Method for electroplating zinc in neodymium iron boron magnet ionic liquid

An ionic liquid, NdFeB technology, applied in the field of electrogalvanizing in NdFeB magnet ionic liquid, NdFeB magnet electrogalvanizing field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

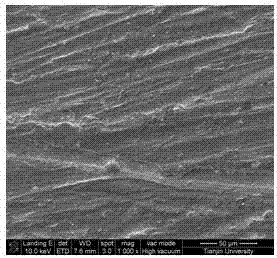

Image

Examples

Embodiment 1

[0041] Implement the method for electroplating zinc in a kind of neodymium-iron-boron magnet ionic liquid of the present invention, this method is to carry out according to the following processing steps:

[0042] (1) Pre-treatment of NdFeB plating: Baking and degreasing at 300°C in muffle furnace for 2 hours; sealing with zinc stearate at 140°C for 30 minutes; ultrasonic degreasing in 30g / L room temperature degreaser solution for 10 minutes; 30g / L Nitric acid, 1.0g / L thiourea, acid cleaning at room temperature for 60s; 25g / L alkyl salicylic acid, 10g / L ammonium bifluoride, activation at room temperature for 30s; ultrasonic washing; 35g / L zinc sulfate, 120g / L sodium pyrophosphate , 8g / L hydrofluoric acid, 8 / L sodium carbonate, zinc dipping at 80°C for 30s.

[0043] (2) Synthesis of ionic liquid: Weigh a certain amount of urea, sodium iodide, and potassium iodide in a molar ratio of 79%: 19.5%: 1.5%, respectively, mix them in a dry beaker and seal them, and place them in a vacu...

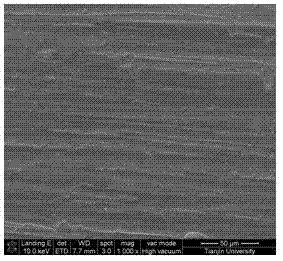

Embodiment 2

[0048] On the basis of the electrogalvanizing method of a neodymium iron boron ionic liquid based on the above-mentioned embodiment 1, the method of example 2 adopts the pulse electroplating power supply to implement electrogalvanizing.

[0049] The thickness of the galvanized layer obtained by this method is 18 μm. The coating is obviously brighter than Example 1 before the light is emitted, almost mirror bright. After passivation, the coating is iridescent, and the bonding strength meets the first-class standard. The neutral salt spray test does not appear after 48 hours. rust.

Embodiment 3

[0051] Implement the method for electrogalvanizing in a kind of neodymium-iron-boron magnet ionic liquid of the present invention, the concrete process step of this method is as follows:

[0052] (1) Pre-treatment of NdFeB plating: Baking and degreasing at 250°C in muffle furnace for 2.5 hours; sealing with zinc stearate at 130°C for 25 minutes; ultrasonic degreasing in 25g / L room temperature degreaser solution for 10min; 25g / L Nitric acid, 0.8g / L thiourea, acid cleaning at room temperature for 40s; 20g / L alkyl salicylic acid, 10g / L ammonium bifluoride, activation at room temperature for 30s; ultrasonic washing; 30g / L zinc sulfate, 100g / L sodium pyrophosphate , 10g / L hydrofluoric acid, 10 / L sodium carbonate, zinc dipping at 70°C for 30s.

[0053] (2) Synthesis of ionic liquids: Weigh a certain amount of urea, sodium bromide, and potassium bromide in a molar ratio of 80%: 18%: 2%, respectively, and disperse them in a dry beaker, seal them, and place them in a vacuum oven at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com