Low-gloss and scratch-resistant polypropylene material and preparation method thereof

A polypropylene material and scratch-resistant technology, which is applied in the field of low-gloss scratch-resistant polypropylene material and its preparation, can solve the problems of reducing gloss and achieve the effects of reducing gloss, simple preparation process, and good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

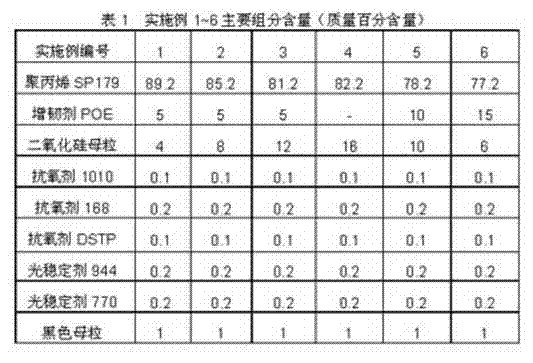

Embodiment 1

[0040] The main components of the low-gloss scratch-resistant polypropylene material of the present invention include 89.2% block polypropylene SP179, 5% toughening agent POE, 4% silica masterbatch, 0.1% antioxidant 1010, and 0.2% antioxidant 168 , 0.1% antioxidant DSTP, 0.2% light stabilizer 944, 0.2% light stabilizer 770, and 1% black masterbatch.

Embodiment 2

[0042] The main components of the low-gloss and scratch-resistant polypropylene material of the present invention include 85.2% block polypropylene SP179, 5% toughening agent POE, 8% silica masterbatch, 0.1% antioxidant 1010, 0.2% antioxidant 168 , 0.1% antioxidant DSTP, 0.2% light stabilizer 944, 0.2% light stabilizer 770, and 1% black masterbatch.

Embodiment 3

[0044] The main components of the low-gloss and scratch-resistant polypropylene material of the present invention include 81.2% block polypropylene SP179, 5% toughening agent POE, 12% silica masterbatch, 0.1% antioxidant 1010, 0.2% antioxidant 168 , 0.1% antioxidant DSTP, 0.2% light stabilizer 944, 0.2% light stabilizer 770, and 1% black masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com