Patents

Literature

71 results about "Titanocene dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanocene dichloride is the organotitanium compound with the formula (η⁵-C₅H₅)₂TiCl₂, commonly abbreviated as Cp₂TiCl₂. This metallocene is a common reagent in organometallic and organic synthesis. It exists as a bright red solid that slowly hydrolyzes in air. It shows antitumour activity and was the first non-platinum complex to undergo clinical trials as a chemotherapy drug.

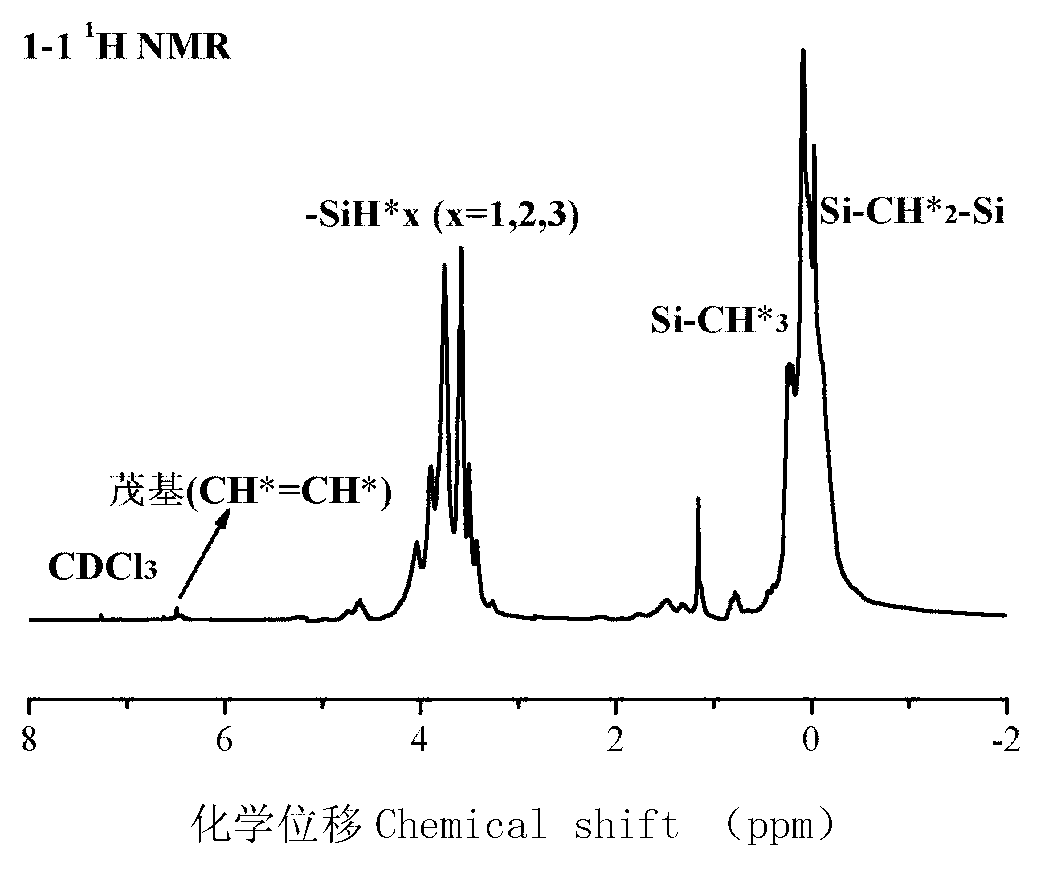

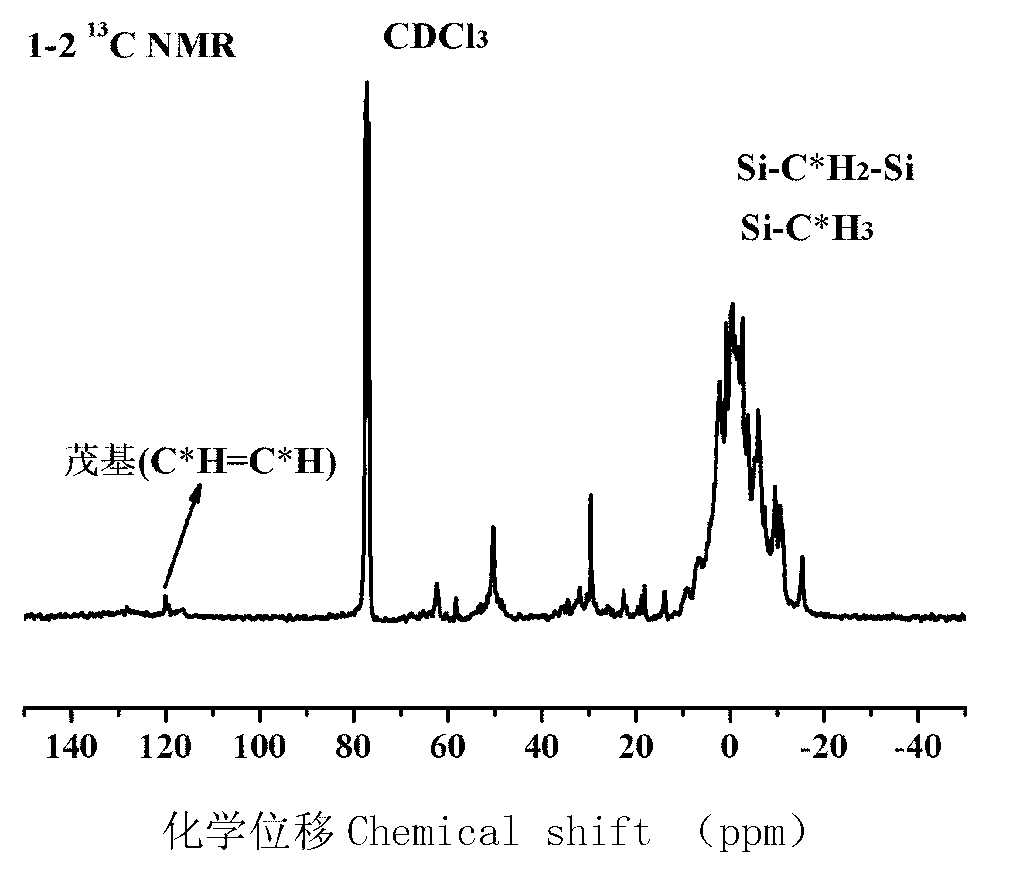

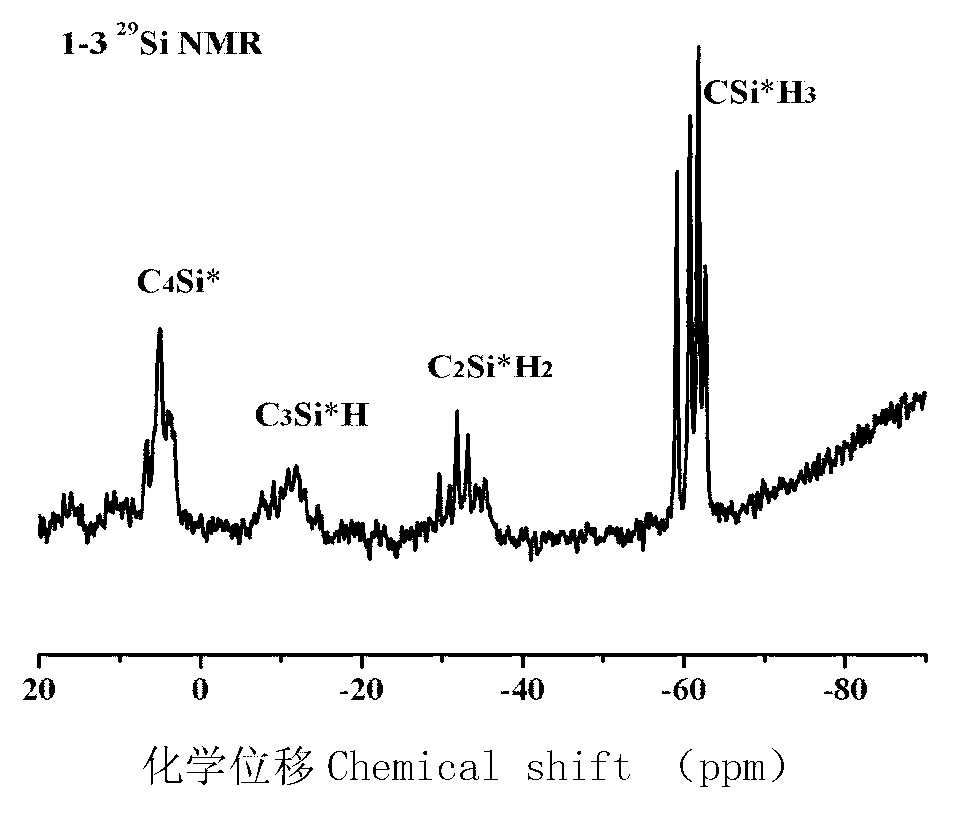

Method for preparing liquid anaerobic polytitanocarbosilane

The invention discloses relates to a preparation method of a compound, in particular to a method for preparing liquid anaerobic polytitanocarbosilane, and provides a method for directly preparing the liquid anaerobic polytitanocarbosilane through binary or ternary polymerization of chloromethylsilane and zirconocene dichloride. The method comprises the steps as follows: 1), under the protection of an inert atmosphere, the chloromethylsilane and the zirconocene dichloride are mixed simultaneously and dissolved in absolute ether; 2), magnesium metals are added into a mixed solution obtained in the step 1) in batches for reaction; 3), under the protection of the inert atmosphere, a reducing agent is added in batches into a reaction mixed material obtained in the step 2) for reaction; and 4), under the protection of the inert atmosphere, an organic solvent is added into a reaction mixed material obtained in the step 3), an organic phase is extracted, standing is performed, an upper-layer organic phase is separated, the organic solvent is removed through filtration, and the liquid anaerobic polytitanocarbosilane is obtained.

Owner:XIAMEN UNIV

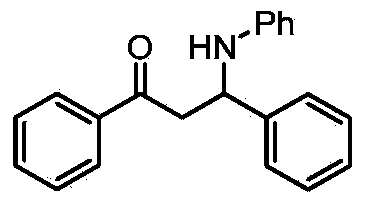

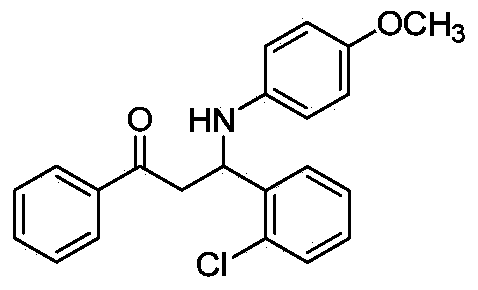

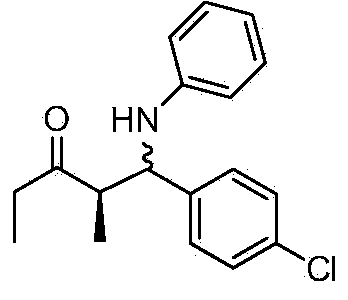

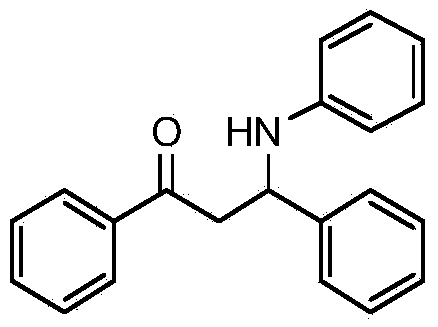

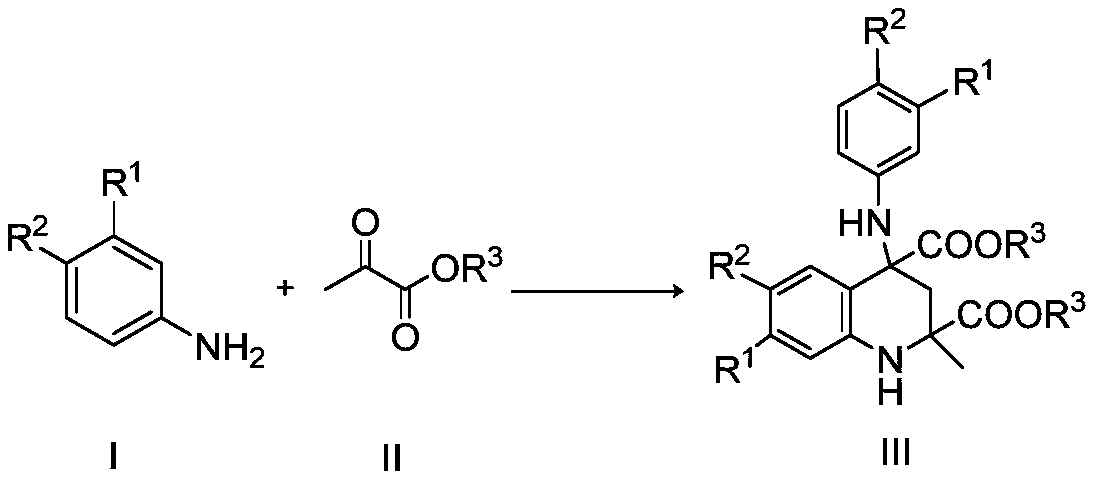

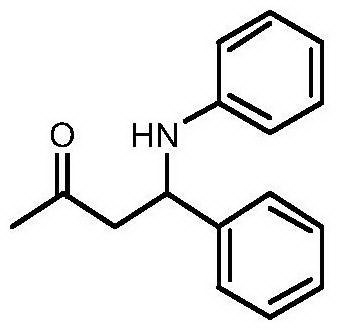

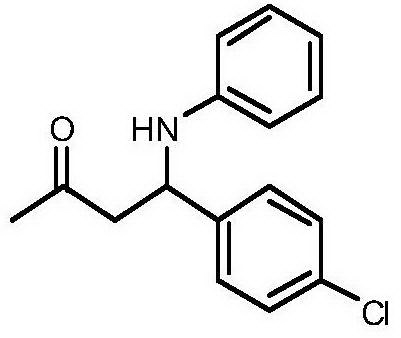

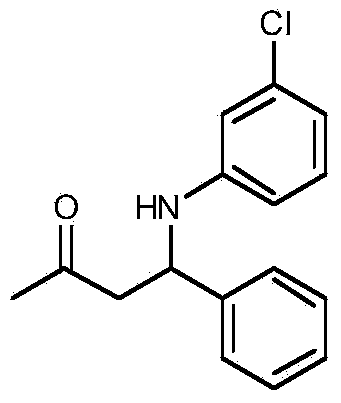

Method for preparing beta-amino-carbonyl compound

InactiveCN103467321AGreat application potentialAtom economy is highOrganic chemistryOrganic compound preparationRoom temperatureKetone

The invention provides a method for preparing a beta-amino-carbonyl compound. Aldehydes, ketones and amines are directly mixed under the condition of synergetic catalysis of titanocene dichloride and a ligand, and react at room temperature to obtain the beta-amino-carbonyl compound, wherein the ligand is salicylic acid or salicylic acid derivatives or structural analogues thereof. According to the method, the catalyst used in the method is low in cost, nontoxic and stable and effective to air and water, the reaction condition is mild, a solvent is not needed, the operation is simple, and the atom economy is high.

Owner:SHAANXI NORMAL UNIV +1

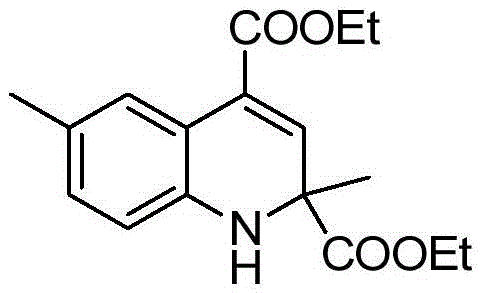

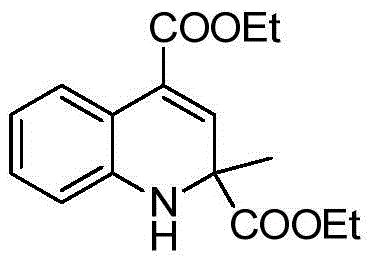

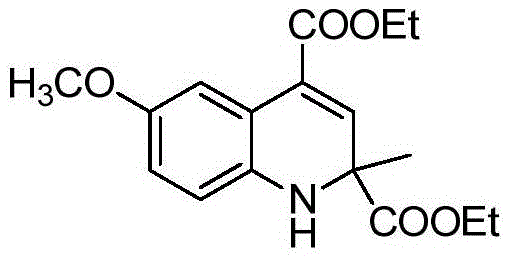

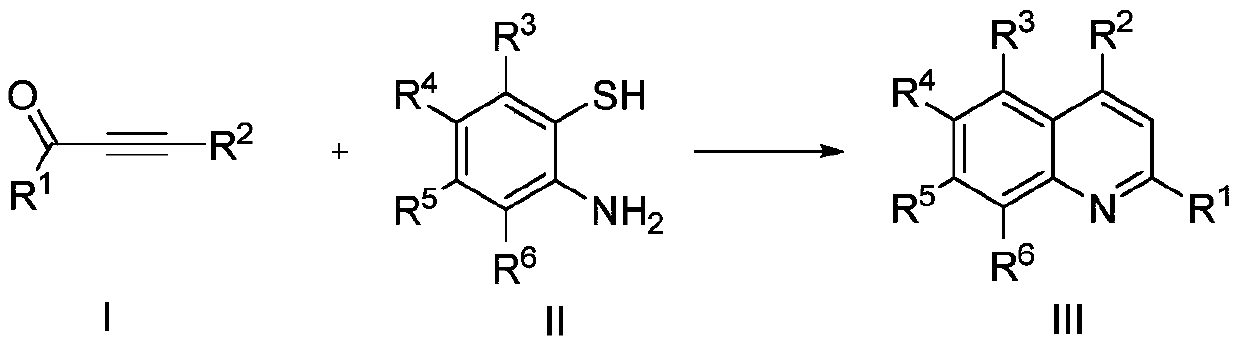

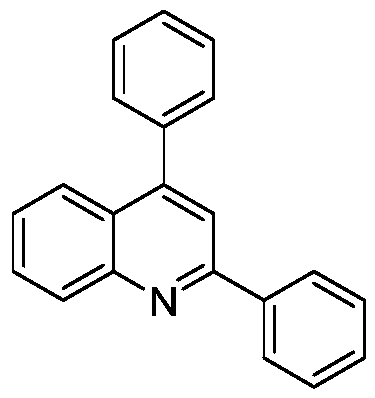

Method for efficiently preparing quinoline derivative from titanocene dichloride in cooperation with with sulfo-benzoic acid in water phase

InactiveCN105461624AGreat application potentialSimple post-processingOrganic chemistryBenzoic acidNatural product

The invention discloses a method for efficiently preparing quinoline derivative from titanocene dichloride in cooperation with with sulfo-benzoic acid in a water phase. According to the method, aromatic amine and pyruvate are used as raw materials, water serves as the solvent, the titanocene dichloride serves as the catalyst, and under the synergistic promotion effect of the sulfo-benzoic acid, the quinoline derivative can be prepared efficiently. Through the method, the dosage of the catalyst is small, the price is low, toxicity is avoided, reaction conditions are mild, reaction time is short, atom economy is high, product yield is high, a new low-cost environment-friendly efficient way is developed for preparation of the quinoline derivative, and the prepared quinoline derivative has huge application potential in preparation of medicine, natural products and organic synthesis intermediates.

Owner:SHAANXI NORMAL UNIV

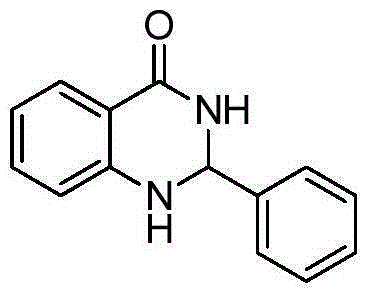

Method for efficiently preparing quinazolinone derivants under promotion of ethyl alcohol and catalysis of titanocene dichloride

The invention discloses a method for efficiently preparing quinazolinone derivants under promotion of ethyl alcohol and catalysis of titanocene dichloride. According to the method, aminobenzamide and aldehyde or ketone are used as raw materials, ethyl alcohol is used as a solvent and a promoter, titanocene dichloride is used as a catalyst, and the quinazolinone derivants are efficiently prepared in high yield under the synergetic promotion action of titanocene dichloride and ethyl alcohol. The catalyst is less in dosage, cheap, nontoxic, and stable to air; the reaction conditions are mild, and the reaction time is short; the operation is simple; the atom economy is high; after the reaction is finished, the product only needs to be subjected to simple separation and recrystallization to obtain the quinazolinone derivants; a new, low-cost, environment-friendly and efficient path is opened up for preparation of the quinazolinone derivants, and wide application prospects are achieved.

Owner:SHAANXI NORMAL UNIV

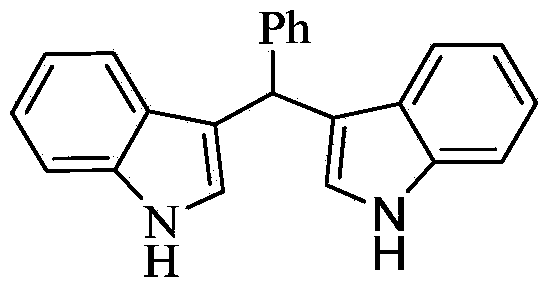

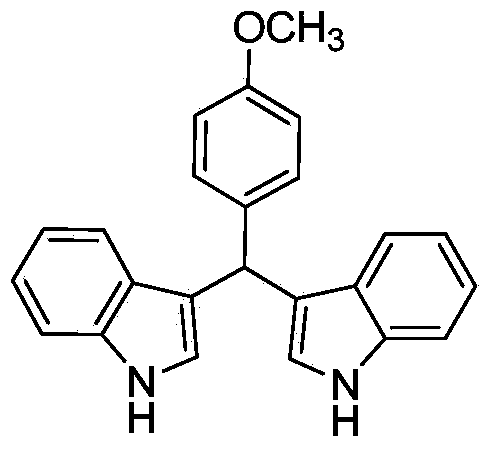

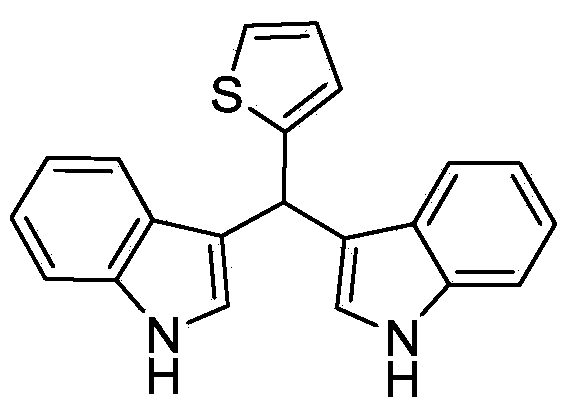

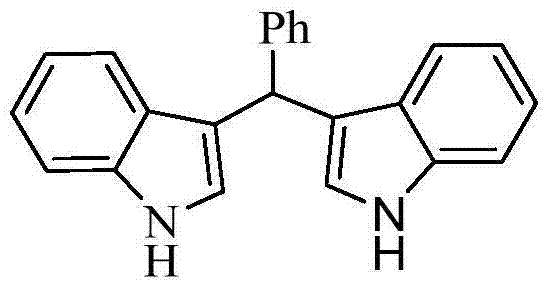

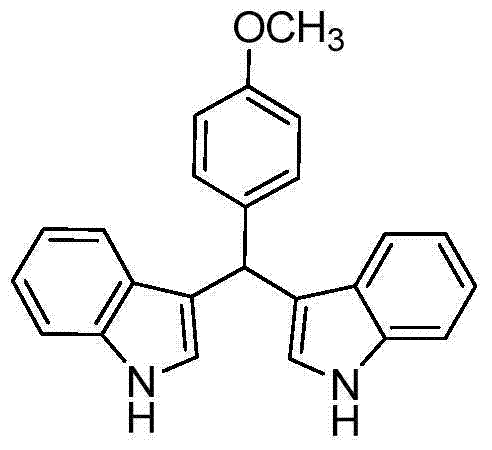

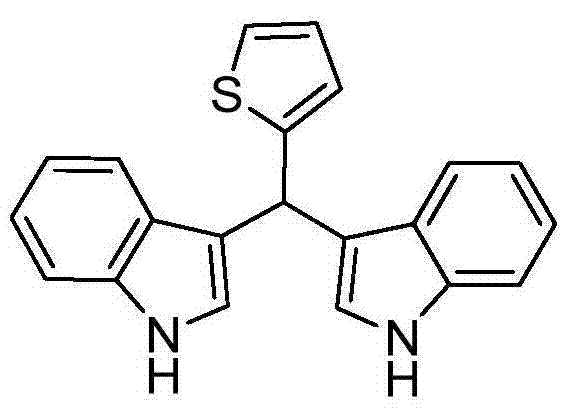

Method for preparing diindolyl methane derivatives

The invention discloses a method for preparing diindolyl methane derivatives. The method comprises the following step: with titanocene dichloride and a ligand as catalysts, reacting indole and aldehyde to obtain the diindolyl methane derivative under an alkaline condition, wherein the ligand can be 8-hydroxyquinoline, catechol and o-aminophenol and the alkali is aniline, pyridine, pyrrole or triethylamine. The method is easy to operate, the reaction is high-efficiency and mild, the catalysts are low in price, non-toxic, stable to air and water, and substrate applicability is good; therefore, the method can be widely applied to preparation of diindolyl methane derivatives.

Owner:SHAANXI NORMAL UNIV +1

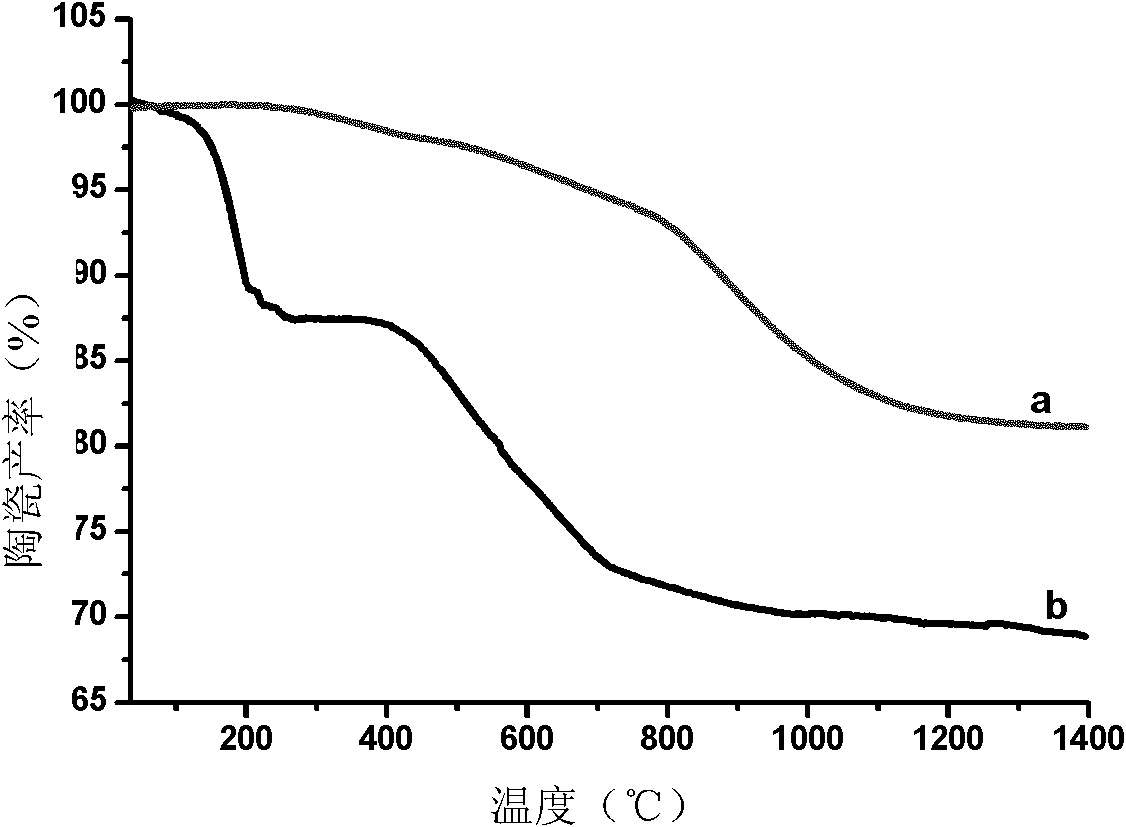

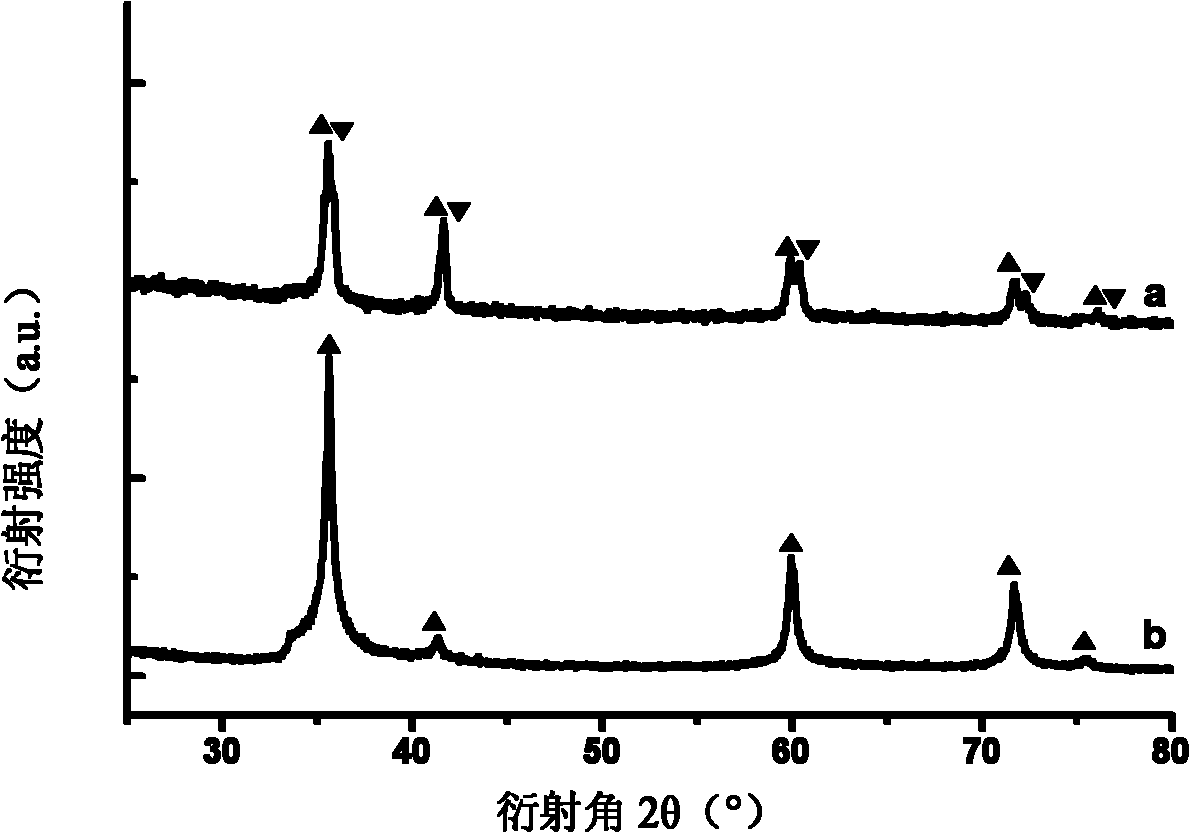

Method for preparing silicon carbide/titanium carbide composite ceramics

The invention provides a method for preparing silicon carbide / titanium carbide composite ceramics, belonging to the field of inorganic non-metallic materials. The method comprises the following steps: under the protection of inert atmosphere, adding titanocene dichloride and hyperbranched polycarbosilane to a solvent to obtain solution; and depriving the solvent in the solution, ensuring the residues to under cracking reaction in the inert atmosphere and obtaining the silicon carbide / titanium carbide composite ceramics immediately after the reaction is completed. The problem that the mechanical property and high temperature resistance of the composite ceramics are degraded because oxygen is introduced in the process of preparing the silicon carbide / titanium carbide composite ceramics by the existing precursor pyrolysis method is solved by the method provided by the invention, the used process is simple, the cost is low and the prepared silicon carbide / titanium carbide composite ceramics have high yield.

Owner:XIAMEN UNIV

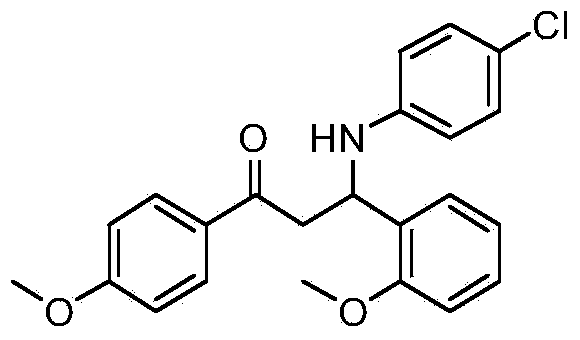

Method for synthesizing beta-amidogen carbonyl compound through poly-aminophenol and titanocene dichloride in heterogeneous catalysis mode

InactiveCN104140374AHigh yieldReduce dosageOrganic chemistryOrganic compound preparationM-aminophenolKetone

The invention discloses a method for synthesizing a beta-amidogen carbonyl compound through poly-aminophenol and titanocene dichloride in a heterogeneous catalysis mode. The beta-amidogen carbonyl compound is obtained by making ketone, aromatic aldehyde and aromatic amine to react at the temperature ranging from 25 DEG C to 50 DEG C at the presence of the titanocene dichloride serving as a catalyst and poly-ortho-aminophenol or poly-m-aminophenol. According to the method, the poly-aminophenol and the titanocene dichloride are added to a reaction system at the same time, a catalytic active species with high activity can be formed in situ, operation is simple, no solvent is added, reaction conditions are mild, the catalyst is low in price, nontoxic, stable in air and water, high in catalytic activity and capable of being repeatedly used, products are prone to separation, and the productivity is high. The method has the advantages that cost is low, environmental friendliness is achieved, and atom economy is high. The method has wide application prospects for the beta-amidogen carbonyl compound.

Owner:SHAANXI NORMAL UNIV

Method for producing photo initiator FMT

InactiveCN101712696AImprove quantum efficiencyImprove thermal stabilityMetallocenesWastewaterTetrahydrofuran

The invention relates to a method for producing a photo initiator FMT which is prepared by the following process steps of: reacting 2,5-dimethoxy tetrahydrofuran with 2,4-difluoroaniline in a low-temperature reaction kettle to generate 2,4- difluorophenylpyrrole; and directly adding titanocene dichloride and solvent in the low-temperature reaction kettle to dechlorinate under the catalysis of organic strong alkali. The method adopts a 'one-pot method' (i.e. the reaction is finished in one reaction kettle); since the process for purifying crude 2,4-difluorophenylpyrrole is saved, the method has easy reaction, high yield, stable product quality and easy purification. The invention simplifies the production process, saves the equipment investment, reduces the production cost, improves the yield of products (up to 85-90 percent), greatly reduces the discharge amount of wastewater and waste liquid, and is beneficial to environmental protection.

Owner:荆门市昱奎化工有限责任公司

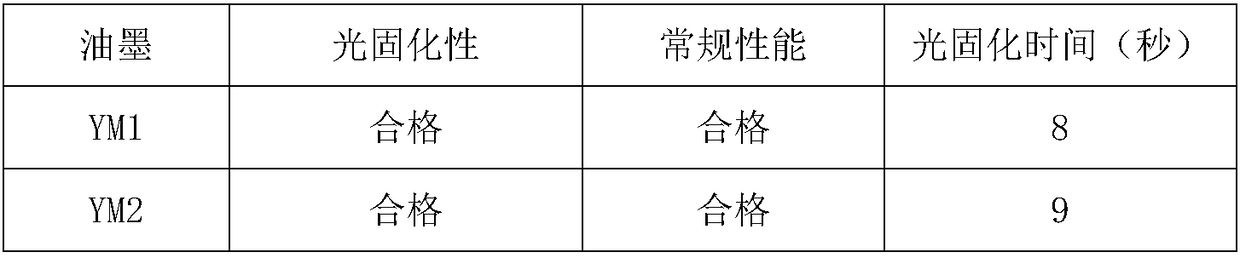

Rapid UV (Ultraviolet) photo-cured ink and application method thereof

The invention relates to rapid UV (Ultraviolet) photo-cured ink and an application method thereof. The DI special ink is prepared from a composite photoinitiator, wherein the composite photoinitiatorconsists of di-2,6-difluoro-3-pyrrole phenyl titanocene dichloride, a ketoxime ester type photoinitiator, a thioxanthone photoinitiator, an acyl phosphine type photoinitiator, an alpha-hydroxyalkyl phenyl ketone photoinitiator and a morpholinyl-containing alpha-aminoketone photoinitiator; the di-2,6-difluoro-3-pyrrole phenyl titanocene dichloride accounts for 5-8% by weight of the total weight ofthe composite photoinitiator; the sum of weights of the other photoinitiators accounts for 90-95% by mass of the total weight of the composite photoinitiator. By adopting the composite photoinitiatorprovided by the invention, the problem that ink cannot be directly cured with ultraviolet light efficiently is solved; because of the low efficiency that ink is cured with ultraviolet light, a very long time for curing common ink is needed, although the problem of precise photo-curing is solved, low-efficiency photo-curing can be still not adopted in the industry.

Owner:深圳市容大感光科技股份有限公司 +1

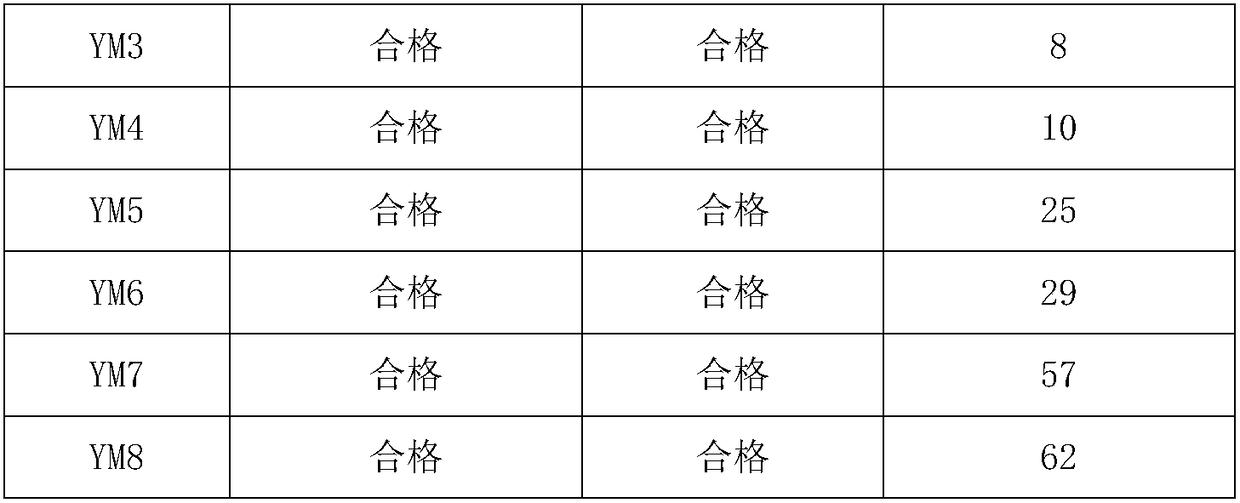

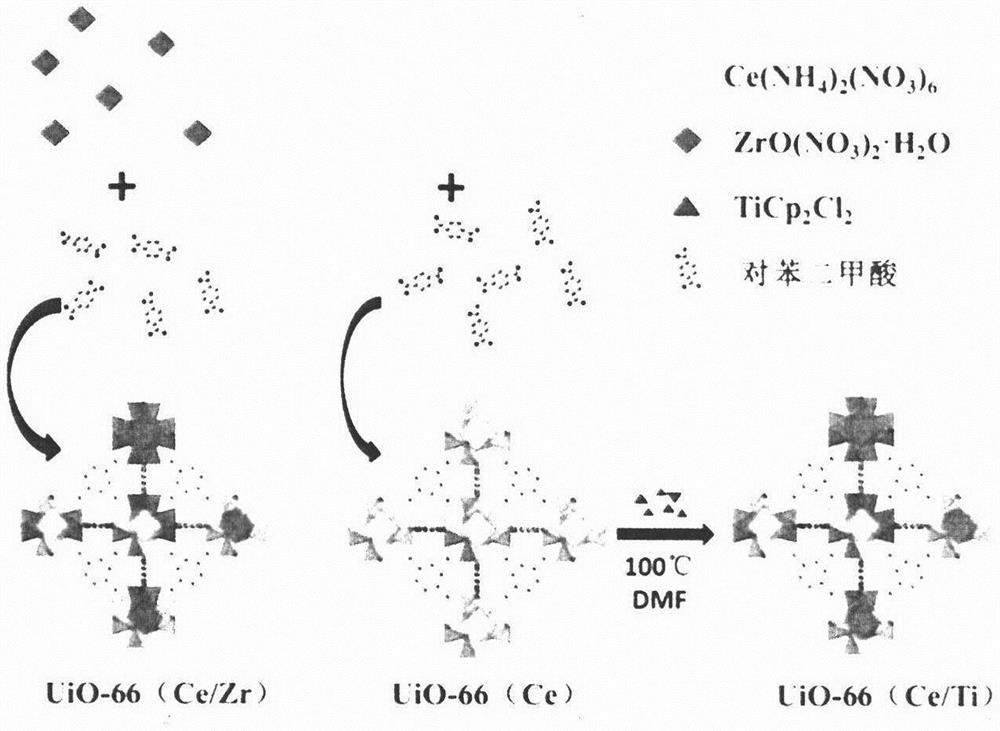

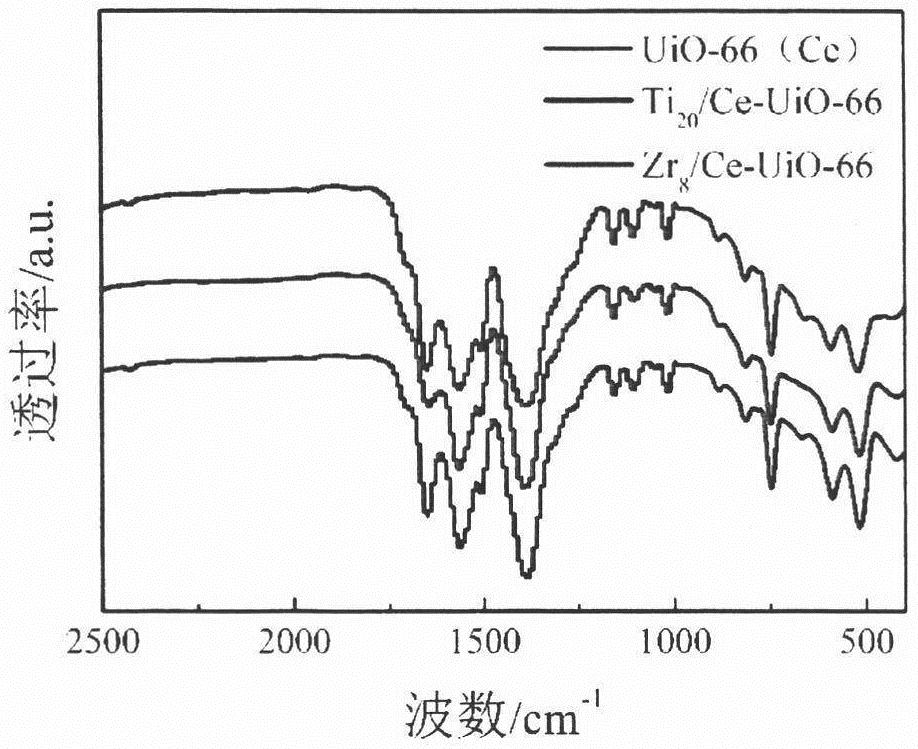

Titanium/zirconium-doped cerium-based metal organic framework material for degrading paraoxon methyl

PendingCN114570431ALow priceEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsTitanium zirconiumMetal-organic framework

The invention discloses a method for applying a titanium / zirconium-doped cerium-based metal organic framework to degradation of methyl paraoxon. According to the invention, ceric ammonium nitrate is used as a metal ion source, terephthalic acid is used as a ligand, and a cerium-based metal organic framework (UiO-66) is synthesized by adopting a solvothermal method; mixing and heating the synthesized UiO-66 and titanocene dichloride by adopting a cation exchange method, so as to synthesize Tix / Ce-UiO-66; the preparation method comprises the following steps: mixing a metal ion source ceric ammonium nitrate and zirconyl nitrate, and synthesizing Zrx / Ce-UiO-66 by adopting a solvothermal method; the synthesized materials are used for degrading methyl paraoxon. The method for degrading methyl paraoxon has the advantages of simplicity in operation, rapidness in preparation, low cost and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production method for photoinitiator GR-FMT

Provided is a production method for a photoinitiator GR-FMT. The production method includes the following steps: adding dimethylbenzene and 2,5- dimethoxy tetrahydrofuran to a reaction kettle with inert atmosphere, cooling to -4 - 5 DEG C, then slowly dropwise adding 2,4-two fluoroaniline, heating to 50-60 DEG C, and maintaining the temperature for 5-10 hours; adding dimethylbenzene, heating to 140-145 DEG C for distillation; adding titanocene dichloride; cooling to -10- 40 DEG C, dropwise adding a catalyst of organic alkali amino lithium salt, reacting and synthesizing to obtain reaction liquid of the photoinitiator GR-FMT at -10 - 40 DEG C; heating to 15-30 DEG C, and chromatographing; maintaining the temperature and crystallizing; chromatographing, washing with dimethylbenzene, and draining to obtain wet product; and vacuum drying and obtaining the photoinitiator GR-FMT. The production method has the advantages of being fast in curing speed and not requiring heating.

Owner:HUBEI GURUN TECH CO LTD

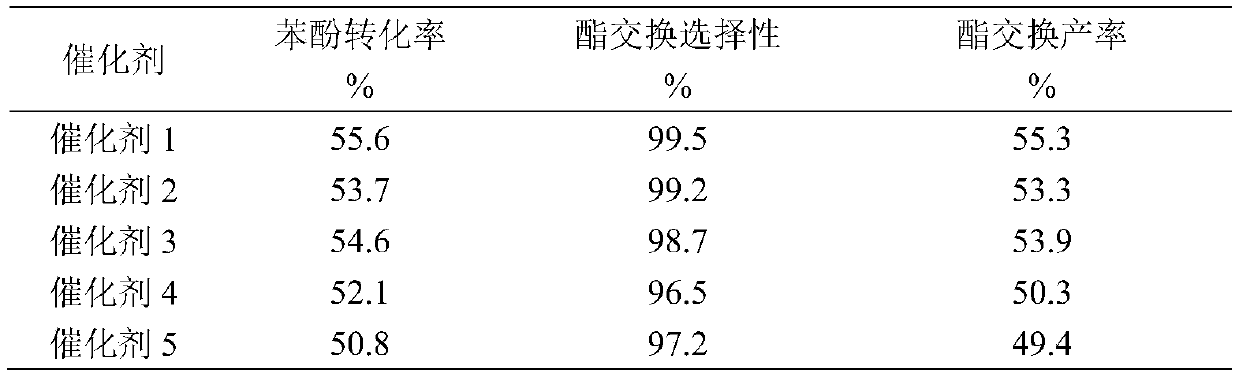

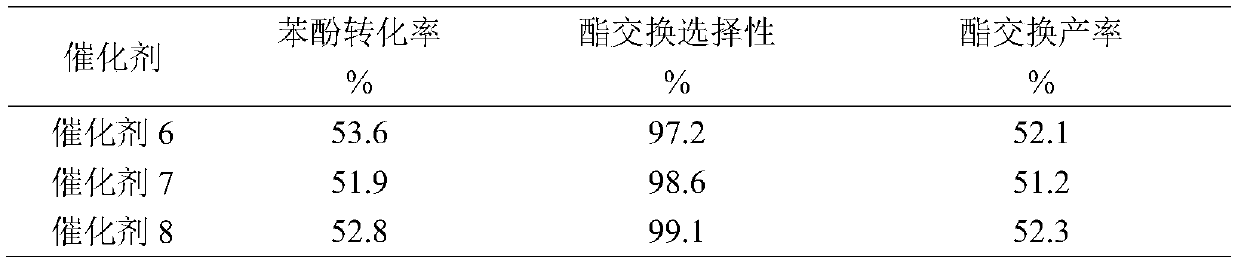

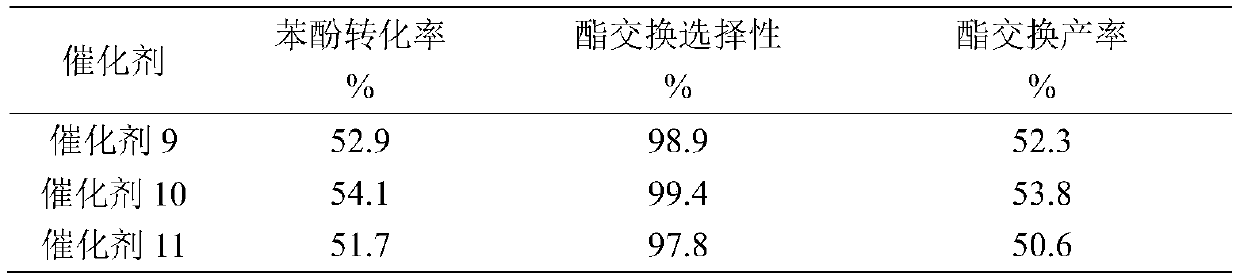

Heterogeneous catalyst for synthesizing diphenyl carbonate, and preparation method thereof

ActiveCN110642718AHigh activityHigh selectivityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidChlorosulfuric acid

The invention discloses a heterogeneous catalyst for synthesizing diphenyl carbonate, and a preparation method thereof, wherein the catalyst comprises a carrier, a titanium source and an organic acid,a mass ratio of the titanium source to the carrier is 10-70:90-30, a molar ratio of the titanium to the organic acid is 0.05-5:1, the titanium source is tetrabutyl titanate, tetraisopropyl titanate,titanyl sulfate, titanocene dichloride, tetraethyl titanate or dicyclopentadiene dimethyl titanium, the carrier is a ZSM-5 molecular sieve, an HZSM-5 molecular sieve, a TS-1 molecular sieve, an MCM-41molecular sieve or SiO2, and the organic acid is acetic acid, succinic acid, adipic acid, sebacic acid, terephthalic acid, benzoic acid or chlorosulfonic acid. The specific preparation method comprises: 1) dissolving a titanium source by adopting a solvent, adding a carrier, carrying out a hydrothermal synthesis reaction for 10-48 h at a temperature of 80-120 DEG C, filtering, and drying the carrier to obtain a catalyst intermediate; and 2) dissolving the catalyst intermediate in a solvent, adding an organic acid in an ice-water bath in a dropwise manner, stirring for 2-4 days at a normal temperature, filtering, washing, and drying to obtain the catalyst. The catalyst of the invention has characteristics of high activity and high selectivity.

Owner:湖北三宁碳磷基新材料产业技术研究院有限公司 +1

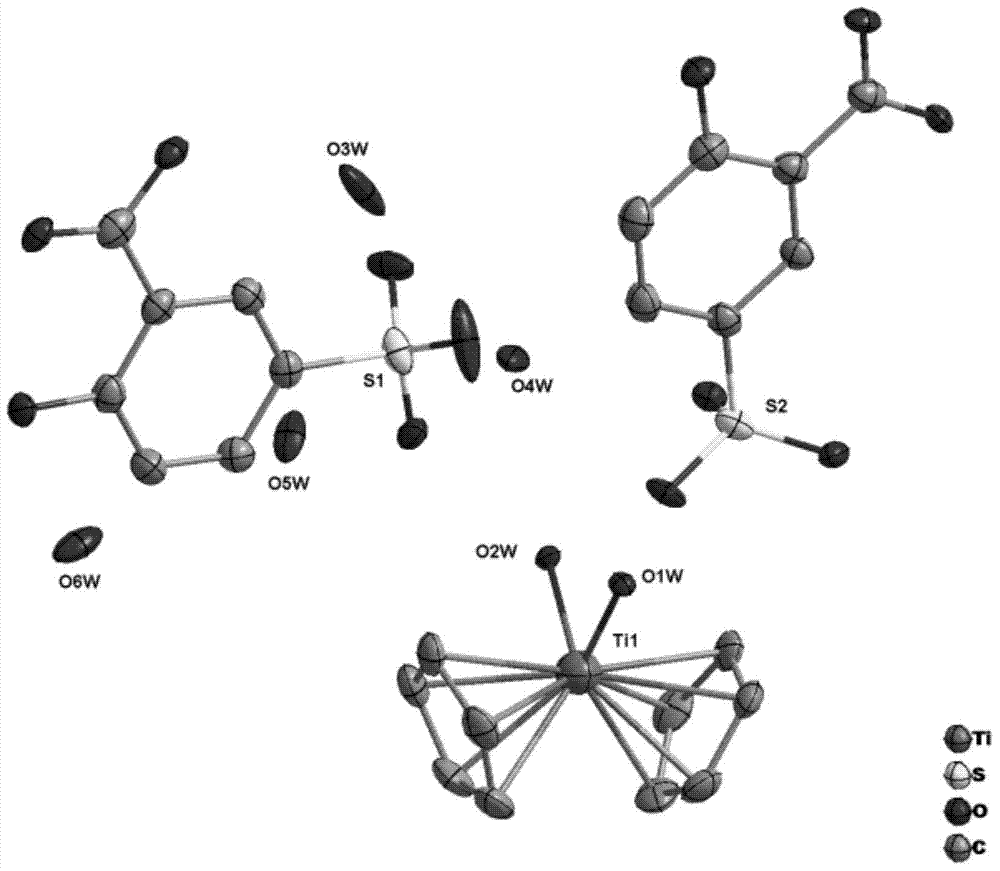

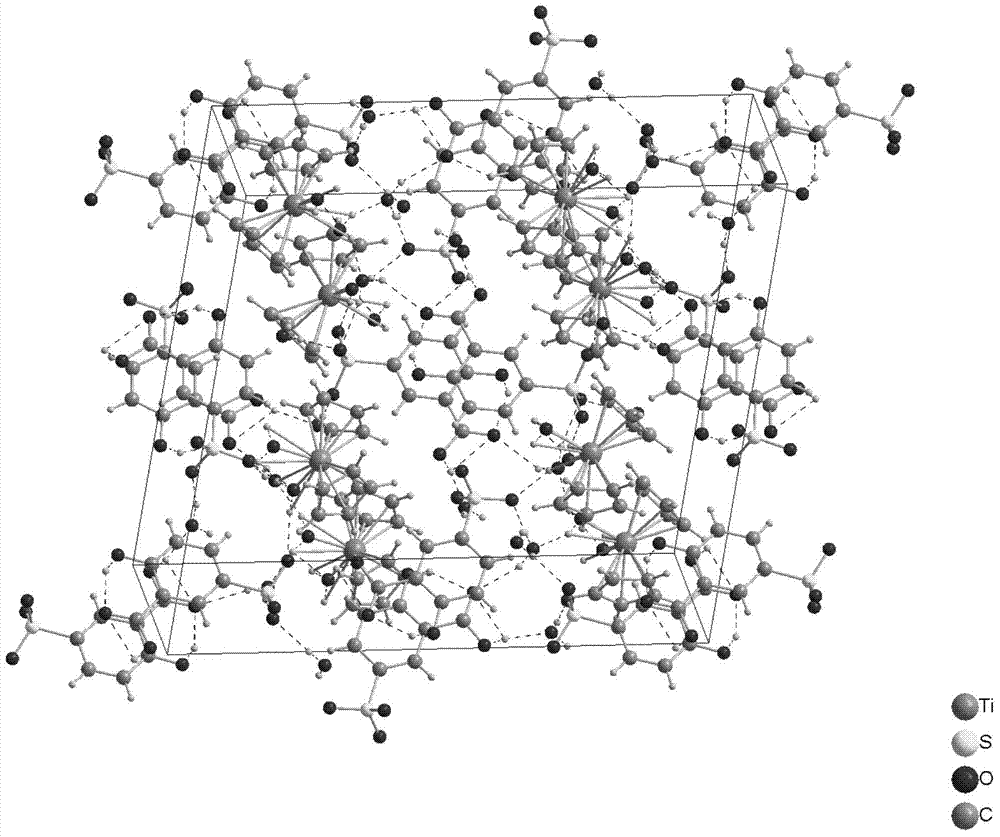

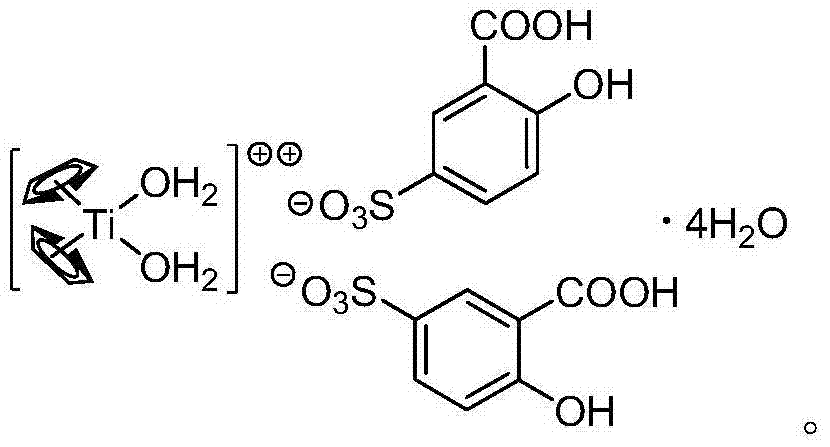

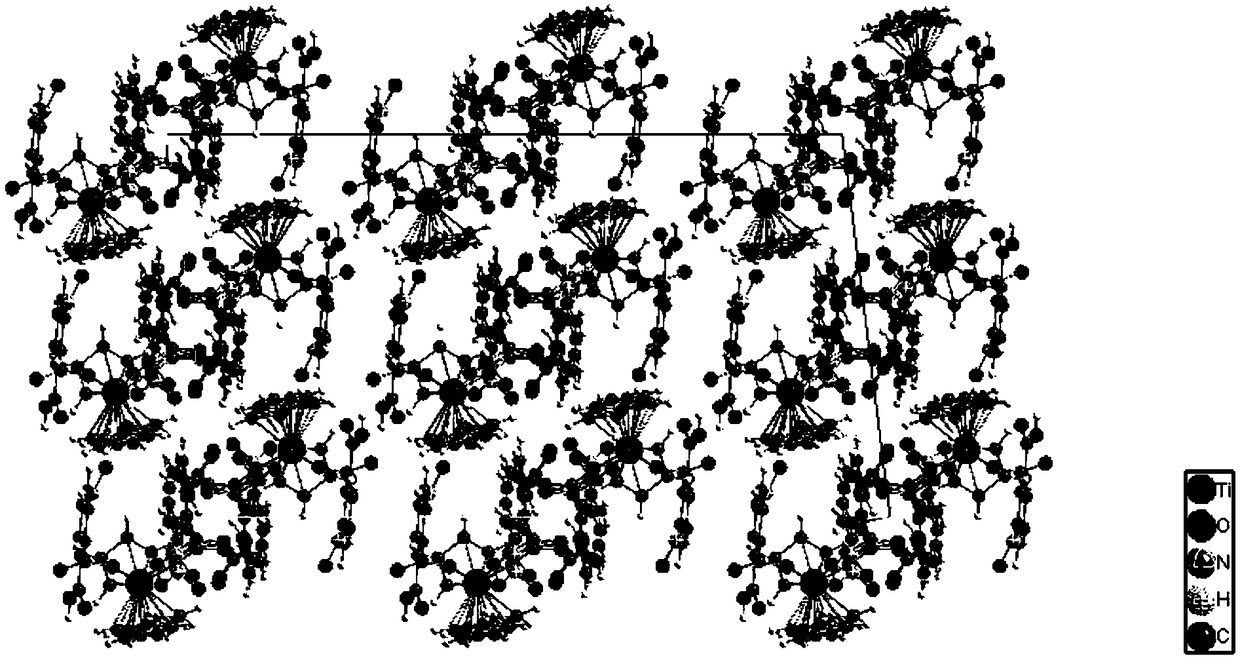

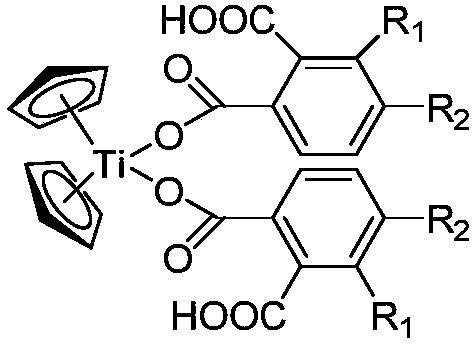

Water-soluble titanocene complex and synthesis method thereof

InactiveCN104262406AWater and air stablePreparation raw materials are cheap and easy to obtainOrganic chemistry methodsMetallocenesSynthesis methodsSulfosalicylic acid

The invention discloses a water-soluble titanocene complex and a synthesis method thereof. The structural formula of the complex is as shown in the specification; and the water-soluble titanocene complex is prepared from titanocene dichloride and 5-sulfosalicylic acid in a mixed system of an organic phase and a water phase at room temperature in the presence of an aromatic carboxylic acid serving as a template catalyst. The complex disclosed by the invention is stable to air and soluble in water; the synthesis method of the water-soluble titanocene complex has the advantages that the used raw materials are cheap and easily available, synthesis steps are simple and feasible; and the post-treatment of the water-soluble titanocene complex is easy, yield is high, and gram-scale preparation of the complex can be realized. The complex disclosed by the invention can be used as a double-acid synergic catalyst or a water-soluble anti-cancer drug.

Owner:SHAANXI NORMAL UNIV

Polydicyclopentadiene composite material and reaction injection molding process thereof

The invention belongs to the technical field of novel materials, and particularly relates to a polydicyclopentadiene composite material and a reaction injection molding process thereof. The compositematerial comprises a component A and a component B, wherein the component A comprises dicyclopentadiene, a boron trifluoride diethyl etherate complex, titanocene dichloride and glass fibers; the massratio of dicyclopentadiene, the boron trifluoride diethyl etherate complex, and the titanocene dichloride is (100-300):1:0.1; the mass of the added glass fibers is 0.1-1% of the mass of the dicyclopentadiene; the component B comprises dicyclopentadiene, a ruthenium carbene catalyst and carbon fibers; the mass ratio of the dicyclopentadiene to the ruthenium carbene catalyst is (100-200):1; and themass of the added carbon fibers is 0.1-0.5% of the mass of the dicyclopentadiene. Compared with the prior art, the polydicyclopentadiene composite material and the reaction injection molding process thereof provided by the invention have the advantages that through scientific matching of the auxiliaries and the auxiliary materials, the strength of a finished product is effectively improved while the finished product has high toughness, so that the service lifetime of the product is prolonged.

Owner:山东腾创新材料科技有限公司

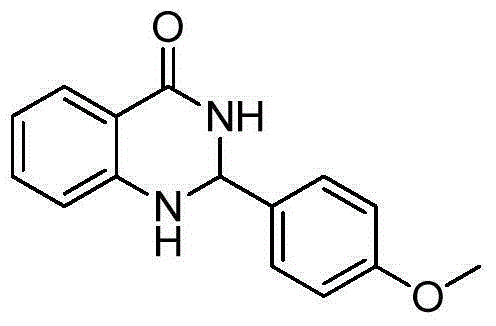

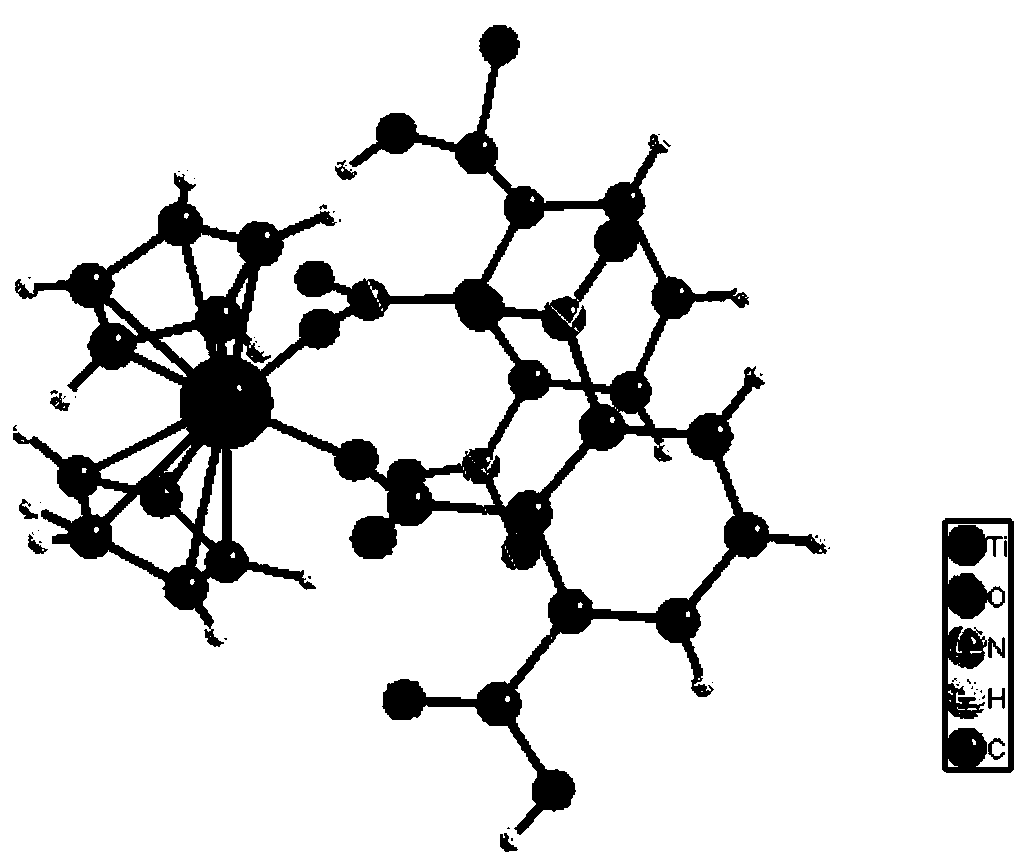

Titanocene complex with oxygen-containing carboxylic acid as ligand as well as preparation method and application of titanocene complex

InactiveCN108659056APreparation raw materials are cheap and easy to obtainEasy to prepare ingredientsOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsM-aminoacetophenoneSynthesis methods

The invention discloses a titanocene complex with oxygen-containing carboxylic acid as well as a preparation method and an application of the titanocene complex. The structural formula of the complexis shown in the description. The titanocene complex is prepared from oxygen-containing carboxylic acid as a ligand, titanocene dichloride as Lewis acid and 5-sulfosalicylic acid as a transitional ligand. The complex is stable to air, the raw materials used in the synthesis method are low in cost and easy to obtain, synthesis steps are simple and easy, post-treatment of the product is simple, conditions are mild, and the yield of the target product is high. The complex is used for catalyzing reaction of 2-aminoacetophenone and aromatic aldehyde for synthesis of 2-aryl-2,3-dihydroquinolinone, and better yield is obtained.

Owner:SHAANXI NORMAL UNIV +1

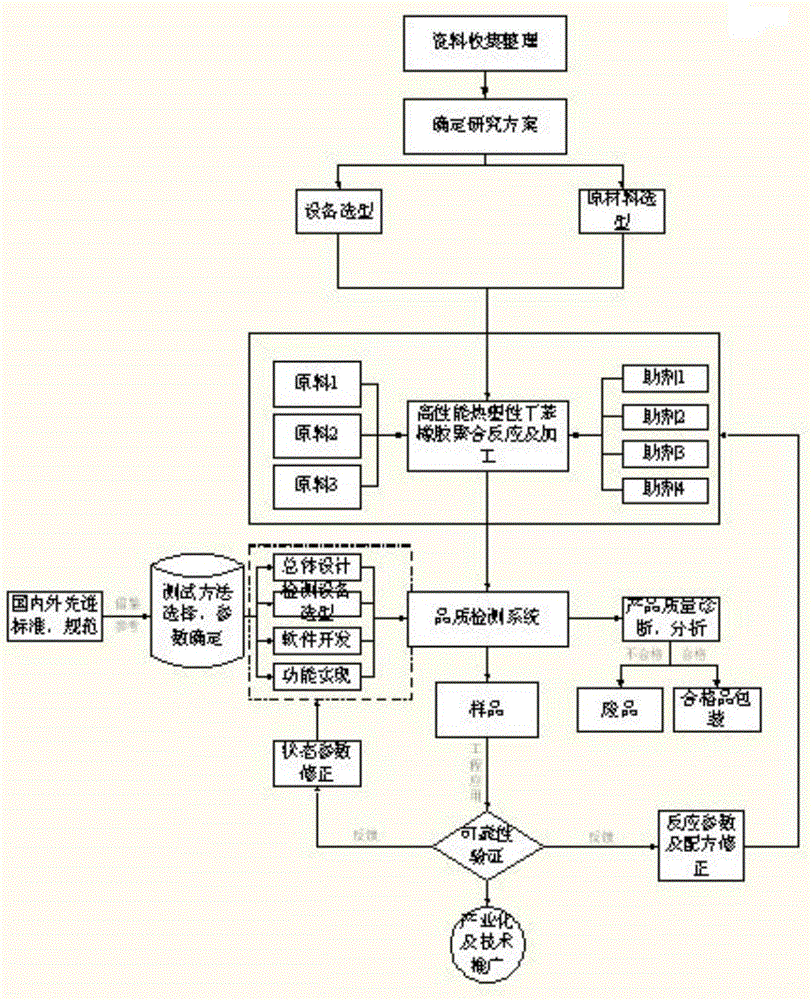

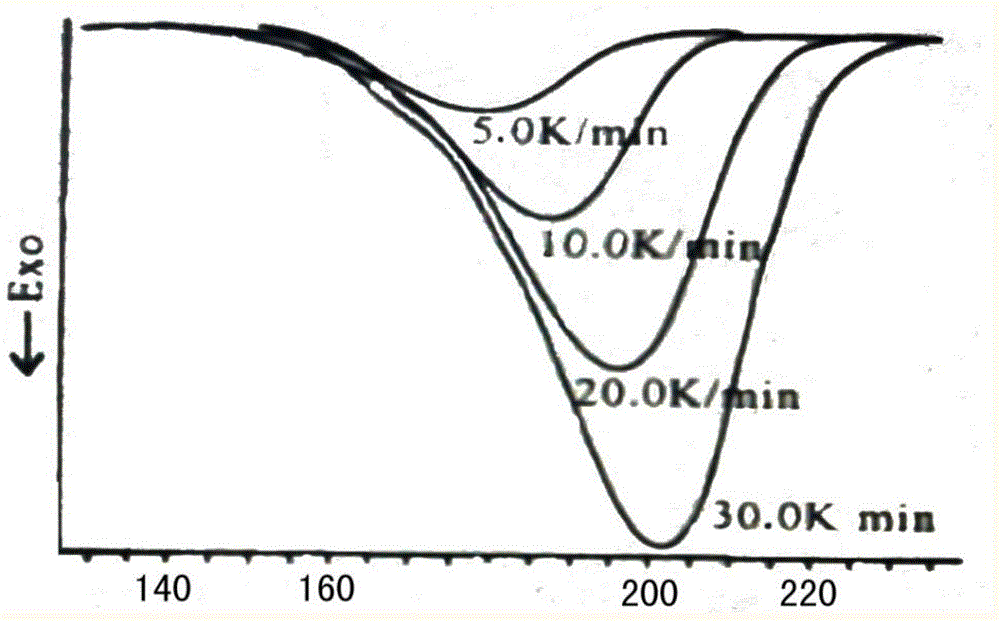

Thermoplastic styrene-butadiene rubber used in medical treatment field and preparation method of thermoplastic styrene-butadiene rubber

InactiveCN104312076AImprove temperature resistanceGood weather resistanceThermoplasticPolymer science

The invention discloses thermoplastic styrene-butadiene rubber used in the medical treatment field. The rubber is prepared from the following components in percentage by weight: 10-40 percent of styrene-butadiene-styrene segmented copolymer, 20-50 percent of naphthenic oil 4006, 0.5-10 percent of n-butyllithium, 1-6 percent of tetrahydrofuran, 0.1-3 percent of titanocene dichloride, 0.1-5 percent of antioxygen, 0.2-3 percent of UL327 and 0.1-0.5 percent of vinyl bistearic amide, the sum of the weight percentage of all components being 100 percent. The thermoplastic styrene-butadiene rubber has the advantages of high temperature tolerance, weather resistance and ultraviolet (UV) resistance, and is free of toxicity, good in flexibility, low in compression deformation and high in sealing performance; 120-DEG C steam sterilization and X-ray irradiation can be borne; the food and drug administration standard of elastic characteristics of styrene type thermoplastic elastomer is met so that the rubber conforms to the food and drug administration (FDA) and can be used for making medical rubber products such as injectors and transfusion instruments.

Owner:NINGBO JENIUS PLASTIC

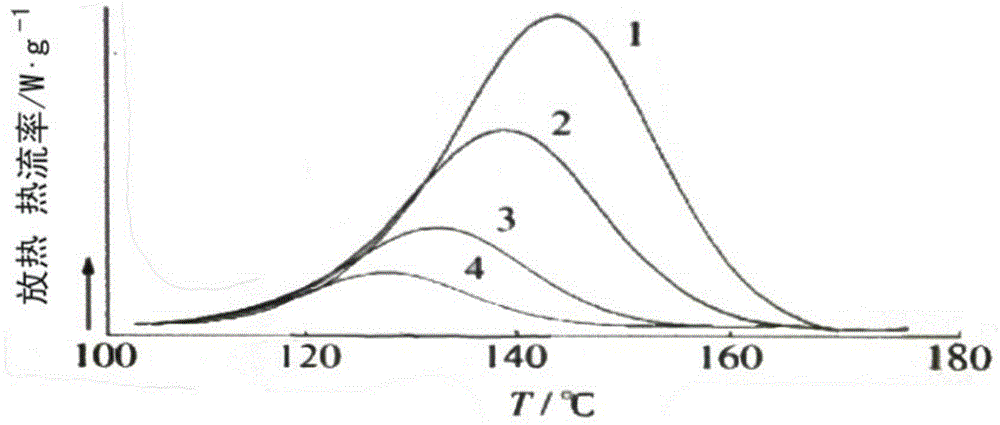

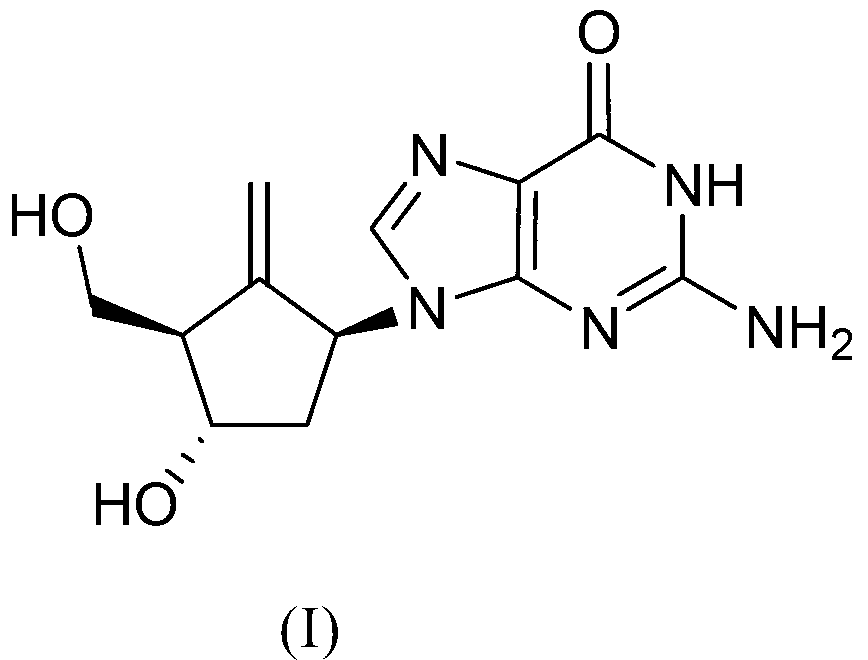

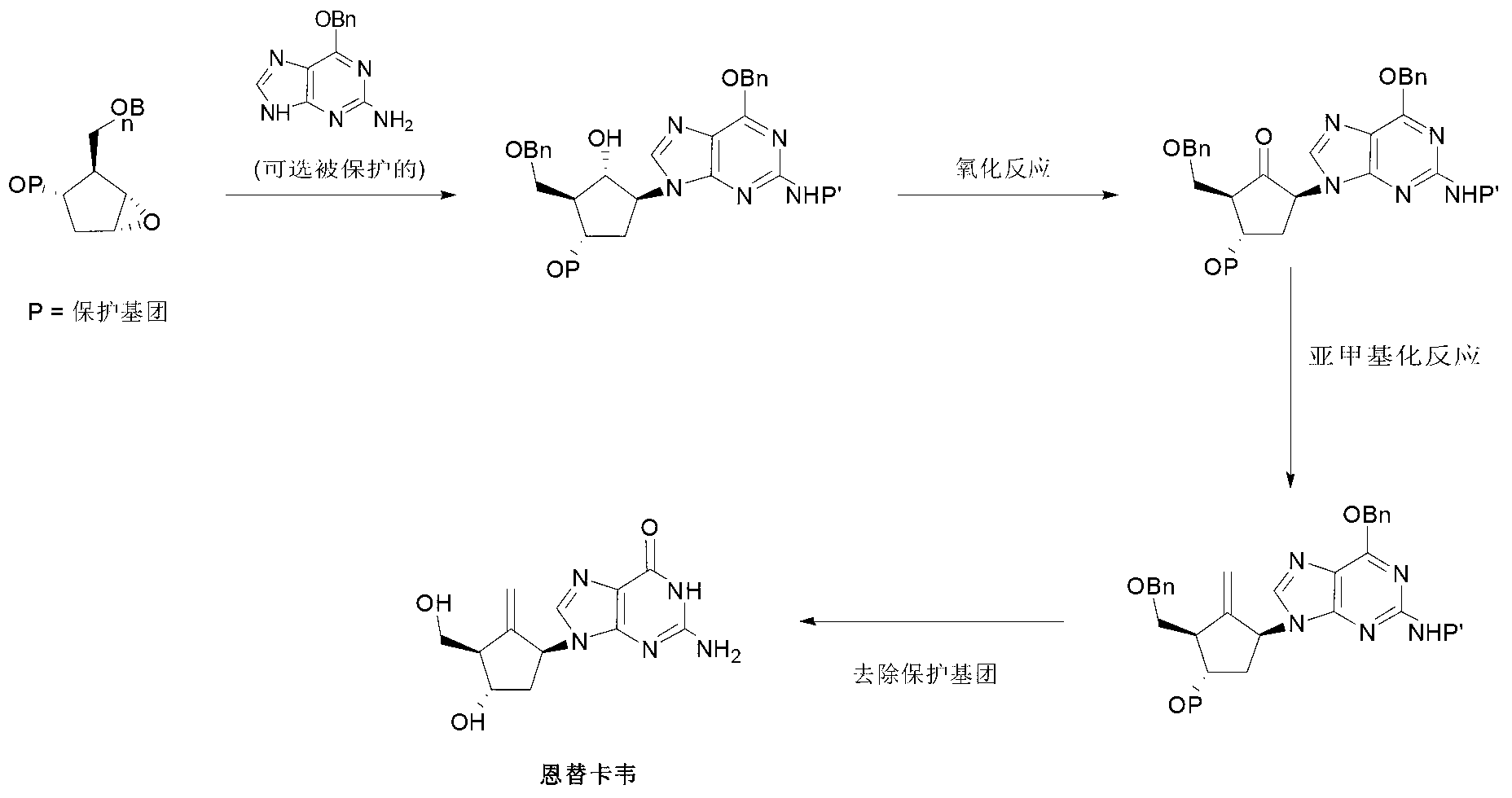

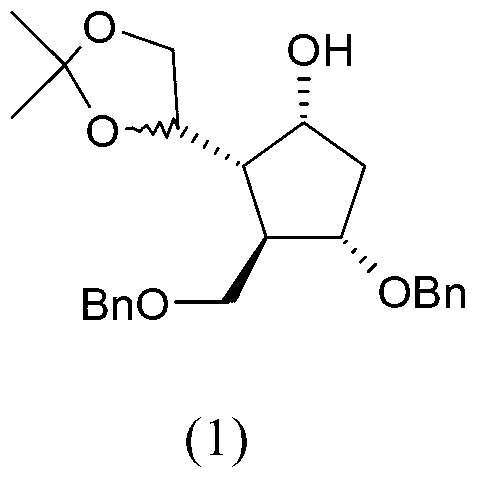

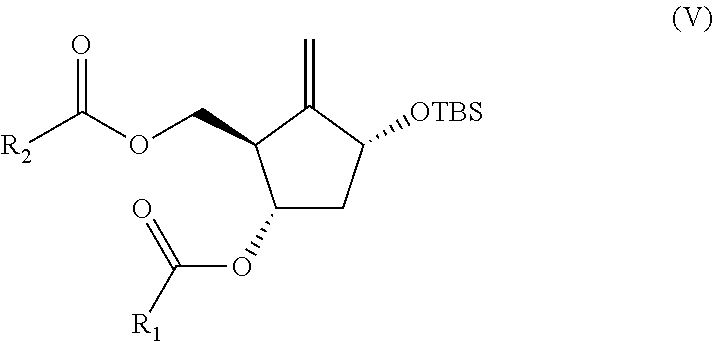

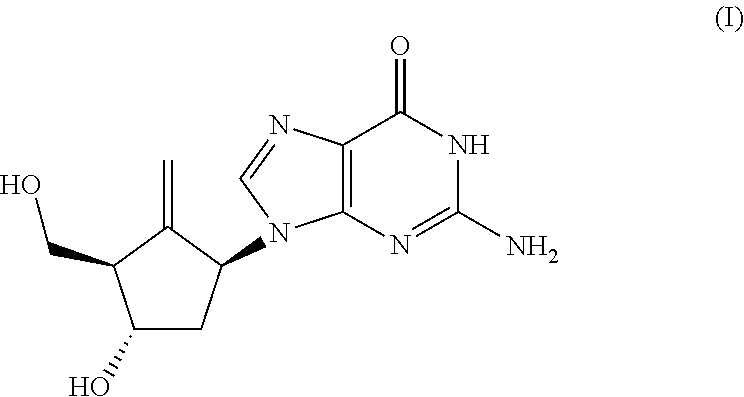

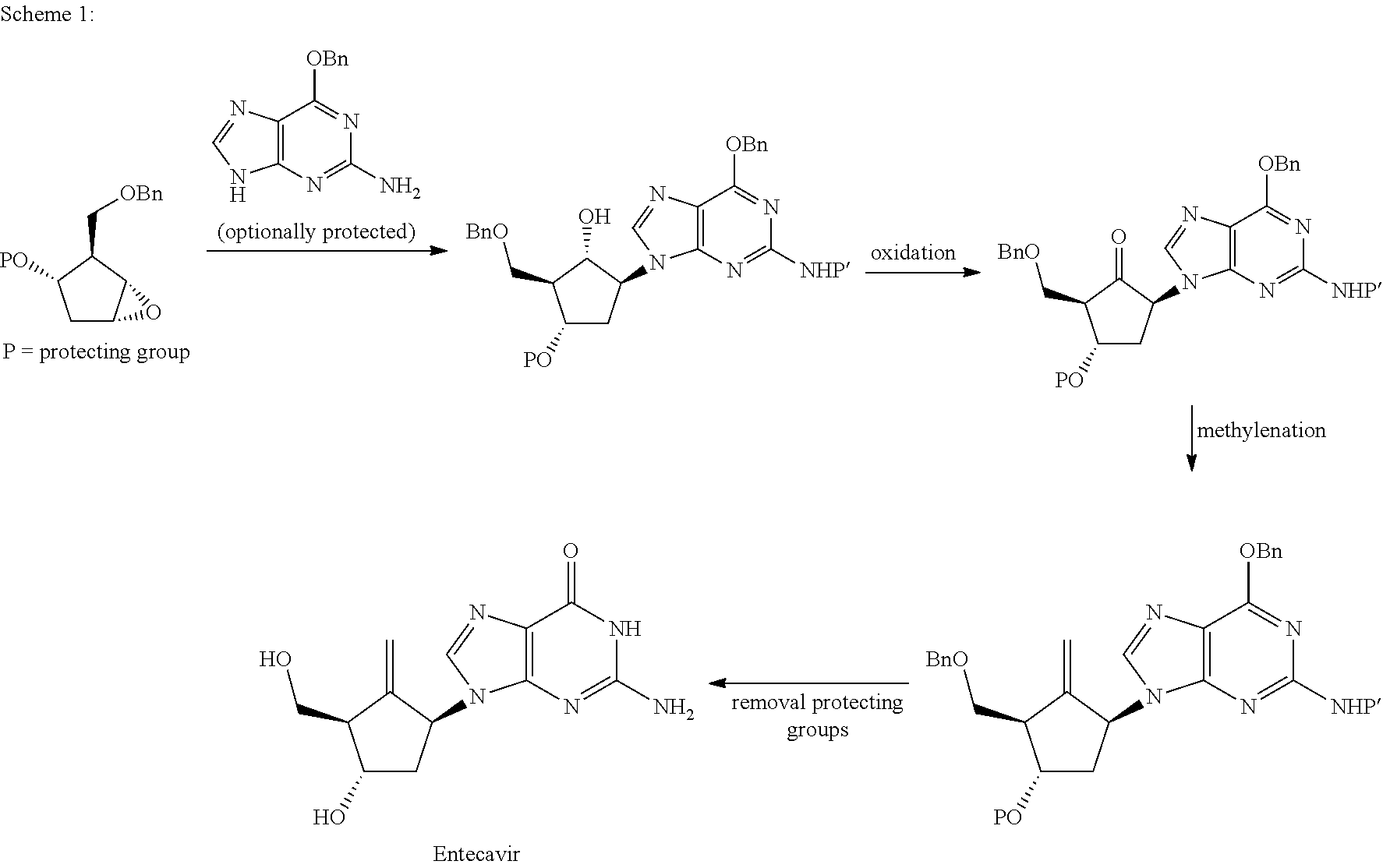

Preparation process of an antiviral drug (entecavir) and intermediates thereof

It comprises a preparation process of entecavir comprising: submitting a (1S, 3R)-3-(tert-butyldimethylsilyloxy)-1 -(oxiran-2-yl)pent-4-yn-1-ol (VIII) to a double esterification and to a radicalary cyclization, yielding a compound of formula (V), where either a compound of formula (VIII) is submitted to a first esterification reaction, then to a catalytic radicalary cyclization using titanocene dichloride as catalyst in the presence of Mn / 2,4,6-collidine HCI or Zn / 2,4,6-collidine / trimethylsilyl chloride, and finally to a second esterification reaction or, alternatively, the compound of formula (VIII) is submitted first to a catalytic radicalary cyclization, and then to an esterification reaction. Entecavir can be obtained by submitting compound (V) to a desilylation reaction to remove the TBS group and then to a Mitsunobu coupling with 2- amino-6-chloroguanine, followed by hydrolysis. It also relates to some new intermediates of the process.

Owner:ESTEVE QUIMICA

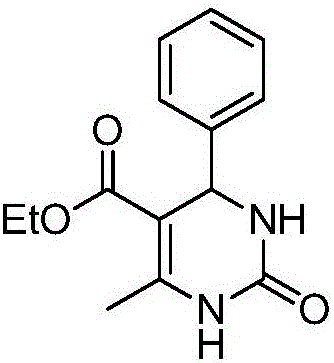

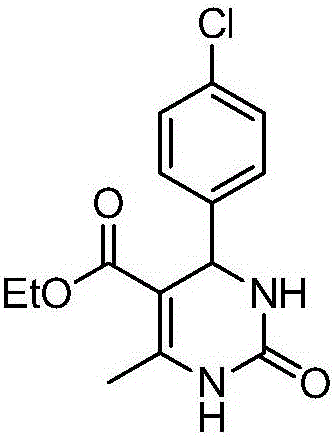

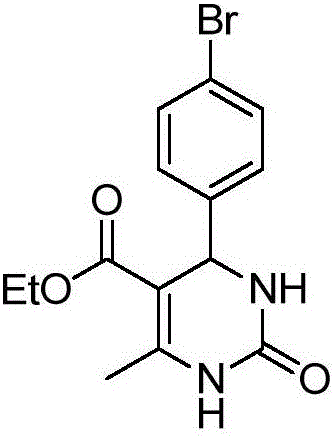

Preparation method of 3, 4-dihydropyrimidine-2-ketone derivative through high-efficient catalyzation of ethyl alcohol promoted titanocene dichloride

The invention discloses a preparation method of 3, 4-dihydropyrimidine-2-ketone derivative through high-efficient catalyzation of ethyl alcohol promoted titanocene dichloride. The method takes aromatic aldehyde, beta-diketone and urea as raw material, takes ethanol as solvent and accelerant, and takes titanocene dichloride as catalyst; under the synergistic promotion effect of ethanol, titanocene dichloride can efficiently prepare 3, 4-dihydropyrimidine-2-ketone derivative with high yield. The catalyst is less in dosage, low in price, toxic free, stable in air; the reaction condition is gentle, time is short, and operation is simple, and atom economy is high; after finishing the reaction, the 3, 4-dihydropyrimidine-2-ketone derivative can be obtained through performing simple column chromatography isolation on products, thus the preparation method opens a new low-cost, green and high-efficient way for the preparation of the 3, 4-dihydropyrimidine-2-ketone derivative, and has an extensive application prospect.

Owner:SHAANXI NORMAL UNIV

Norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymerization catalyst and ternary copolymerization method

The invention relates to a norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymerization catalyst and a ternary copolymerization method. The norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymerization catalyst is characterized in that a preparation method for the norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymerization catalyst comprises the steps of dissolving titanocene dichloride and a ligand in a first solvent in a 3-mouth flask in a dry inert atmosphere; dripping aluminum alkyl to the 3-mouth flask at 130-170 rpm; after the dripping is finished, stirring the materials at a constant temperature of 30-60 degrees centigrade for 30-60 minutes to obtain a titanium-aluminum complex catalyst; taking norbornene, octafluorocyclopentene and N-phenyl maleimide monomers according to a mole ratio of 1:1:1; adding the norbornene, octafluorocyclopentene and N-phenyl maleimide monomers to a nitrogen charged reaction kettle which is vacuumized for multiple times; adding a second solvent to the reaction kettle to dissolve the monomers; and then adding the titanium-aluminum complex catalyst to the reaction kettle and enabling the materials in the reaction kettle to react at a certain temperature and under a certain pressure; pouring a reaction product into ethanol solution containing 4-5wt% hydrochloric acid; washing obtained precipitates by using ethanol to be neutral; and drying the washed precipitates in a vacuum manner to obtain a norbornene, octafluorocyclopentene and N-phenyl maleimide ternary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

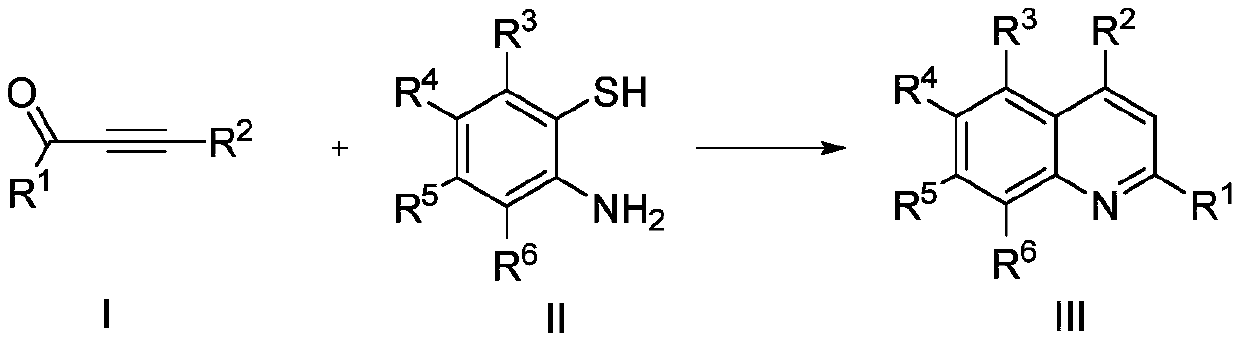

Method for preparing quinoline compounds under catalysis of zirconocene dichloride

ActiveCN110156673AReduce dosageMild reaction conditionsOrganic chemistryN dimethylformamideQuinoline

The invention discloses a method for preparing quinoline compounds under catalysis of zirconocene dichloride. According to the method, 3-butyne-2-one compounds and an o-aminophenylmercaptan compound are taken as raw materials, zirconium dichloride is taken as a catalyst, L-phenylalanine, tyrosine and the like are taken as catalyst ligands, and N,N-dimethylformamide is used as a solvent, and elemental iodine, hydrogen peroxide, peroxy tert-butyl alcohol and the like are used as oxidizing agents, so that the quinoline compound can be prepared in a high-efficiency and high-yield manner. The catalyst used in the method is less in use amount, low in cost and stable in air, reaction conditions are mild, and operation is simple. After the reaction is finished, the product is extracted and washed,simple column chromatography separation is carried out, and then the quinoline compound can be obtained. The method provides a low-cost efficient way for preparation of the quinoline compound and hasa wide application prospect.

Owner:SHAANXI NORMAL UNIV

Preparation process of an antiviral drug (entecavir) and intermediates thereof

InactiveUS20130296558A1Reduce formationLower reaction conditionsSilicon organic compoundsAntiviralsTrimethylsilyl chlorideAntiviral drug

It comprises a preparation process of entecavir comprising: submitting a (1S,3R)-3-(tert-butyldimethylsilyloxy)-1-(oxiran-2-yl)pent-4-yn-1-ol (VIII) to a double esterification and to a radicalary cyclization, yielding a compound of formula (V), where either a compound of formula (VIII) is submitted to a first esterification reaction, then to a catalytic radicalary cyclization using titanocene dichloride as catalyst in the presence of Mn / 2,4,6-collidine HCl or Zn / 2,4,6-collidine / trimethylsilyl chloride, and finally to a second esterification reaction or, alternatively, the compound of formula (VIII) is submitted first to a catalytic radicalary cyclization, and then to an esterification reaction. Entecavir can be obtained by submitting compound (V) to a desilylation reaction to remove the TBS group and then to a Mitsunobu coupling with 2-amino-6-chloroguanine, followed by hydrolysis. It also relates to some new intermediates of the process.

Owner:ESTEVE QUIMICA

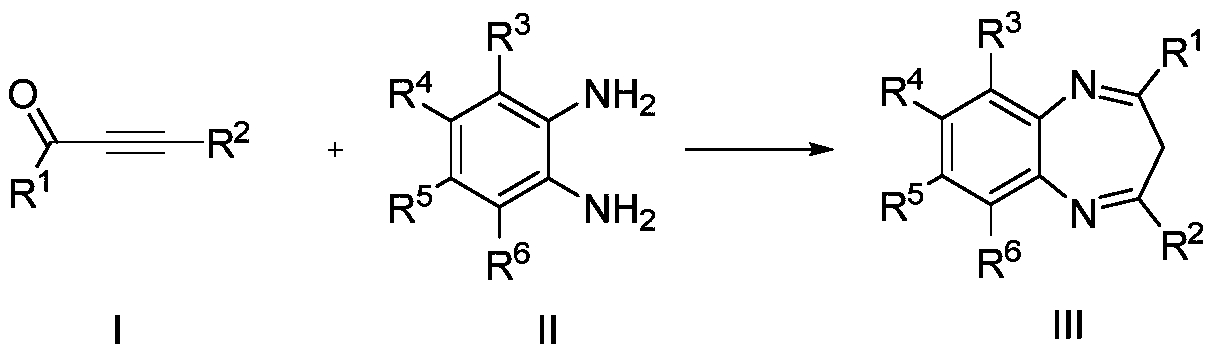

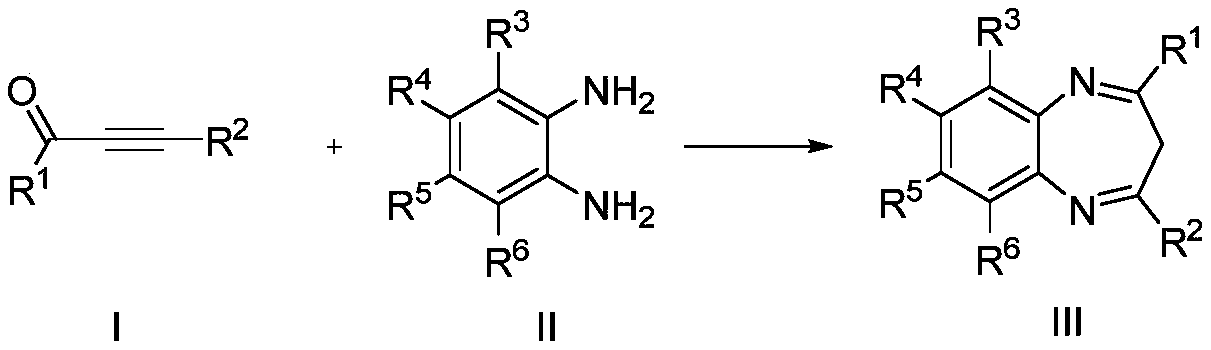

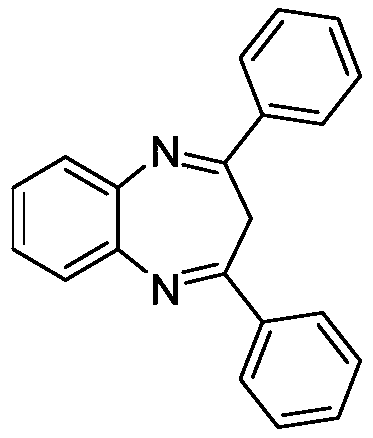

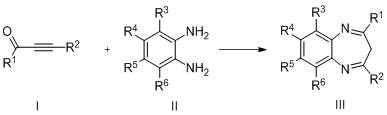

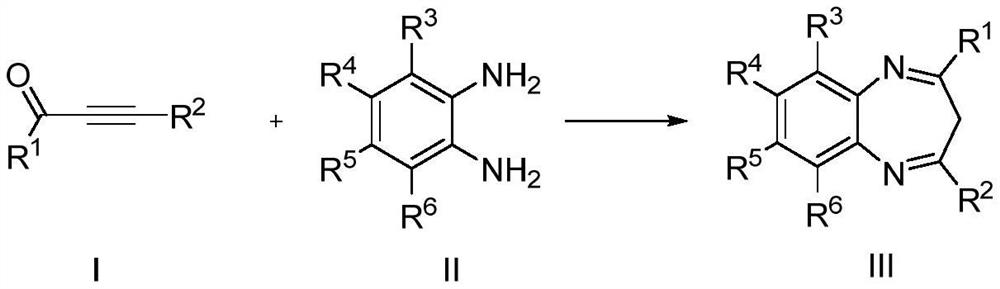

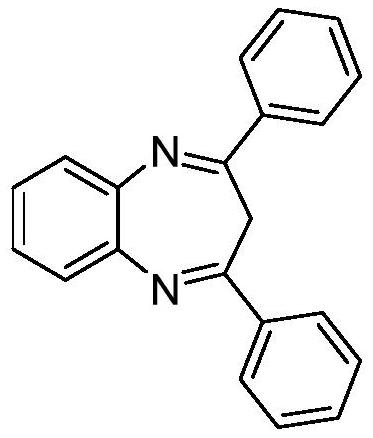

Method for catalytically preparing benzodiazepine compound by using titanocene dichloride

ActiveCN110256365AReduce dosageBroad biological activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSalicylic acidKetone

The invention discloses a method for catalytically preparing a benzodiazepine compound by using titanocene dichloride. According to the method, a 3-butyne-2-ketone compound and an o-phenylenediamine compound are taken as raw materials, ethanol or methanol is taken as a solvent and an accelerant, titanocene dichloride is taken as a catalyst, and isophthalic acid and 2-hydroxy nicotinic acid or salicylic acid is taken as a ligand to high efficiently prepare the 2,4-diphenyl-3-H-1,5-benzodiazepine derivative in a high-yield mode. The usage amount of the catalyst used in the method is low, and the catalyst is low in price, is free of toxicity and is stable in air; the reaction is mild in conditions, short in time and simple in operation; and after the reaction is finished, only simple column chromatography separation is needed to be carried out on the product to obtain the 2,4-diphenyl-3-H-1,5-benzodiazepine derivative. A novel low-cost green and efficient way is developed for preparation of the 2,4-diphenyl-3-H-1,5-benzodiazepine derivative, and the method has a wide application prospect.

Owner:SHAANXI NORMAL UNIV

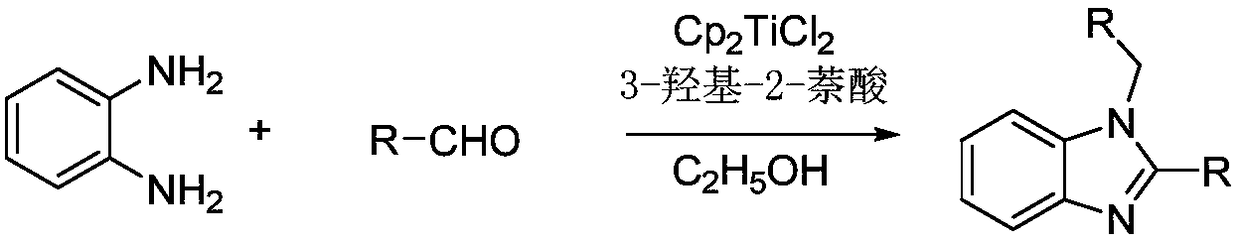

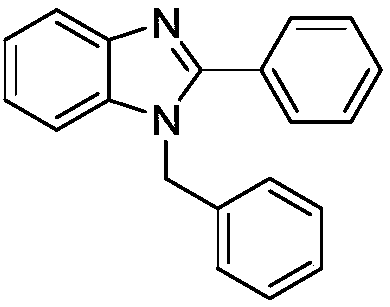

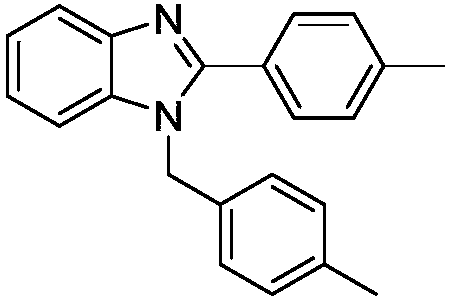

Method for synthesizing 1,2-disubstituted benzimidazole compounds from 3-hydroxy-2-naphthoic acid assisted with titanocene dichloride

The invention discloses a method for synthesizing 1,2-disubstituted benzimidazole compounds from 3-hydroxy-2-naphthoic acid assisted with titanocene dichloride. According to the method, o-phenylenediamine and aldehyde are used as raw materials, ethanol or methanol is used as a solvent, titanocene dichloride is used as a catalyst assisted with 3-hydroxy-2-naphthoic acid, and the 1,2-disubstituted benzimidazole compounds can be synthesized efficiently and selectively. The method provided by the invention is simple to operate, less in catalyst dosage, high in atomic economy, mild in reaction condition, short in reaction time, high in product yield, environmentally friendly, and excellent in selectivity for reaction products, and has broad application prospects for the synthesis of the 1,2-disubstituted benzimidazole compounds.

Owner:SHAANXI NORMAL UNIV

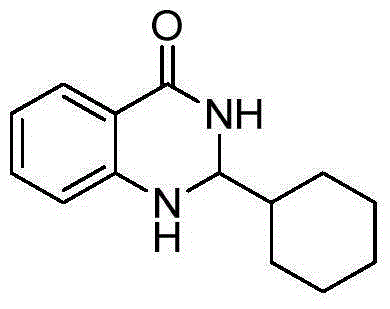

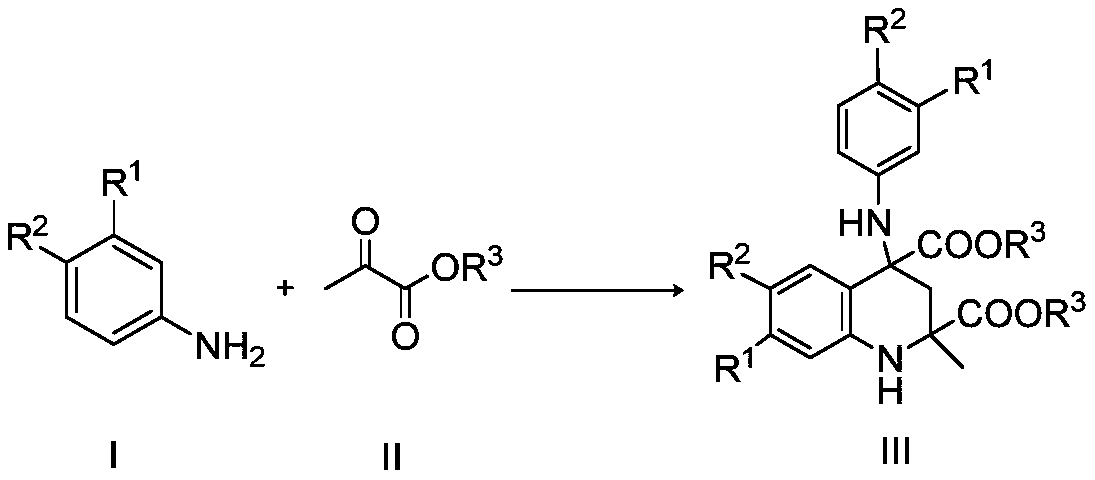

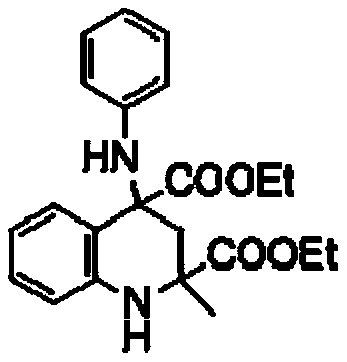

Method for synthesizing tetrahydroquinoline compounds from arylamine and alpha-ketoester under catalysis of titanocene/Bronsted acid

The invention discloses a method for synthesizing tetrahydroquinoline compounds from arylamine and alpha-ketoester under the catalysis of titanocene / Bronsted acid. According to the method, 3,5,6-trichlorosalicylic acid or 5-nitrosalicylic acid and titanocene dichloride are cooperatively used for catalyzing the synthesis of tetrahydroquinoline compounds from arylamine and alpha-ketoester in a greensystem composed of lower aliphatic alcohol (methanol, ethanol, etc.) and water. The titanocene dichloride used in the invention is cheap and easily available and is stable in air and water; a reaction system is green and environmentally friendly; no precious metal is needed; the pre-synthesis of a catalyst and a substrate is avoided; the mild, green and easy-to-operate synthesis method is established for the synthesis of tetrahydroquinoline derivatives; and the method has the advantages of mild reaction conditions, short reaction time, high atomic economy and high target product yield.

Owner:SHAANXI NORMAL UNIV

Synthesis method of titanocene dichloride

ActiveCN108440606AMild reaction conditionsEasy to operateMetallocenesChemical synthesisN dimethylformamide

The invention discloses a synthesis method of simple and environment-friendly titanocene dichloride. The synthesis method comprises the following steps: successively adding diethylamine and cyclopentadiene into an N,N-dimethylformamide solution, uniformly mixing and carrying out reflux reaction; after the reaction is ended, cooling to room temperature, decompressing and evaporating a solvent to dryness; then adding ice water for stirring, precipitating red precipitate, carrying out vacuum suction filtration and washing a solid with the ice water to obtain a titanocene dichloride coarse product; fully dissolving the titanocene dichloride coarse product with N,N-dimethylformamide, carrying out vacuum suction filtration and spin drying on filtrate to obtain the solid; recrystallizing the solid by using an ice water-dichloromethane-ethanol mixed solution, and filtering to obtain red acicular crystal and carrying out vacuum drying to obtain the titanocene dichloride. The method disclosed bythe invention has the advantages that the yield of the reaction is greatly improved under the condition of reducing the reaction time; meanwhile, an economical and environment-friendly solvent is used, so that the use of toxic and harmful solvents is avoided; the synthesis method has little hazard to the environment and is in line with the green and environment-friendly chemical synthesis concept.

Owner:湖北优仁新材料有限公司

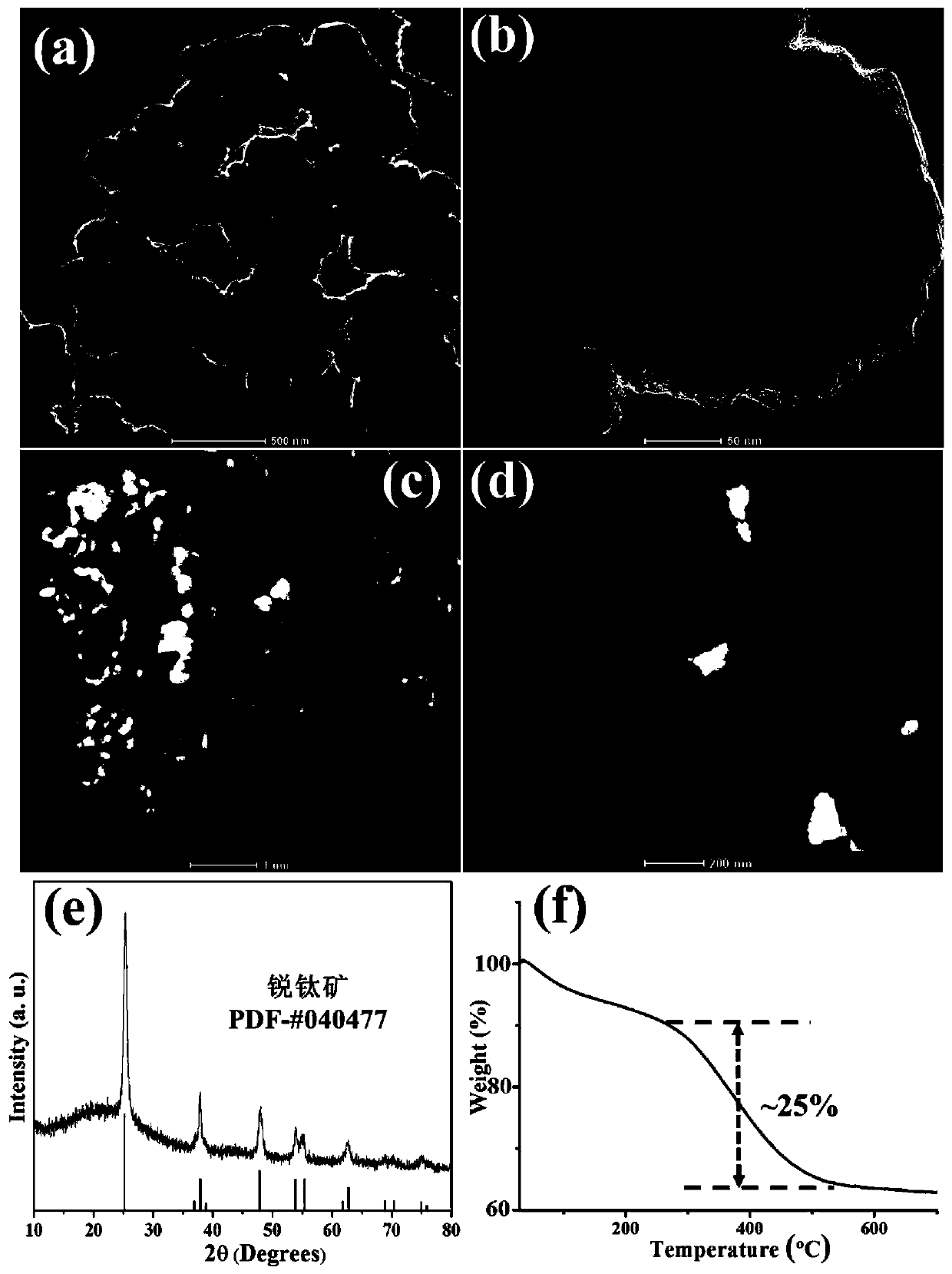

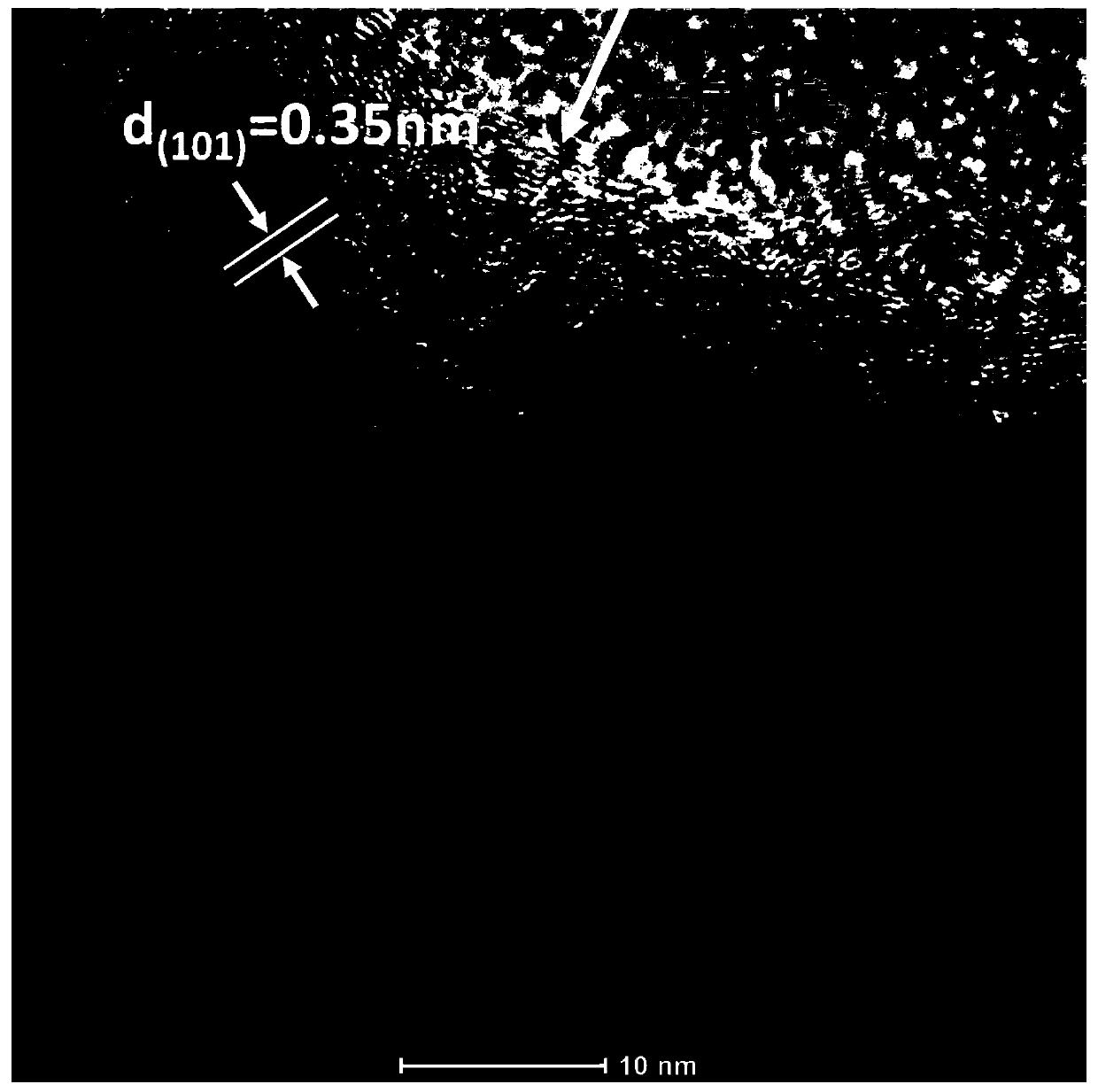

Titanium dioxide nano-cluster@carbon sphere multistage composite structure material as well as preparation method and application thereof

ActiveCN110975852ASimple methodReduced electron-hole recombination ratePhysical/chemical process catalystsWater/sewage treatment by irradiationAlkaneCarboxylic acid

The invention relates to the technical field of photocatalytic materials, in particular to a titanium dioxide nano-cluster@carbon sphere multistage composite structure material as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing titanocene dichloride, liquid straight-chain carboxylic acid and liquid straight-chain alkane, carrying out solvothermal reaction, and carrying out solid-liquid separation to obtain the titanium dioxide nano-cluster@carbon sphere multistage composite structure material. According to the invention, titanocene dichloride is used as a titanium source, liquid straight-chain carboxylic acid is used as a solvent, liquid straight-chain alkane is used as a mixed solvent, the titanium dioxide nano-cluster@carbon sphere multistage composite structure material can be obtained through a one-step solvothermal process, the method is simple and efficient, a titanium dioxide nano-structure with photocatalytic activity is completely exposed on the surface of the material, and a good organic pollutant removal effect is achieved.

Owner:UNIV OF JINAN

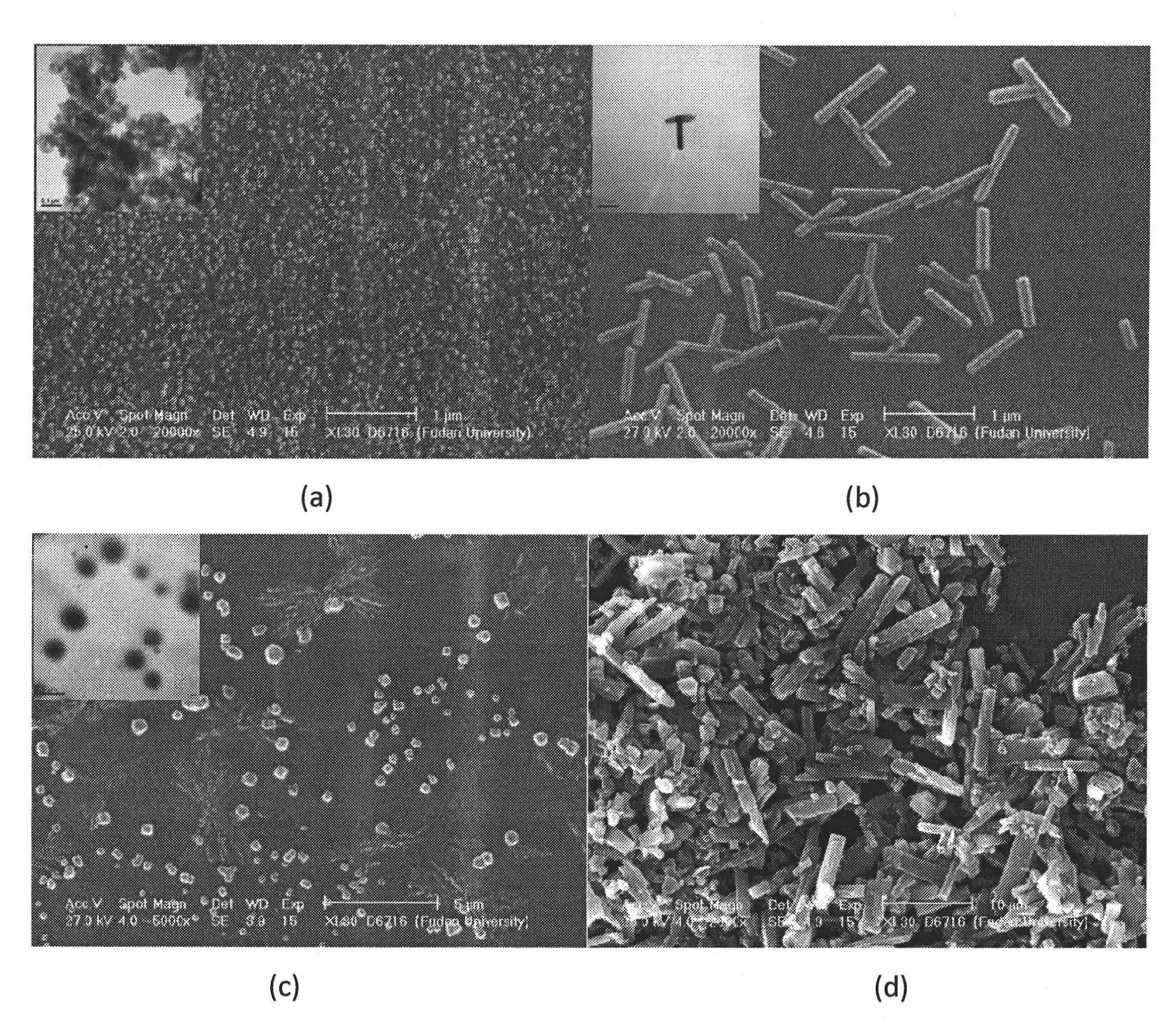

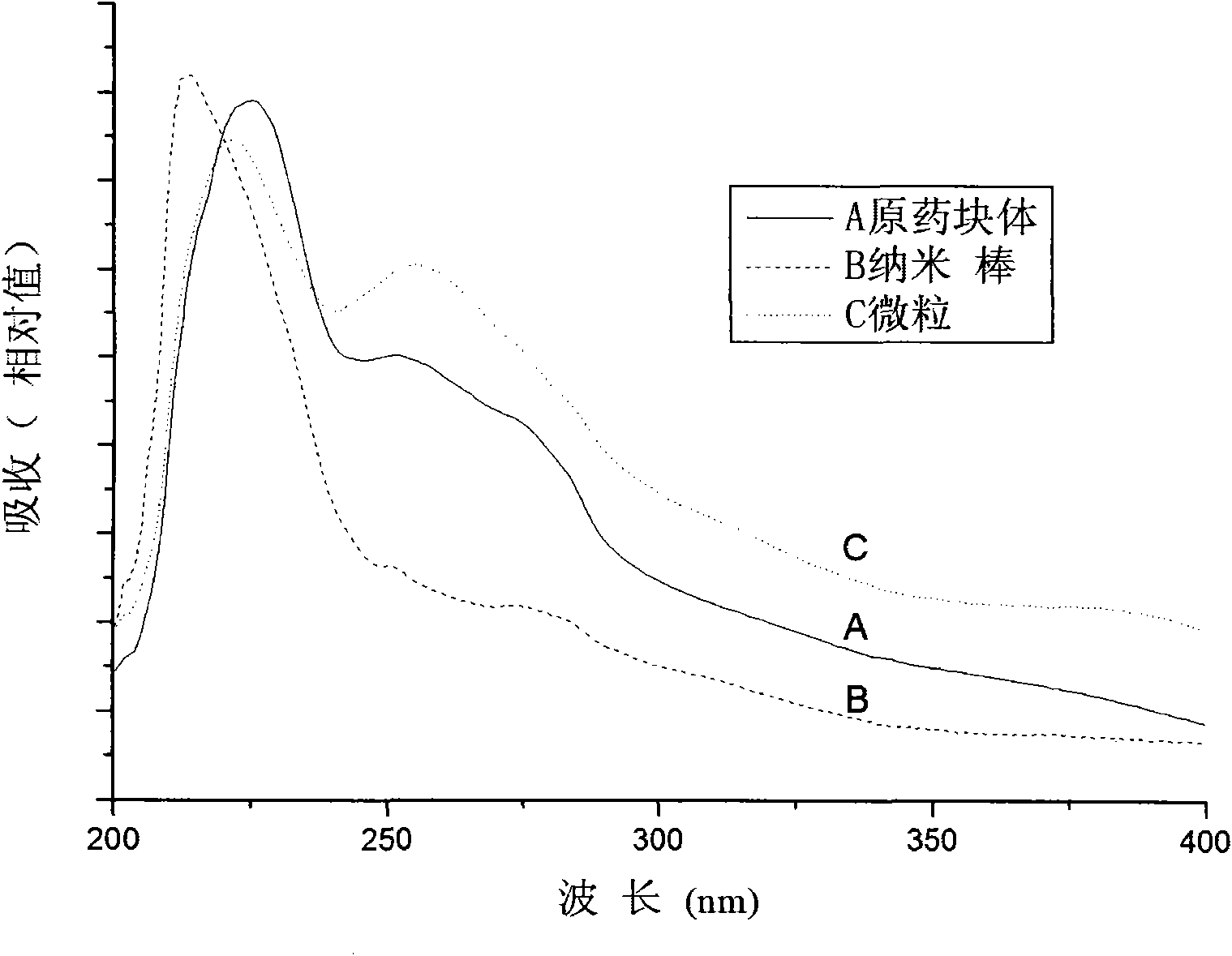

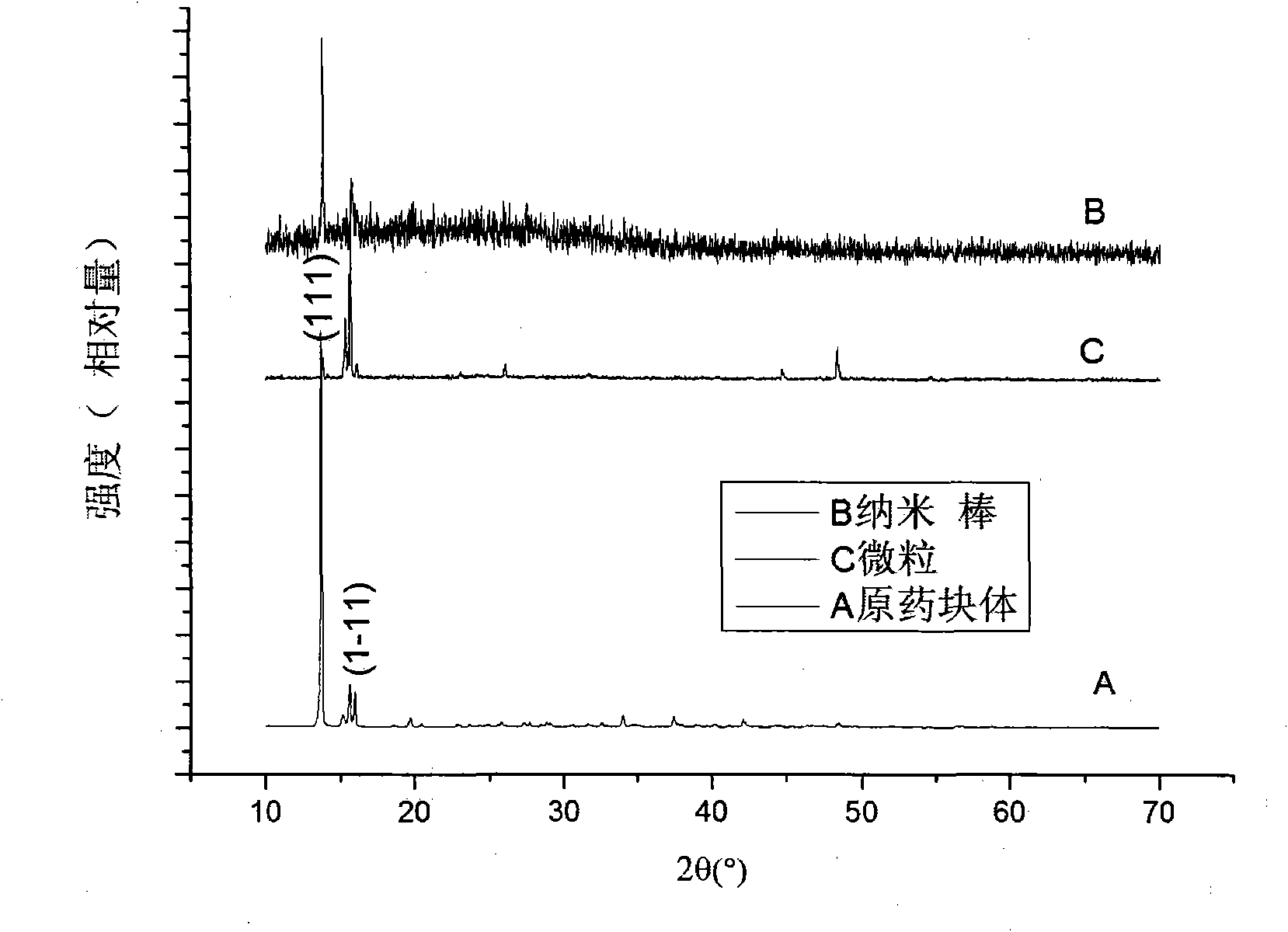

Method for preparing dichloro dicyclopentadienyl titanium and cis-platinum nano-particles by atomization ultrasound polarity difference technology

InactiveCN101773803AEasy to prepareReduce manufacturing costRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPharmaceutical product form changeMicroparticleSolvent

Belonging to the field of nano biomedicine and material, the invention in particular relates to the atomization ultrasound polarity difference technology for preparing organic metal anti-cancer drug-dichloro dicyclopentadienyl titanium and cis-platinum nano-particles. The method comprises the following steps: preparing solution A with an appropriate concentration; placing the solution A into a squeezing type sprayer and spraying the solution A into solution B; controlling environment temperature to range from 15 DEG C to 25 DEG C, environment humidity to range from 45% to 50%, ultrasound intensity to be 100w and jet mass velocity to range from 0.4mL / min to 0.5mL / min; wherein the whole reaction system is in an ultrasound environment. The method of the invention features simple equipment, convenient preparation process and low production cost. Medicine size and shape of the product can be controlled by controlling conditions such as medicine concentration in the solution A, reaction time and the like; therefore controlled production of the medicine is expected to be realized by further studies, thus providing more choices for multi-drug administration of the medicine. The method of the invention has the advantages of simple and convenient operation, short production cycle, controlled production, freedom from addition agent and easy realization of industrialization, thus being of great value for industrialized application and expected to be promoted to achieve large-scale application. In addition, the product features even distribution, difficult agglomeration, high purity and easy realization of industrialized production.

Owner:TONGJI UNIV

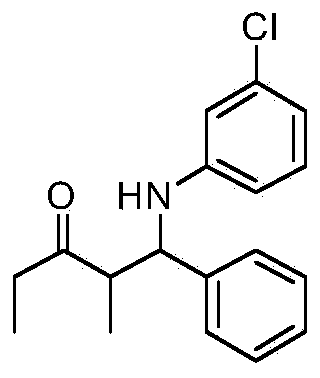

Method for preparing beta-amino carbonyl compound through synergetic catalysis of titanocene dichloride and aminophenol ligand

InactiveCN104045573ASimple post-processingEasy to operateOrganic chemistryOrganic compound preparationNatural productOrganic synthesis

The invention discloses a method for preparing a beta-amino carbonyl compound through synergetic catalysis of titanocene dichloride and an aminophenol ligand. The method comprises the following step: directly reacting aliphatic ketone, aromatic aldehyde and aromatic amine under the synergetic catalysis condition of titanocene dichloride and the aminophenol ligand to obtain the beta-amino carbonyl compound. According to the method, a solvent does not need to be added, the used catalysts are cheap, nontoxic and stable to air and water, the operation is simple, the reaction conditions are mild, the reaction time is short, the atom economy is high, the product yield is high, and the prepared beta-amino carbonyl compound has very high application potential in preparation of drugs, natural products and organic synthetic intermediates.

Owner:SHAANXI NORMAL UNIV

Method for preparing diindolyl methane derivatives

Owner:SHAANXI NORMAL UNIV +1

Method for preparing benzodiazepine derivatives catalyzed by dichlorotitanocene

ActiveCN110256365BReduce dosageBroad biological activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSalicylic acid

The invention discloses a method for preparing benzodiazepine compounds by catalyzing titanocene dichloride. The method uses 3-butyne-2-ketone compounds and o-phenylenediamine compounds as raw materials, and ethanol or methanol as Solvent and accelerator, using titanium dichloride as catalyst and isophthalic acid, 2-hydroxynicotinic acid or salicylic acid as ligand, can prepare 2,4-diphenyl-3-H-with high efficiency and high yield 1,5‑Benzodiazepine derivatives. The catalyst used in the present invention is low in consumption, cheap, non-toxic, stable to air, mild in reaction conditions, short in time, and simple in operation. Phenyl-3-H-1,5-benzodiazepine derivatives, for the preparation of 2,4-diphenyl-3-H-1,5-benzodiazepine derivatives has opened up a new low-cost and It is a green and efficient way with broad application prospects.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com