and other processes has the excellent antistatic performance, and is full in hand feeling and good in breathability, the drapability of the fabric is excellent, and the finally prepared knitted fabric is stable in quality and still has the good antistatic effect after being washed many times. The antistatic kitted fabric is low in production technical cost, and has obvious economic value and applicability.

Owner:BAOJI JINJIAN DIGITAL KNITTING LIMITED LIABILITY

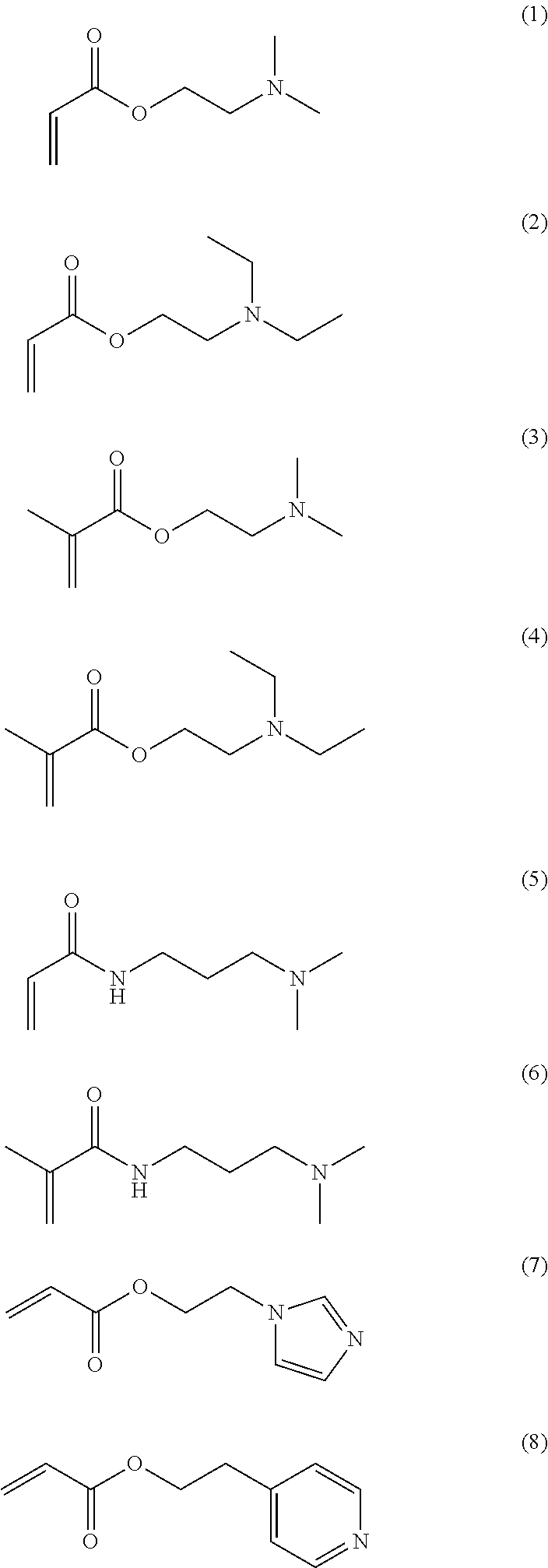

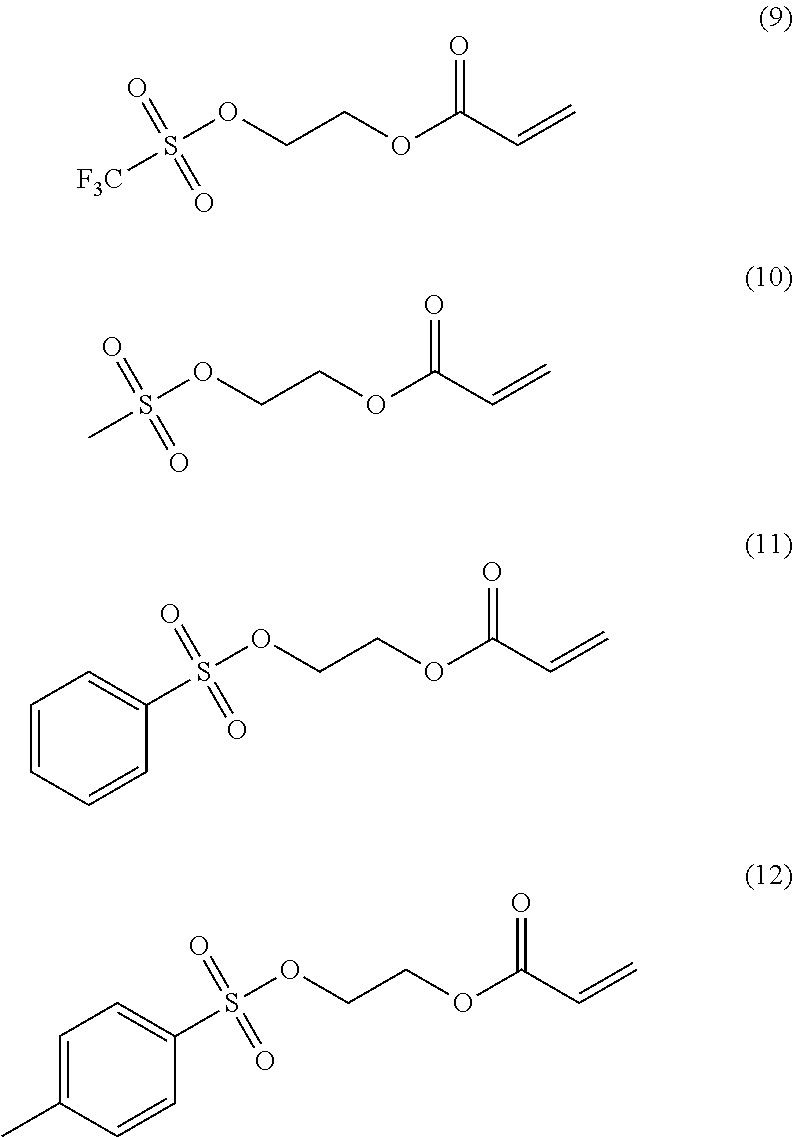

Hydrophobic polyquaternary-ammonium-salt antistatic agent for oil products and preparation method of hydrophobic polyquaternary-ammonium-salt antistatic agent

ActiveCN106190369AGood antistatic propertiesReduce system viscosityLiquid carbonaceous fuelsChemistryAntistatic agent

The invention relates to a hydrophobic polyquaternary-ammonium-salt antistatic agent for oil products and a preparation method of the hydrophobic polyquaternary-ammonium-salt antistatic agent. The preparation method includes the steps of firstly, dissolving methyl acrylyl oxyethyl trimethyl ammonium chloride, long chain alkyl acrylate and initiator azodiisobutyronitrile into a low-molecular-weight alcohol solvent to form a monomer solution; secondly, adding a hydrocarbon solvent into a container, stirring, heating, and dropwisely adding the monomer solution obtained in the first step after the heating; thirdly, heating after the dropwise adding, and then preserving the heat; fourthly, washing the solution after the reaction in cold water, and stirring fast to obtain a crude product; fifthly, subjecting the crude product to vacuumizing filtration, and then performing vacuum drying to obtain the hydrophobic polyquaternary-ammonium-salt antistatic agent. The testing results obtained by using distilled aviation kerosene and standard base oil as testing oil show that the novel antistatic agent prepared by the method is excellent in antistatic performance and can be used as the antistatic agent for the oil products.

Owner:NORTHWEST UNIV

Antistatic molded article and antistatic coating

InactiveUS20050230666A1Without deteriorating surface smoothnessGood antistatic propertiesLayered productsConductive materialSmooth surfaceSurface resistivity

An antistatic molded article obtained only by coating a substrate with an antistatic paint, which antistatic molded article has smooth surface, does not deteriorate the transparency and coloration of substrate and excels in antistatic properties. In particular, an antistatic molded article comprising a substrate of complex configuration such as three-dimensional configuration having irregularity and, superimposed thereon, an antistatic layer. There is also provided an antistatic paint whose application is easy, which antistatic paint does not need any after treatment and excels in transparency, surface smoothness and antistatic properties. More specifically, there are provided an antistatic molded article comprising a substrate and, superimposed on a surface thereof, an antistatic layer from an antistatic paint containing a conductive metal oxide, which antistatic molded article exhibits a surface resistivity of 1×104 to 1×109 Ω / □ and a surface roughness (Ra) of 5 to 50 nm; and an antistatic paint for use therein.

Owner:SEKISUI CHEM CO LTD

Antistatic agent, preparation method and application of antistatic agent

The invention discloses an antistatic agent. The antistatic agent mainly comprises, by weight, 15-50% of sulfur-containing surfactant and 85-50% of polyamide polymers. The antistatic agent can be applied to polyester, polyamide and polyolefin. The materials containing the antistatic agent have excellent durable antistatic performance, and excellent performance of original polymers can be maintained.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Conductive rubber sole composition

InactiveCN104479176AGood antistatic propertiesExcellent coefficient of slip resistanceSolesCarbon blackStearic acid

The invention discloses a conductive rubber sole composition. The conductive rubber sole composition is prepared from the following raw materials in parts by weight: 7-14 parts of butadiene-acrylonitrile rubber, 5-10 parts of acetylene black, 4-8 parts of anti-aging agent, 10-15 parts of high styrene, 10-20 parts of natural rubber, 4-8 parts of nano zinc oxide, 7-10 parts of antimony trioxide, 6-12 parts of dibutyl ester, 5-10 parts of zinc carbonate, 3-9 parts of stearic acid, 5-10 parts of sulfur, 8-14 parts of salicylic acid, 5-10 parts of dioctyl ester, 7-14 parts of white carbon black, 6-12 parts of solid coumarone, 5-10 parts of magnesia and 6-10 parts of argil. The conductive rubber sole composition disclosed by the invention is good in anti-electrostatic property, excellent in skidding and moistness resisting coefficient, low in cost, good in use effect and high in wear resistance.

Owner:QINGDAO LAOXIANG TEA PROD

Water-resistant wear-resistant antistatic polyester film and preparation method thereof

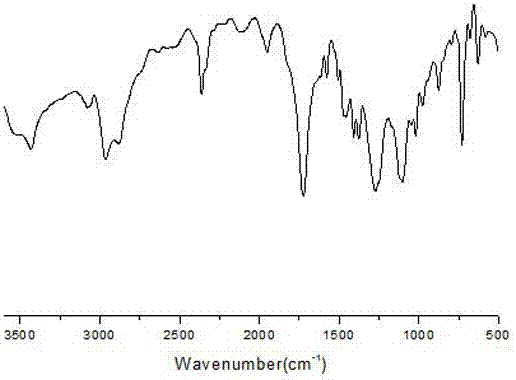

ActiveCN113336991AGood antistatic propertiesExcellent moisture resistance and long-lasting antistaticEpoxy resin coatingsAntistatic MaterialsMeth-

The invention relates to a water-resistant wear-resistant antistatic polyester film, which is obtained by coating the surface of polyester with an antistatic material solution and then stretching and curing, wherein the antistatic material solution comprises the following raw materials: a mixed monomer, epoxy acrylic resin, a pi-conjugated conductive polymer, an alcohol-water mixed solvent, an emulsifier and an initiator, the mixed monomer comprises 2-acrylamido-2-methylpropanesulfonic acid, a hydrophobic anionic monomer, (methyl) hydroxy acrylate and polyethylene glycol diacrylate. The antistatic polyester film developed by the invention can still keep excellent antistatic performance in a high-humidity saturated environment or after multiple times of friction, and has more excellent moisture resistance and durable antistatic property.

Owner:佛山杜邦鸿基薄膜有限公司

Anti-electrostatic UV (Ultraviolet)-curable coating material and preparation method thereof

InactiveCN103788827AGood antistatic propertiesHigh strengthEpoxy resin coatingsPolyester coatingsBisphenol AHardness

The invention relates to an anti-electrostatic UV (Ultraviolet)-curable coating material. The anti-electrostatic UV-curable coating material is prepared from the following raw materials in parts by weight: 2-3 parts of 2,4,6-trimethyl benzoyl-diphenyl phosphine oxide, 34-38 parts of bisphenol A epoxy acrylate, 10-13 parts of polyester acrylate, 5-8 parts of allyl heptanoate, 0.3-0.4 part of benzophenone, 4-6 parts of 2,2-bishydroxymethyl propionic acid, 6-9 parts of hexanediol diacrylate, 0.5-0.7 part of ethyl acetoacetate, 2-4 parts of green earth, 5-7 parts of 10-15% HCl, 6-9 parts of 95% ethanol, 2-3 parts of AEO-9 and 4-5 parts of auxiliaries. According to the UV coating material disclosed by the invention, due to the addition of green earth powder, the coating material has good electrostatic resistance, and the strength is improved; the coating material is high in hardness and has excellent water resistance, hot-water resistance, adhesion and toughness; due to the auxiliaries, the dispersity of the coating material is improved, the leveling property is good, and a coating layer is smooth and bright.

Owner:WUHU BAOYI AMUSEMENT EQUIP

High-efficiency antistatic coating

InactiveCN105647347AGood antistatic propertiesGood mechanical propertiesEpoxy resin coatingsElectrically-conductive paintsEmulsionCalcium carbonate

The invention discloses high-efficiency antistatic coating, which is prepared from the flowing components in parts by weight: 60 to 80 parts of matrix resin, 40 to 60 parts of acrylate polymer emulsion, 5 to 8 parts of polyisocyanate curing agent, 5 to 12 parts of carbon nano tube, 5 to 10 parts of nanosilicon dioxide, 10 to 15 parts of ground calcium carbonate, 3 to 5 parts of graphite powder, 2 to 4 parts of wetting agent, 3 to 5 parts of coupling agent, 0.5 to 1.5 parts of methyl ethyl ketoxime, 5 to 10 parts of film-forming agent and 3 to 5 parts of leveling agent. According to the high-efficiency antistatic coating disclosed by the invention, through the reasonable formulation design, the obtained antistatic coating has excellent antistatic property when the usage amount of an antistatic agent (carbon nano tube) is relatively lower, has excellent mechanical property, and has wide application prospect.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Water-based antistatic acrylic resin and preparation method thereof

ActiveCN113956733AGood antistatic propertiesLow tearing voltageElectrically-conductive paintsComposite materialEthyl ester

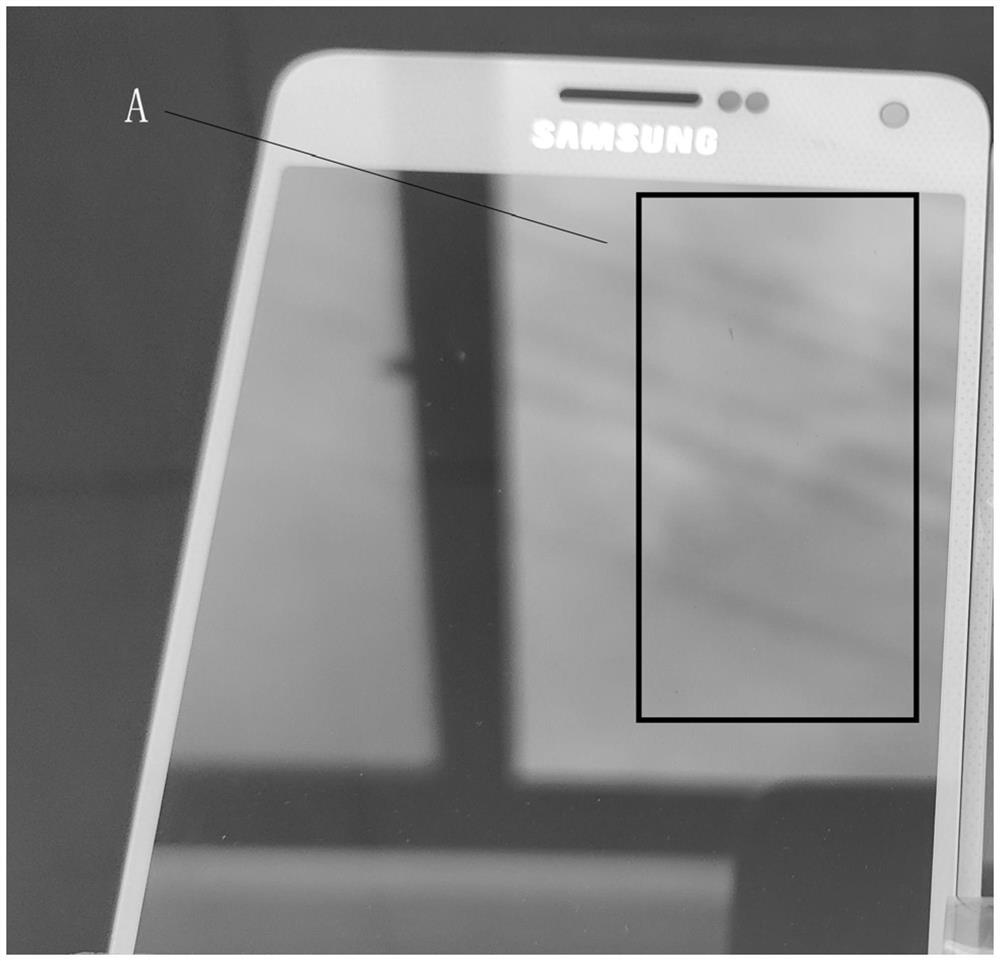

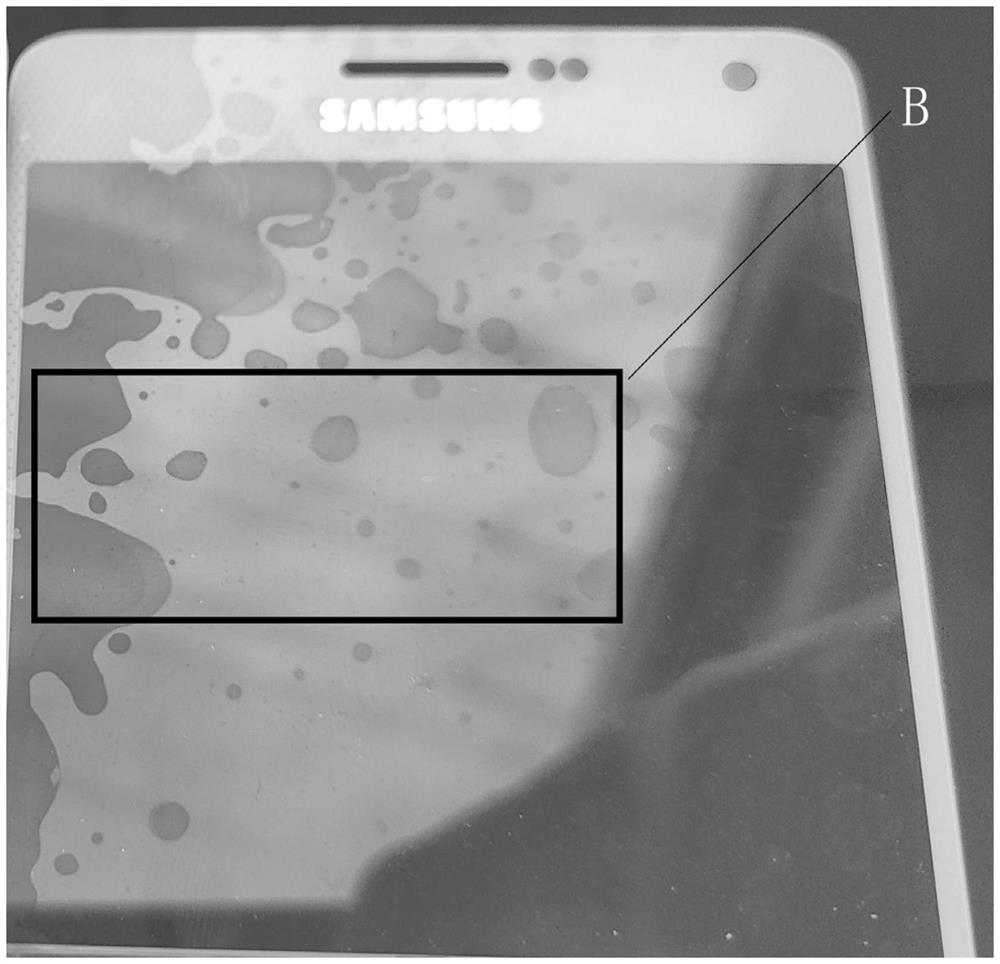

The invention provides a water-based antistatic acrylic resin and a preparation method thereof. The water-based antistatic acrylic resin comprises a water-based acrylic resin coating, a cross-linking curing agent and a composite ionic liquid antistatic agent, the weight ratio of the water-based acrylic resin coating to the cross-linking curing agent to the composite ionic liquid antistatic agent is 100: (0.5-2): (0.5-5), and the composite ionic liquid antistatic agent is prepared from 1-ethyl-3-methylimidazole ethylsulfate, trihydroxyethyl methyl ammonium methylsulfate and tri-n-butyl methyl ammonium bis(trifluoromethanesulfonyl)imine according to the weight ratio of (80-90): (5-15): 5. The antistatic agent provided by the invention is added into the water-based acrylic resin coating to prepare water-based antistatic acrylic resin, the water-based antistatic acrylic resin is coated on a PET base material, and the water-based antistatic acrylic resin has good antistatic performance and low film tearing voltage, and can protect a display screen when being used on the display screen of an electronic product; and the antistatic performance does not become worse along with the change of time and environment, and the water-based antistatic acrylic resin is not prone to being contaminated by dust, and has the permanent antistatic characteristic.

Owner:艾力利荣化工科技(惠州)有限公司

Anti-adhesion antistatic polyester film

ActiveCN111040219AGood antistatic propertiesGood effectPolyurea/polyurethane coatingsElectrically-conductive paintsPolyesterPolymer chemistry

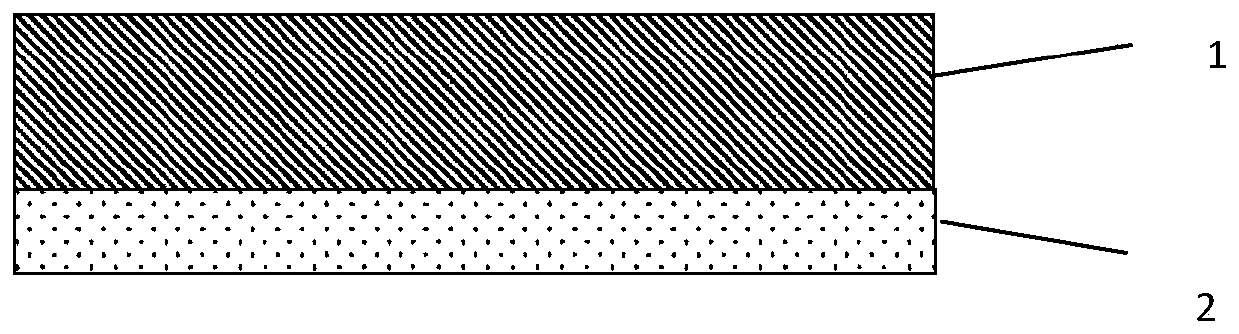

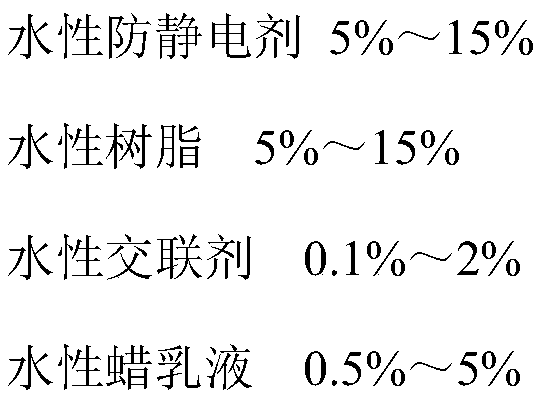

The invention provides an anti-adhesion antistatic polyester film. The anti-adhesion antistatic polyester film comprises a base material layer and an anti-adhesion antistatic layer, wherein the anti-adhesion antistatic layer contains water-based resin, a water-based antistatic agent, a water-based cross-linking agent, a water-based wax emulsion, a water-based wax micro-dispersion, a water-based wetting agent and water. According to the invention, the surface of a polyester film is coated with prepared coating liquid, and then drying and rolling are carried out to obtain the anti-adhesion antistatic polyester film. The results of measurement show that the surface resistance of the film can reach 106-1010 ohms, the antistatic performance is excellent, the anti-adhesion effect is excellent, the anti-adhesion antistatic layer and a back ink processing layer cannot be adhered during winding, and the film can be widely applied to the field of anti-adhesion antistatic films for electronics, panel display, IMR and the like.

Owner:HEFEI LUCKY SCI & TECH IND

Antistatic modified hot melt adhesive and preparation method thereof

InactiveCN106753233AStrong adhesionGood antistatic propertiesNon-macromolecular adhesive additivesPolyesterCarbon black

The invention discloses an antistatic modified hot melt adhesive and a preparation method thereof. The antistatic modified hot melt adhesive contains the following components in parts by mass: 15-25 parts of a polyester hot melt adhesive, 10-20 parts of paraffin, 20-30 parts of a thermoplastic high polymer, 5-15 parts of chopped carbon fibers, 1-3 parts of an antioxidant, 10-20 parts of hot melting powder, 5-15 parts of basalt fibers, 10-12 parts of conductive carbon black, 4-6 parts of petroleum, 2-4 parts of medical stone, 10-20 parts of polyamide resin and 20-40 parts of water. The hot melt adhesive prepared by virtue of the preparation method is stable in adhesive force, good in antistatic performance, high in crystal curing rate, convenient to use and low in environmental influence, particularly the crystal curing rate is superior to that of a hot melt adhesive in the prior art at a low-temperature environment, and the production efficiency is greatly improved.

Owner:钦州市科学技术开发中心

Antistatic graphene coating and preparation method thereof

InactiveCN111303679AReduce surface resistanceGood antistatic propertiesPolyurea/polyurethane coatingsElectrically-conductive paintsGraphene coatingCetyl alcohol

The invention belongs to the technical field of graphene coatings, in particular to an antistatic graphene coating and a preparation method thereof, and in particular to the antistatic graphene coating which is prepared from the following components in parts by weight: 7-15 parts of graphene powder; 24-32 parts of terpene resin; 16 to 28 parts of epoxy-terminated modified polyurethane resin; 4-9 parts of sodium polyphosphate; 2-5 parts of zirconium silicate; 3-6 parts of vanadium diboride; 2-5 parts of Arabic gum; 2-6 parts of cyclodextrin; 1-5 parts of cetyl alcohol, 3-6 parts of sodium benzoate, 4-8 parts of nano attapulgite, 1-4 parts of dimethyl dimercaptoacetic acid isooctyl ester tin, 3-7 parts of magnesium sulfate, 4-9 parts of butylated hydroxyanisole, 1-5 parts of an isobutyltriethoxysilane coupling agent, 2-6 parts of gamma-mercaptopropyltrimethoxysilane, 4-7 parts of leveling agent and 60-100 parts of a solvent. The surface resistance of the graphene coating is lower than 8* 10 < 3 > ohm, and the graphene coating is good in antistatic property, high in hardness, strong in adhesive force, high in impact strength, scratch-resistant, long in service life and good in comprehensive performance; meanwhile, the preparation process is simple, low in manufacturing cost and suitable for general application and popularization.

Owner:上海碳源汇谷新材料科技有限公司

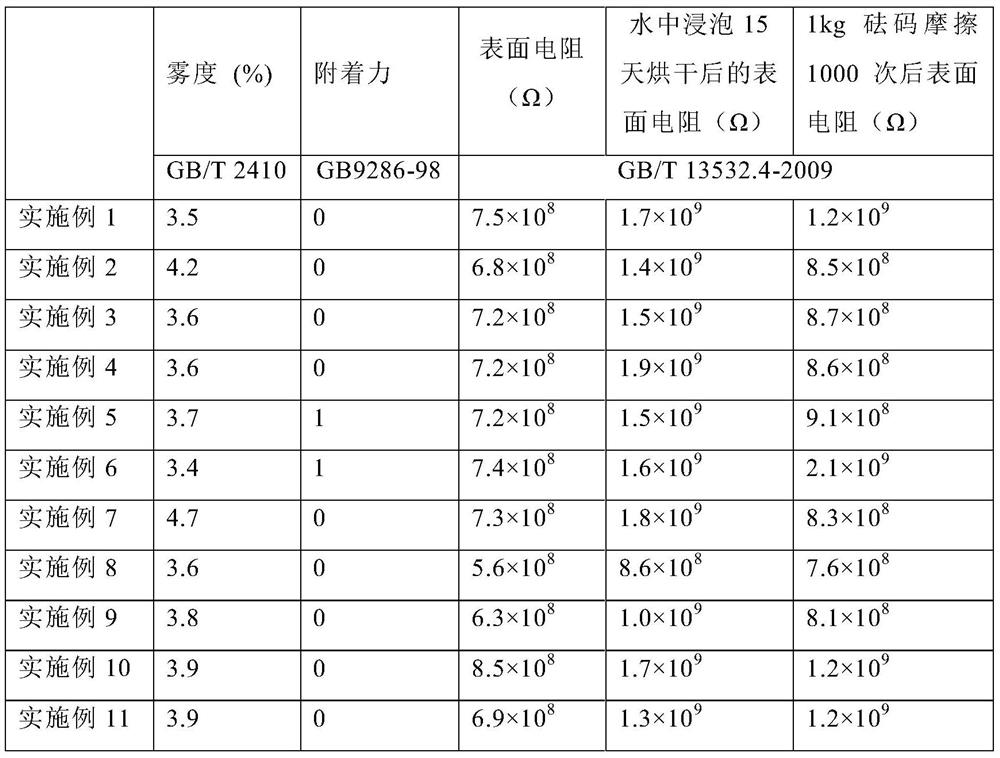

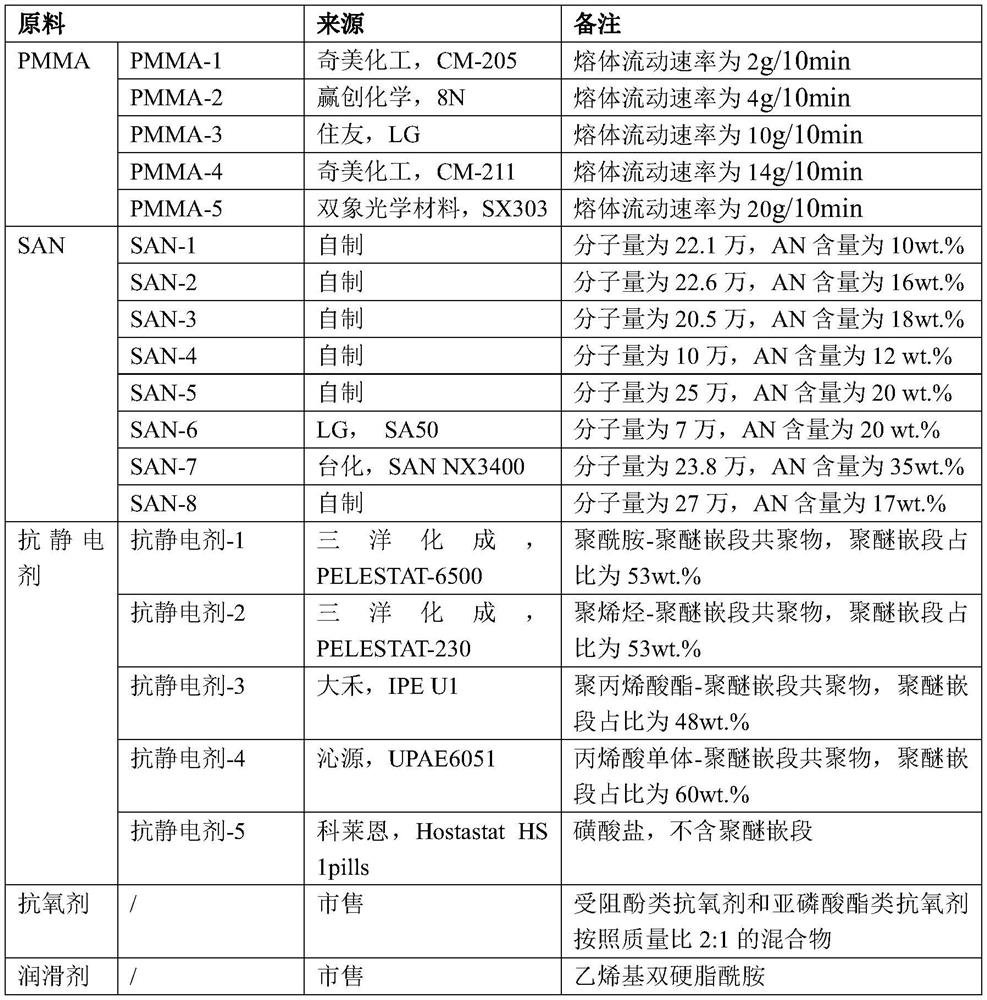

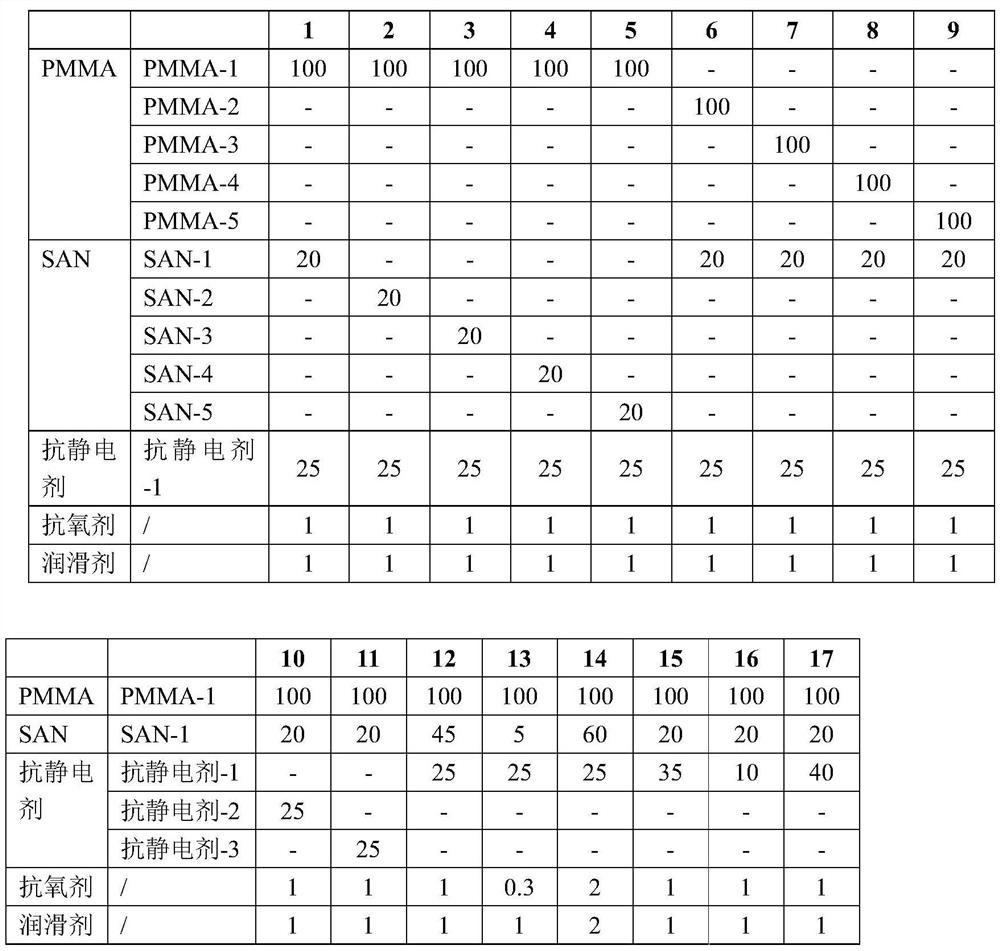

High-impact antistatic PMMA (polymethyl methacrylate) composition as well as preparation method and application thereof

The invention discloses a high-impact antistatic PMMA (polymethyl methacrylate) composition as well as a preparation method and application thereof. The PMMA composition comprises the following components in parts by weight: 100 parts of PMMA, 5-60 parts of SAN (Styrene Acrylonitrile), 10-40 parts of an antistatic agent, 0.3-2 parts of an antioxidant and 1-2 parts of a lubricant, the antistatic agent is one or more of a polyamide-polyether block copolymer, a polyolefin-polyether block copolymer or a polyacrylate-polyether block copolymer; the weight-average molecular weight of the SAN is 10,000-25,000, and the content of acrylonitrile in the SAN is 10wt.%-20wt.%. The antistatic agent brings excellent antistatic performance to the PMMA composition, and the SAN enables the PMMA composition to have excellent toughness. The surface resistivity of the PMMA composition is less than or equal to 4.5 * 10 < 9 > omega, the light transmittance is more than or equal to 80%, and the notch impact strength is more than or equal to 2.8 KJ / m < 2 >.

Owner:KINGFA SCI & TECH CO LTD

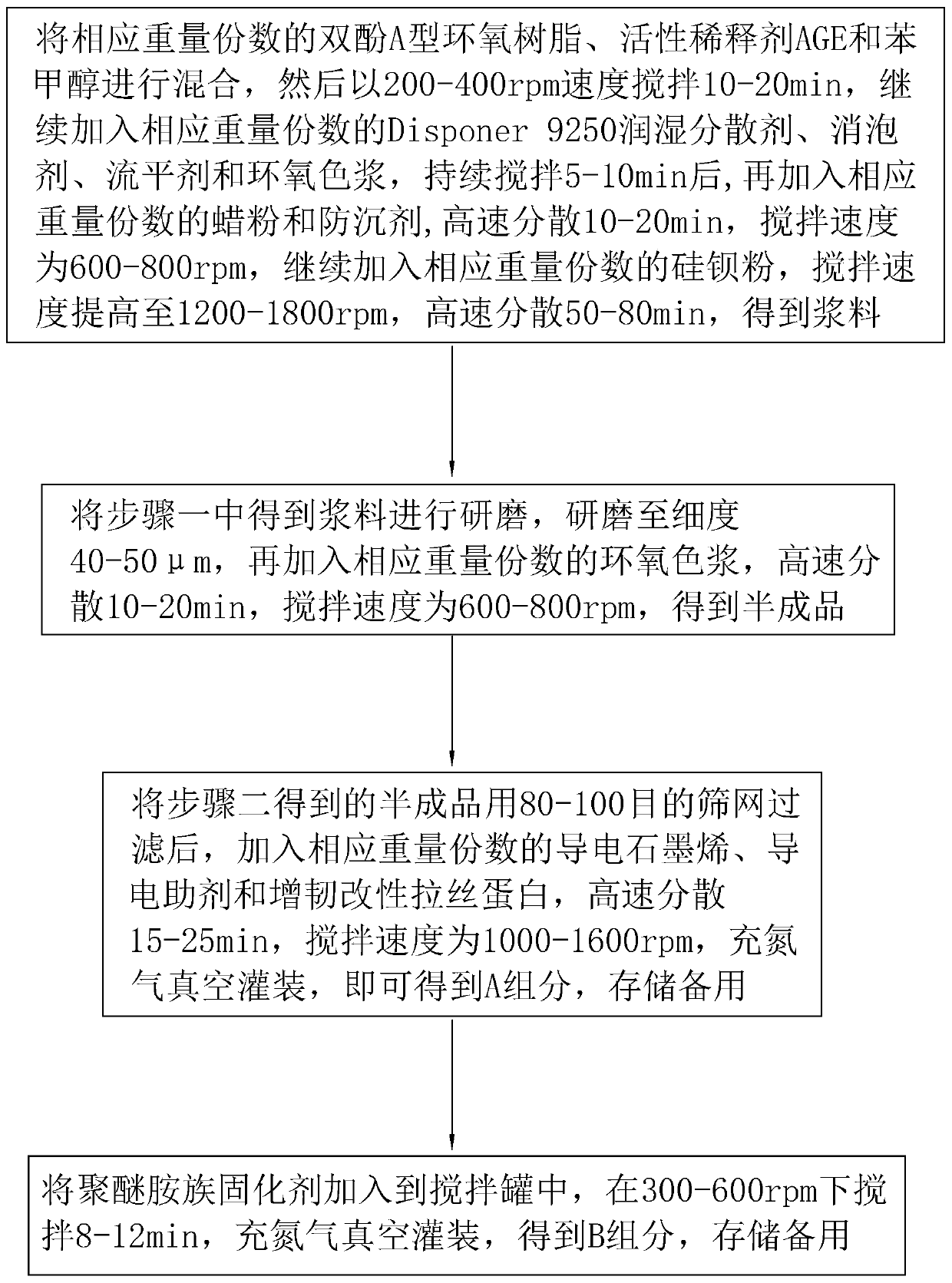

Epoxy self-leveling antistatic topcoat and preparation method thereof

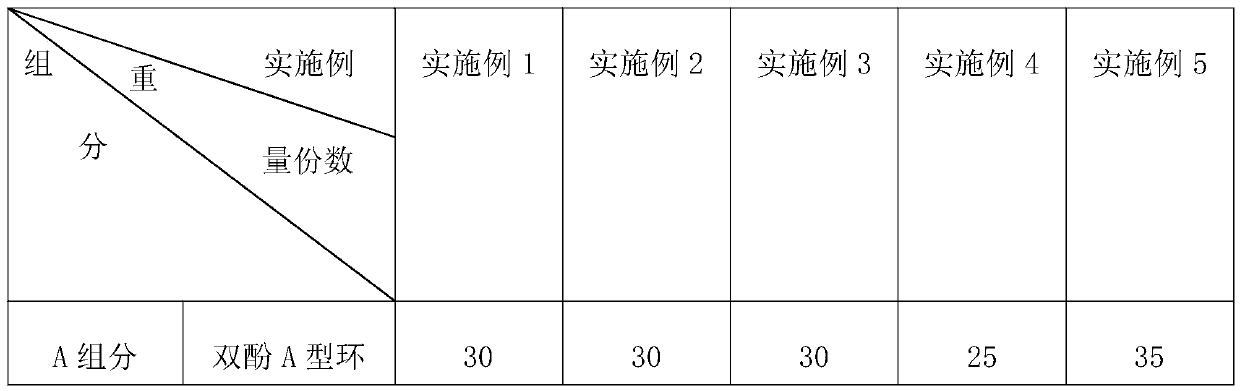

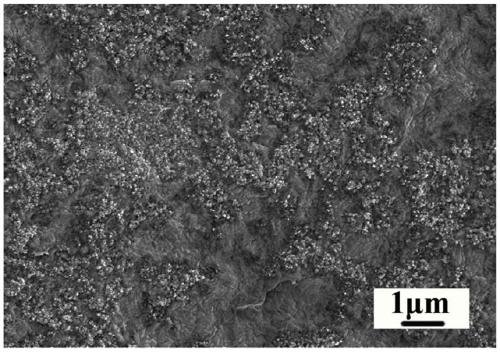

ActiveCN111205741AGood antistatic propertiesAvoid large accumulationsEpoxy resin coatingsElectrically-conductive paintsBENZYL ALCOHOL/WATERFirming agent

The invention discloses an epoxy self-leveling antistatic topcoat and a preparation method thereof, and relates to the technical field of epoxy floor coatings. The problem that a coating film easily generates micro-cracks due to frequent friction or impact is solved and an accident caused by micro-cracks is prevented. The epoxy self-leveling antistatic topcoat comprises a component A and a component B, the component A and the component B are independently stored and mixed according to the weight part ratio of (4-6): 1, the component A comprises the following raw materials in parts by weight: 25-35 parts of bisphenol A type epoxy resin; 1.1 to 1.5 parts of an active diluent AGE; 1.4 to 1.8 parts of benzyl alcohol; 0.8 to 1.2 parts of a Disponer 9250 wetting and dispersing agent; 0.3 to 0.5part of a defoaming agent; 0.5 to 0.9 part of a leveling agent; 0.6 to 1.2 parts of wax powder; 0.6 to 0.9 part of an anti-settling agent; 40 to 50 parts of silicon barium powder; 8 to 16 parts of epoxy color paste; 4 to 10 parts of electro-conductive graphene; 2.5 to 5.5 parts of an electro-conductive auxiliary agent; and 4-6 parts of toughened modified wiredrawn proteins; and the component B isa polyether amine curing agent. The provided epoxy self-leveling antistatic topcoat can maintain a good and stable antistatic performance.

Owner:上海博歌建材有限公司

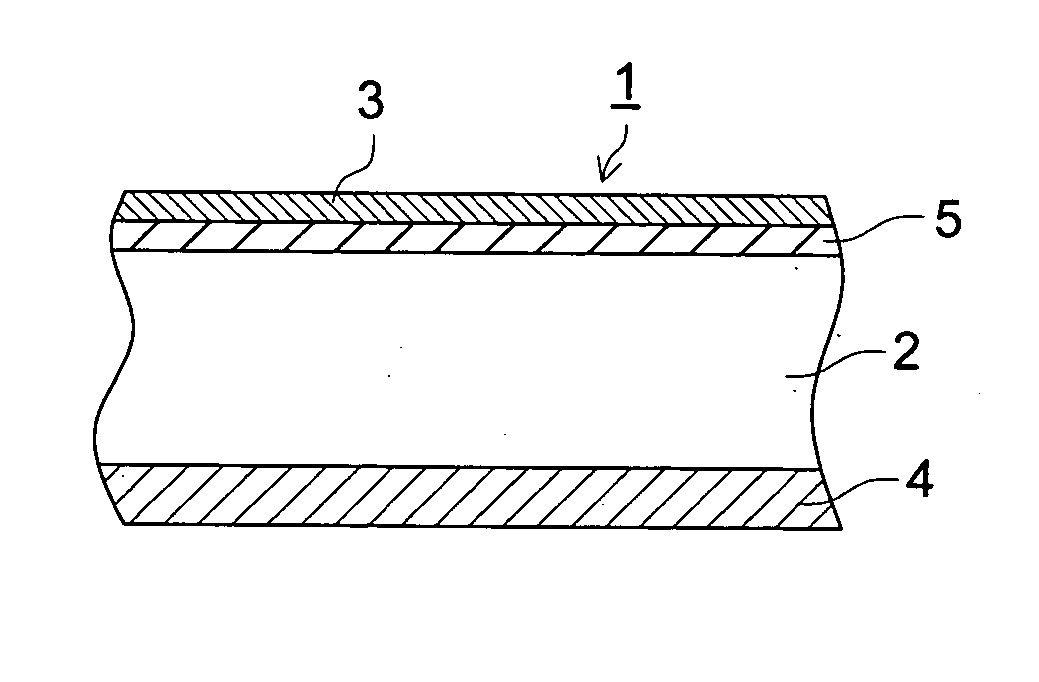

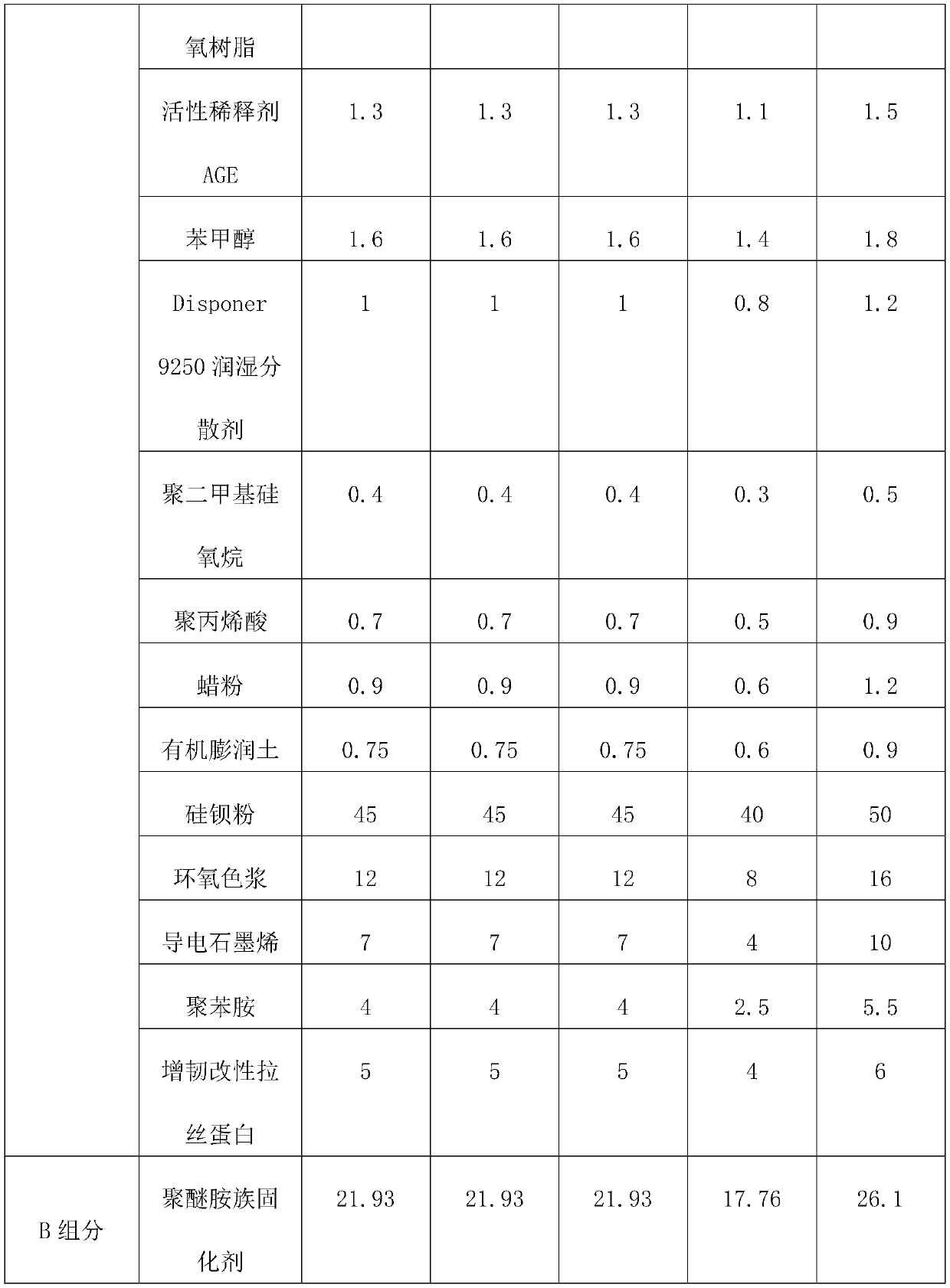

Temperature-regulating moisture transported fabric garment with cooling mat

InactiveCN104687377AGood antistatic propertiesImprove hygroscopicityProtective garmentSpecial outerwear garmentsFastenerEngineering

The invention relates to a temperature-regulating moisture transported fabric garment with a cooling mat. The temperature-regulating moisture transported fabric garment comprises a garment body (1); the cooling mat (2) is sewn at the sweep back of the garment body (1); snap fastener male halves (3) are arranged on the cooling mat (2) at the positions opposite to the sewing part of the cooling mat (2) and the garment body (1); snap fastener female halves (4) are arranged at the waist back of the garment body; the garment body is made of a fabric; the fabric comprises a surface layer and a lining; the surface layer is an air conditioning fiber blended yarn layer; the lining is a polyester filament yarn coral fleece layer; and the surface layer is connected with the lining by connecting threads. The temperature-regulating moisture transported fabric garment is convenient to carry. The temperature-regulating moisture transported fabric garment has excellent heat resistance, warmth retention and cooling effect.

Owner:张荣德

Method for preparing antistatic black master batch from graphene-coated carbon black, and product

PendingCN111363346AGood antistaticGood antistatic propertiesElectroconductive/antistatic filament manufacturePigment addition to spinning solutionCarbon blackGraphite oxide

The invention discloses a method for preparing antistatic black master batch from graphene-coated carbon black. The method is characterized by comprising the following steps: (1) modifying carbon black by using a dispersing agent to obtain modified carbon black, uniformly mixing the graphene oxide and the modified carbon black in a solvent, and carrying out post-treatment to obtain graphene oxidecoated modified carbon black, wherein the dispersing agent is one or more of sodium dodecyl benzene sulfonate, APS, DL-602 and sodium lauryl sulfate; (2) reducing the obtained graphene oxide coated modified carbon black by using a reducing agent, and carrying out post-treatment to obtain graphene-coated carbon black; and (3) melting and uniformly mixing the obtained graphene-coated carbon black and a matrix master batch, and granulating to obtain the antistatic black master batch. The black antistatic master batch prepared by the method can greatly improve the dispersity, color uniformity andantistatic property of carbon black in the matrix material.

Owner:ZHEJIANG SCI-TECH UNIV

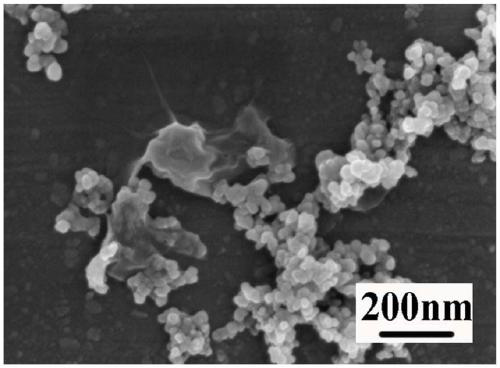

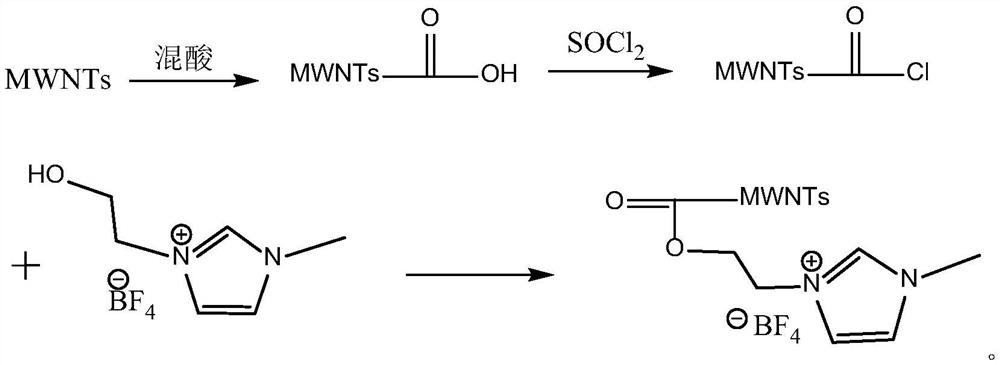

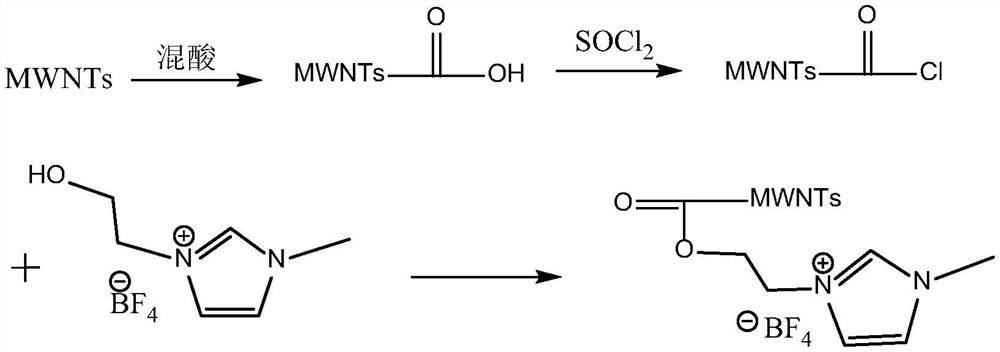

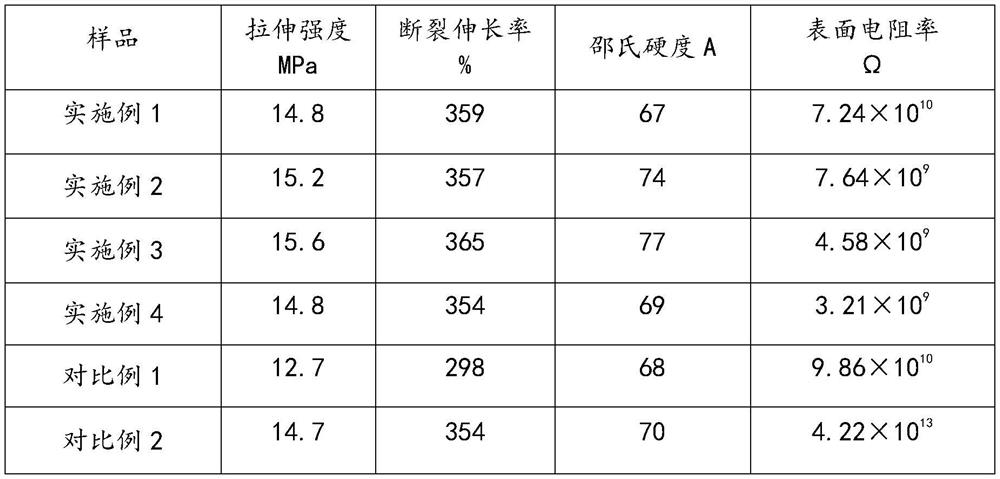

Antistatic sealing strip and preparation method thereof

InactiveCN114316473AImprove dispersion performanceGood antistatic propertiesFluoroboric acidCarbon nanotube

The invention belongs to the technical field of sealing strips for vehicles, and particularly relates to an antistatic sealing strip. The sealing strip comprises the following components in parts by weight: 100 parts of PVC resin, 65-80 parts of a plasticizer, 15-30 parts of ethylene propylene diene monomer, 8-18 parts of calcium carbonate, 8-16 parts of zinc oxide, 8-14 parts of carbon black, 15-25 parts of an antistatic agent, 5-8 parts of a calcium-zinc stabilizer, 0.2-1 part of zinc stearate, 0.5-2 parts of dibenzenesulfonyl hydrazide ether and 1-5 parts of a flame retardant. The antistatic agent is a multi-walled carbon nanotube grafted and modified by an ionic liquid, and the ionic liquid is 1-hydroxyethyl-3-methylimidazolium tetrafluoroborate; the antistatic sealing strip has the beneficial effects that the surface-grafted carbon nanotubes are adopted as the antistatic agent, so that the dispersing performance of the antistatic agent is improved, and the prepared sealing strip is better in antistatic performance and better in color; and the processing manufacturability is better, and the mechanical property is better.

Owner:马云浩

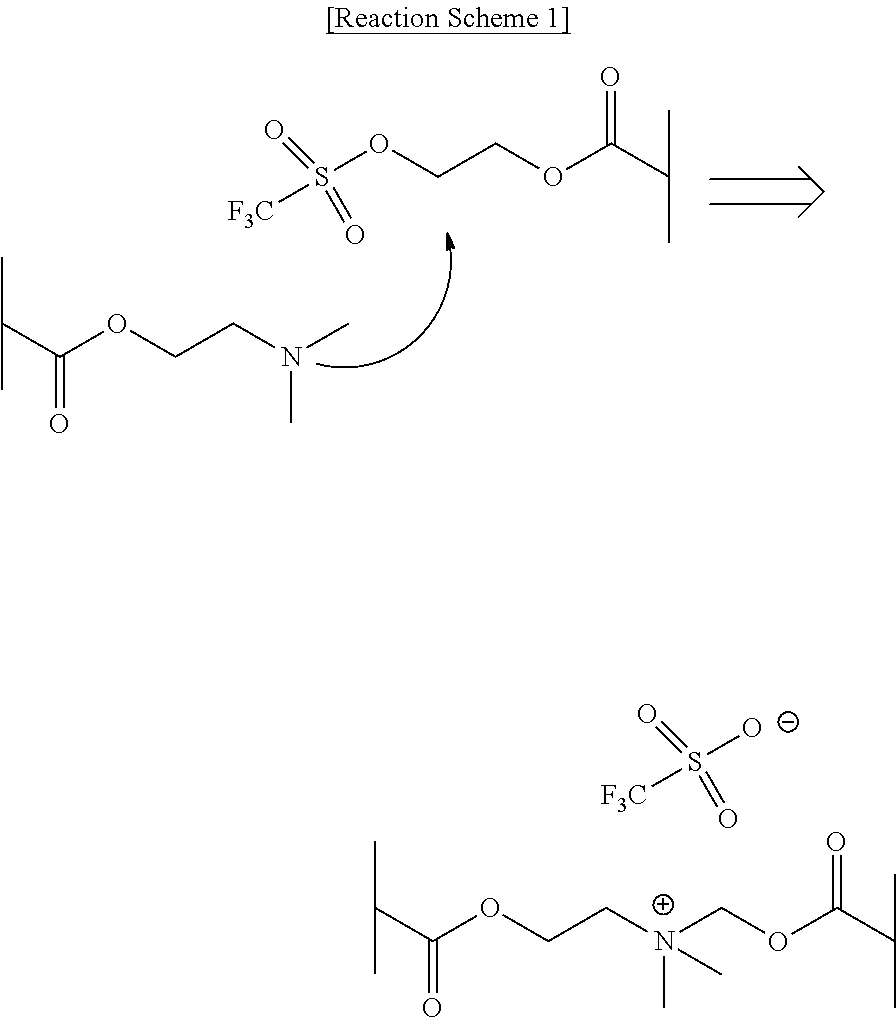

Adhesive composition and polarizing plate comprising same

ActiveUS20170101563A1Good antistatic propertiesGood durabilityVinyl-pyridine polymer adhesivesNon-macromolecular adhesive additivesLiquid-crystal displayAcrylic acid

The present invention provides an adhesive composition comprising a tertiary amine group-containing acrylic copolymer and a sulfonate group-containing acrylic copolymer, a polarizing plate and a liquid crystal display device comprising the adhesive composition. The adhesive composition of the present invention comprises a tertiary amine group-containing acrylic copolymer and a sulfonate group-containing acrylic copolymer wherein an ionic functional group can be introduced by cross-linking reaction thereof, thereby exhibiting good antistatic properties and excellent durability.

Owner:DONGWOO FINE CHEM CO LTD

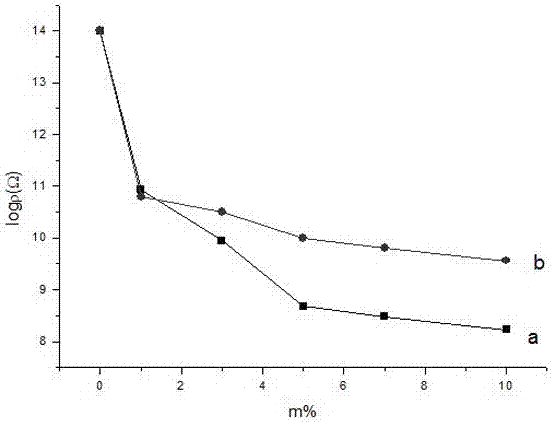

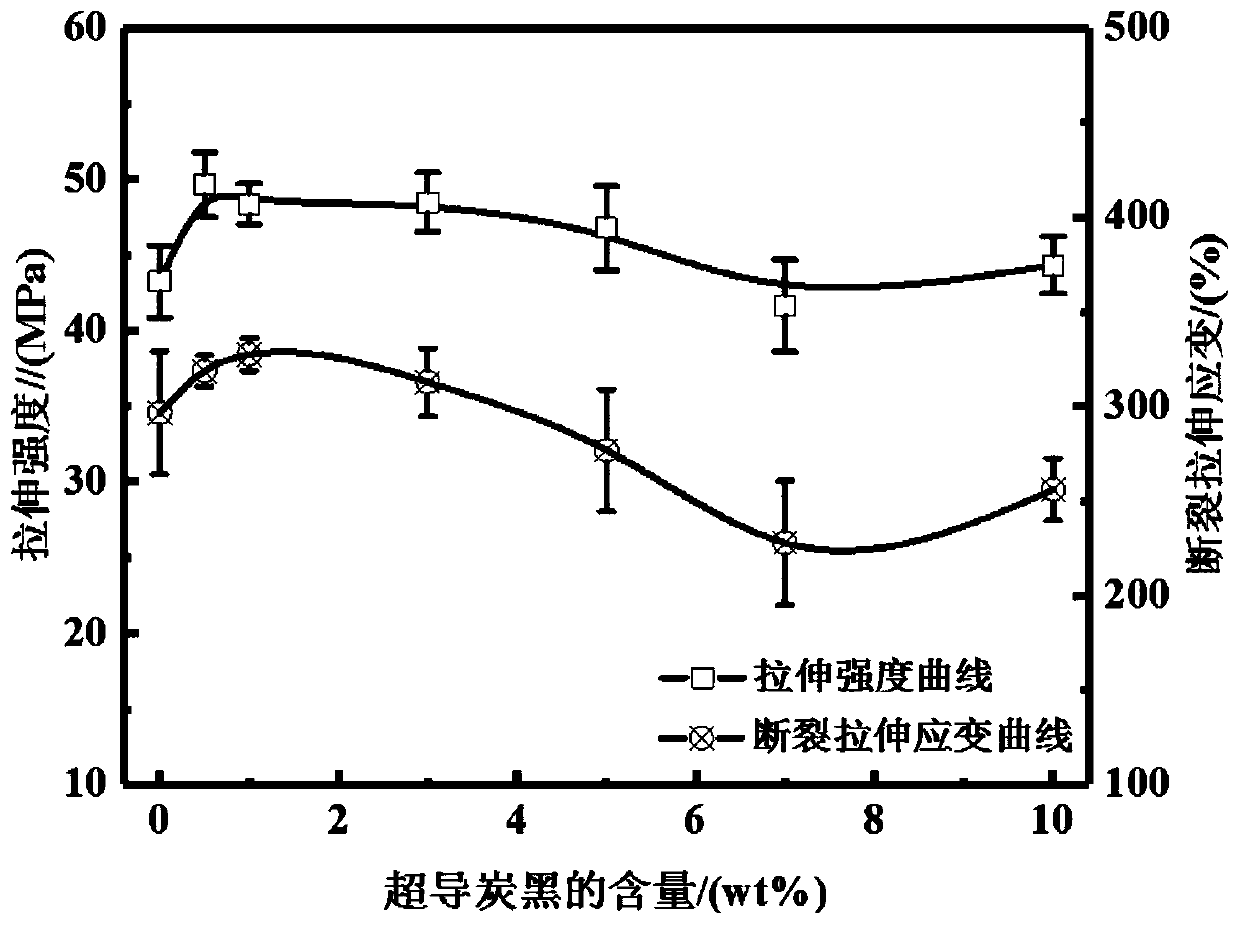

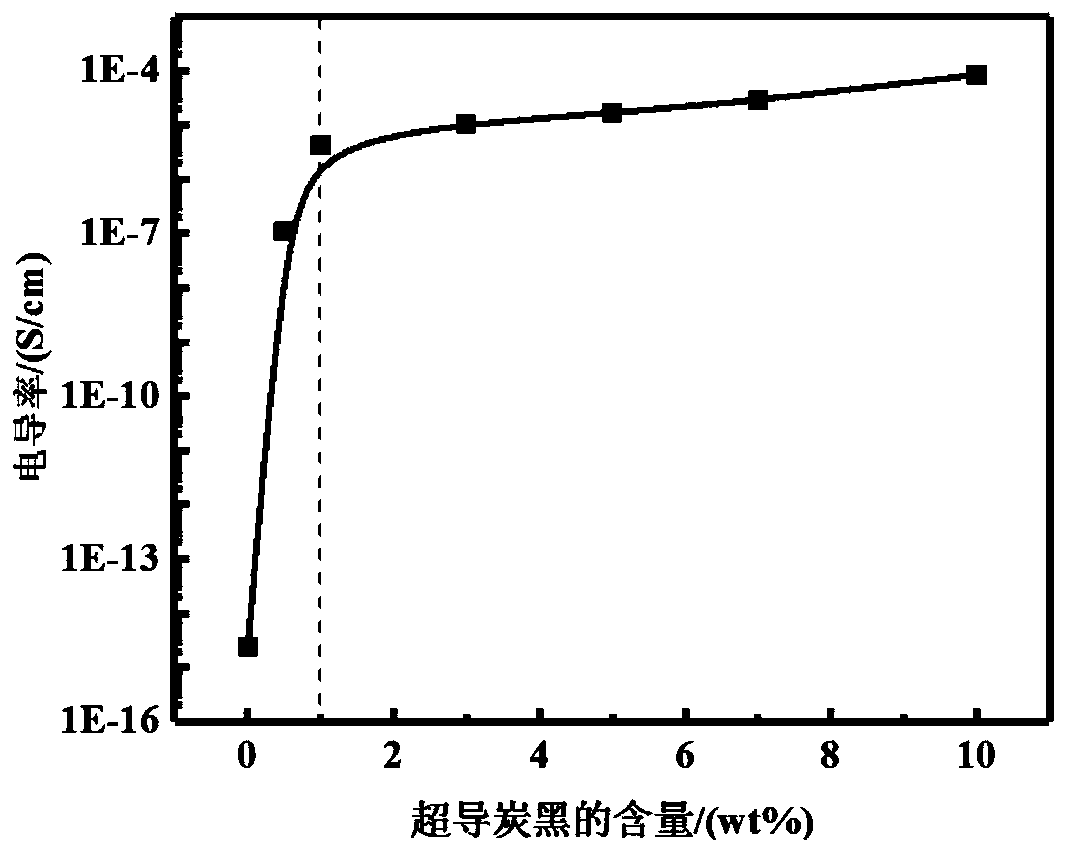

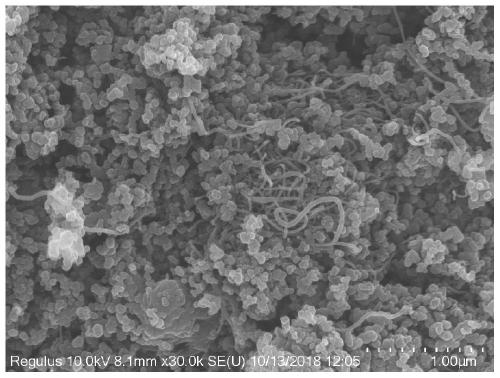

High-strength and low-percolation UHMWPE (ultrahigh molecular weight polyethylene)/superconductive carbon black composite material and preparation method thereof

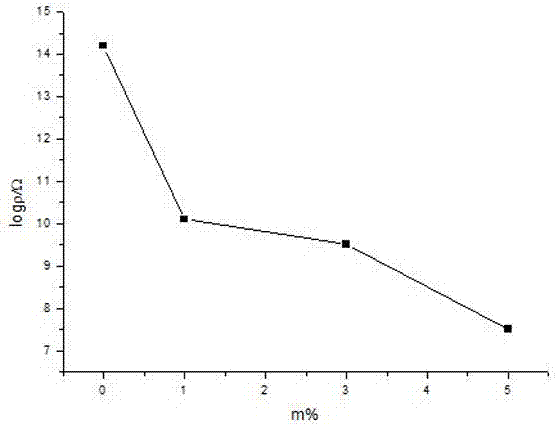

The invention discloses a high-strength and low-percolation UHMWPE / superconductive carbon black composite material and a preparation method thereof. The high-strength and low-percolation UHMWPE / superconductive carbon black composite material is composed of, by weight parts of 85-98.9 parts of UHMWPE powder, 1-14.8 parts of superconductive carbon black, 0.1-0.6 part of antioxidant and 0.1-0.6 partof coupling agent. The preparation method of the high-strength and low-percolation UHMWPE / superconductive carbon black composite material comprises raw material drying, high-speed mixing and preparation of UHMWPE / superconductive carbon black hybrid particles, and high-temperature press forming. When the added amount of the superconductive carbon black is 1 wt%, the high-strength and low-percolation UHMWPE / superconductive carbon black composite material achieves a conductivity up to 10<-5> s / cm and is low in percolation value and high in tensile strength and tenacity. A conductive sheet press-formed by the high-strength and low-percolation UHMWPE / superconductive carbon black composite material is not only endowed with excellent mechanical performance comparable with that of the ultrahigh molecular weight polyethylene, but also endows ultrahigh molecular weight polyethylene engineering plastics with new special functions such as anti-static property and electromagnetic shielding.

Owner:FUJIAN NORMAL UNIV

Antistatic softening agent with high antistatic performance

InactiveCN111074630AGood antistatic propertiesImprove antistatic performanceGrip property fibresBoronic acidTriethanolamine

The invention discloses an antistatic softening agent with the high antistatic performance. The antistatic softening agent comprises a component A, a component B and a component C, wherein the mixingmass ratio of the component A to the component B is (1 : 2) to (1 : 5); the mixing mass ratio of a mixture of the component A and the component B to the component C is (1 : 1) to (1 : 3); and raw materials of the component A in parts by mass include 18-23 parts of amino silicon oil, 2-3 parts of p-chloroxylenol, 6-10 parts of sodium lauroyl sarcosinate, 1-1.5 parts of calcium chloride and 7-10 parts of 2-undecylimidazoline; and raw materials of the component B in parts by mass include 15-25 parts of cyclopentanone, 5-6 parts of urea, 40-60 parts of ammonium dihydrogen phosphate, 6-11 parts oftriethanolamine borate, 5-10 parts of ethylene bis stearamide and 3-6 parts of coconut oil amine polyoxyethylene ether; and raw materials of the component C in parts by mass include 6-10 parts of polyvinyl alcohol, 17-27 parts of octamethyltetrasiloxane, 13-16 parts of sodium dodecyl sulfate, 11-22 parts of dimethyl disiloxane, 3-7 parts of a coupling agent, 15-17 parts of polyethoxylated fatty alcohol, 11-14 parts of ascorbic acid and 10-14 parts of colza oil acid methyl ester.

Owner:福盈化学(苏州)有限公司

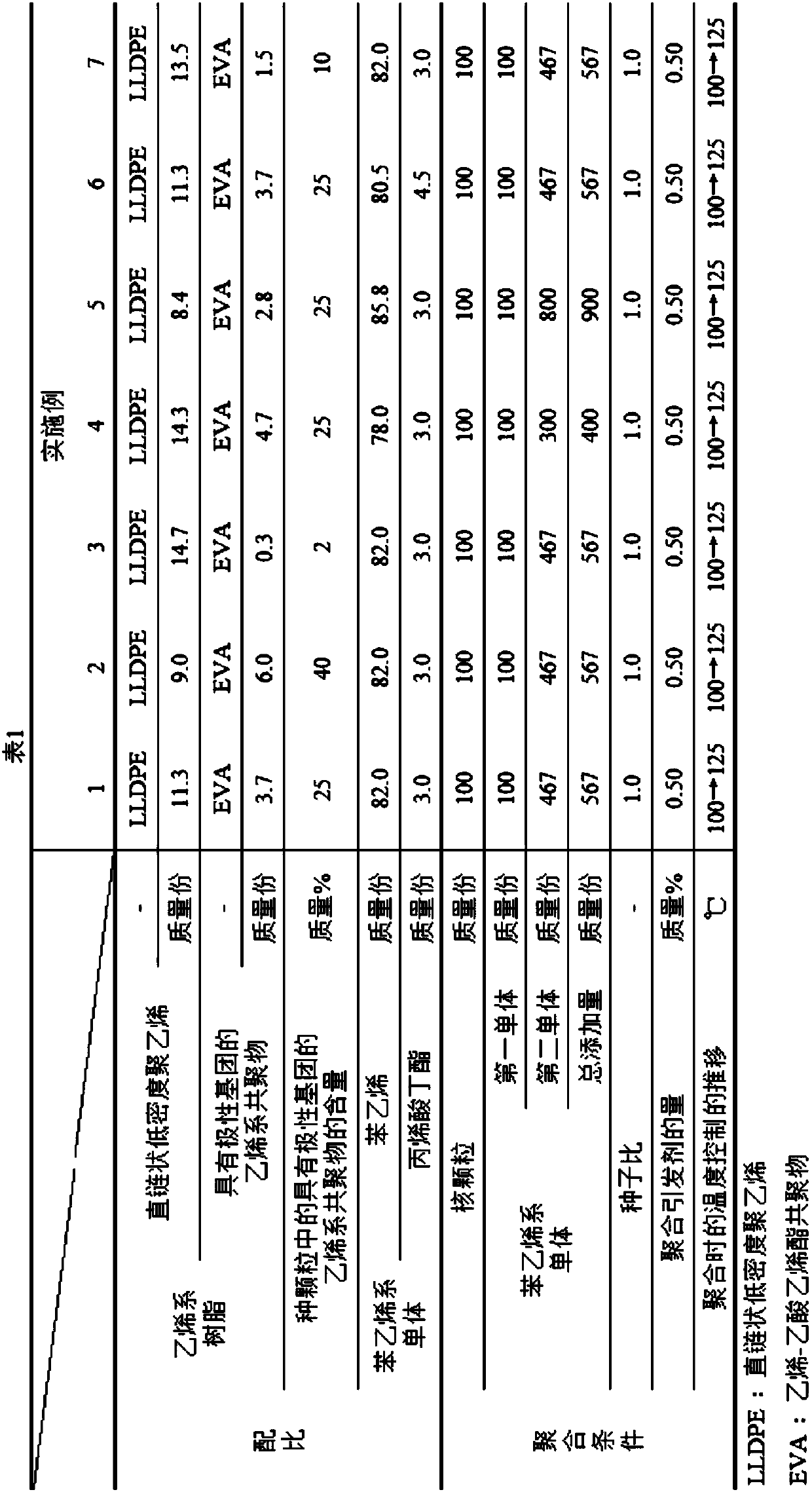

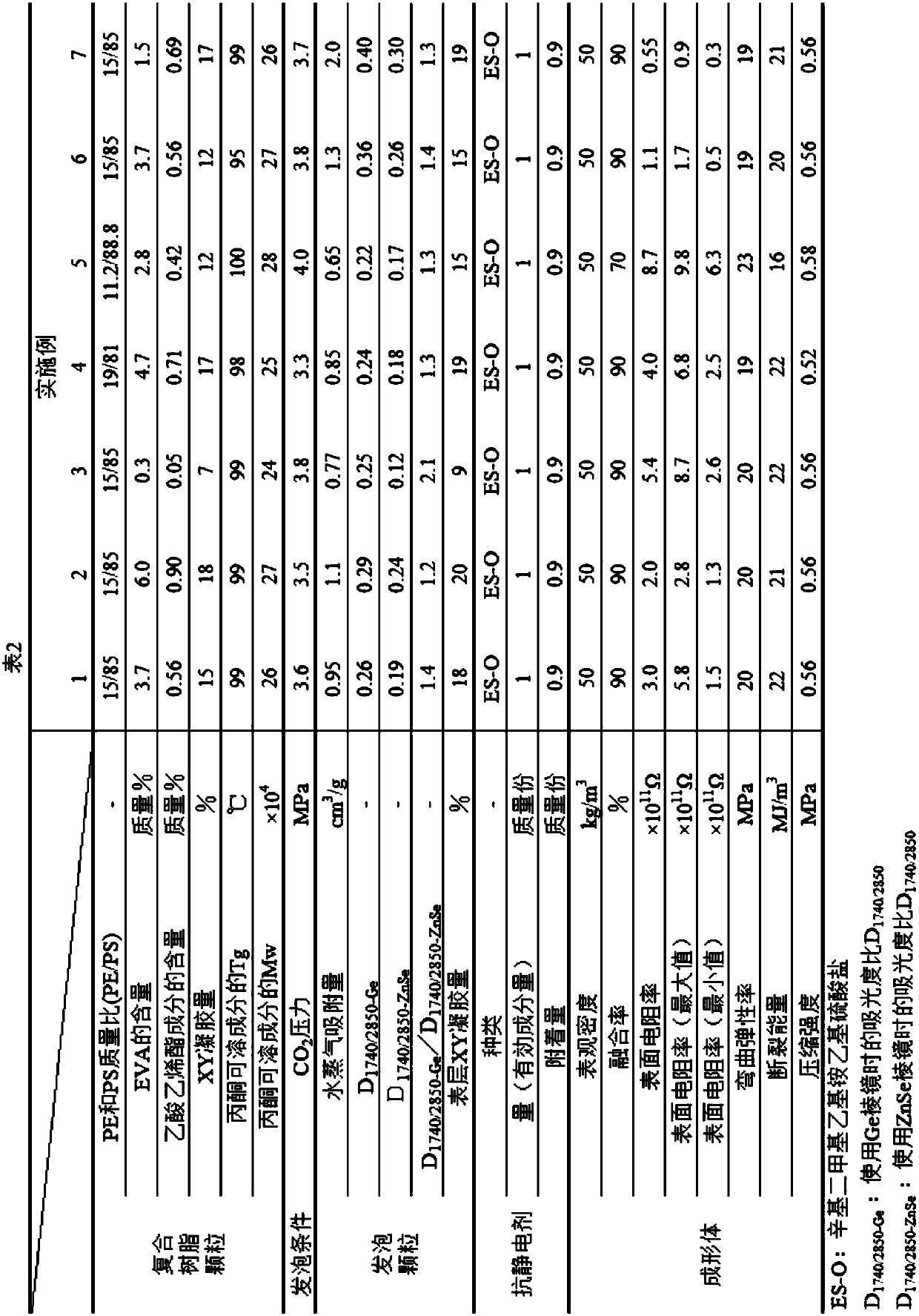

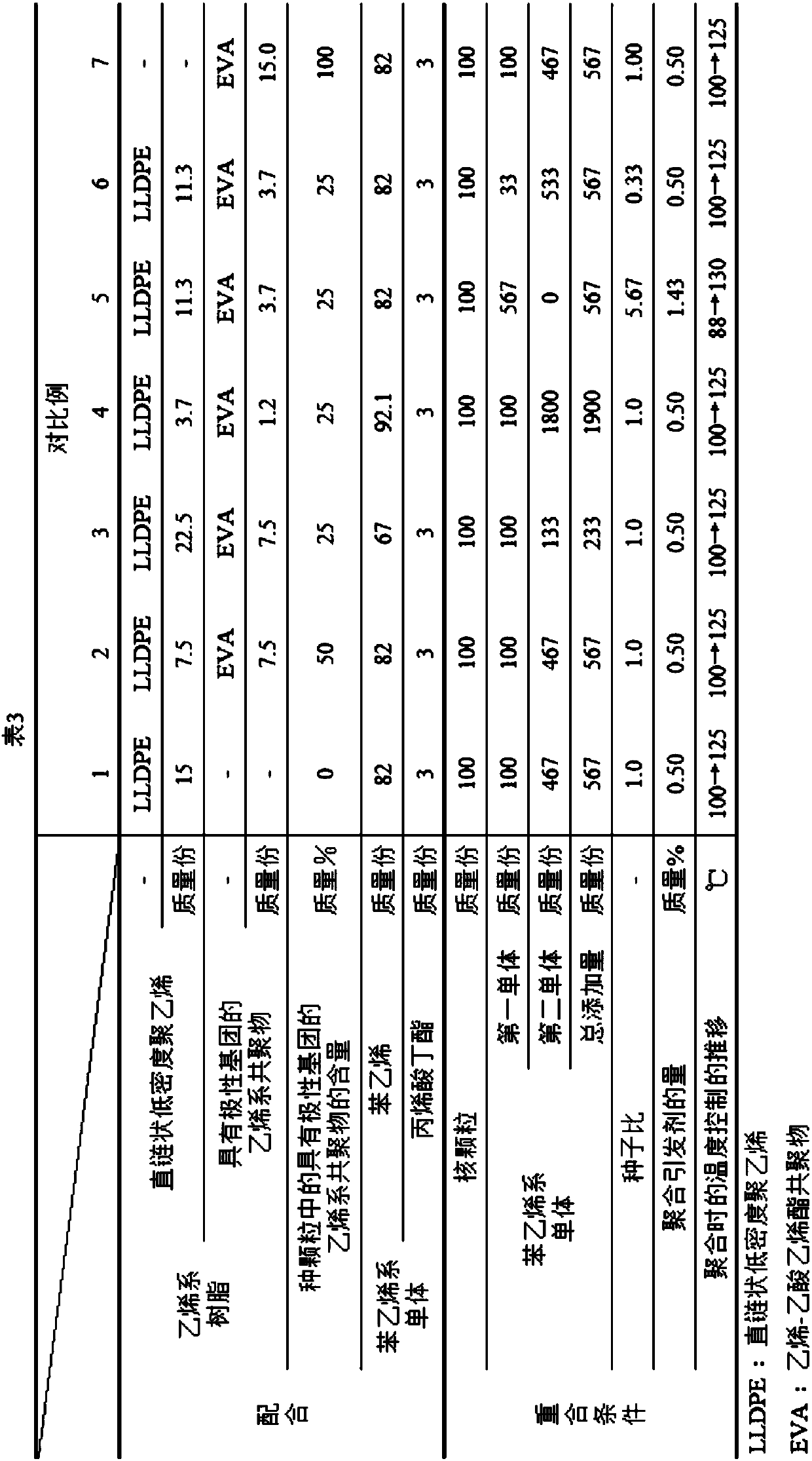

Composite resin foamed particle, antistatic composite resin foamed particle and composite resin foamed particle molded body

InactiveCN107778519AInhibit the outflow of antistatic agentGood antistatic propertiesLow-density polyethyleneAntistatic agent

[Problem] To provide a composite resin foamed particle capable of stably obtaining a molded body with a relatively high proportion of a styrene resin component in a composite resin, good internal fusion and excellent antistatic property, an antistatic composite resin foamed particle and a molded body using the antistatic composite resin foamed particle. [Solution] A composite resin foamed particleusing a composite resin formed by impregnating a polymerized styrene monomer in an ethylene resin as a base material resin, an antistatic composite resin foamed particle wrapped by an antistatic agent and a molded body of the antistatic composite resin foamed particle. The composite resin contains a component derived from an ethylene resin and a component derived from a styrene monomer in a specified proportion. The ethylene resin is a mixture of straight chain-shaped low-density polyethylene and an ethylene copolymer having a polar group, and the content of the ethylene copolymer having thepolar group in the ethylene resin is adjusted to be within a specified range. The water vapor adsorption amount of the composite resin foamed particle is not less than 0.50 cm3 / g.

Owner:JSP CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com