Method for electroplating zinc in neodymium iron boron magnet ionic liquid

An ionic liquid, NdFeB technology, applied in the field of electro-galvanizing in Nd-Fe-B magnet ionic liquid, Nd-Fe-B magnet electro-galvanizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

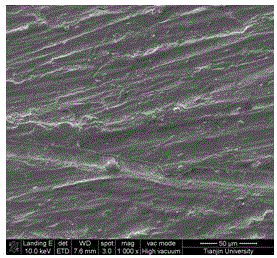

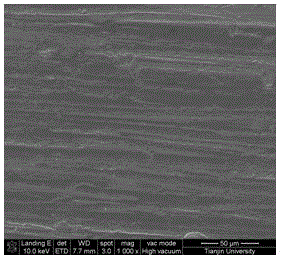

Image

Examples

Embodiment 1

[0041] A method for electroplating zinc in a neodymium iron boron magnet ionic liquid of the present invention is carried out according to the following process steps:

[0042] (1) Pretreatment for NdFeB plating: baking in a muffle furnace at 300°C for 2 hours; sealing with zinc stearate at 140°C for 30 minutes; 30g / L normal temperature degreasing agent solution ultrasonic degreasing for 10 minutes; 30g / L Nitric acid, 1.0g / L thiourea, acid washing at room temperature for 60s; 25g / L alkyl salicylic acid, 10g / L ammonium bifluoride, room temperature activation for 30s; ultrasonic washing; 35g / L zinc sulfate, 120g / L sodium pyrophosphate , 8g / L hydrofluoric acid, 8 / L sodium carbonate, dipping zinc at 80℃ for 30s.

[0043] (2) Ionic liquid synthesis: molar ratio 79%: 19.5%: 1.5%. Weigh a certain amount of urea, sodium iodide, and potassium iodide, mix them in a dry beaker and seal them, and place them in a vacuum drying oven at 80°C. Heat for 5 hours, wait until all of it is dissolved, ...

Embodiment 2

[0048] Based on the method for electroplating zinc with neodymium-iron-boron ionic liquid in the above-mentioned embodiment 1, the method of the embodiment 2 adopts a pulsed electroplating power supply to implement electroplating with zinc.

[0049] The thickness of the galvanized layer obtained by this method is 18μm, and the coating before light is obviously brighter than that of Example 1, almost mirror-bright, the coating is rainbow-colored after passivation, and the bonding strength meets the first-class standard. The neutral salt spray test did not appear for 48 hours. Rust.

Embodiment 3

[0051] A method for electroplating zinc in a neodymium iron boron magnet ionic liquid of the present invention is implemented, and the specific process steps of the method are as follows:

[0052] (1) Pretreatment for NdFeB plating: baking in a muffle furnace at 250°C for 2.5 hours; sealing with zinc stearate at 130°C for 25min; 25g / L normal temperature degreasing agent solution ultrasonic degreasing for 10min; 25g / L Nitric acid, 0.8g / L thiourea, acid washing at room temperature for 40s; 20g / L alkyl salicylic acid, 10g / L ammonium bifluoride, room temperature activation for 30s; ultrasonic washing; 30g / L zinc sulfate, 100g / L sodium pyrophosphate , 10g / L hydrofluoric acid, 10 / L sodium carbonate, dipping zinc at 70℃ for 30s.

[0053] (2) Ionic liquid synthesis: 80% by molar ratio: 18%: 2%. Weigh a certain amount of urea, sodium bromide, and potassium bromide, mix them in a dry beaker and airtight them, and place them in a vacuum at 80°C. Heat in the box for 4 hours, wait until all of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com