Hydrogenated pentablock styrene thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and styrene technology, which is applied in the field of hydrogenated pentablock styrene thermoplastic elastomer and its preparation, can solve the problems of poor fluidity and large permanent deformation, and achieves simple operation, reduced micro-domain deformation, The effect of improving fluidity and permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

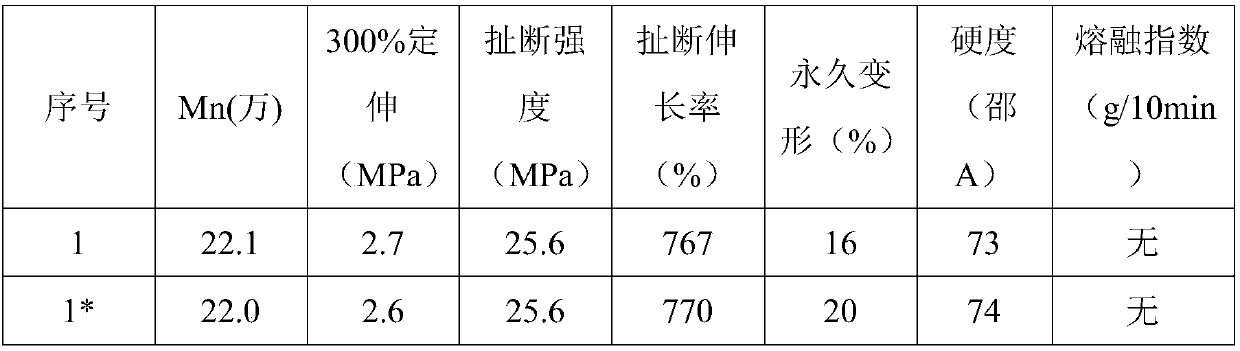

Embodiment 1

[0044] Add 2400g of cyclohexane, 30g of styrene, and 0.1g of activator into the polymerization kettle, add 1.4mmol of n-butyllithium at 50-60°C, and react for 30 minutes. After the monomer reaction is complete, add 105g of butadiene, Control the reaction temperature below 110°C and react for 30 minutes. After the monomer reaction is complete, add 30g of styrene and react for 30 minutes. After the monomer reaction is complete, add 105g of butadiene, control the reaction temperature below 110°C, and react After 30 minutes, after the monomer reaction is complete, add 30 g of styrene, react for 30 minutes, take samples to measure molecular weight and molecular weight distribution.

[0045] The glue solution prepared above was treated with N 2 Press into the hydrogenation tank, start stirring for hydrogenation, and pass in H 2 Carry out the termination reaction for 8-10 minutes, raise the temperature to 65-70° C., add 0.6 mmol of titanocene dichloride catalyst, control the hydroge...

Embodiment 2

[0049] Add 2400g of cyclohexane, 30g of styrene, and 0.1g of activator into the polymerization kettle, add 1.67mmol of n-butyllithium at 50-60°C, and react for 30 minutes. After the monomer reaction is complete, add 105g of butadiene, Control the reaction temperature below 110°C and react for 30 minutes. After the monomer reaction is complete, add 30g of styrene and react for 30 minutes. After the monomer reaction is complete, add 105g of butadiene, control the reaction temperature below 110°C, and react After 30 minutes, after the monomer reaction is complete, add 30 g of styrene and react for 30 minutes. After the monomer reaction is complete, take a sample to measure the molecular weight and molecular weight distribution.

[0050] The glue solution prepared above was treated with N 2 Press into the hydrogenation tank, start stirring for hydrogenation, and pass in H 2 Carry out termination reaction for 8-10min. Raise the temperature to 65-70°C, add 0.6 mmol titanocene dich...

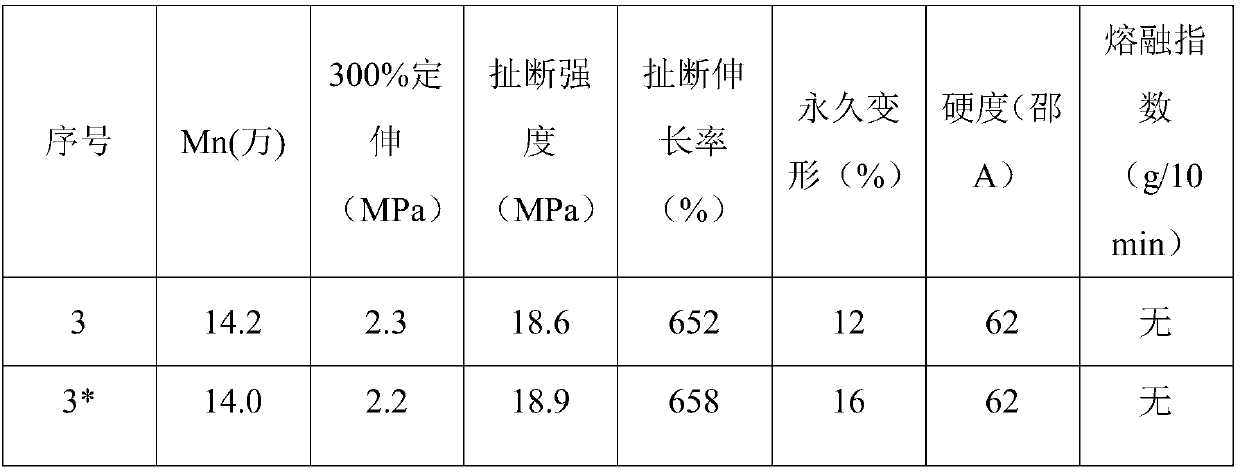

Embodiment 3

[0054] Add 2400g of cyclohexane, 30g of styrene, and 0.1g of activator into the polymerization kettle, add 2.14mmol of n-butyllithium at 50-60°C, and react for 30 minutes. After the monomer reaction is complete, add 105g of butadiene, Control the reaction temperature below 110°C and react for 30 minutes. After the monomer reaction is complete, add 30g of styrene and react for 30min. Minutes, after the monomer reaction is complete, add 30g of styrene, react for 30 minutes, take a sample to measure the molecular weight and molecular weight distribution.

[0055] The glue solution prepared above was treated with N 2 Press into the hydrogenation tank, start stirring for hydrogenation, and pass in H 2 Carry out the termination reaction for 8-10 minutes, raise the temperature to 65-70° C., add 0.6 mmol of titanocene dichloride catalyst, control the hydrogen pressure at 1.0-1.8 MPa, react for 2 hours, and discharge. The solvent was removed from the glue, and samples were taken for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com