High reflectivity PET material for photovoltaic film

A photovoltaic film and high reflectivity technology, which is applied in the field of PET materials, can solve the problem that the reflectivity of photovoltaic films cannot meet the needs of the market, etc., and achieve the effects of improving reflection characteristics, low preparation cost, and improving reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

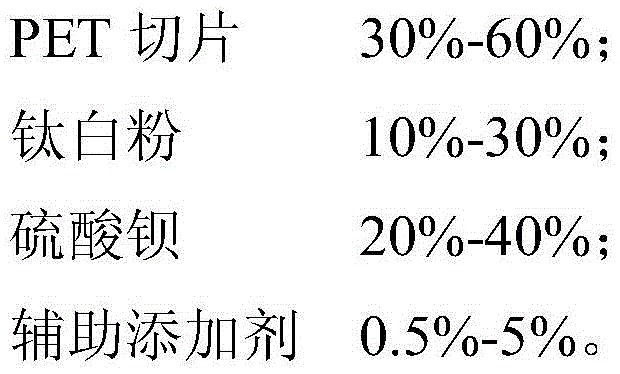

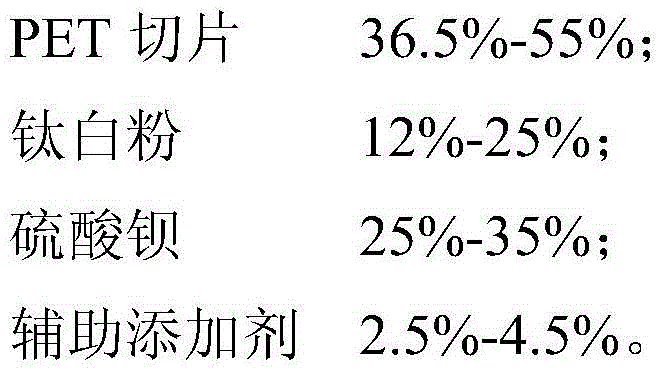

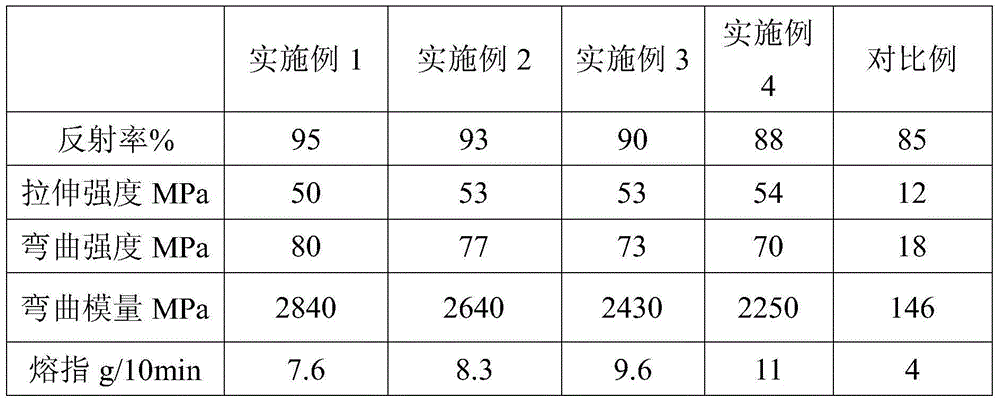

[0034] A high-reflectivity PET material for photovoltaic thin films, including the following raw material components in the weight ratio: 30%-60% of PET chips; 10%-30% of titanium dioxide; 20%-40% of barium sulfate; auxiliary additives 0.5%-5%. The PET chips of the present invention have a certain viscosity, and medium-viscosity and low-viscosity PET chips can be selected. When the medium-viscosity PET chips are selected, the intrinsic viscosity number is 0.59dl / g-0.72dl / g, preferably 0.63dl / g-0.67dl / g. When low-viscosity PET chips are used, the intrinsic viscosity is 0.49dl / g-0.63dl / g, preferably 0.52dl / g-0.61dl / g. Among them, the titanium dioxide adopts rutile type titanium dioxide, the particle size of the titanium dioxide and the barium sulfate are both 1 micron to 5 micron,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com