Surface treatment method of titanium alloy carbon and nitrogen compound permeation

A technology of surface treatment and composite infiltration, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems that can not meet the needs of use, the performance improvement of titanium alloy is not ideal, and achieve accelerated collision and adsorption. Effects of increased speed and reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: acetylene+nitrogen:

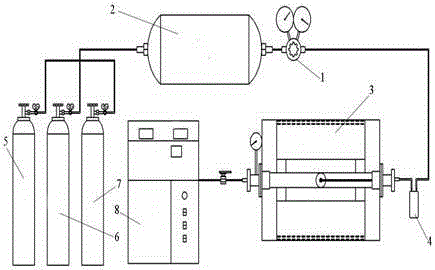

[0034] Pretreatment of TC4 titanium alloy samples before infiltration (arranging, cleaning and activation of samples, etc.), put the pretreated samples into the reactor tank, seal the reaction tank, check for leaks and exhaust air, and then pass the vacuum The system 8 is evacuated and the reactor is heated by means of a vacuum tube furnace 3 in the reactor tank.

[0035] The specific operation of the carbon-nitrogen compound infiltration is as follows: before the titanium alloy sample is put into the furnace, the argon (0.1MPa) in the high-purity argon tank 6 is used to exhaust it twice, and the first exhaust is used for leak detection. And exhaust the gas in the vacuum reaction tank, the second exhaust is used to ensure that the air in the high temperature reactor has been exhausted to prevent oxidation of the workpiece. After exhausting, start vacuuming and raise the temperature of the furnace to 900°C for 1 hour for degassing and...

Embodiment 2

[0037] Example 2: nitrogen + (acetylene + argon):

[0038] Perform pre-infiltration pretreatment on the TC4 titanium alloy sample (sample arrangement, cleaning and activation treatment, etc.), put the pretreated sample into the reactor tank, and seal the reactor tank, leak detection, and exhaust Finally, the vacuum is evacuated by the vacuum system 8, and the reaction tank is heated by the vacuum tube heating furnace 3 in the reactor tank.

[0039] The specific operation of the compound infiltration of carbon and nitrogen gas is: before the vacuum reactor is put into the furnace, it is exhausted twice with argon (0.1MPa) in the high-purity argon tank 6, and the first exhaust is used for leak detection and discharge. The air in the reaction tank, the second exhaust is mainly to ensure that the air in the high temperature reaction tank has been exhausted to prevent the oxidation of the workpiece. After exhausting, start vacuuming and raise the temperature of the furnace to 900°...

Embodiment 3

[0041] Example 3: (acetylene + argon) + (nitrogen + argon):

[0042] Pretreatment of TC4 titanium alloy samples before infiltration (arrangement, cleaning and activation of samples, etc.), put the pretreated samples into the reactor tank, seal the reaction tank, leak detection and exhaust, and then pass the vacuum The system 8 is evacuated, and the reaction tank is heated by the vacuum tube heating furnace 3 in the reactor tank.

[0043] The specific operation of the carbon-nitrogen compound infiltration is as follows: before the titanium alloy sample is put into the furnace, the argon (0.1MPa) in the high-purity argon tank 6 is used to exhaust it twice, and the first exhaust is used for leak detection. And exhaust the gas in the vacuum reaction tank, the second exhaust is used to ensure that the air in the high temperature reactor has been exhausted to prevent oxidation of the workpiece. After exhausting, start vacuuming and raise the temperature of the furnace to 900°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com