Ceramic armour and method of construction

a technology of ceramic armour and construction method, which is applied in the field of armor, can solve the problems of bulging deformation of the back surface of the armor, insufficient protection or any protection against armor piercing and/or high-energy projectiles, so as to improve the penetration resistance, reduce deformation, and high-energy projectiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

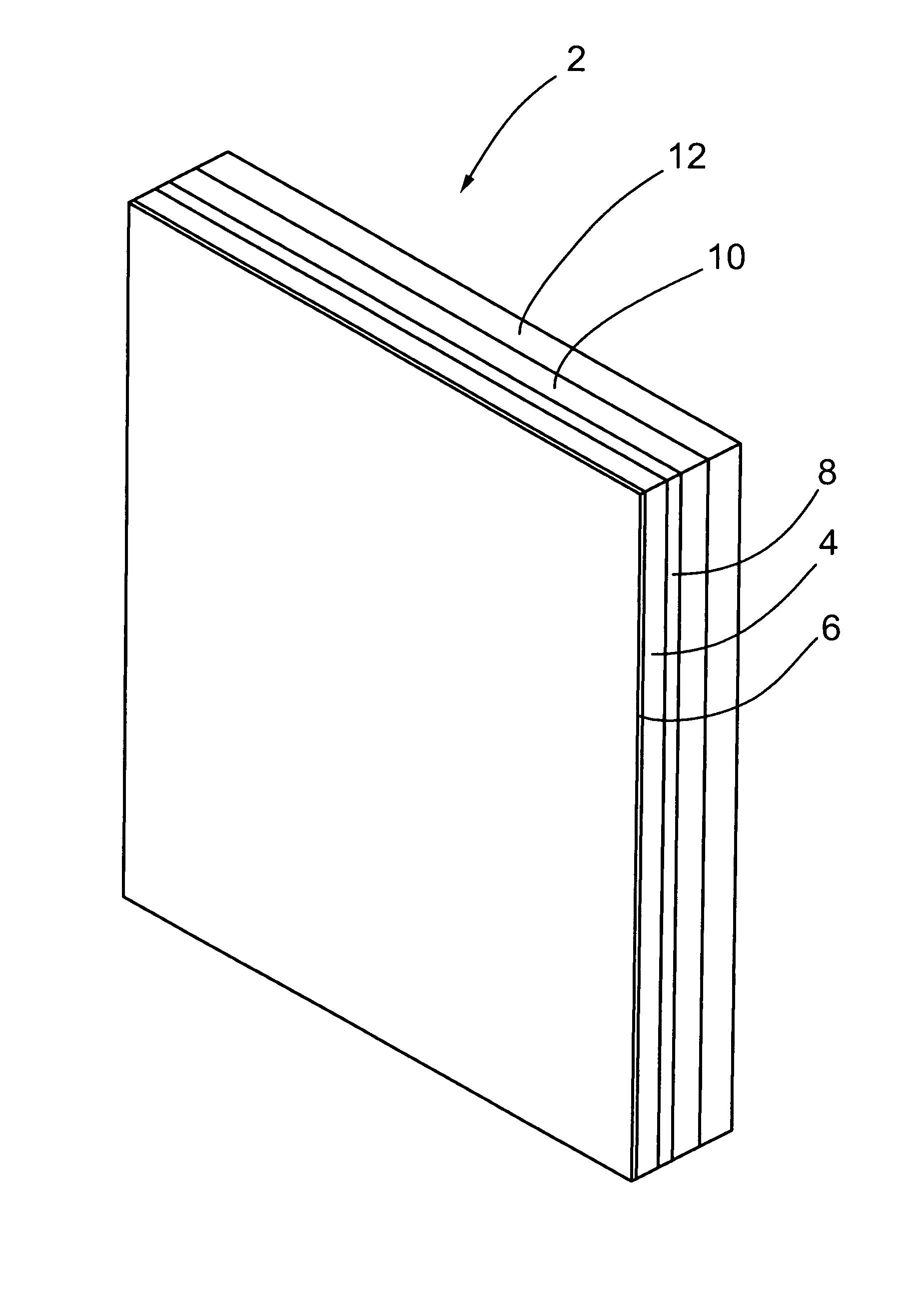

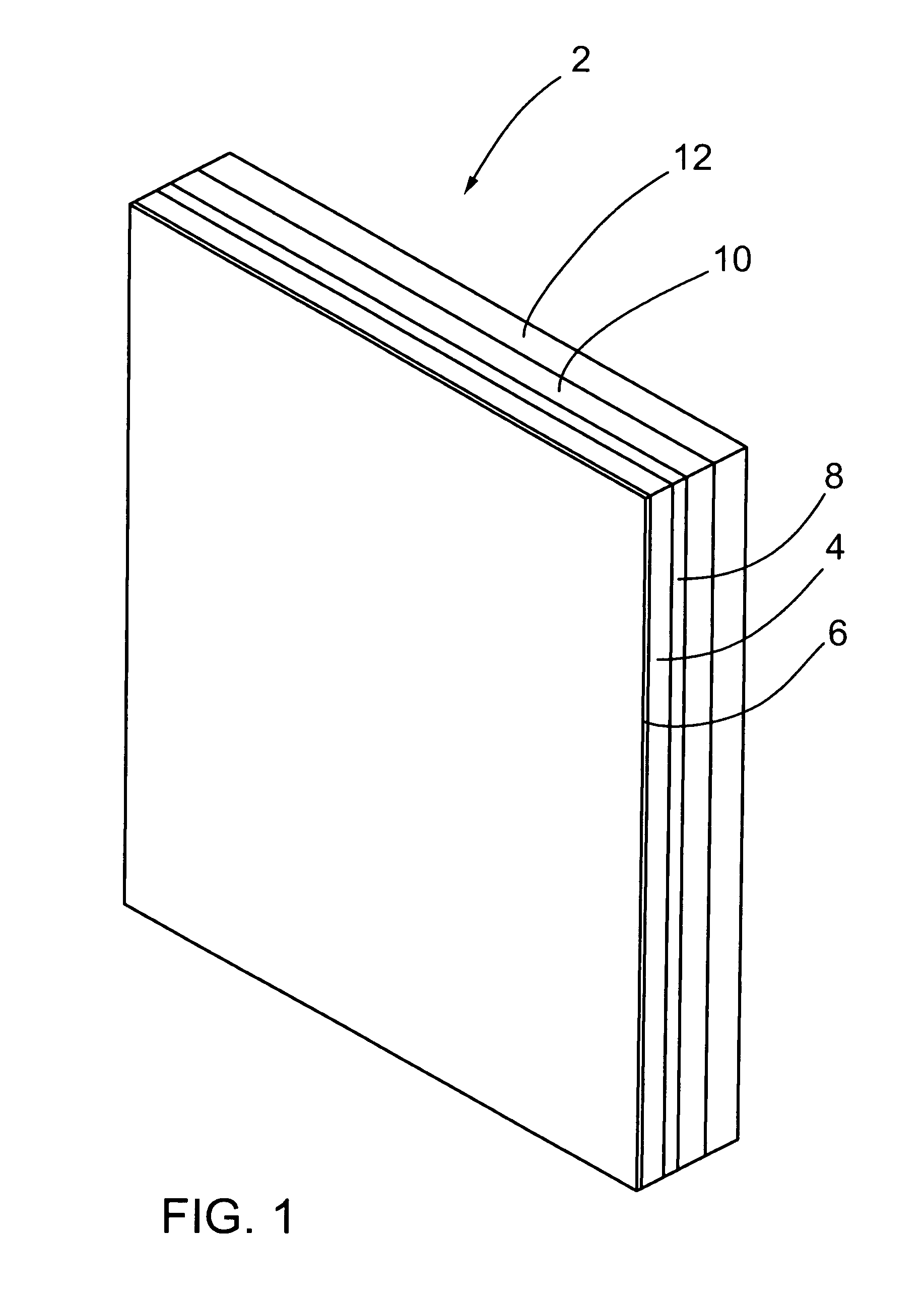

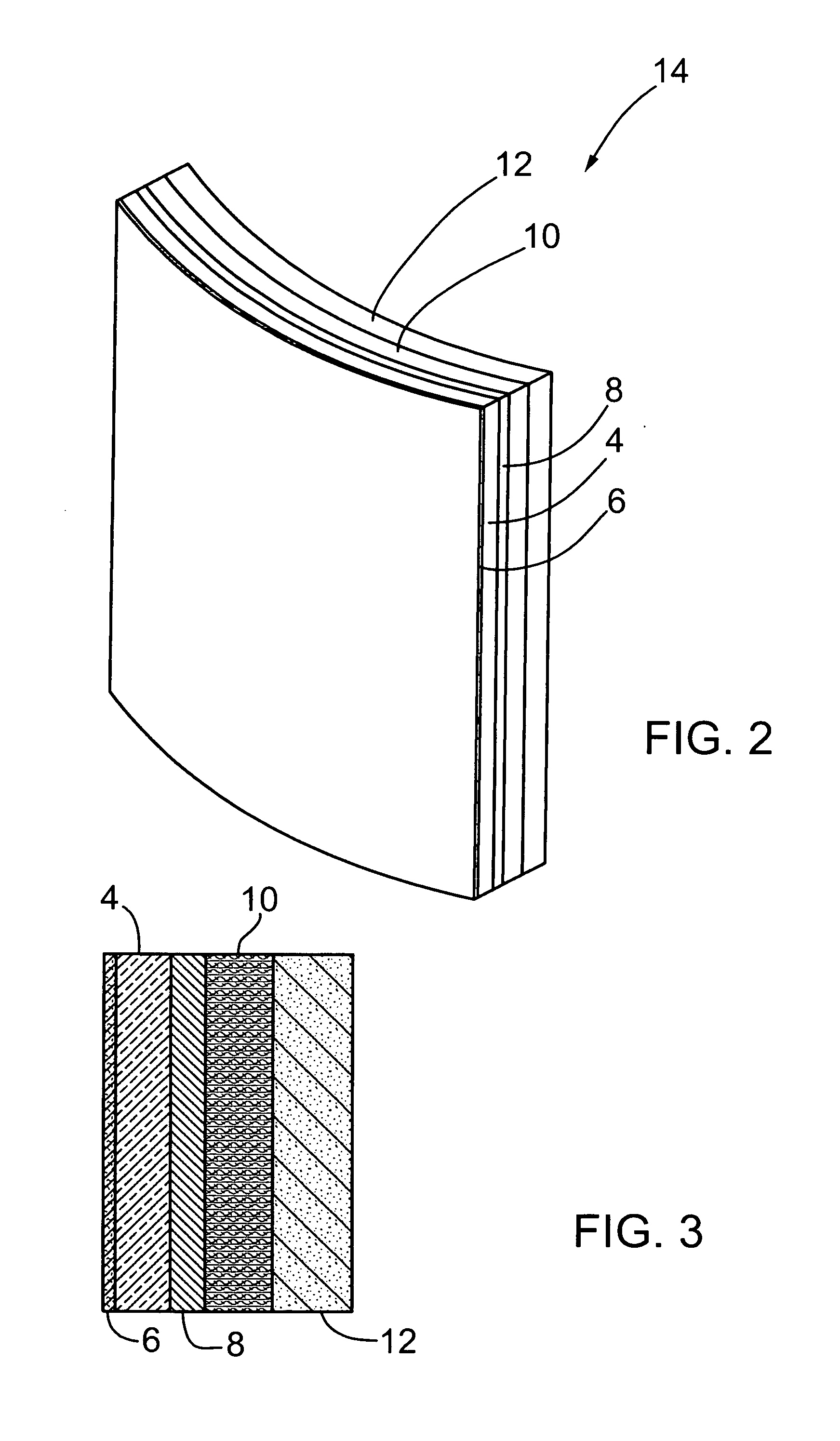

[0050]A multi-component armor plate has a confinement layer 6, ceramic layer 4 and first metal layer 8 that is 250 mm wide and 300 mm in height. The ballistic composite layer 10, a second metal layer 22 and anti-trauma layer 12 have dimensions of 250 mm in width by 300 mm in height. The total mass is approximately 4.8 kg.

[0051]In Example 1, the layers have the following thicknesses:

ThicknessMaterial2mmConfinement Layer (S-Glass with Structural Adhesive)11.1mmCeramic Layer (Silicon Carbide Manufactured by Saint-Gobain)1mmFirst Metal Layer—Titanium18.5mmBallistic composite layer consisting of 37 Layers ofKevlar ™ 129 with PVB Phenolic Matrix1mmSecond Metal Layer—Titanium15mmAnti-Trauma Layer

[0052]All layers in the example are bonded using a structural adhesive such as a urethane-based adhesive.

[0053]The design set out in Example 1 was evaluated using NIJ (National Institute of Justice) Standard 0101.04 (June 2001) (an applicable ballistic testing standard at the time of testing), whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com