Nickel-based alloy wire for welding of LNG storage tank as well as preparation method and welding process

A technology of nickel-based alloy and welding process, which is applied in the field of preparation of nickel-based alloy welding wire, which can solve the problems of decreased plasticity and toughness of welding wire, failure of welding wire to meet production requirements, increase of hardness and strength, etc., to improve drawing accuracy and avoid hydrogen Embrittlement and internal stress generation, and the effect of improving low-temperature impact toughness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method for a nickel-based alloy welding wire for LNG storage tank welding, the steps of which are:

[0026] A. Alloy smelting, batching is carried out according to the above components, the raw materials are put into a vacuum induction furnace for smelting, and cast into electrode rods;

[0027] B. Electroslag remelting, using the existing atmosphere-protected electroslag remelting furnace, the surface of the electrode rod is polished and inserted into the slag as a consumable electrode. The electroslag remelting process is protected by argon gas, and the heavy The composition of the slag material is SiO 2 : 1%, Al 2 o 3 : 22%, FeO: 0.1%, TiO 2 : 3%, MgO: 5%, CaF 2 : 48%, CaO: 20%, current 2100~2300A, steel ingot capping and feeding current 0~1500A, capping time 3~5min, power off and cooling for 5~10min, take off the ingot, cool to room temperature in the air, and get nickel-based alloy ingot , and use a lathe to remove the scale on the surface of the...

Embodiment 1

[0042] In this embodiment, the welding wire (φ1.6mm) is selected to weld the 06Ni9DR steel test plate by automatic submerged arc welding. The size of the base metal is 300mm×150mm×25mm, V-shaped groove is adopted, and the opening angle is 55°; welding current: 370A , Welding voltage: 28V, welding speed: 58mm / min, current type: AC, welding line energy should be controlled below 45KJ / cm, and interlayer temperature should be controlled below 100°C. After the 06Ni9DR steel test plate is welded, the sample processing and mechanical properties are tested according to the requirements in GB / T13814. The tensile properties are shown in Table 1:

[0043] Table 1:

[0044]

[0045] It can be seen from the above table that when welding at room temperature, the deposited metal of this welding wire has a high tensile strength, which meets the requirements for the performance of the weld deposited metal of the LNG storage tank material 06Ni9DR steel. At the same time, it has a good elong...

Embodiment 2

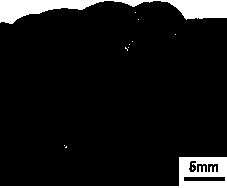

[0055] The microstructure of the welding wire weld metal in this embodiment is as follows: image 3 As shown in the figure, it can be seen that the appearance of the weld obtained by automatic submerged arc welding multi-layer and multi-pass welding is good, the width is consistent, the weld metal is well fused with the base metal, and there are no welding cracks, pores, slag inclusions, and no fusion after welding. and other defects. Inspection standard EN970, using visual inspection and welding inspection ruler, the inspection results are shown in Table 4:

[0056] Table 4:

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com