Method for reducing coating hydrogen embrittlement degree

A level, coating technology, applied in the field of electroplating, can solve problems such as hydrogen embrittlement, achieve the effects of improving production efficiency, preventing hydrogen embrittlement, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

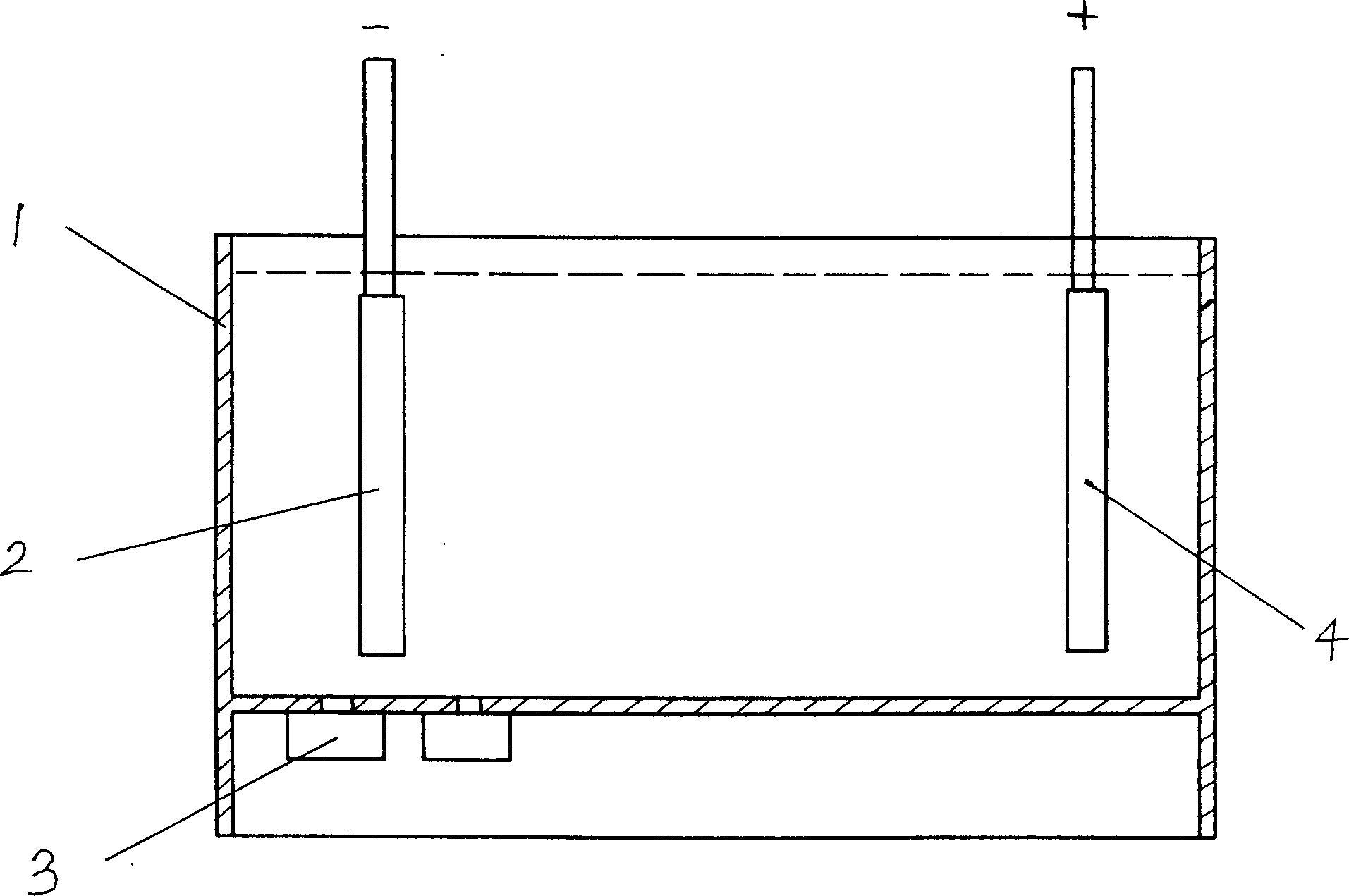

[0008] As shown in the figure, an ultrasonic generator 3 is arranged at the cathode end of the electroplating tank 1, that is, the end where the plated piece is located, and emits ultrasonic waves to the plated piece during the electroplating process. The ultrasonic frequency used in the embodiment is 45KHz, and the power intensity per square meter It is 300W.

[0009] During electroplating, the ultrasonic generator works, and the ultrasonic wave begins to bombard the surface of the plated piece. At this time, the plating solution also begins to roll along with the vibration. Due to the cavitation effect generated by the ultrasonic wave, the small molecule hydrogen generated on the surface of the bombarded plated piece is detached, and the plated piece The small molecular hydrogen on the surface is eliminated, which increases the density of the coating and enhances the bonding force. The overall reflection is that the brightness of the coating is improved, the shear strength is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com