Polyether-ether-ketone heat conduction composite material and preparation method thereof

A heat-conducting composite material, polyether ether ketone technology, applied in the field of plastics, can solve the problems of restricting wide application, poor thermal conductivity and antistatic performance, lack of filler components, etc., and achieve broad market prospects, excellent thermal conductivity, good resistance The effect of electrostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

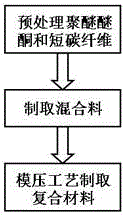

[0016] figure 1 It is a process step chart of the preparation method of polyether ether ketone thermally conductive composite material according to the embodiment of the present invention; the raw material components contained in the composite material include polyetheretherketone resin, copper powder, and short carbon fiber, and the preparation method includes the following steps: a) Pretreatment of polyether ether ketone and short carbon fiber, b) preparation of mixture, c) molding process to prepare composite material.

[0017] The polyetheretherketone heat-conducting composite material mentioned in the present invention uses polyetheretherketone as a matrix, uses micron-sized copper powder and short carbon fibers as compound heat-conducting fillers, and is prepared by compression molding. Among them, copper powder has high thermal conductivity, and short carbon fiber has a certain aspect ratio and high thermal conductivity, which can well play a bridging role and is conduc...

Embodiment 1

[0019] The specific preparation method is as follows:

[0020] a) Pretreatment of polyether ether ketone and short carbon fibers, the specific preparation process is as follows: first, place the polyether ether ketone resin in a 150 ° C drying oven for 2 hours to remove the moisture in it; 2) then use a plasma processor to treat The surface treatment of short carbon fibers is carried out, and the treatment time is 6 minutes.

[0021] b) To prepare the mixture, first weigh 80% polyether ether ketone resin, 10% copper powder, and 10% short carbon fiber according to the mass percentage, and then put the polyetheretherketone resin, copper powder, and short carbon fiber into the high-speed In a blender, stir at a high speed for 40 minutes to obtain a mixture.

[0022] c) Composite materials are prepared by molding process. The specific preparation process is as follows: first, put the prepared mixture into a self-made mold, and keep the pressure on a 2.5MPa flat vulcanizer for 5 m...

Embodiment 2

[0024] The specific preparation method is as follows:

[0025] a) Pretreatment of polyether ether ketone and short carbon fibers, the specific preparation process is as follows: first, place the polyether ether ketone resin in a 150 ° C drying oven for 2 hours to remove the moisture in it; 2) then use a plasma processor to treat The surface treatment of short carbon fibers is carried out, and the treatment time is 6 minutes.

[0026] b) To prepare the mixture, first weigh 75% polyether ether ketone resin, 10% copper powder, and 15% short carbon fiber according to the mass percentage, and then put the polyether ether ketone resin, copper powder, and short carbon fiber into the high-speed In a blender, stir at a high speed for 40 minutes to obtain a mixture.

[0027] c) Composite materials are prepared by molding process. The specific preparation process is as follows: first, put the prepared mixture into a self-made mold, and keep the pressure on a 2.5MPa flat vulcanizer for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com