Technique and method for preparing mineral additive of multi-function concrete

A mineral additive and multi-functional technology, applied in the field of building materials, can solve the problems such as the inability to meet the requirements of diversified functions of concrete admixtures, the reduction of the actual efficiency of high-efficiency water-reducing agents, and the slump loss of fresh concrete. Social and economic benefits, physical and mechanical properties are not affected, and the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

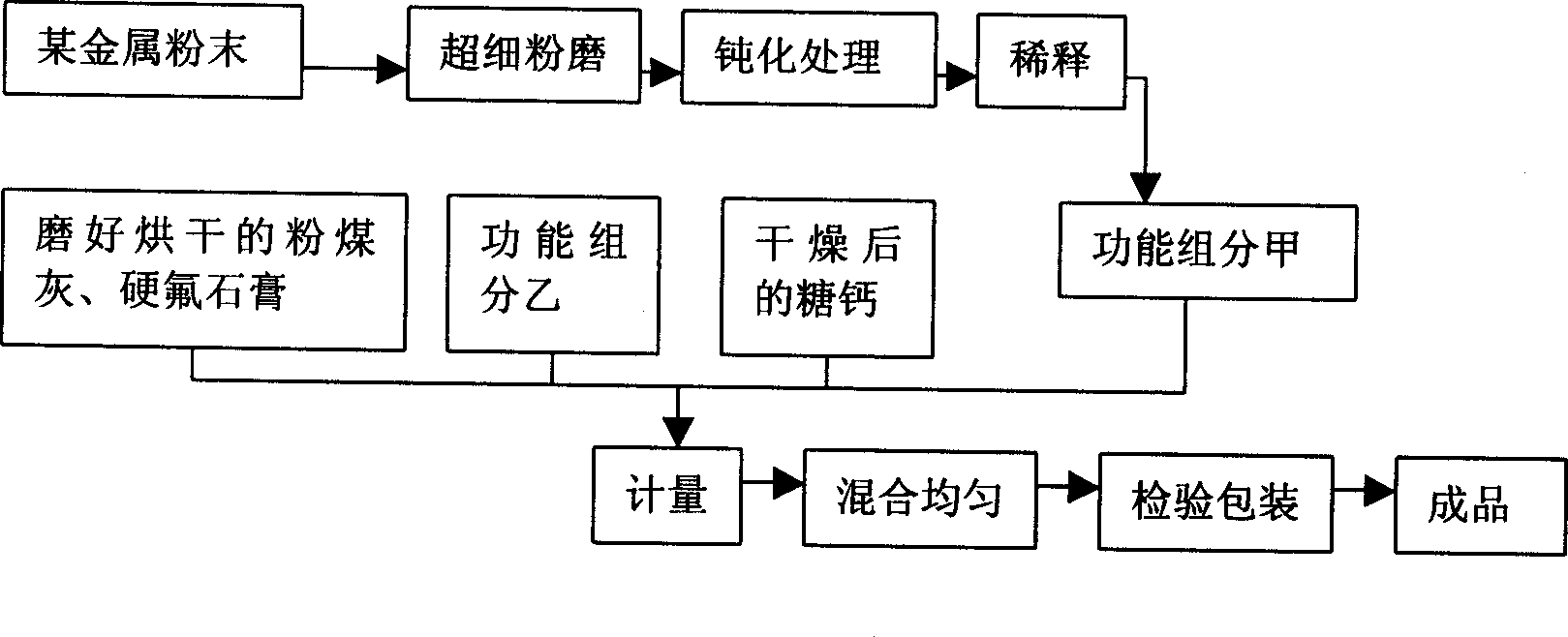

Method used

Image

Examples

Embodiment

[0029] Table 1 Formula of multifunctional mineral additives

[0030] Composition and dosage serial number of multifunctional mineral additives

[0031] Fluorogypsum + fly ash + B + A + modifier content (cement weight%) H 35% + 52% + 5% + 3% + 5% 12I 30% + 56% + 5% + 4% + 5 % 12G 33%+57%+3%+4%+3% 12

[0032] Table 2 Mixing ratio of multifunctional mineral additive H concrete test

[0033] Content of each component (kg / m 3 ) sample

[0034]Cement Sand Stone Water FDN Mineral Additive H UEAA0 439 478 1188 195 3.95 0 0A1 386 478 1188 195 3.95 0 53A2 386 478 1188 195 3.95 53 0

[0035] Table 3 Free linear expansion rate of mortar specimen

[0036] Free expansion rate (×10 -4 ) No. Expansion agent (dosage)

[0037] 1d 3d 5d 7d 11dB0 0 -1.8 -1.8 -1.9 -1.9 -2.0B1 UEA(12%) -0.4 0.6 2.6 2.6 2.6B2 H(12%) 0.9 1.5 2.4 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com