Water-soluble titanocene complex and synthesis method thereof

A synthesis method and complex technology, applied in organic chemistry methods, chemical instruments and methods, metallocenes, etc., can solve the problems of expensive raw materials, complicated preparation process, limited development and application, etc., and achieve easy post-processing and simple synthesis steps Ease of operation and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

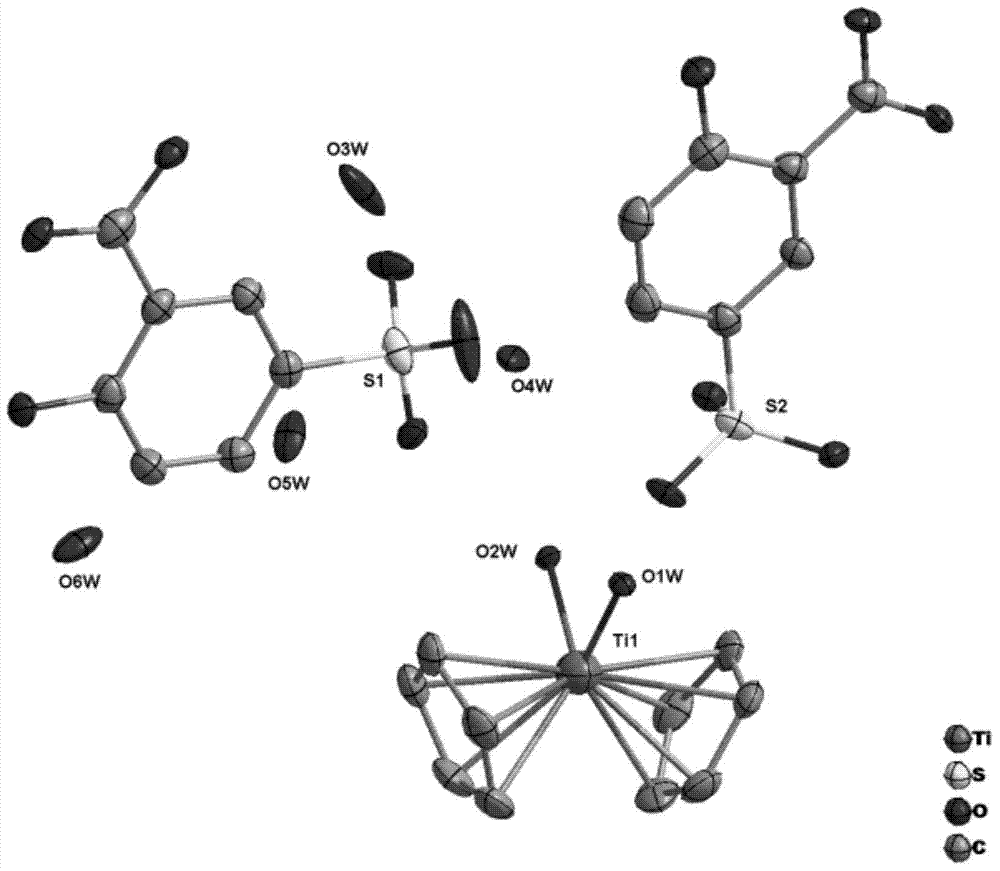

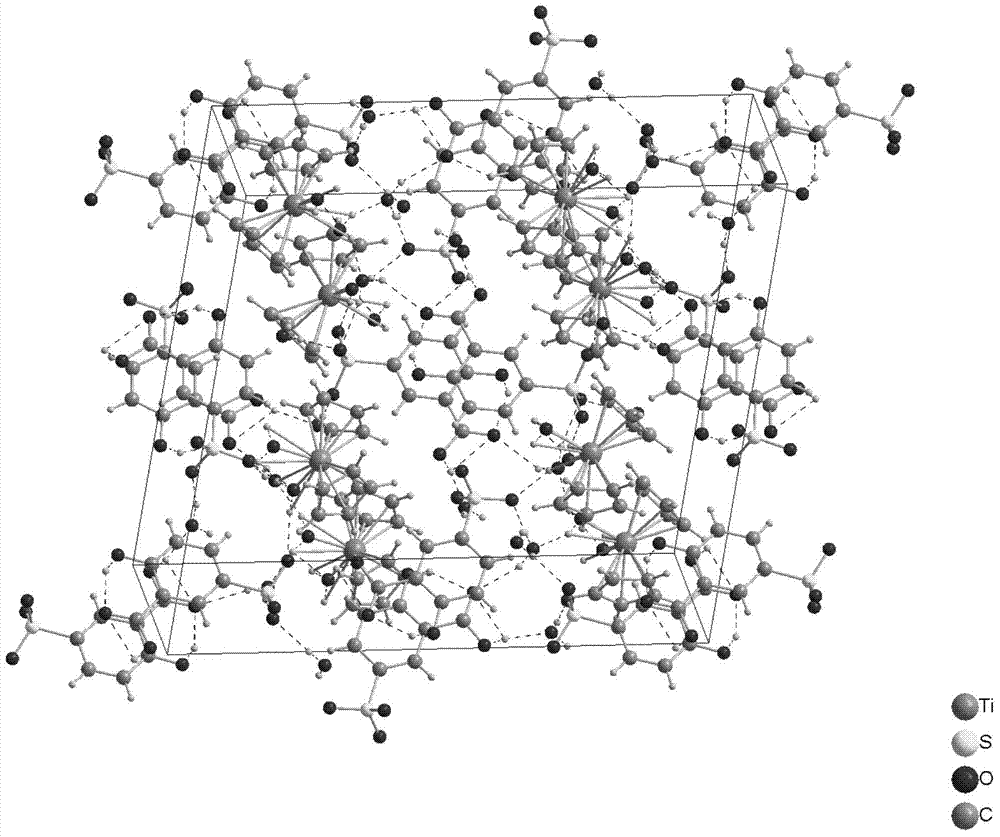

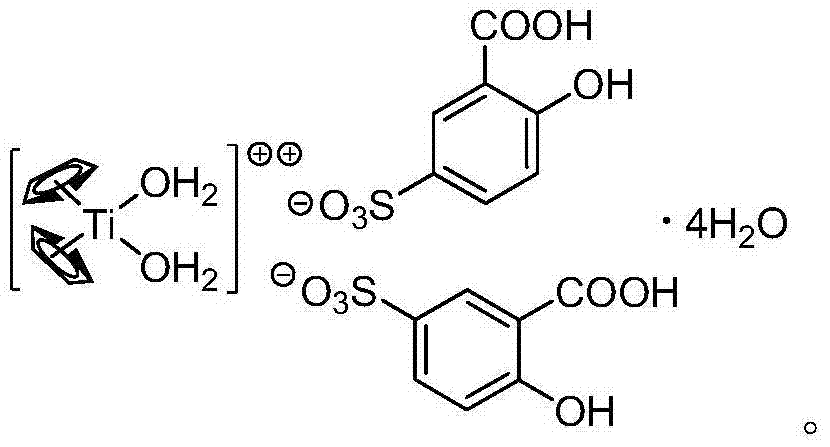

[0015] 0.25g (1.0mmol) titanocene dichloride and 0.24g (2.0mmol) benzoic acid were dissolved in 30mL chloroform, 0.51g (2.0mmol) 5-sulfosalicylic acid was dissolved in 15mL distilled water, and then the two The two solutions were mixed, stirred at room temperature for 2 hours, and the aqueous phase was separated with a separatory funnel, concentrated under reduced pressure to 5 mL, and crystallized to obtain 0.64 g of an orange-yellow water-soluble titanocene complex with a yield of 81%. The X-ray single crystal structure of the complex is shown in figure 1 As shown, the unit cell packing structure diagram is shown in figure 2 As shown, it belongs to the monoclinic crystal system, P2 1 / c space group, unit cell parameter a is 6.9743(2) b is 19.9147(4) c is 21.8983(5) V is 3017.54(13) α is 90°, β is 97.134(2)°, γ is 90°, Z=4, Ti1-O1=2.057(5), Ti1-O2=2.003(5), S1-O8=1.450(3), S1 -O11=1.452(4), S1-O12=1.454(3), S1-O16=1.450(4), S1-O17=1.411(5), S1-O18=1.378(5), O2-Ti1-...

Embodiment 2

[0017] Dissolve 0.25g (1.0mmol) titanocene dichloride and 0.33g (2.0mmol) phthalic acid in 30mL chloroform, dissolve 0.51g (2.0mmol) 5-sulfosalicylic acid in 15mL distilled water, and then The two solutions were mixed, stirred at room temperature for 2 hours, the water phase was separated with a separatory funnel, the water phase was concentrated under reduced pressure to 5 mL, and crystallized to obtain 0.61 g of an orange water-soluble titanocene complex with a yield of 77%.

Embodiment 3

[0019] Dissolve 0.25g (1.0mmol) titanocene dichloride and 0.67g (4.0mmol) 2-naphthoic acid in 30mL 1,2-dichloroethane, and dissolve 0.51g (2.0mmol) 5-sulfosalicylic acid Dissolve in 15 mL of distilled water, then mix the two solutions, stir at room temperature for 2 hours, separate the water phase with a separatory funnel, concentrate the water phase to 5 mL under reduced pressure, and crystallize to obtain 0.58 g of an orange-yellow water-soluble titanocene complex. The rate is 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com