Patents

Literature

46results about How to "Physical and mechanical properties are not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel low odor polypropylene composite material and preparation thereof

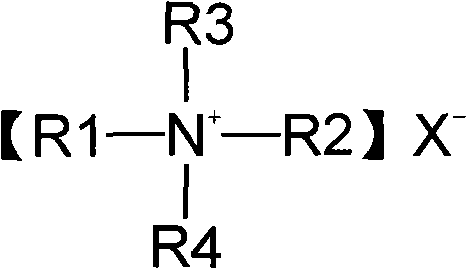

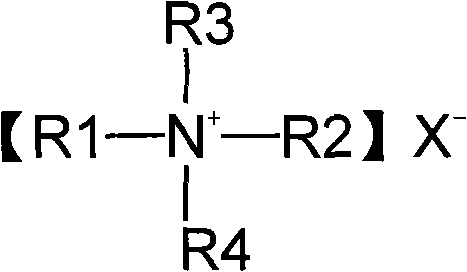

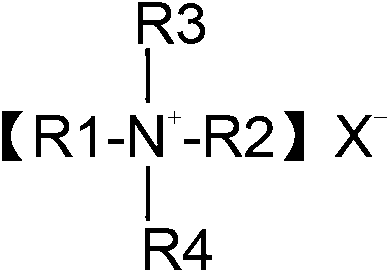

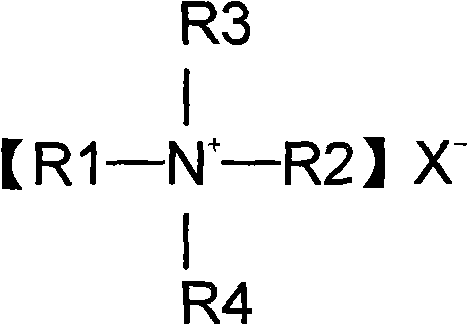

The invention relates to novel low odor polypropylene composite material and a preparation method thereof. The low odor polypropylene composite material comprises the following components by weight percentage: 50 to 95 percent of polypropylene, 0 to 45 percent of inorganic filler, 0 to 20 percent of flexibilizer POE, 1.0 to 5.0 percent of hydrophobic type odor agglomerate, and 0.1 to 5.0 percent of other additives. The preparation method comprises the following steps: firstly mixing 20 to 70 percent basal body resin and 30 to 80 percent attapulgite which is modified by a quaternary ammonium salt surfactant, and carrying out extrusion and granulation to form the high concentration hydrophobic type odor agglomerate; and then mixing the high concentration hydrophobic type odor agglomerate with the polypropylene, the inorganic filler, the flexibilizer POE and the other additives, placing the mixture in a double screw extruder, and obtaining the low odor polypropylene composite material after melted extrusion and granulation. The method is characterized in that the method can make the forming and processing of the composite material be free of any impact, and make the composite material have excellent comprehensive physical and chemical properties and a good odor characteristic.

Owner:CHONGQNG PRET NEW MATERIAL +1

Low-odor, low-emission, high abrasion-resistant and high-temperature-resistant nylon and preparing method thereof

The invention relates to low-odor, low-emission, high abrasion-resistant and high-temperature-resistant nylon and a preparing method thereof. The material is prepared by the steps of stirring and mixing 90-98 parts of high-temperature-resistant nylon, 1-5 parts of a hydrophobic high-temperature-resistant odor-adsorption masterbatch, 1-5 parts of surface treated nano silicon carbide, 0.1-0.5 part of a solid lubricant, 0.2-1.0 part of a lubricant and 0.1-1 part of an antioxidant and then carrying out melting extrusion granulation through a twin-screw extruder. Tetraethoxysilane and a coupling agent are used for composite surface treatment of the nano silicon carbide, the dispersity of the nano silicon carbide as a wear-resisting agent in matrix resin is increased, and thus the cohesive property of the wear-resisting agent and the high-temperature-resistant nylon matrix is improved, the prepared high-temperature-resistant nylon has significant improvement in wear resistance; at the same time, with use of the hydrophobic high-temperature-resistant odor-adsorption masterbatch, the product is kept a low-odor characteristic in processing and application processes.

Owner:HEFEI GENIUS NEW MATERIALS

Antistatic polypropylene composite material and method for preparing same

The invention discloses an antistatic polypropylene composite material and a method for preparing the same and belongs to the technical field of modifying and processing polymers. The antistatic polypropylene composite material is prepared from the following raw materials in percentage by weight: 50 to 98 percent of polypropylene, 0 to 30 percent of inorganic filler, 0 to 20 percent of flexibilizer POE, 1 to 5 percent of antistatic agent, 0.1 to 1 percent of antioxidant and 0 to 1 percent of other auxiliary agents. The composite material and the method have the advantages that: 1, a proper amount of tin oxide is added in the composite material system, so that the prepared polypropylene composite material has better antistatic property; 2, under a condition of guaranteeing the antistatic property, the physical mechanical properties of the prepared polypropylene composite material are hardly affected; and 3, the method for improving the antistatic property of the polypropylene composite material is simple in preparation process and low in production cost.

Owner:SHANGHAI PRET COMPOSITES

Wood protective agent

InactiveCN1727142AAnti-leakageExcellent flame retardant functionWood impregnation detailsWater softeningAlcohol

Owner:BEIJING SHUANGCHENGMU TECH

Conductive polypropylene composite material and preparation method thereof

InactiveCN101759918AGood electrical conductivityGuaranteed electrical conductivityNon-conductive material with dispersed conductive materialPolypropylene compositesLinear low-density polyethylene

The invention discloses a conductive polypropylene composite material, which is prepared by the following materials by weight percentage: 60-89 percent of polypropylene, 5-15 percent of linear low density polyethylene, 5-20 percent of conductive black, 0.05-3 percent of coupling agents, 0.1-1 percent of antioxidants and 0-1 percent of other auxiliaries; the auxiliary which can effectively improve the electric conducting performance is added in a basic formula of the polypropylene composite material, so as to prepare the polypropylene composite material with better electric conducting performance. The invention has the advantages that: 1. proper conductive black is used in a composite material system, so as to lead the prepared polypropylene composite material to have better electric-conduction characteristic; 2. while the prepared polypropylene composite material ensures the electric conducting performance of the material, all physical mechanical property of the material can not be affected basically; 3. in the method for improving the electric conducting performance of the polypropylene composite material, the preparation process is simple and has no environment pollution.

Owner:SHANGHAI PRET COMPOSITES

Light aging resistant polypropylene composition and preparation method thereof

ActiveCN101759922AGood long-term light aging resistanceGuaranteed light aging resistancePolypropylene compositesPolymer science

The invention discloses a light aging resistant polypropylene composition. The light aging resistant polypropylene composition is prepared from the following raw materials in percentage by weight: polypropylene 55-99, inorganic filler 0-42, flexibilizer POE 0-20, light stabilizer 0.1-0.5, antioxidant 0.1-1 and other assistants 0-5. The invention has the advantages that: 1, a macro-molecular-weight hindered-amine light stabilizer is added in the polypropylene composition, so the polypropylene composite material prepared has high long-term light aging resistance; 2, the prepared polypropylene composition can ensure the light aging resistance of a material and prevent the physical mechanical properties of the material from being influenced; and 3, the method for improving the light aging resistance of the polypropylene composition, which is provided by the invention, has an extremely simple preparation process and low production cost.

Owner:CHONGQNG PRET NEW MATERIAL +2

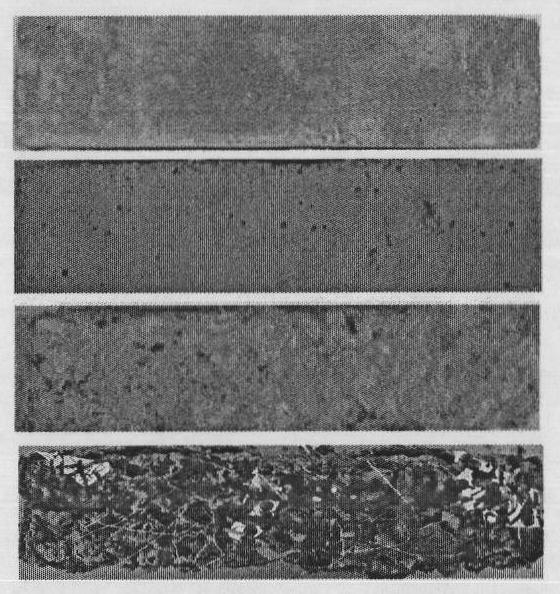

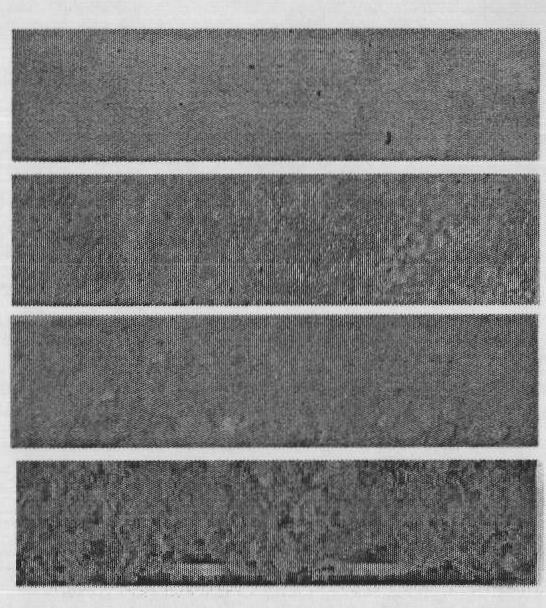

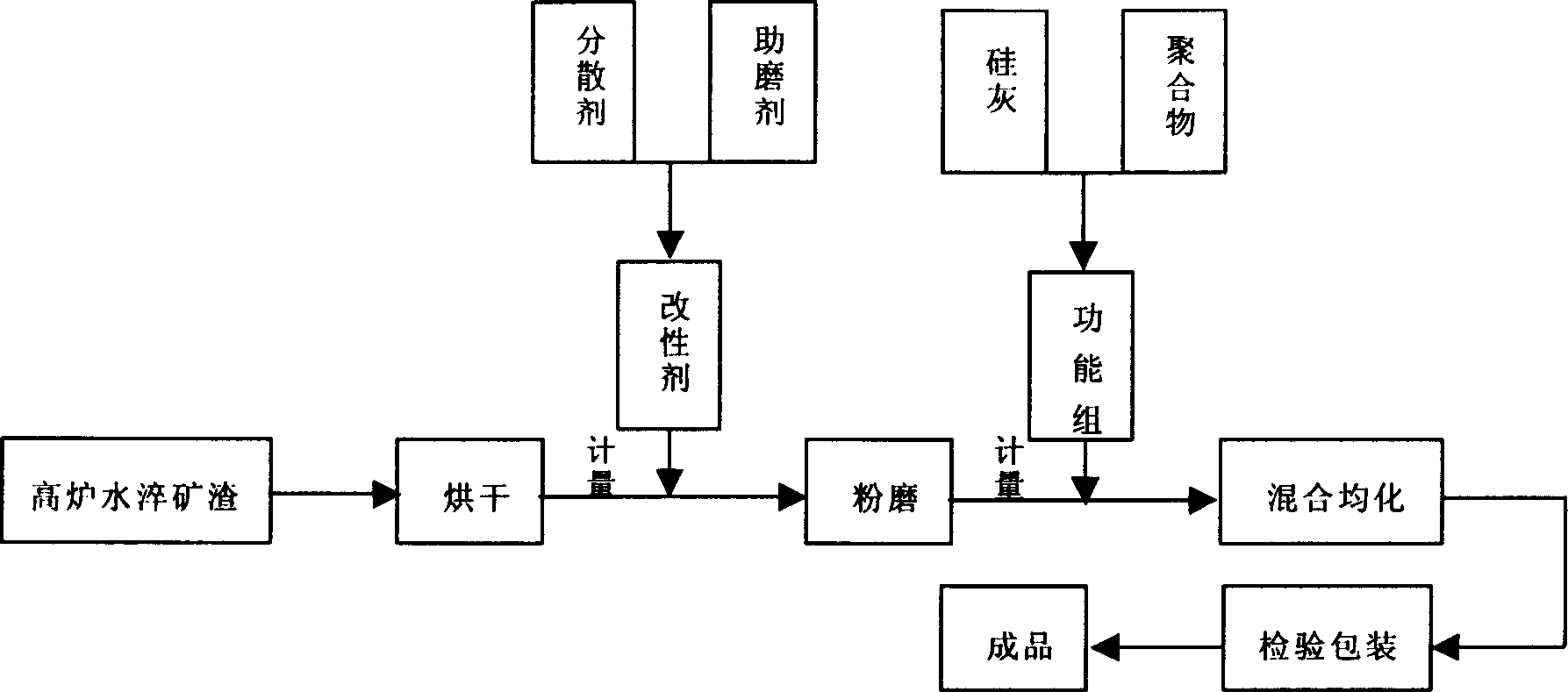

Acid rain corrosion resisting concrete additive and preparation method thereof

InactiveCN101851080AImproved particle size distributionHigh activitySolid waste managementFiberChemical admixture

The invention relates to an acid rain corrosion resisting concrete additive and a preparation method thereof. The acid rain corrosion resisting concrete additive is characterized by mainly comprising the following materials in parts by weight: 100 parts of grounded furnace slag, 150-300 parts of high-lime fly ash, 10-50 parts of siliceous dust, a polymer, organic fiber and a function intensifyingcomponent, and the addition quantities of the polymer, the organic fiber and the function intensifying component respectively account for 3-5%, 0.5-2.5% and 3-8% of the total mass of the grounded furnace slag, the high-lime fly ash and the siliceous dust, wherein the function intensifying component is a chemical additive prepared by compounding an exciting agent and a dispersing agent in the massratio of 1:0.02-0.08. The acid rain corrosion resisting concrete additive is applied to concrete in acid rain environment, can obviously increase the acid rain corrosion resistance of the concrete, can extend the service life of concrete structures, and is low in price.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Novel low-odor and low-emission ABS resin compound and preparation method thereof

The invention discloses a low-odor and low-emission ABS resin compound which contains the following materials by weight proportion: 100 ABS, 1.0-5.0 hydrophobic odor adsorption master batch, 0.1-1.0 antioxidant and 0-5.0 other auxiliaries. The invention has the advantages that a hydrophobic odor adsorption system is adopted, so the low-odor and low-emission ABS resin compound prepared through the method can ensure the characteristic of low odor of the material, the processing of the material is not affected and the physical mechanical properties of the material are not affected.

Owner:CHONGQNG PRET NEW MATERIAL +2

Polypropylene composite material with excellent illumination aging resisting performance and preparing method thereof

InactiveCN101210088AGood light aging resistanceImprove anti-separation performanceMolecular sievePolypropylene composites

The invention discloses a polypropylene composite material that has excellent light and aging resistant performance and a preparation method thereof. The polypropylene composite material that has excellent light and aging resistant performance consists of raw materials comprising 55 to 95wt percent of polypropylene, 0 to 40wt percent of inorganic filler, 0 to 20wt percent of toughener POE, 0.1 to 5wt percent of molecular sieve activator powder, 0.1 to 1wt percent of main chemical inhibitor, 0.1 to 1wt percent of secondary chemical inhibitor, 0.1 to 2wt percent of light stabilizer agent and 0 to 5.0wt percent of other additives. By adding powder molecular sieve into basic formulation of the polypropylene composite material, the dispersibility of the light stabilizer agent in the polypropylene composite material is effectively improved, thus improving the light and aging resistant performance of the polypropylene composite material.

Owner:SHANGHAI PRET COMPOSITES

PVC cladded polypropylene micro-foamed plastic and its preparation technology

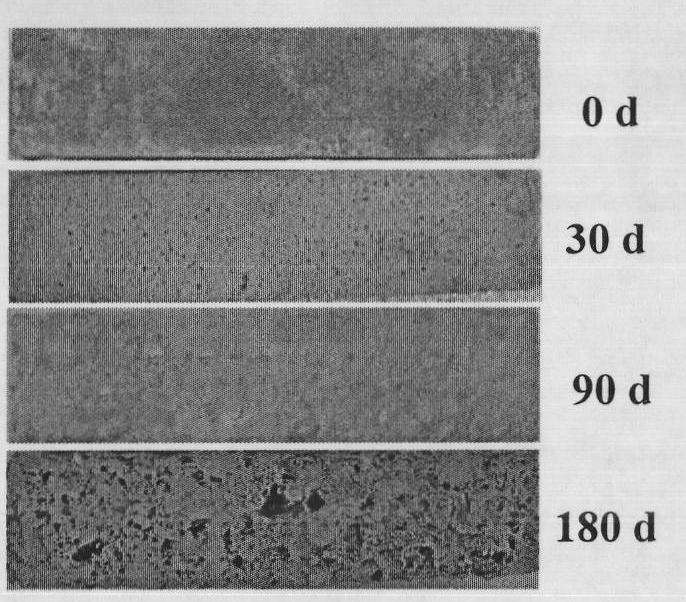

InactiveCN102514330AGood lookingSimple preparation processSynthetic resin layered productsAntioxidantPolypropylene composites

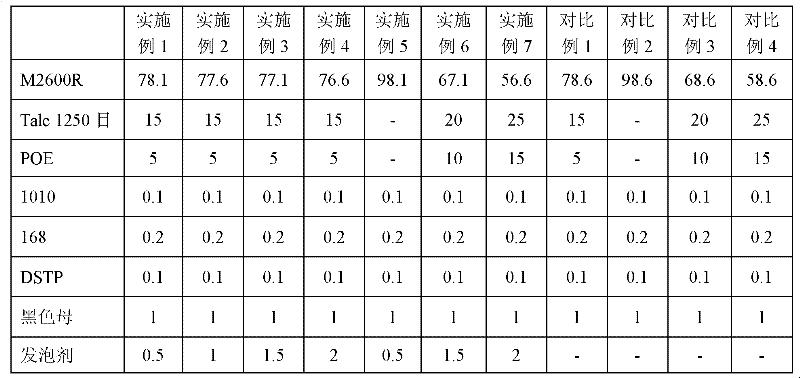

The invention discloses a PVC (polyvinyl chloride) cladded polypropylene micro-foamed plastic and its preparation technology. The preparation technology comprises: mixing 98-99.5 wt% of a polypropylene composite material and 0.5-2 wt% of a foaming agent uniformly, then subjecting the mixture and PVC to integrated injection molding in a die cavity. The polypropylene composite material is prepared by the following raw materials by weight percent: 56-98% of polypropylene, 0-25% of an inorganic filling material, 0-15% of a toughening agent POE (polyethylene-octene elastomer), 0.1-1% of antioxidants, and 0-3% of other assistant. And the foaming agent is azodicarbonamide. The technology of the invention has the advantages that: 1. an appropriate amount of the foaming agent is used in a composite material system so as to make the prepared product has better appearance; 2. while guaranteeing the appearance of the composite material, the product prepared in the invention also has various physical mechanical properties basically not influenced; and 3. the preparation technology for improving PVC cladded polypropylene micro-foamed plastic articles has the advantages of simplicity and low production cost.

Owner:SHANGHAI PRET COMPOSITES

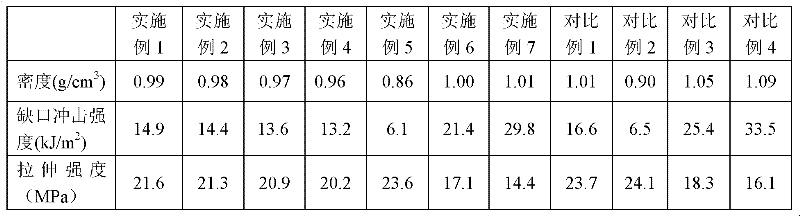

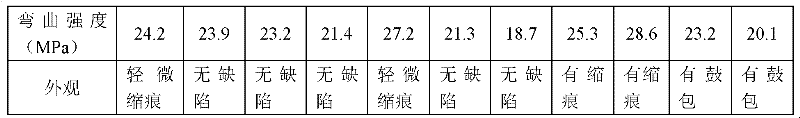

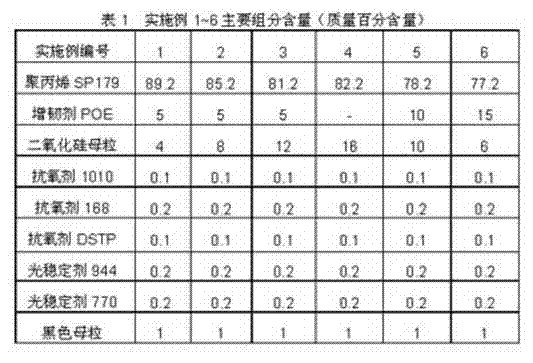

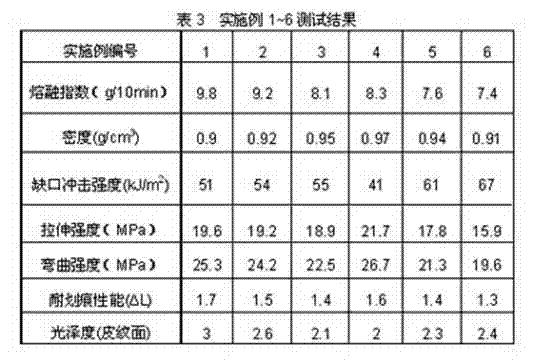

Low-gloss and scratch-resistant polypropylene material and preparation method thereof

The invention provides a low-gloss and scratch-resistant polypropylene material and a preparation method thereof. The low-gloss and scratch-resistant polypropylene material comprises the following components in percent by weight: 77-90 percent of polypropylene, 0-15 percent of toughening agent POE (Polyolefin Elastomer), 4-16 percent of silicon dioxide master batches, 0.1-2 percent of antioxidant, 0.1-1 percent of light stabilizer and 0.1-3 percent of other additives. The preparation method comprises the following steps of: firstly adopting linear low-density polyethylene as matrix resin, blending the linear low-density polyethylene with nano silicon dioxide to prepare master batches, then mixing the polyethylene, the silicon dioxide master batches, the antioxidant, the light stabilizer, other auxiliaries and the like according to the ratio, and carrying out melt extrusion and granulation. The invention has the advantages that the preparation process is simple, no environmental pollution is caused, and the prepared polypropylene material has good low-gloss and scratch-resistant performances, and simultaneously also has good dynamic performance.

Owner:SHANGHAI PRET COMPOSITES

Scratch-resistant imitated-metal-effect polypropylene composite material and preparation method thereof

InactiveCN105504483AImprove scratch resistanceGuaranteed wear resistancePolypropylene compositesAntioxidant

The invention discloses a scratch-resistant imitated-metal-effect polypropylene composite material and a preparation method thereof. The scratch-resistant imitated-metal-effect polypropylene composite material is prepared from the following raw materials in percentage by weight: 41-92% of polypropylene, 0-25% of inorganic filler, 0-15% of toughener, 0.1-4% of effect pigment, 0.1-4% of scratch resisting agent, 0.1-1% of light stabilizer and 0.1-1% of antioxidant. By adding a right amount of scratch resisting agent into the imitated-metal-effect polypropylene composite material, the prepared imitated-metal-effect polypropylene has better scratch resistance. Various physical mechanical properties of the prepared imitated-metal-effect polypropylene composite material are basically not influenced on the premise of ensuring the wear resistance of the material. The method for improving the wear resistance of the imitated-metal-effect polypropylene composite material has the advantages of simple preparation technique and low production cost.

Owner:SHANGHAI PRET COMPOSITES

Temperature-resistant and wear-resistant modified polypropylene composite material

InactiveCN105885213AHigh surface glossGood strength and impact resistanceWear resistantPolytetrafluoroethylene

The invention discloses a temperature-resistant and wear-resistant modified polypropylene composite material. The polypropylene composite material comprises the following components in parts by weight: 65-75 parts of polypropylene resin, 10-20 parts of nanoscale polytetrafluoroethylene ultrafine powder (mineral filler), 5-12 parts of toughening agents, 8-15 parts of wear resistant fillers (wear resistant agents) and 0.2-2 parts of auxiliaries. The polypropylene composite material has the advantages and beneficial effects that by adding the nanoscale polytetrafluoroethylene ultrafine powder and the wear resistant fillers to the polypropylene resin, various physical and mechanical properties of the material are basically not affected while the wear resistance of the material is ensured; the obtained material has high surface gloss and has better impact resistance and strength.

Owner:林建君

Water-soluble antirust insulating paint and preparation method therefor

ActiveCN104974625APromote passivationImprove rust resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPhosphoric acid

The invention provides a water-soluble antirust insulating paint and a preparation method therefor. The water-soluble antirust insulating paint disclosed by the invention consists of the following components in parts by weight: 18-25 parts of an antirust base material, 20-30 parts of an insulation base material, 2-4 parts of a rust transforming agent , 2-3 parts of a passivation preservative, 0.5-0.9 part of a drying agent, 1.3-1.6 parts of an auxiliary, 20-30 parts of a pigment filling, and 30-40 parts of water, wherein the base material is the mixture of nonsoap aqueous acrylic ester, epoxy resin and polyurethane; the rust transforming agent consists of mica ferric oxide and phosphoric acid; the phosphoric acid is industrial hydrochloric acid of which the content is 85%; the weight ratio of the mica ferric oxide to the phosphoric acid is 1:1-1.5. The antirust paint is scientific and reasonable in formula, can use water to replace petroleum and benzene as a solvent, and has dual functions of rust removal and rust prevention, so that the antirust paint can be widely used for anticorrosive construction and anticorrosive construction of steel structures.

Owner:HUZHOU HUJIE PAINT CO LTD

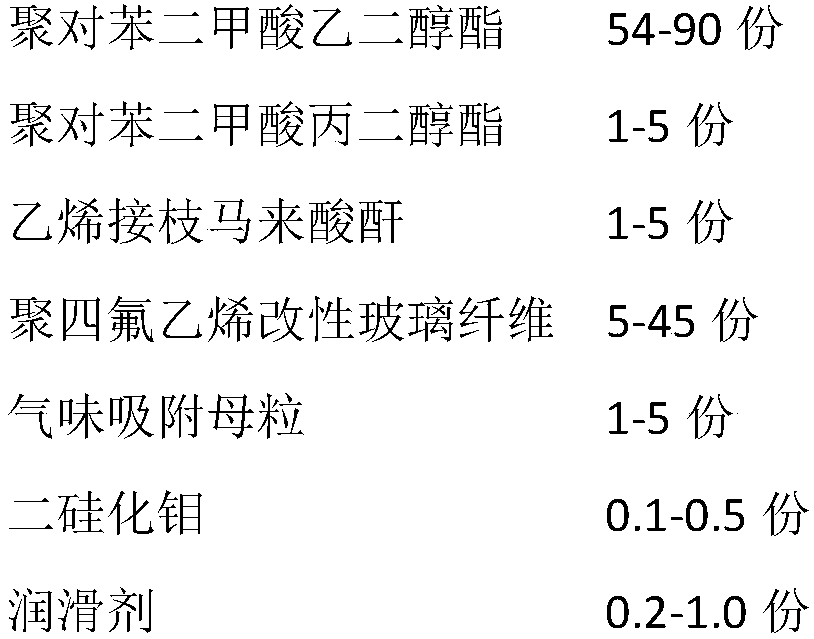

Modified nylon composition and preparation method thereof

The invention provides a modified nylon composition and a preparation method thereof, and relates to the technical field of macromolecular materials. The modified nylon composition is prepared from the following raw materials: nylon 6, nylon 66, POE grafted maleic anhydride, polytetrafluoroethylene modified glass fibers, an odor adsorption masterbatch, silicon carbide, a lubricant and an antioxidant. The modified nylon composition has the characteristics of low odor and good wear resistance. The nylon composition prepared by coordinating action of the raw materials has remarkable improvement in wear resistance and keeps excellent mechanical properties, and the forming and processing properties of the material are not affected.

Owner:HEFEI GENIUS NEW MATERIALS

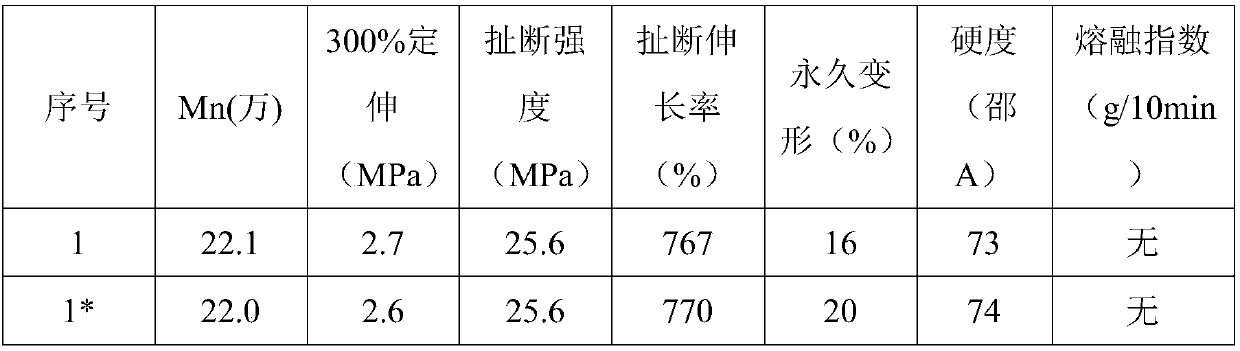

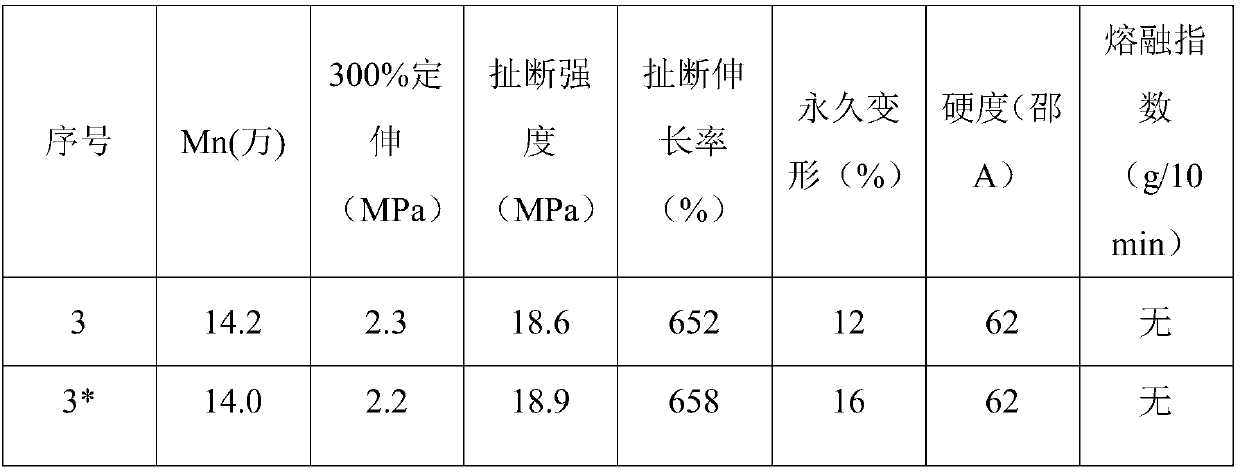

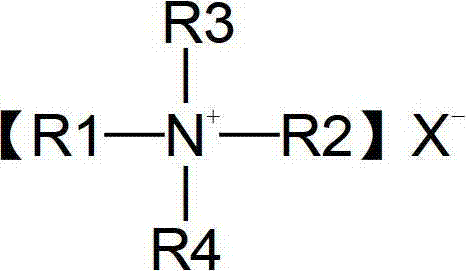

Hydrogenated pentablock styrene thermoplastic elastomer and preparation method thereof

InactiveCN109836547AImprove liquidityImprove permanent deformationThermoplastic elastomerMechanical property

The invention discloses a hydrogenated pentablock styrene thermoplastic elastomer and a preparation method thereof. The hydrogenated pentablock styrene thermoplastic elastomer is prepared by hydrogenation of a styrene-b-butadiene-b-styrene-b-butadiene-b-styrene pentablock copolymer. The preparation method includes: conducting segmented polymerization by anionic polymerization process to obtain a styrene-b-butadiene-b-styrene-b-butadiene-b-styrene pentablock copolymer sol, and then performing hydrogenation. The hydrogenated pentablock styrene thermoplastic elastomer provided by the invention has high fluidity and small permanent deformation, and at the same time has good mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel low-odor and low-emission ABS resin compound and preparation method thereof

Owner:CHONGQNG PRET NEW MATERIAL +2

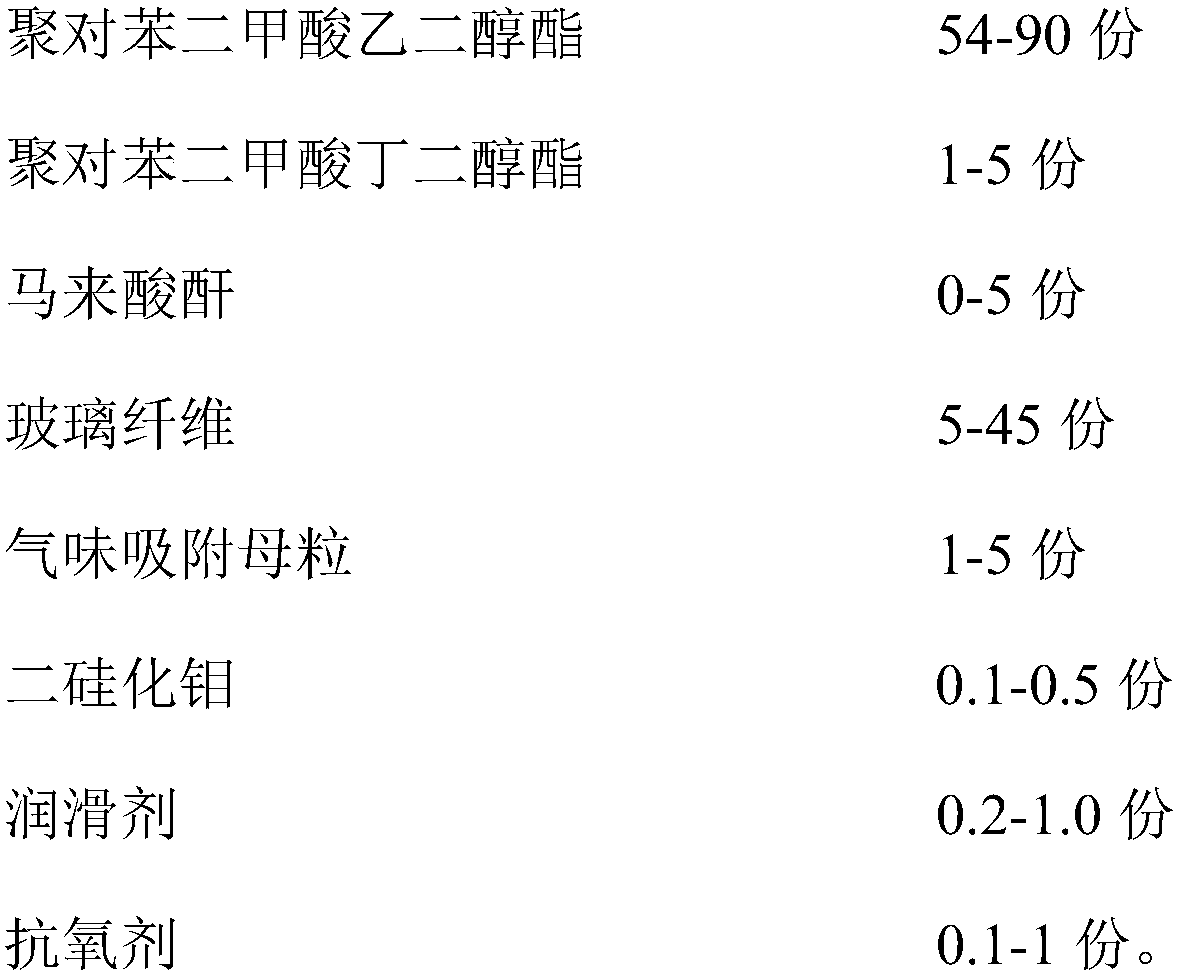

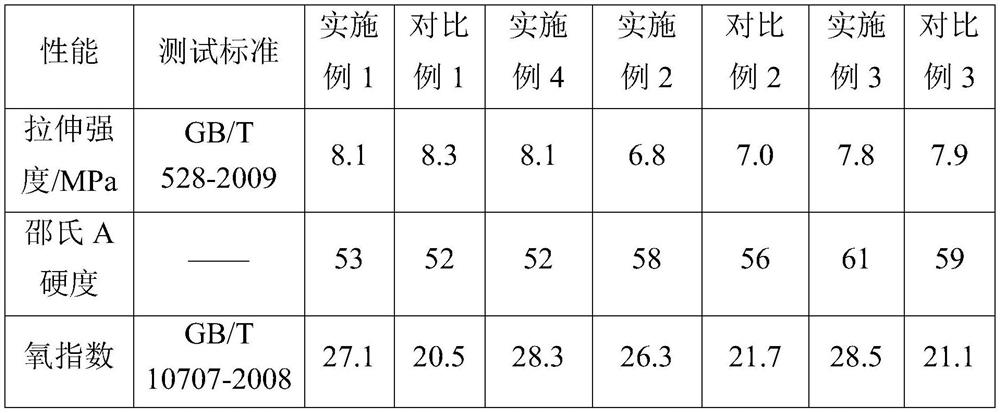

Low-odor, low-volatilization and high-wear-resistance polyethylene glycol terephthalate composition and preparation method thereof

The invention discloses a low-odor, low-volatilization and high-wear-resistance polyethylene glycol terephthalate composition and a preparation method thereof. The composition is prepared from, by weight, 54-90 parts of polyethylene glycol terephthalate, 1-5 parts of polybutylene terephthalate, 0-5 parts of maleic anhydride, 5-45 parts of glass fiber, 1-5 parts of odor adsorption masterbatch, 0.1-0.5 part of molybdenum disilicide, 0.2-1.0 part of a lubricant, and 0.1-1 part of an antioxidant. The glass fiber is subjected to immersion treatment with polyphenyltetramethylamide dispersion liquid,the dispersion of the glass fiber in a polyethylene glycol terephthalate base is greatly improved, the wear resistance of the prepared composition is significantly improved, and meanwhile the composition maintains excellent mechanical properties. The odor adsorption masterbatch is used for reducing the content of small molecules in the composition, and the content of a total volatile organic compound (TVOC) is significantly reduced; the low odor property of the composition is ensured, and the various physical and mechanical properties and the material molding processing properties are not affected.

Owner:HEFEI GENIUS NEW MATERIALS

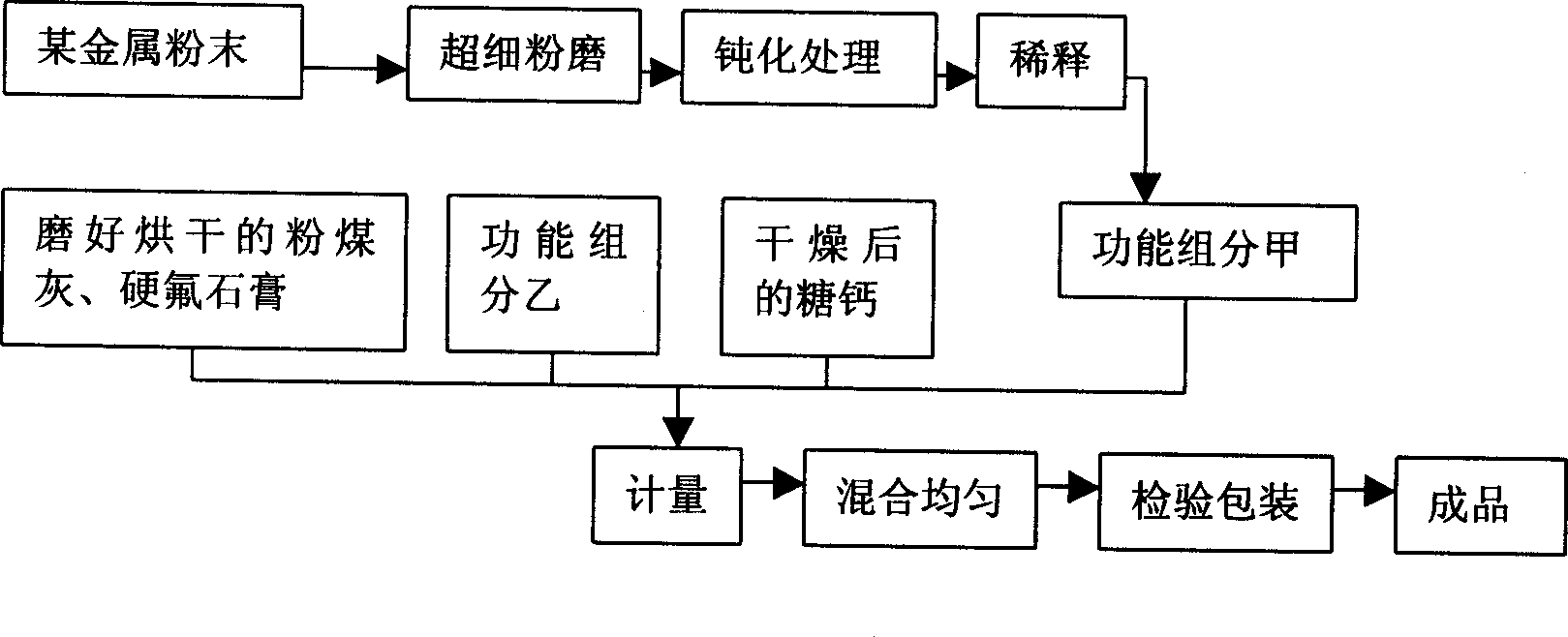

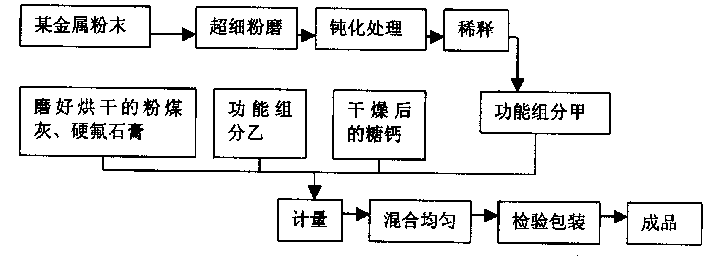

Technique and method for preparing mineral additive of multi-function concrete

InactiveCN1431161AImprove impermeabilityImprove frost resistanceSolid waste managementSodium sulfateWaste material

A multifunctional mineral additive for concrete is prepared through superfine grinding of metal powder, purifying, diluting with quartz powder to obtain component A, proportionally mixing the industrial waste whose main component is ferrous sulfate with sodium sulfate, grinding to obtain component B, and proportionally mixing said A and B with dried calcium saccharide, fine powdered coal ash and anhydrite. It can control the slump loss of concrete and improve the antifreezing and impervious performance of concrete.

Owner:WUHAN UNIV OF TECH

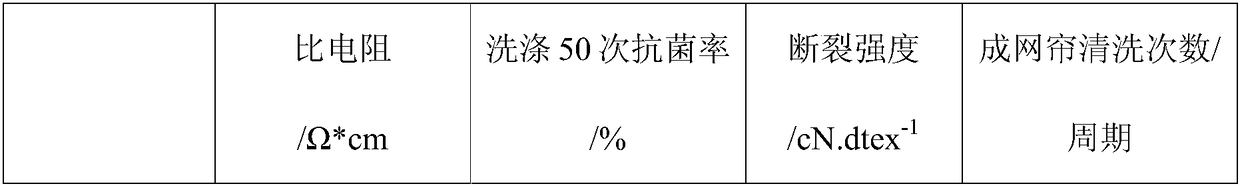

Antistatic and antibacterial acrylic nonwoven fabric and preparation method thereof

ActiveCN108796831AFix compatibility issuesSolve antistaticElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentSocial benefitsAntistatic agent

The invention relates to an acrylic nonwoven fabric, in particular to an antistatic and antibacterial acrylic nonwoven fabric and a preparation method thereof. The antistatic and antibacterial acrylicnonwoven fabric is prepared from polyacrylonitrile dry power dry basis, antistat, antibacterial agent, pore-foaming agent, synergist, anti-sticking agent and solvent; the synergist is glycerinum, andthe pore-foaming agent is polyethylene glycol; the anti-sticking agent is polyoxyethylene; and the weight-average molecular weight of the polyacrylonitrile dry power is 70000-100000. The antistatic and antibacterial acrylic nonwoven fabric has the advantages that the pore-foaming agent and the synergist are introduced, the problems that the compatibility is poor when the antistat and the antibacterial agent are added into the polyacrylonitrile simultaneously, the antistatic and antibacterial performance is poor, and the effect of simultaneous addition of the antistat and antibacterial agent descends than that of single addition of the antistat and antibacterial agent are solved, the prepared nonwoven fabric has a significant antistatic and antibacterial effect, the effect of the simultaneous addition of the antistat and antibacterial agent is greatly improved than that of the single addition of the antistat and antibacterial agent, and the physical and mechanical properties of the nonwoven fabric cannot not be affected. The invention further provides the preparation method, the materials are obtained easily, the industrialized production is easy, and the economic and social benefits are better.

Owner:CHINA PETROLEUM & CHEM CORP

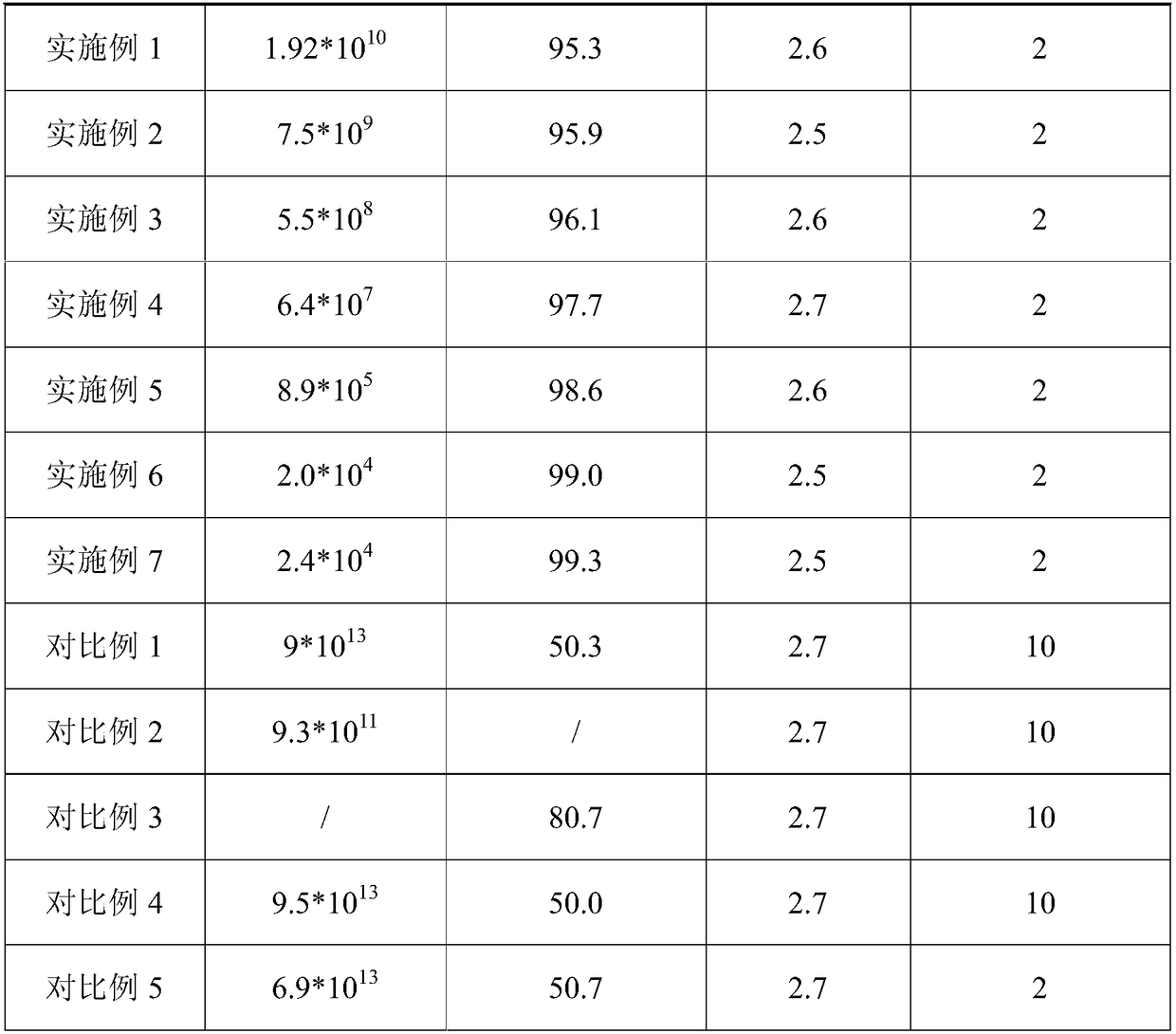

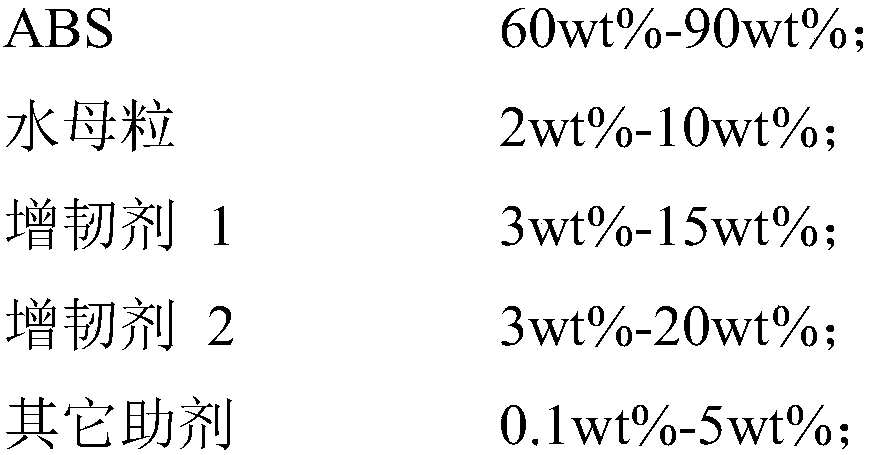

Commercial vehicle interior decoration plate environmentally-friendly ABS resin composition

ActiveCN107629386AImproved notched impact strength and elongationImprove cold resistanceVolatile organic compoundBulk polymerization

The present invention relates to the technical field of vehicle interior decoration plates, particularly to a commercial vehicle interior decoration plate environmentally-friendly ABS resin composition, which comprises: 60-90 wt% of ABS, 2-10 wt% of aqueous masterbatch, 3-15 wt% of a toughening agent 1, 3-20 wt% of a toughening agent 2, and 0.1-5 wt% of other auxiliary agents, wherein the ABS is apolymer formed through emulsion polymerization or bulk polymerization and having different impact strengths and fluidities. According to the present invention, with the technical scheme, on the basisof no influence on various physical and mechanical properties of the material, the produced product has advantages of less volatile organic compound and low product odor, can be used in environmentally-friendly vehicle interior decoration plate application places having high requirements on the transverse performance and the longitudinal performance of extruded plates and having high requirementson the odor and the total carbon volatilization, and further has good application market and sale prospect.

Owner:大韩道恩高分子材料(上海)有限公司

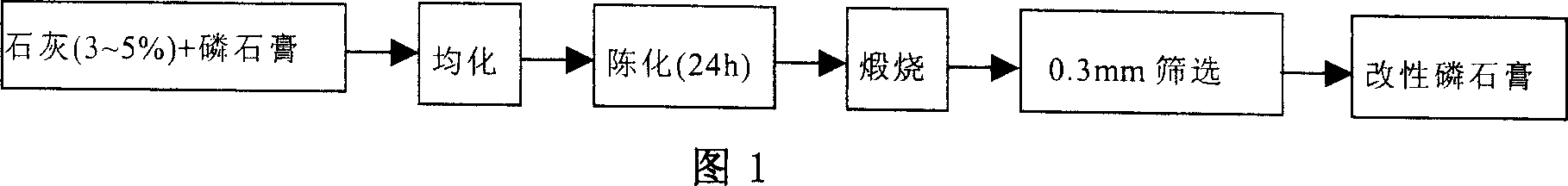

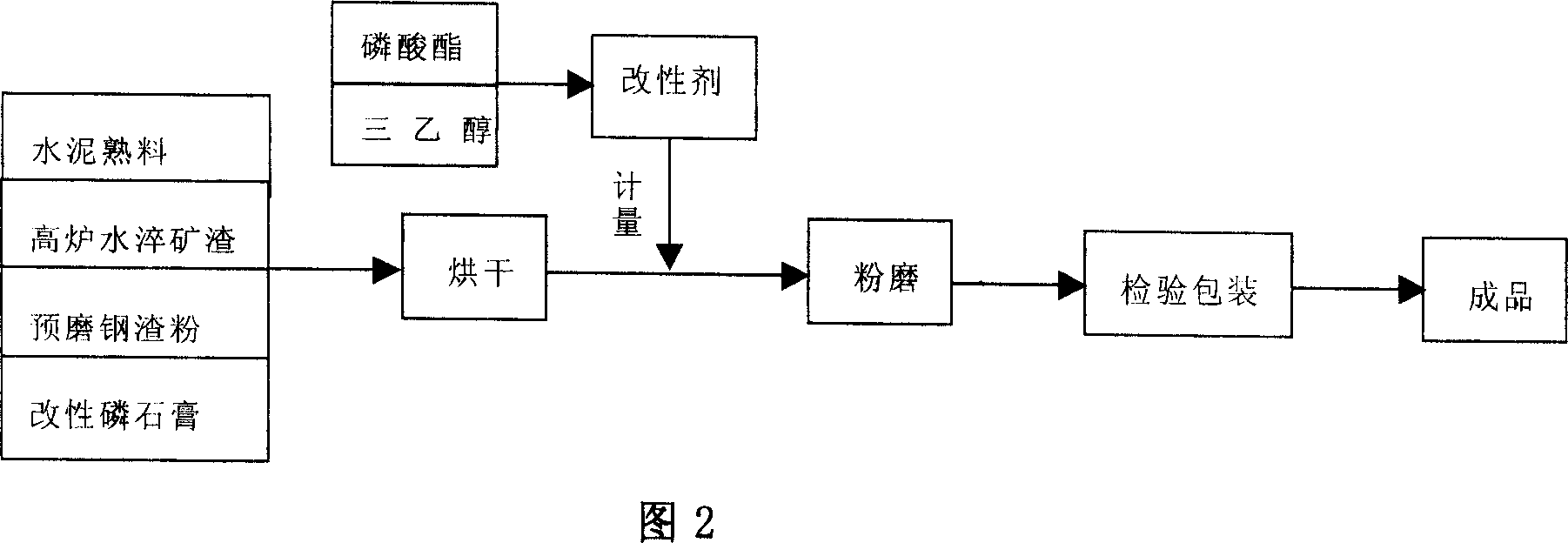

High sulfide resistant cement demixture and preparation thereof

InactiveCN1792972AImprove penetration resistanceReduce contentSolid waste managementHigh resistanceSulfur

A cement additive with high resistance to sulfur is proportionally prepared from the water-quenched slags of blast furnace, the shrinkage reducing component consisting of alkylenediol or polyoxyalkylene glycol and wollastonite, and the modifier consisting of polycarboxylic acid type super-disperser and triethanolamine. It can resist against the corrosion of multiple sulfates.

Owner:WUHAN UNIV OF TECH

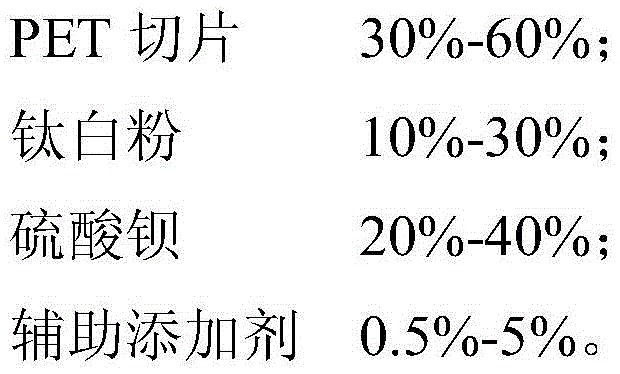

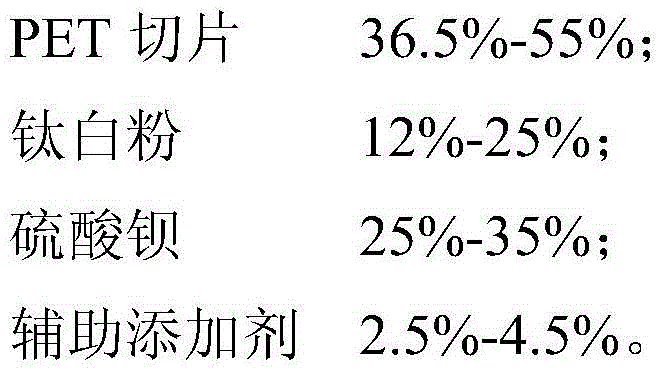

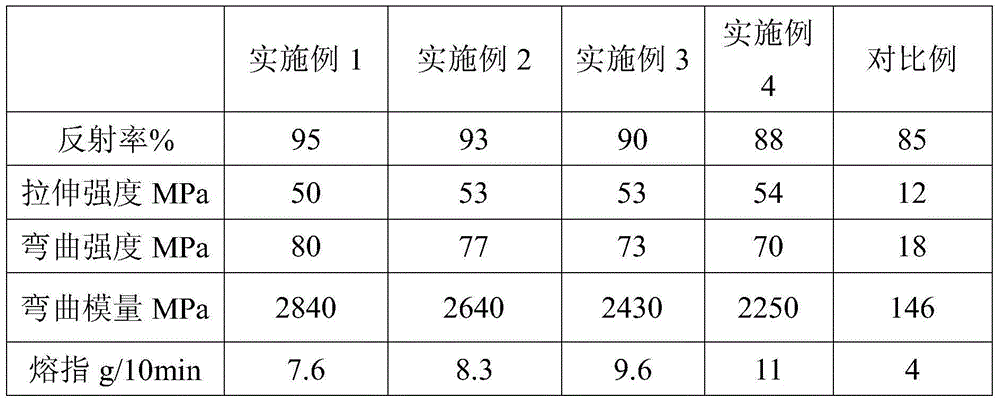

High reflectivity PET material for photovoltaic film

InactiveCN105462181AImprove reflectivityLittle influence of molding processPolymer scienceRefractive index

The present invention relates to the technical field of polymer modification and processing, and in particular relates to a PET material. A formula of a high reflectivity PET material for a photovoltaic film is as below: 30%-60% of PET chips, 10%-30% of titanium dioxide, 20%-40% of barium sulfate and 0.5-5% of auxiliary additive. The preparation steps are as below: weighing the materials, sending the materials into a high-speed mixer, feeding the mixture into a twin-screw extruder, and conducting melt extrusion and granulation to obtain the product. According to the technical scheme, the PET material has greatly improved reflectivity compared to the product of the prior art, minimizes the influence on molding processing of PET film, maintains the physical and mechanical properties of unaffected. The preparation process is simple, and low in production cost.

Owner:大韩道恩高分子材料(上海)有限公司

High efficient wide-spectrum sulfide resistant gelled material and preparation process thereof

InactiveCN100344569CImprove penetration resistancePrevent intrusionSolid waste managementSulfateSulfur

Owner:WUHAN UNIV OF TECH

Polyformaldehyde composition and preparation method thereof

The invention provides a polyformaldehyde composition and a preparation method thereof, and relates to the technical field of high polymer materials. The polyformaldehyde composition is prepared fromthe following raw materials: polyformaldehyde, ultra-high-molecular-weight polyethylene modified glass fibers, odor-adsorption master batches, molybdenum disulfide, a lubricant and an antioxidant. Thepolyformaldehyde composition disclosed by the invention has low odor and good wear resistance and stability. Through the adoption of the matching effect of the raw materials such as the ultra-high-molecular-weight polyethylene modified glass fibers, the odor-adsorption master batches and the like, the low-odor characteristic of the polyformaldehyde composition is ensured, and the physical and mechanical properties of the polyformaldehyde composition and the moulding processability of the material are not affected at the same time.

Owner:HEFEI GENIUS NEW MATERIALS

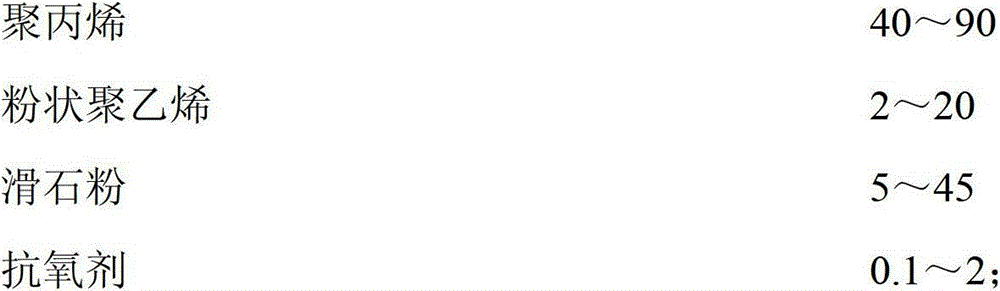

High-rigidity and high-heat resistance polypropylene composite material and preparation method thereof

The invention discloses a high-rigidity and high-heat resistance polypropylene composite material, which is prepared from the following ingredients in percentage by weight: 40 to 90 of polypropylene, 2 to 20 of powdery polyethylene, 5 to 45 of talcum, 0.1 to 2 of antioxidizers and 0 to 5 of other accessory agents. The powdery polyethylene which can effectively solve the problem of difficult material feeding in a system for preparing the polypropylene composite material is added into a basic recipe of the polypropylene composite material, so the high-rigidity and high-heat resistance polypropylene composite material can be prepared. The invention has the advantages that 1, the dispersing capability of the talcum in the composite material system can be obviously improved through using a proper amount of powdery polyethylene, so the obtained polypropylene composite material maintains the characteristics of high rigidity and high heat resistance; 2, the prepared polypropylene composite material ensures the successful material feeding, and at the same time, each physical-mechanical property is basically not influenced; and 3, the provided method for solving the problem of difficult material feeding of the polypropylene composite material has the advantages of simple preparation process and low production cost.

Owner:CHONGQNG PRET NEW MATERIAL +2

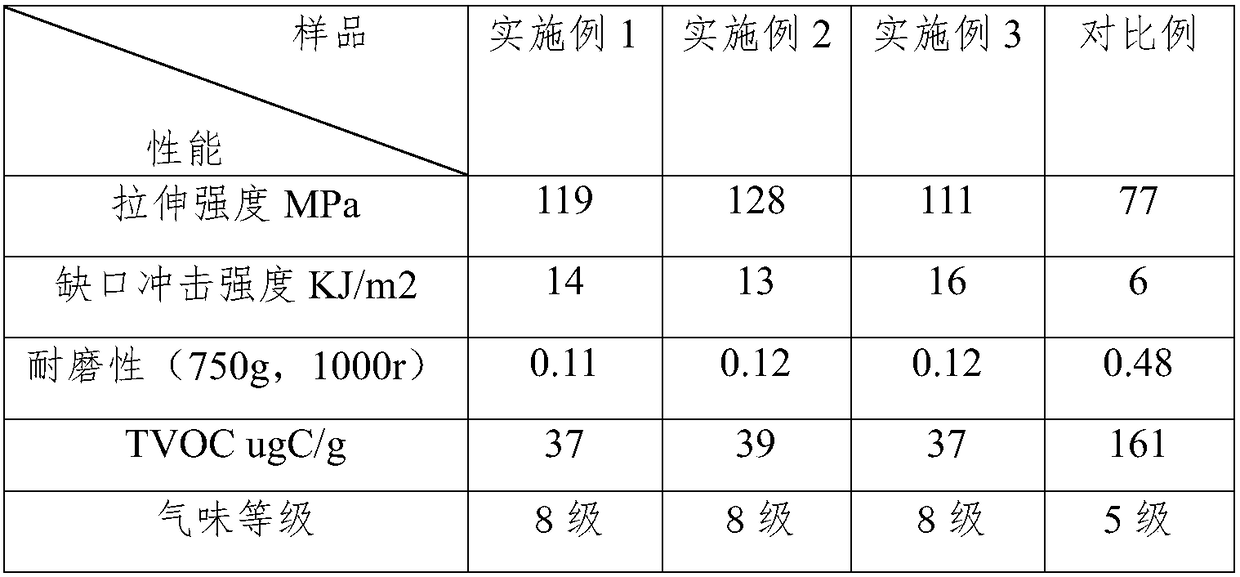

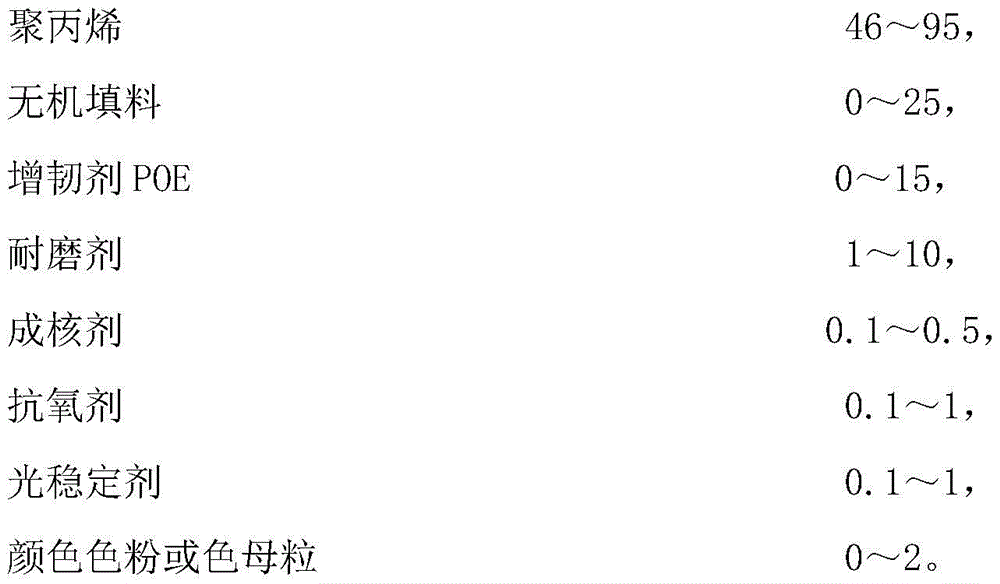

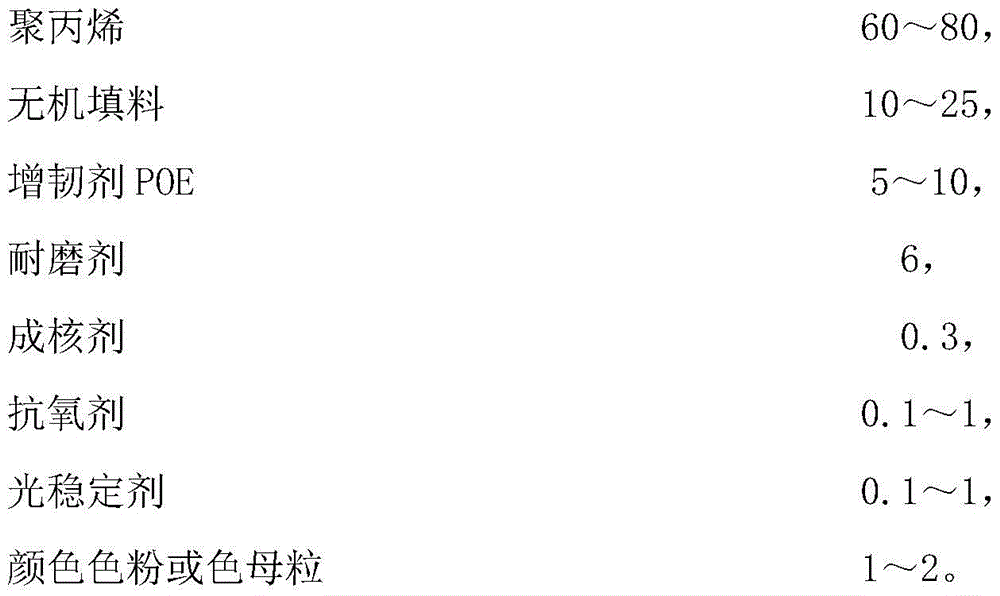

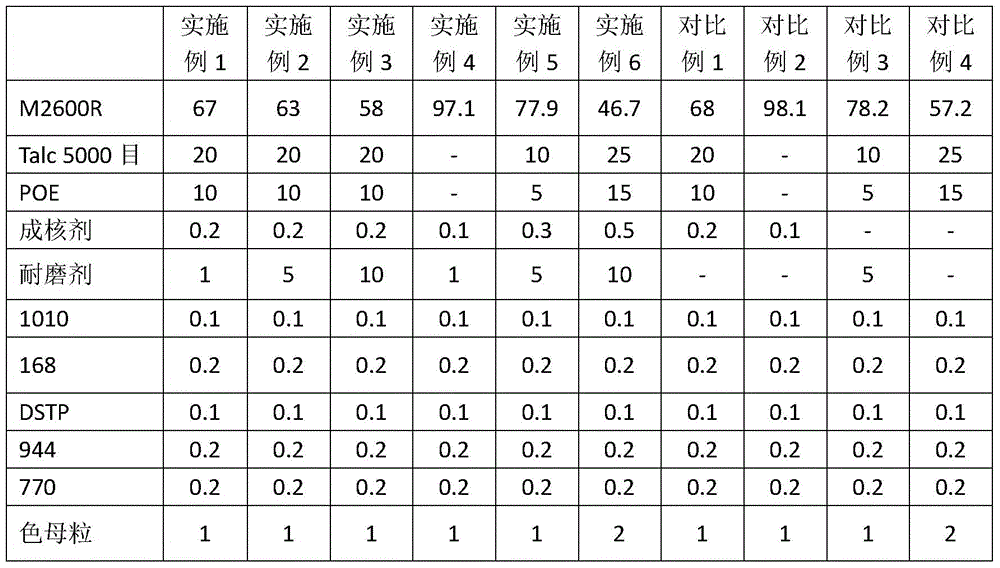

A kind of wear-resistant polypropylene composite material and preparation method thereof

ActiveCN103756132BImprove wear resistanceGuaranteed wear resistancePolypropylene compositesPolymer science

The invention discloses a wear-resisting polypropylene composite material and a preparation method thereof. The wear-resisting polypropylene composite material is composed of the following raw materials in percentage by weight: 46-95 parts of polypropylene, 0-25 parts of inorganic fillers, 0-15 parts of a toughening agent POE (Polyoxyethylene), 1-10 parts of a wear-resisting agent, 0.1-0.5 part of a nucleating agent, 0.1-1 part of an antioxidant, 0.1-1 part of a light stabilizing agent and 0-2 parts of color toner or color master batch. The raw materials are put into a high-speed mixer to be mixed for 3-5 minutes; the mixed raw materials are put into a double-screw extruder; then mixed raw materials are subjected to melt extrusion and granulation. The process is as follows: the temperature of a first zone is 190-200 DEG C, the temperature of a second zone is 200-210 DEG C, the temperature of a third zone is 210-220 DEG C and the temperature of a fourth zone is 205-215 DEG C; the staying time of a whole extruding process is 1-2 minutes and the pressure is 12-18MPa. According to the wear-resisting polypropylene composite material and the preparation method thereof, the wear-resisting agent and the nucleating agent are added in a basic formula of the polypropylene composite material so as to prepare the polypropylene material with a good wear-resisting performance. The wear-resisting polypropylene composite material has the advantages that the wear-resisting performance of the material is guaranteed and physical and mechanical properties of the materials are basically not influenced; the preparation process is simple and the production cost is low.

Owner:CHONGQNG PRET NEW MATERIAL +2

Low odor and emission nylon 6 composition and preparation method thereof

ActiveCN101760010BLow Odor PropertiesPhysical and mechanical properties are not affectedAntioxidantAdditive ingredient

The invention discloses low odor and distribute nylon 6 combination which comprises the following components in proportion by weight: 55 to 99% of nylon 6, 0 to 6% of polypropylene grafted with maleic anhydride, 0 to 30% of inorganic filler, 0.5 to 3.5 of hydrophobic odor adsorbent, 0.1 to 1% of antioxidant, 0 to 2% of lubricant and 0 to 3% of other accessory ingredient. The invention has the advantages that a hydrophobic odor adsorbent system is used, when the low odor characteristics of the materials are ensured by the low odor and distribute nylon 6 combinations, various physical mechanics capabilities of the materials are not influenced, and the contour machining property of the materials is not influenced.

Owner:SHANGHAI PRET COMPOSITES

Low-odor and high-wear-resistant PET composition and preparation method thereof

ActiveCN108929526AGood dispersionImprove wear resistancePolymer sciencePolyethylene terephthalate glycol

The invention provides a low-odor and high-wear-resistant PET composition and a preparation method thereof, wherein the low-odor and high-wear-resistant PET composition is prepared from the followingcomponents in parts by weight: polyethylene glycol terephthalate, polypropylene glycol terephthalate, ethylene grafted maleic anhydride, polytetrafluoroethylene modified glass fibers, an odor adsorption masterbatch, molybdenum disilicide, a lubricant and an antioxidant. The glass fibers impregnated with polytetrafluoroethylene greatly improve the dispersion in a matrix, the wear resistance of theprepared composition is improved remarkably, and excellent mechanical properties are maintained. In addition, the odor adsorption masterbatch reduces the small molecular content in the composition, and the total volatile organic compounds TVOC are reduced remarkably; moreover, while the low odor characteristics of the composition are guaranteed, the physical and mechanical properties and the forming and processing properties of the material are not affected.

Owner:HEFEI GENIUS NEW MATERIALS

Flame-retardant two-component polyurethane adhesive and preparation method thereof

PendingCN114395360ARealization of flame retardant modificationWith flame retardant functionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention provides a flame-retardant two-component polyurethane adhesive and a preparation method thereof. The flame-retardant double-component polyurethane adhesive comprises a main agent and a curing agent which are mixed according to a set proportion. The main agent takes a brominated polyol prepolymer, polyester and / or polyether polyol as main components, and inorganic filler and a catalyst are added at the same time; the curing agent is mainly composed of a polyisocyanate compound. The flame-retardant double-component polyurethane adhesive has the advantages that the raw materials are convenient to obtain, the manufacturing process is simple, the obtained product can be cured at room temperature, the adhesive has intrinsic flame retardance, the flame-retardant effect is lasting and stable, and the finished product is good in physical and mechanical properties and high in bonding strength.

Owner:杭州得力科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com