High efficient wide-spectrum sulfide resistant gelled material and preparation process thereof

A cementitious material, broad-spectrum technology, applied in the field of building materials, can solve the problems of reducing production cost, low utilization rate of industrial waste, and high production cost, and achieves the effect of reducing the source of reaction, increasing the permeability resistance, and preventing the intrusion channel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

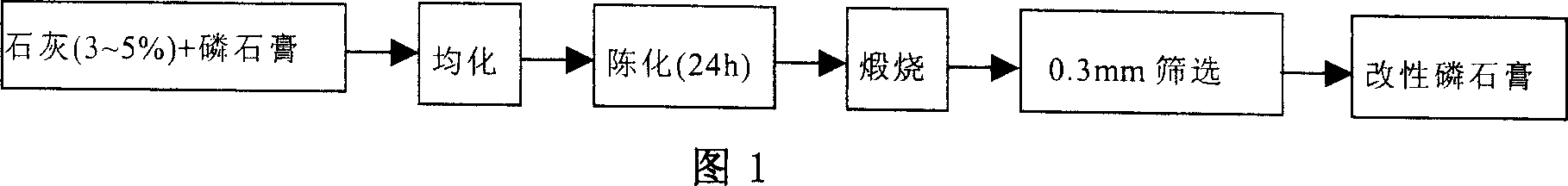

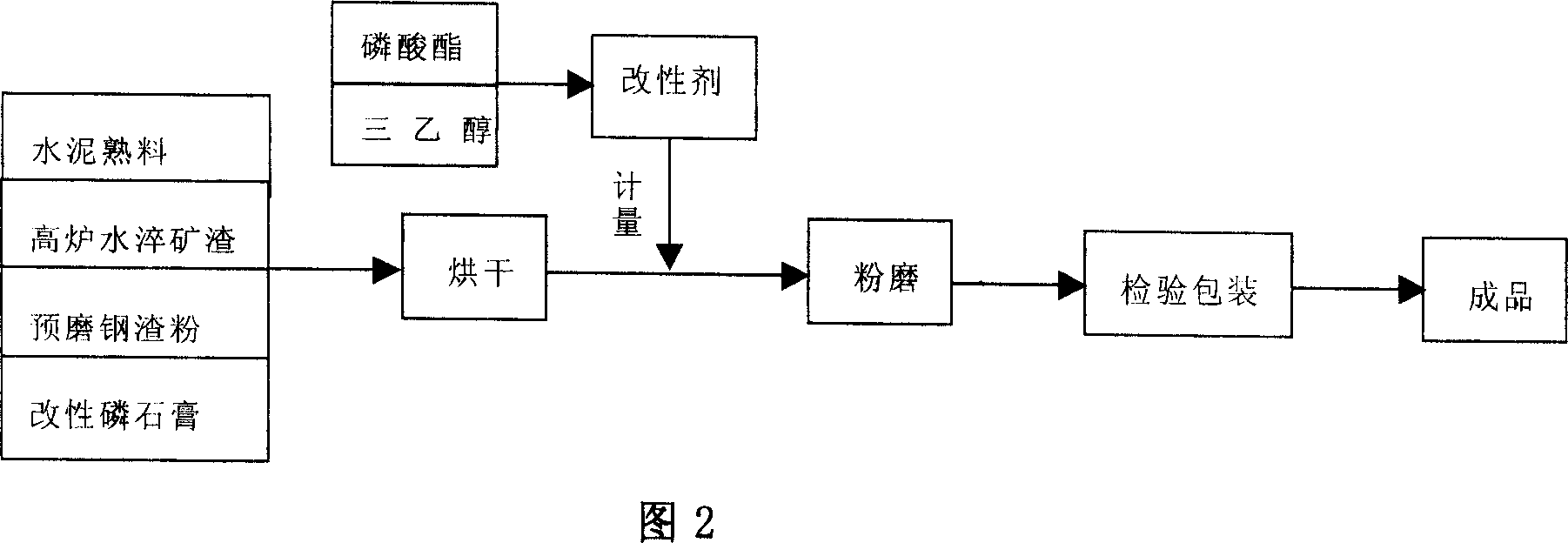

[0040] Embodiment 1: as shown in Figure 2, the preparation method of broad-spectrum sulfur-resistant cementitious material comprises the following steps: 1). The pretreatment of blast furnace water-quenched slag: select the commercially available blast-furnace water-quenched slag that meets national standards, and It is dried, and the moisture content after drying is 0.5-1.9%, and it is ready for use; 2). Preparation of pre-ground steel slag powder: the converter steel slag processed by the shallow pan water quenching process, the grain size of the incoming grinding is less than 5%, and the Blaine specific surface area 350-400m 2 / kg, after the pre-grinding iron removal process, the moisture content after drying is less than 2%; its f-CaO content is less than 5%, and the MgO content is less than 8%, so pre-grinding steel slag powder is obtained for future use; 3). Preparation: As shown in Figure 1, the functional component is modified phosphogypsum, and the preparation of modi...

Embodiment 2

[0051] Embodiment 2: as shown in Figure 2, the preparation method of broad-spectrum sulfur-resistant cementitious material comprises the following steps: 1). The pretreatment of blast furnace water-quenched slag: select the commercially available blast-furnace water-quenched slag that meets the national standard, and It is dried, and the moisture content after drying is required to be less than 2%, and it is used for standby; 2). Preparation of pre-grinded steel slag powder: the converter steel slag processed by the shallow pan water quenching process, the grain size of the incoming grinding is less than 5%, and the iron is removed by pre-grinding process, the moisture content after drying is less than 2%; its f-CaO content is less than 5%, and the MgO content is less than 8%, so as to obtain pre-ground steel slag powder for future use; 3). Preparation of functional components: the functional components To modify phosphogypsum, the preparation of modified phosphogypsum: accordi...

Embodiment 3

[0052] Embodiment 3: as shown in Figure 2, the preparation method of broad-spectrum sulfur-resistant cementitious material comprises the following steps: 1). The pretreatment of blast furnace water-quenched slag: select the commercially available blast-furnace water-quenched slag that meets the national standard, and It is dried, and the moisture content after drying is required to be less than 2%, and it is used for standby; 2). Preparation of pre-grinded steel slag powder: the converter steel slag processed by the shallow pan water quenching process, the grain size of the incoming grinding is less than 5%, and the iron is removed by pre-grinding process, the moisture content after drying is less than 2%; its f-CaO content is less than 5%, and the MgO content is less than 8%, so as to obtain pre-ground steel slag powder for future use; 3). Preparation of functional components: the functional components In order to modify phosphogypsum, the preparation of modified phosphogypsum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com