High-rigidity and high-heat resistance polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of preparing modified polypropylene composite materials, can solve problems such as difficult feeding, uneven mixing, and insufficient talcum powder addition, and achieve low production costs and improved dispersion capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment, the present invention is described in further detail:

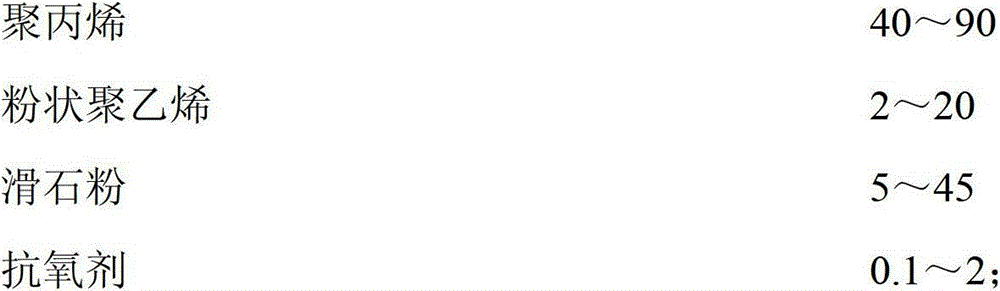

[0026] In the formulations of the composite materials of the examples and comparative examples, polypropylenes are high crystalline homopolypropylene and block copolymerized polypropylene with different fluidity, and the dosage is 40-75% (wt%), and the comonomer of block copolymerized polypropylene is common. It is ethylene, and its content is in the range of 4 to 10 mol%. The melt flow rate (230° C.×2.16 kg) of polypropylene is 5 to 60 g / 10 min. The crystallinity of high crystalline polypropylene is above 70%, and the isotacticity is greater than 99%. The particle size range of the inorganic filler talc powder is 1-10 microns. The powdery polyethylene is the unprocessed powdery polyethylene directly synthesized by the synthesis tower. Between 45 microns and 850 microns. Described main antioxidant is DSTP that British ICE company produces, trade name is Negonox DSTP, chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com