High sulfide resistant cement demixture and preparation thereof

A cement admixture, high sulfur resistance technology, applied in the field of building materials, can solve the problems of reduced production cost, high production cost, single type of sulfate corrosion, etc., and achieves the effect of increasing permeability resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

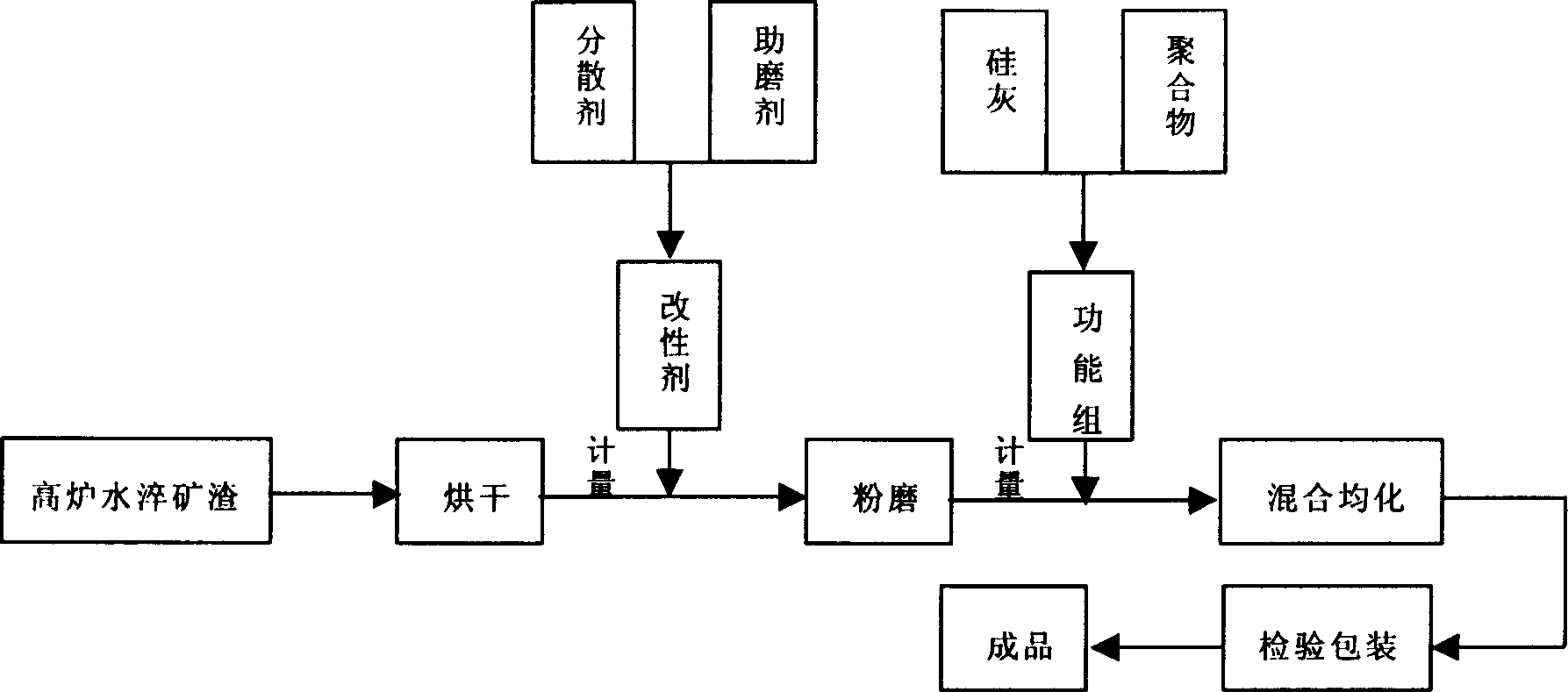

[0037] Such as figure 1 As shown, the preparation method of high-sulfur-resistant cement admixture includes the following steps: 1). Pretreatment of blast furnace water-quenched slag: select commercially available blast-furnace water-quenched slag that meets national standards, dry it, and dry it. The water content is less than 2%, ready for use; 2) Preparation of modifier: use a polycarboxylic acid type hyperdispersant with a solid solution ratio of 1:2-3 to mix with triethanolamine grinding aid at a mass ratio of 1:1 3). Preparation of shrinking functional components: Alkylene glycol or polyoxyalkylene glycol and silica fume are mixed at a mass ratio of 1:15-20, ready for use; 4). Quenched by blast furnace water The mass ratio of slag to modifier is 100:0.01. Select pretreated blast furnace water-quenched slag and modifier, and add modifier to the pre-treated blast furnace water-quenched slag for mixed grinding to make its Blaine specific surface area. Reach 400-450m 2 / Kg, the ...

Embodiment 2

[0048] The preparation method of high-sulfur-resistant cement admixture includes the following steps: 1). Pretreatment of blast furnace water-quenched slag: select commercially available blast-furnace water-quenched slag that meets national standards, dry it, and moisture content after drying 0.5-1.9%, ready for use; 2). Preparation of modifier: It is made by mixing a polycarboxylic acid type hyperdispersant with a solid solution ratio of 1:2 and a triethanolamine grinding aid at a mass ratio of 1:0.7. Spare; 3). Preparation of shrinkage functional components: Alkylene glycol and silica fume are mixed at a mass ratio of 1:15, and spare; 4). The mass ratio of blast furnace water quenching slag to modifier is 100: 0.01 Select the pre-treated blast furnace water-quenched slag and modifier, and add the modifier to the pre-treated blast furnace water-quenched slag for mixed grinding to make the Blaine's specific surface area reach 400-450m 2 / Kg, the mixed abrasive is obtained; then th...

Embodiment 3

[0050] The preparation method of high-sulfur-resistant cement admixture includes the following steps: 1). Pretreatment of blast furnace water-quenched slag: select commercially available blast-furnace water-quenched slag that meets national standards, dry it, and moisture content after drying 0.5-1.9%, ready for use; 2). Preparation of modifier: a polycarboxylic acid type hyperdispersant with a solid solution ratio of 1:3 and a triethanolamine grinding aid are mixed at a mass ratio of 1:1. Spare; 3). Preparation of shrinkage functional components: polyoxyalkylene glycol and silica fume are mixed at a mass ratio of 1:20, and spare; 4). The mass ratio of blast furnace water quenched slag to modifier is 100: 0.02 Select the pretreated blast furnace water-quenched slag and modifier, and add the modifier to the pre-treated blast furnace water-quenched slag for mixed grinding to make the Blaine's specific surface area reach 400-450m 2 / Kg, the mixed abrasive is obtained; then the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com