Thermoplastic styrene-butadiene rubber used in medical treatment field and preparation method of thermoplastic styrene-butadiene rubber

A styrene-butadiene rubber and thermoplastic technology, which is applied in the field of thermoplastic styrene-butadiene rubber and its preparation, can solve the problems of high energy consumption and high product cost, and achieve the effect of little loss of mechanical properties, no need for vulcanization, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

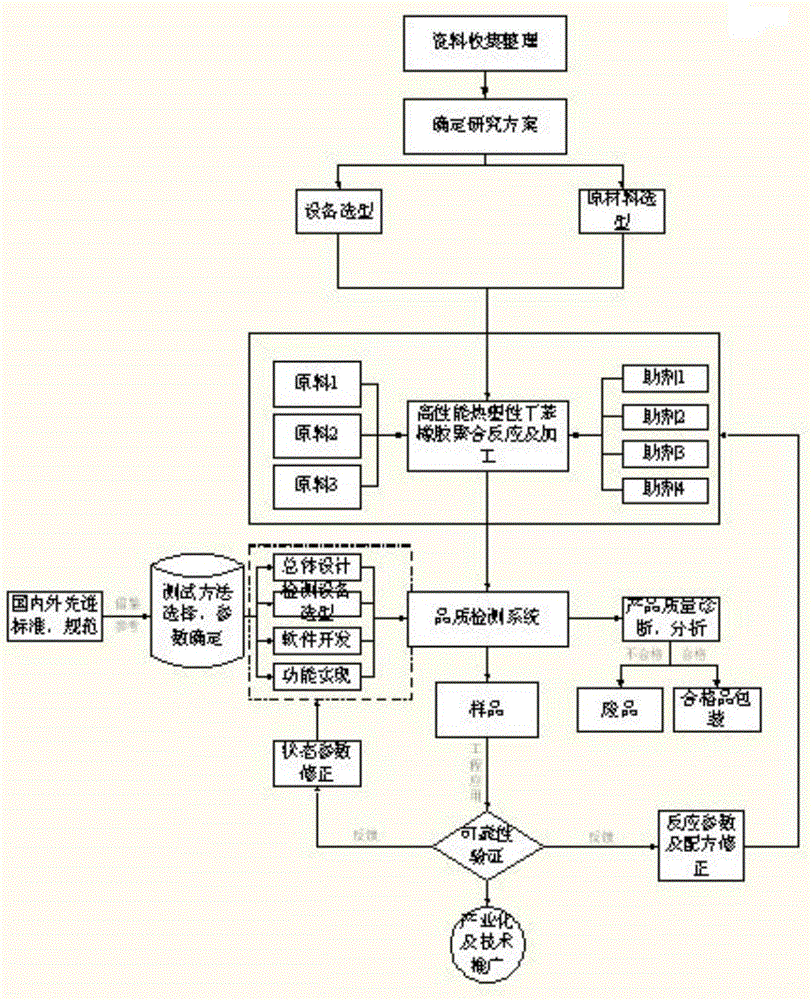

Method used

Image

Examples

Embodiment

[0025] (1) First, according to the formula ratio, using naphthenic oil 4006 as the solvent, n-butyllithium as the initiator, tetrahydrofuran (THF) as the polarity regulator, using a three-step feeding synthesis process, first adding styrene monomer The polymerization reaction temperature and polymerization time are 50°C-70°C for one period, and the reaction time is 15-30 minutes; then add butadiene monomer and polymerize in the second stage, the temperature is less than 95°C, and the time is 40-45 minutes; after adding styrene monomer, carry out the third stage Polymerization, temperature 70°C-80°C, reaction time 15-30 minutes; obtain styrene-butadiene-styrene block copolymer; (three-stage styrene monomer in the above steps: butadiene monomer: styrene The molar ratio of the monomers is 1:13:1)

[0026] (2) Take by weighing the p-styrene-butadiene-styrene block copolymer prepared by the formula ratio step (1), and the metallocene catalyst of the formula ratio---titanocene dichl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com