Antistatic and antibacterial acrylic nonwoven fabric and preparation method thereof

A non-woven, anti-static technology, applied in conductive/anti-static filament manufacturing, non-woven fabric, rayon manufacturing and other directions, can solve the problems of decreased anti-static and antibacterial properties, poor compatibility, etc., and achieve good economic benefits and social benefits, improved effects, and easy availability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

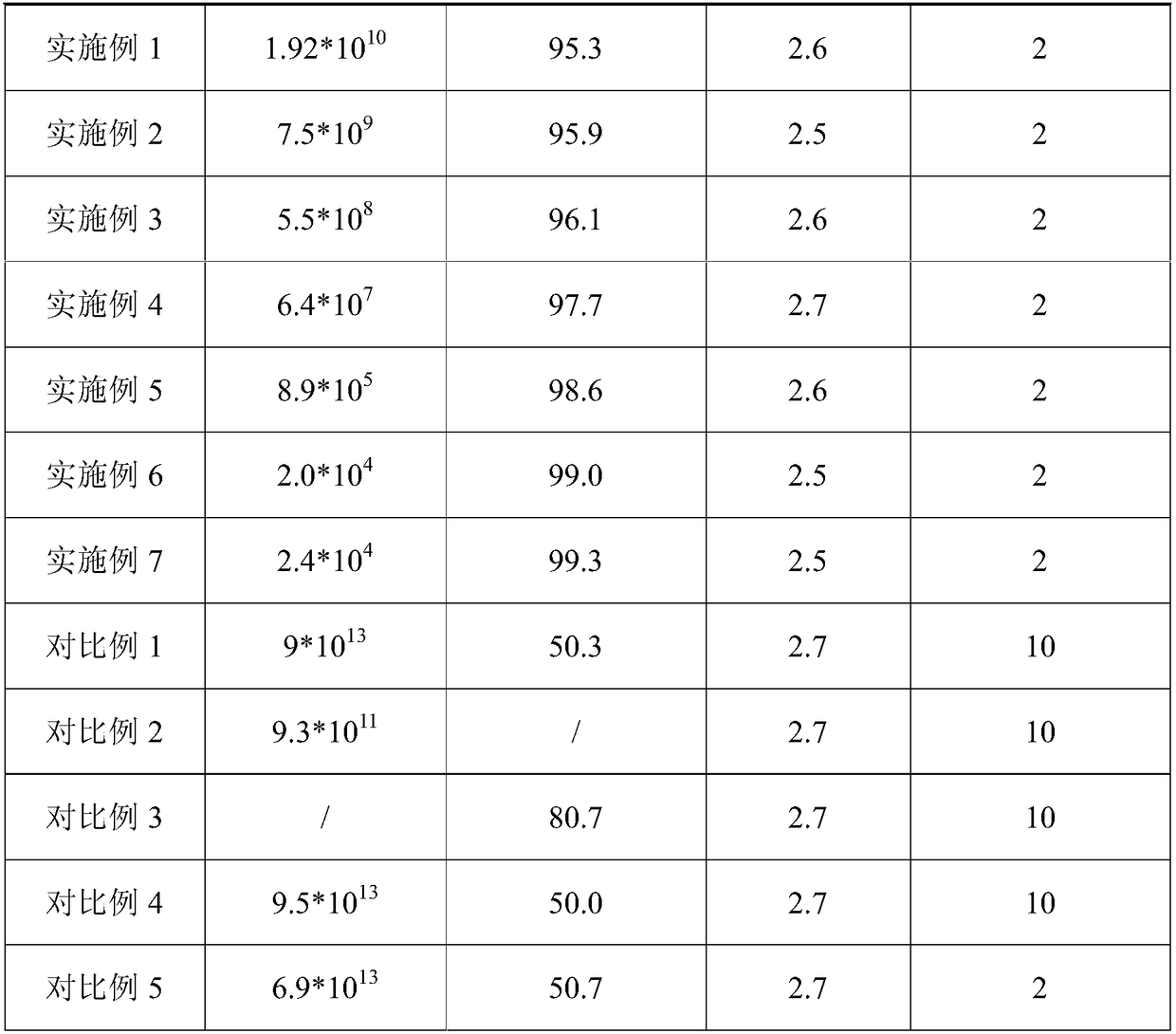

Examples

Embodiment 1

[0021] The polyacrylonitrile resin with a molecular weight of 70,000 was dried for later use, and 0.5g of conductive polyaniline, 0.5g of nano-silver, 0.1g of polyethylene glycol with a molecular weight of 4,000, 0.5g of glycerin, and 0.5g of polyethylene oxide with a molecular weight of 1,000,000 were dissolved in 300gN , N-dimethylformamide, then add 100g polyacrylonitrile dry powder, heat and stir at 60°C for 1 hour to make spinning solution, then pour the spinning solution into special spinning equipment to start melt blown spinning to The non-woven fabric was prepared on the web curtain, and the hot air temperature during spinning was 150°C. The prepared acrylic non-woven fabric was washed in a 70°C water bath for 30 minutes. After the washing was completed, it was placed in a 90°C Dry it in an oven to constant weight to finally obtain an antistatic and antibacterial acrylic nonwoven fabric.

Embodiment 2

[0023] The polyacrylonitrile resin with a molecular weight of 100,000 was dried for later use, and 0.9g of conductive polyaniline, 0.7g of nano-silver, 0.3g of polyethylene glycol with a molecular weight of 3000, 0.8g of glycerin, and 0.8g of polyethylene oxide with a molecular weight of 2,000,000 were dissolved in 300gN , N-dimethylformamide, then add 100g polyacrylonitrile dry powder, heat and stir at 80°C for 1 hour to make spinning solution, then pour the spinning solution into special spinning equipment to start melt blown spinning to The non-woven fabric is prepared on the web curtain, and the hot air temperature during spinning is 170°C. The prepared acrylic non-woven fabric is washed in an 80°C water bath for 30 minutes. After the washing is completed, it is placed in a 100°C Dry it in an oven to constant weight to finally obtain an antistatic and antibacterial acrylic nonwoven fabric.

Embodiment 3

[0025] The polyacrylonitrile resin with a molecular weight of 90,000 was dried for later use, and 1.5g of conductive polyaniline, 1.1g of nano-silver, 0.3g of polyethylene glycol with a molecular weight of 4,000, 0.8g of glycerin, and 0.8g of polyethylene oxide with a molecular weight of 3,000,000 were dissolved in 250gN , N-dimethylformamide, then add 100g polyacrylonitrile dry powder, heat and stir at 90°C for 1 hour to make spinning solution, then pour the spinning solution into special spinning equipment to start melt blown spinning to The non-woven fabric was prepared on the web curtain, and the hot air temperature during spinning was 170°C. The prepared acrylic non-woven fabric was washed in a 90°C water bath for 30 minutes. After the washing was completed, it was placed in a 110°C Dry it in an oven to constant weight to finally obtain an antistatic and antibacterial acrylic nonwoven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com