Patents

Literature

138 results about "Pulse electroplating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

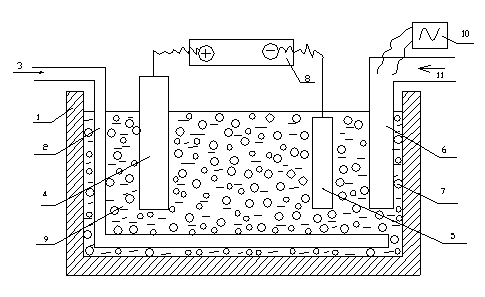

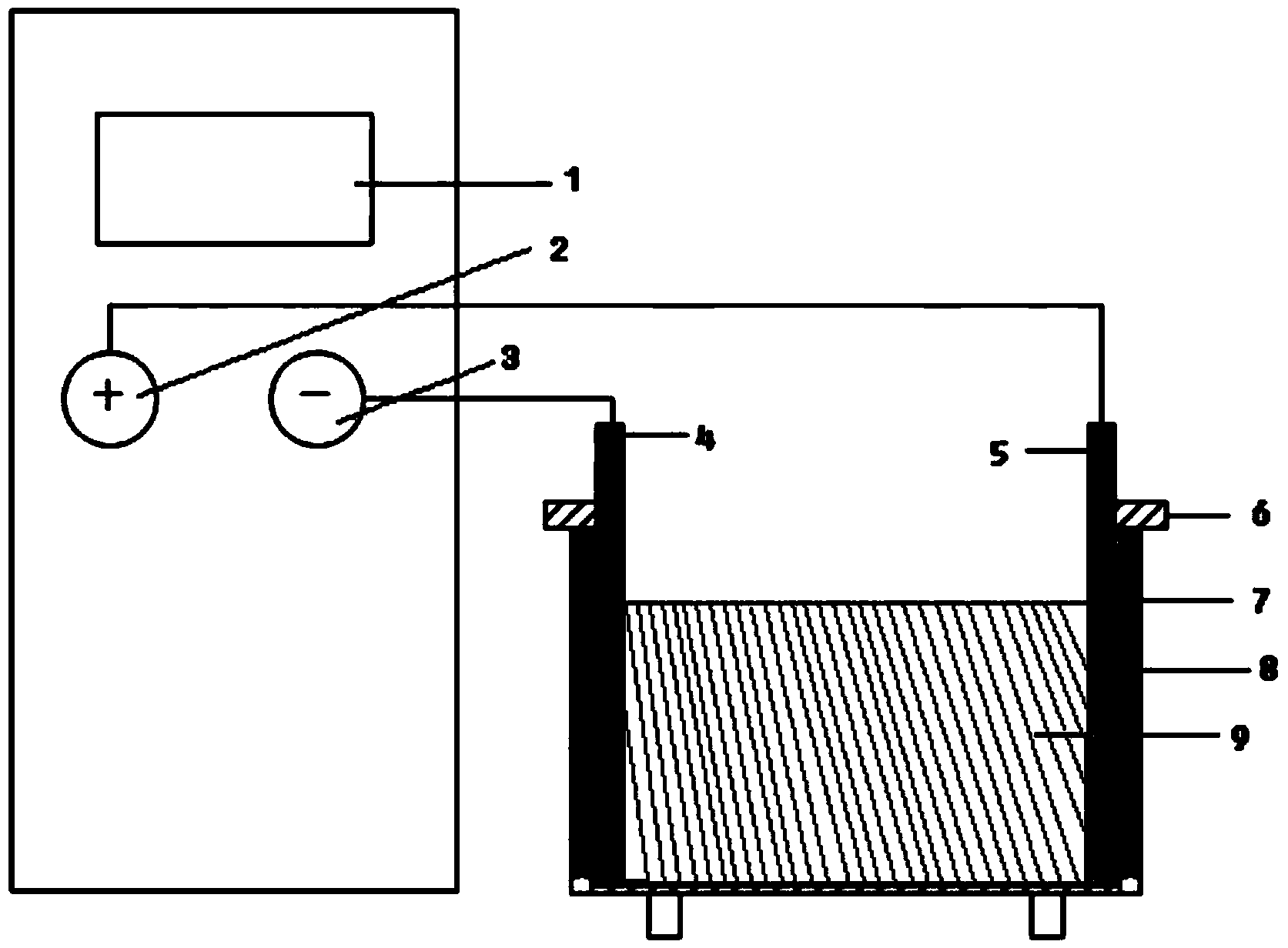

Wearable compound layer material for machine parts and manufacturing method and equipment thereof

The invention relates to a wearable compound layer material for machine parts and a manufacturing method and equipment thereof. The wearable compound layer material is a metal-based wearable compound layer material which is composed of a matrix metal and lots of particles or fibers dispersed and distributed in the matrix metal, thereby having a multi-phase structure. The wearable compound layer material is manufactured by a direct-current electroplating or pulse electroplating method. The direct-current electroplating or pulse electroplating equipment is composed of parts such as an electroplating power source, an electroplating tank, a metal anode or a metal alloy anode, a machine part substrate cathode, a stirring device, a solution circulating device, a heating and temperature control device, an additive supplementing device and the like. The wearable compound layer material for machine parts provided by the invention is obviously superior in performance to good-quality cast iron wearable parts, good-quality cast steel wearable parts and wearable parts for surface heat treatment of common steel and good-quality steel commonly employed in the present product. The wearable compound layer also has high-temperature abrasive resistance and excellent corrosion resistance while having excellent abrasive performance; and the internal stress of the coating is very low.

Owner:肖云捷

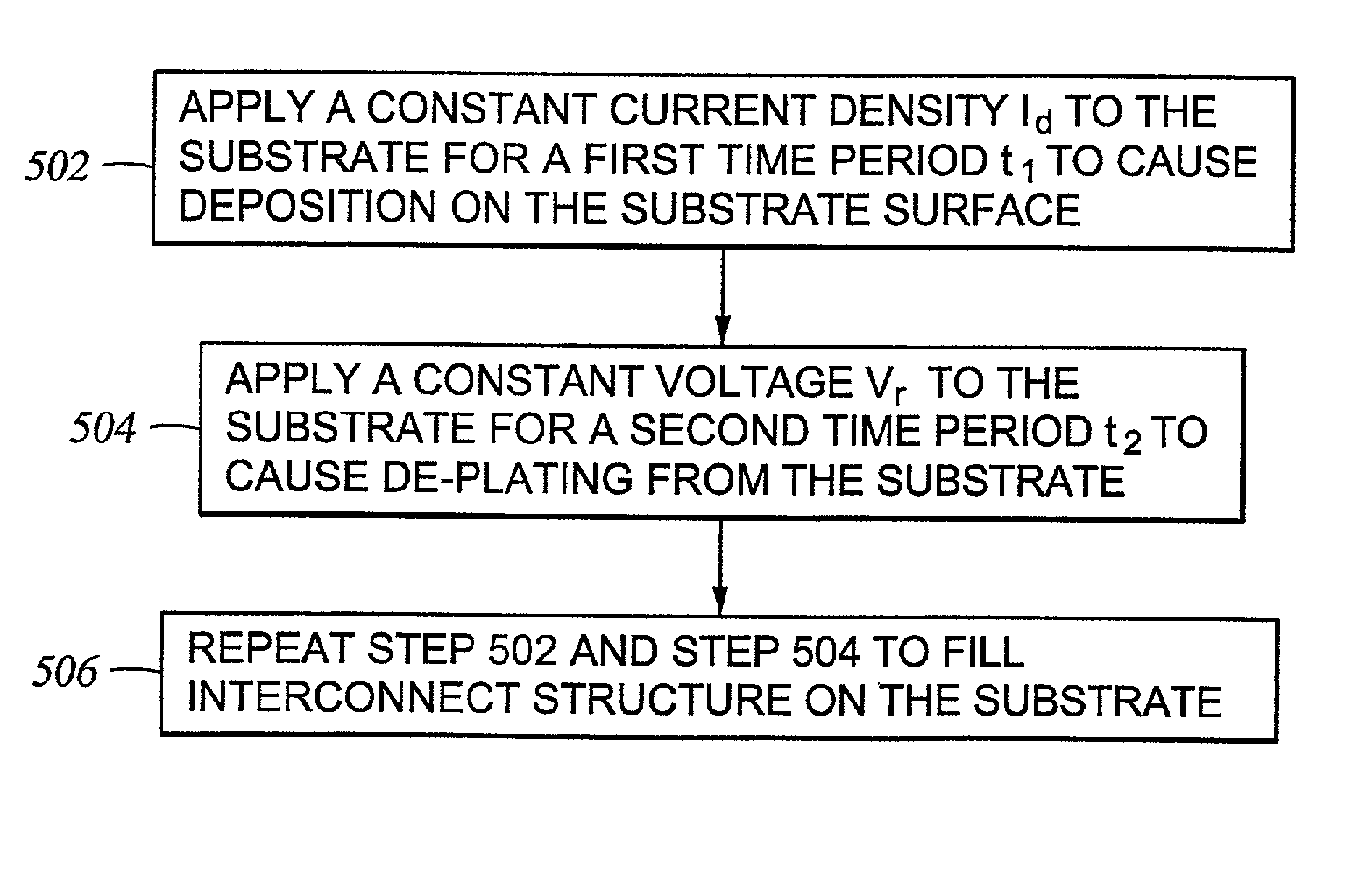

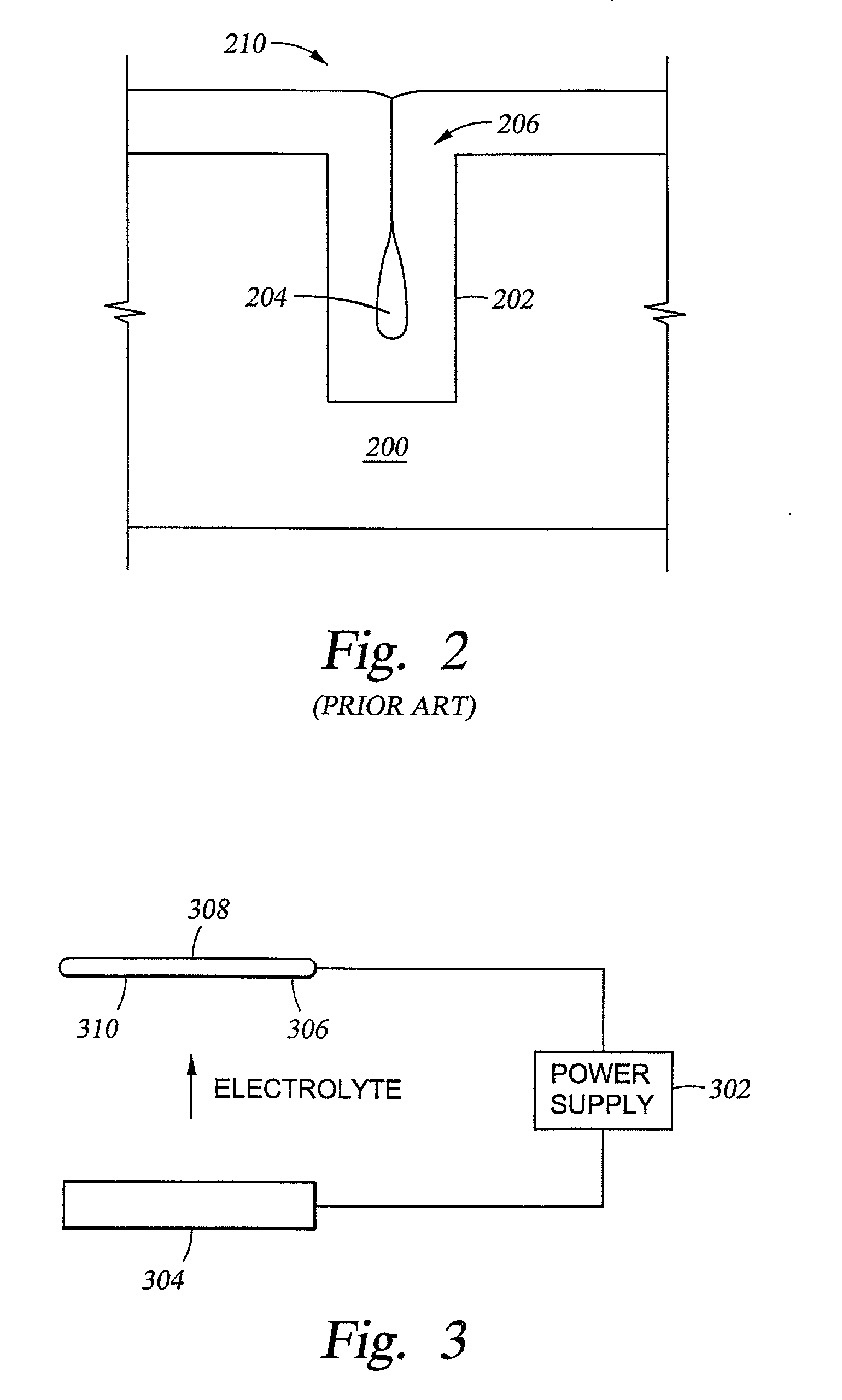

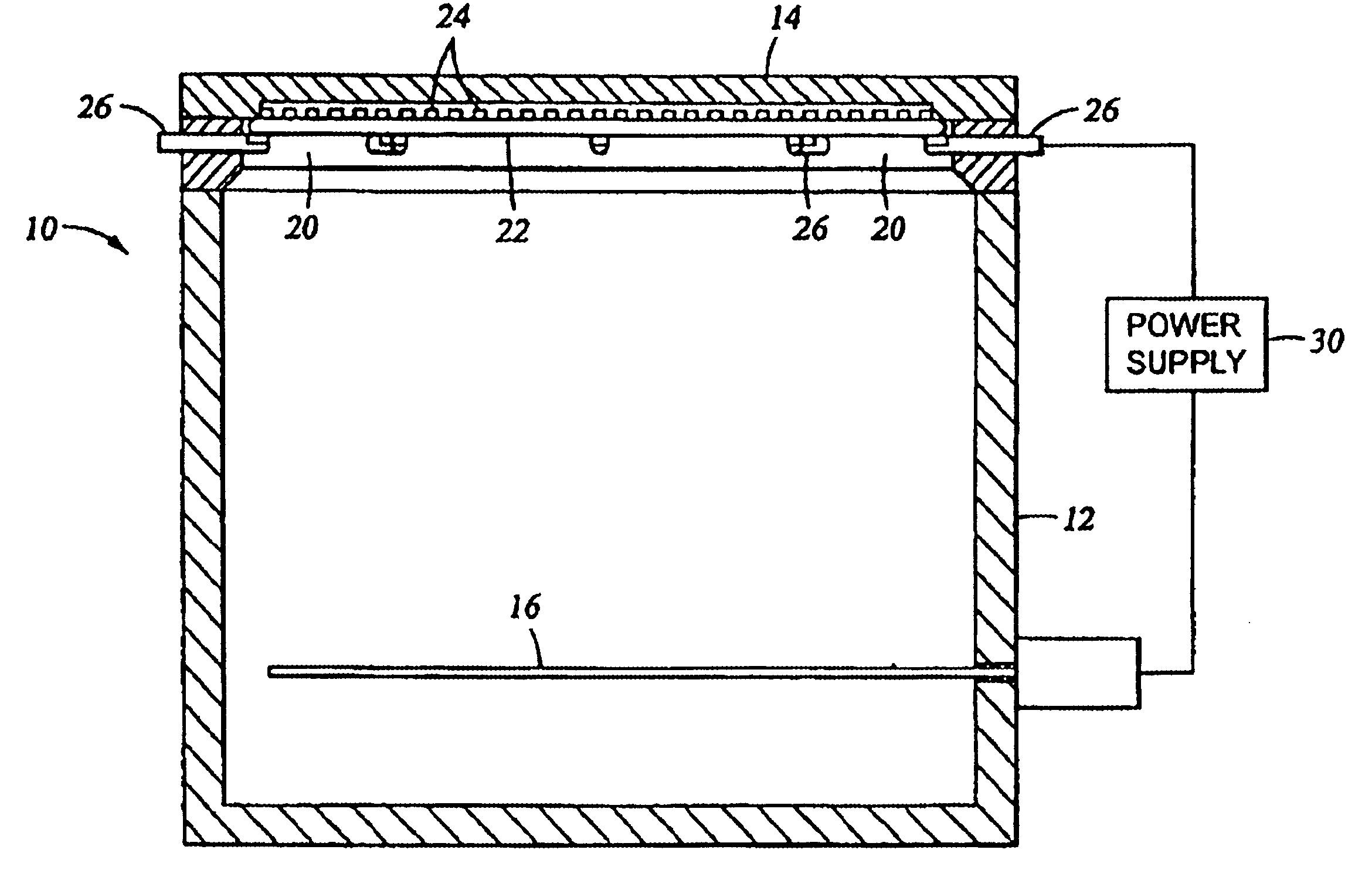

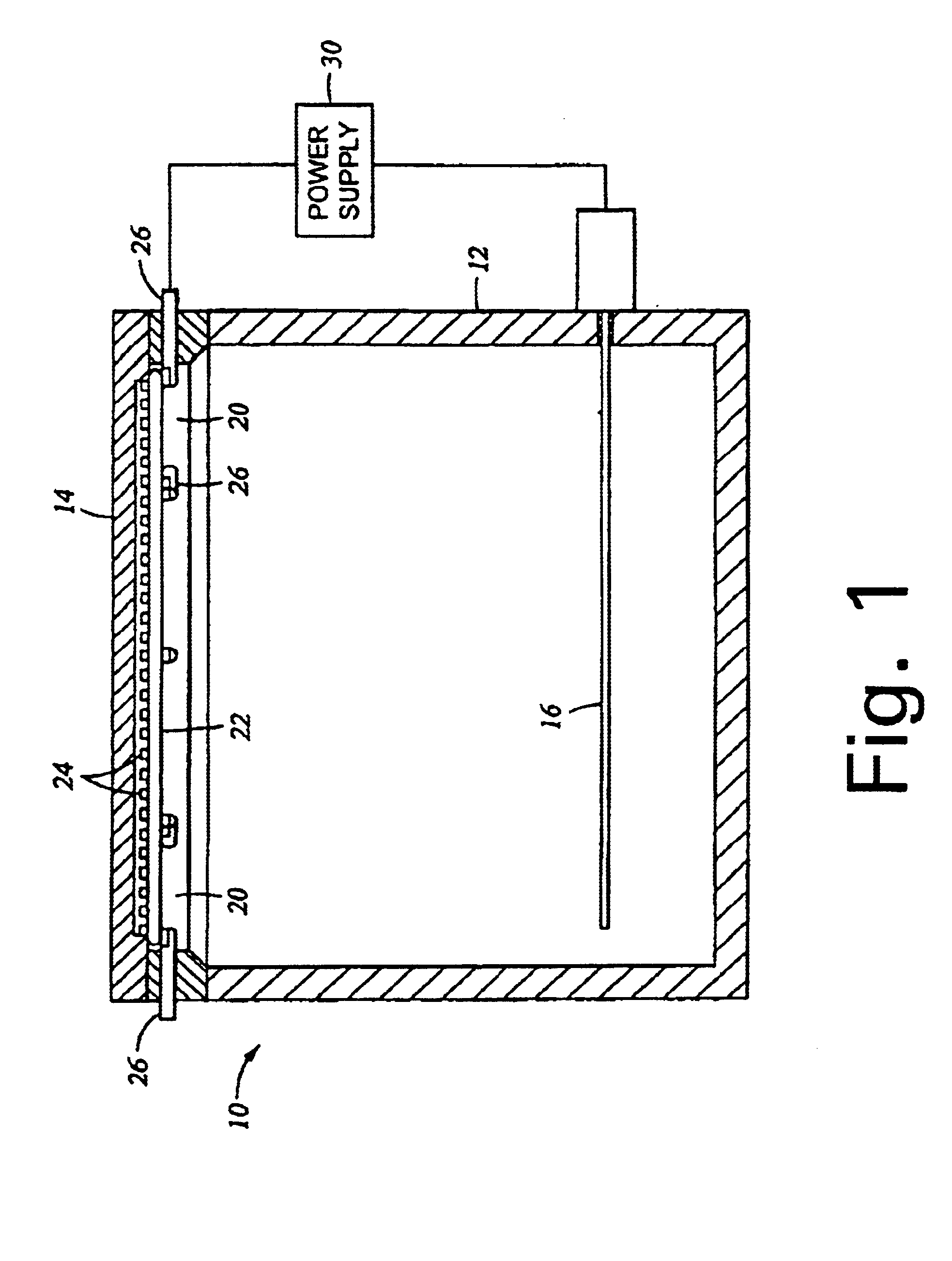

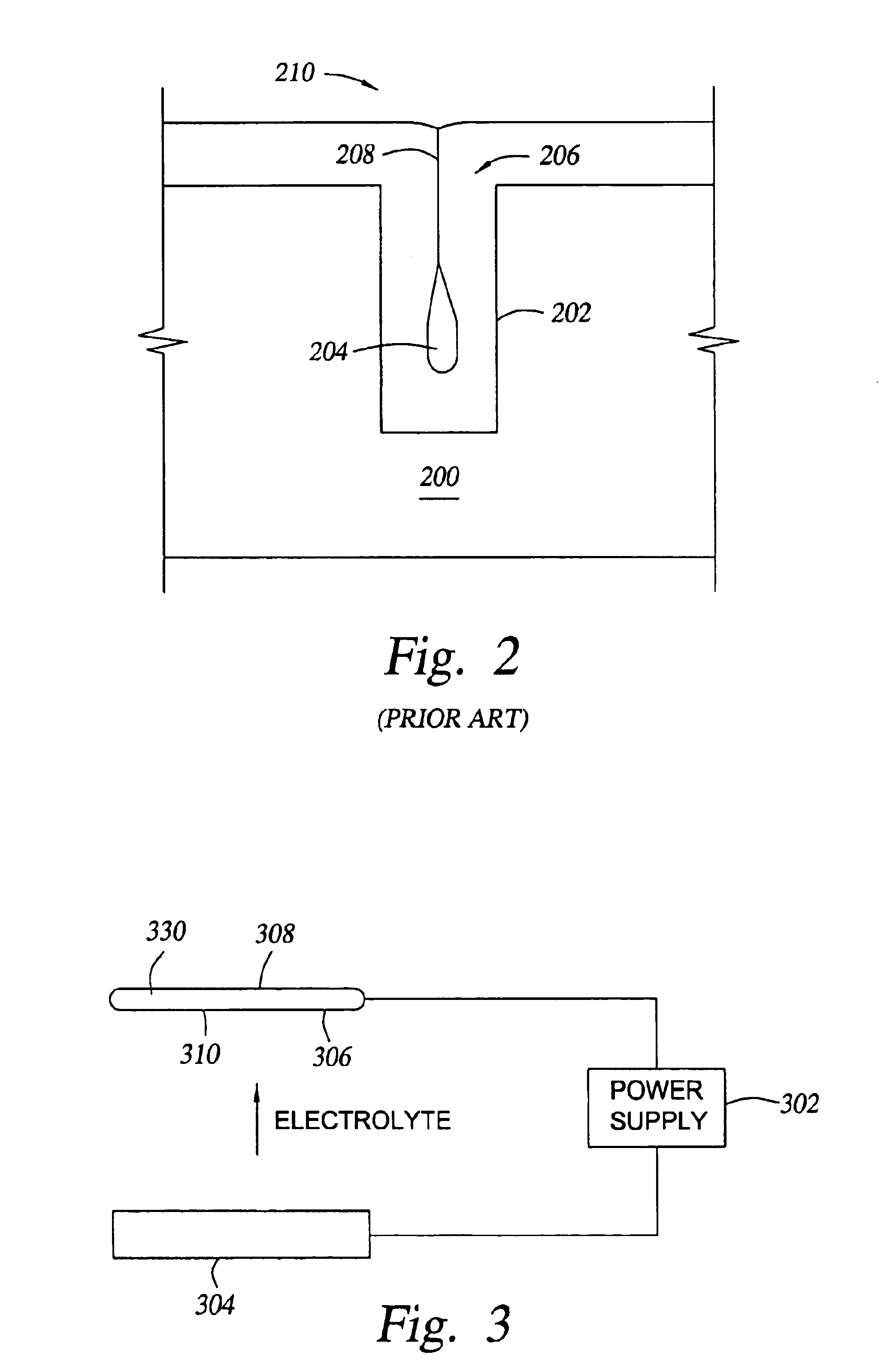

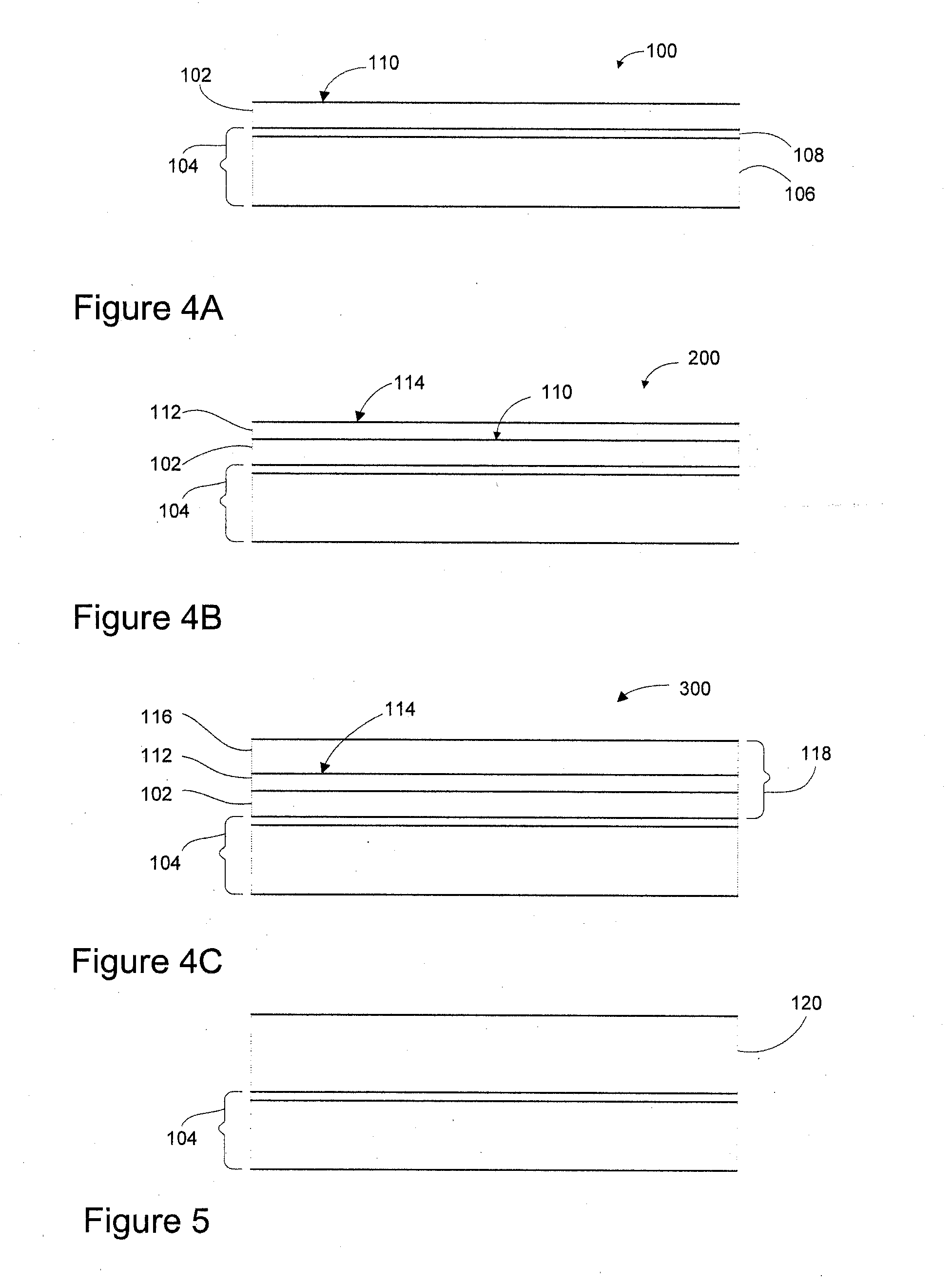

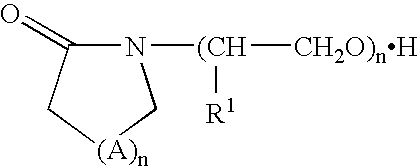

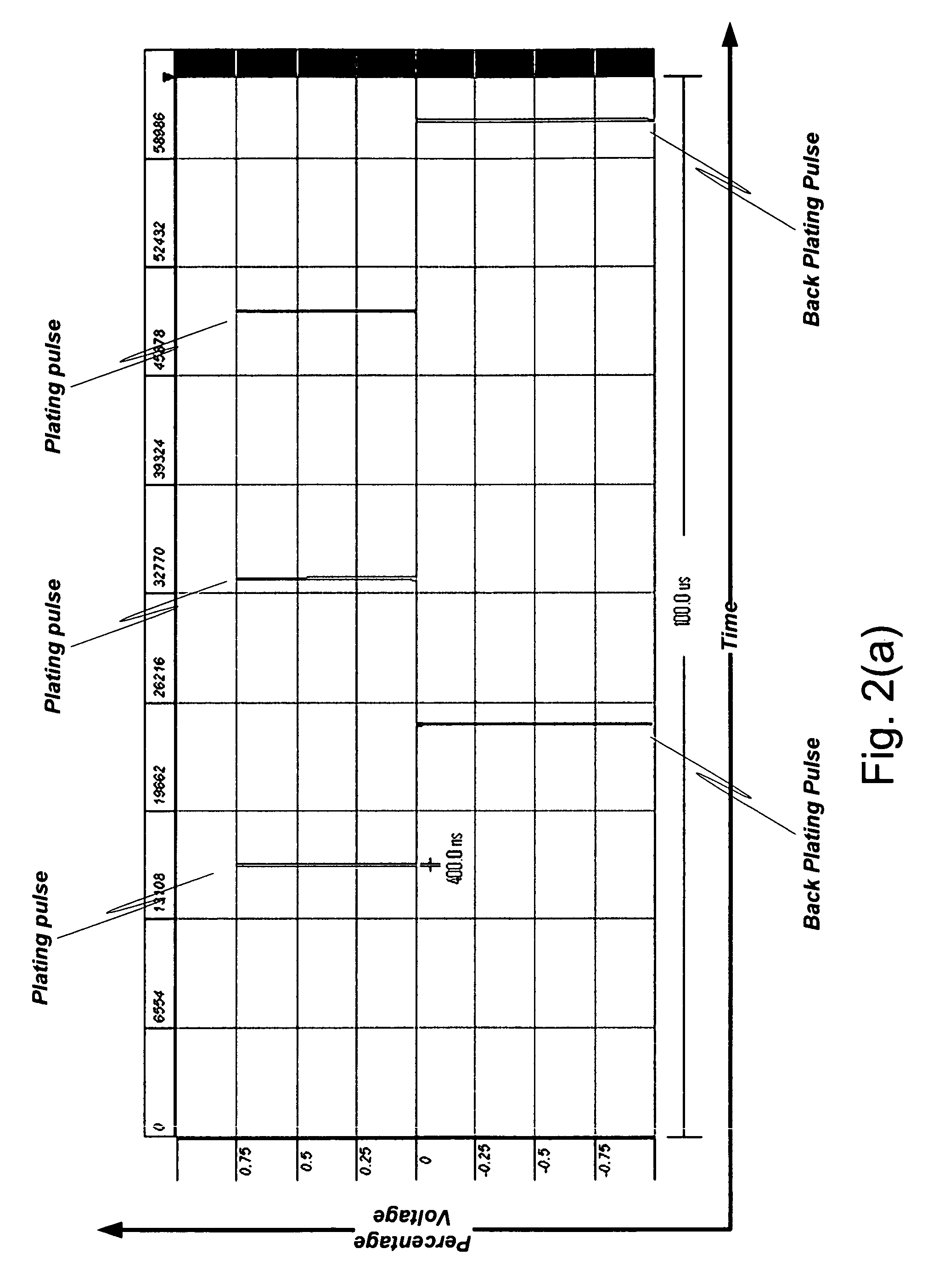

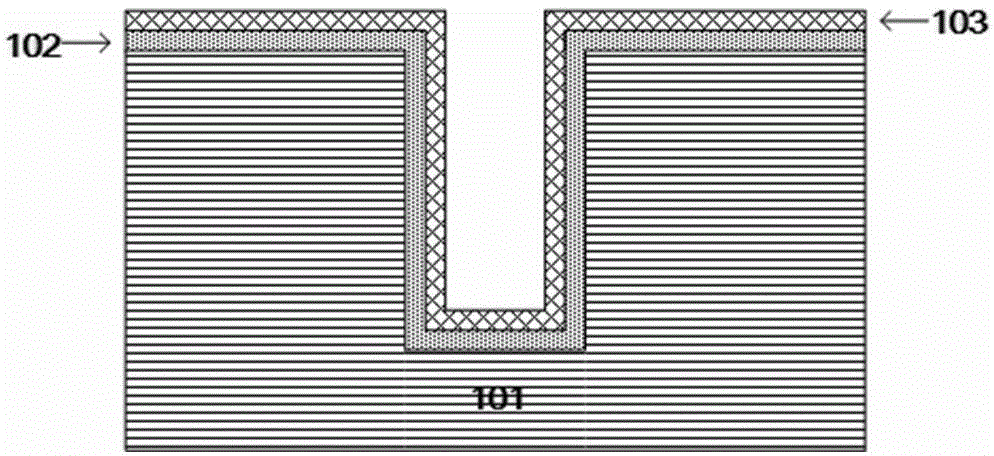

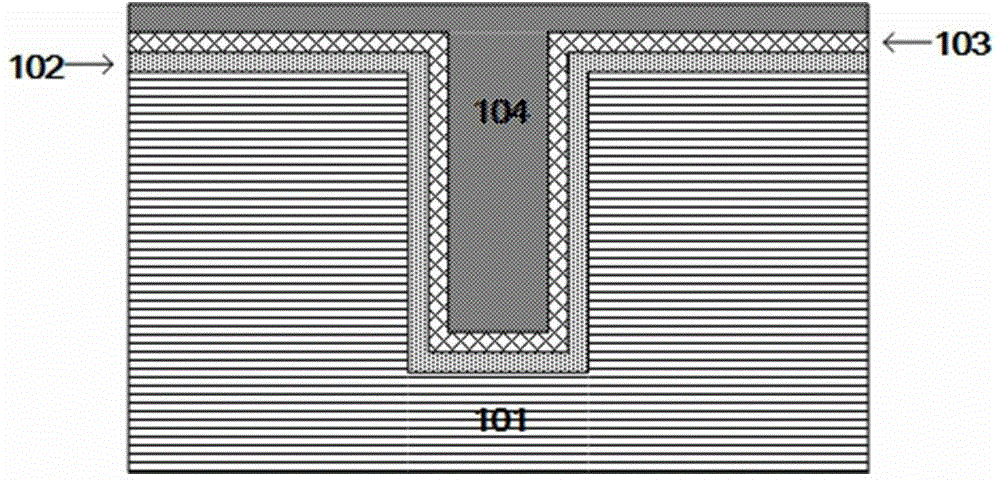

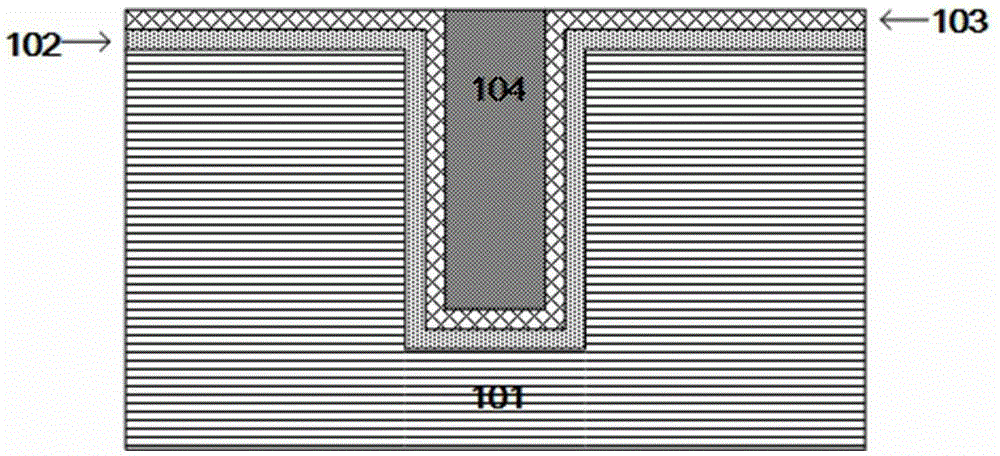

Dynamic pulse plating for high aspect ratio features

A method for depositing a metal on a substrate is provided. The metal is deposited by sequentially applying a electrodeposition pulse followed by an electrodissolution pulse to the substrate. After each electrodissolution pulse an before the next electrodeposition pulse there is provided at least one time interval of zero electrical voltage or current, also known as an "off-time", between the pulses. The first two electrodeposition pulses should preferably have the same time durations. Thereafter, the time durations of subsequent electrodeposition pulses are gradually decreased to provide a void-free and seam-free deposition of metal in high aspect ratio features.

Owner:APPLIED MATERIALS INC

Dynamic pulse plating for high aspect ratio features

A method for depositing a metal on a substrate is provided. The metal is deposited by sequentially applying a electrodeposition pulse followed by an electrodissolution pulse to the substrate. After each electrodissolution pulse an before the next electrodeposition pulse there is provided at least one time interval of zero electrical voltage or current, also known as an “off-time”, between the pulses. The first two electrodeposition pulses should preferably have the same time durations. Thereafter, the time durations of subsequent electrodeposition pulses are gradually decreased to provide a void-free and seam-free deposition of metal in high aspect ratio features.

Owner:APPLIED MATERIALS INC

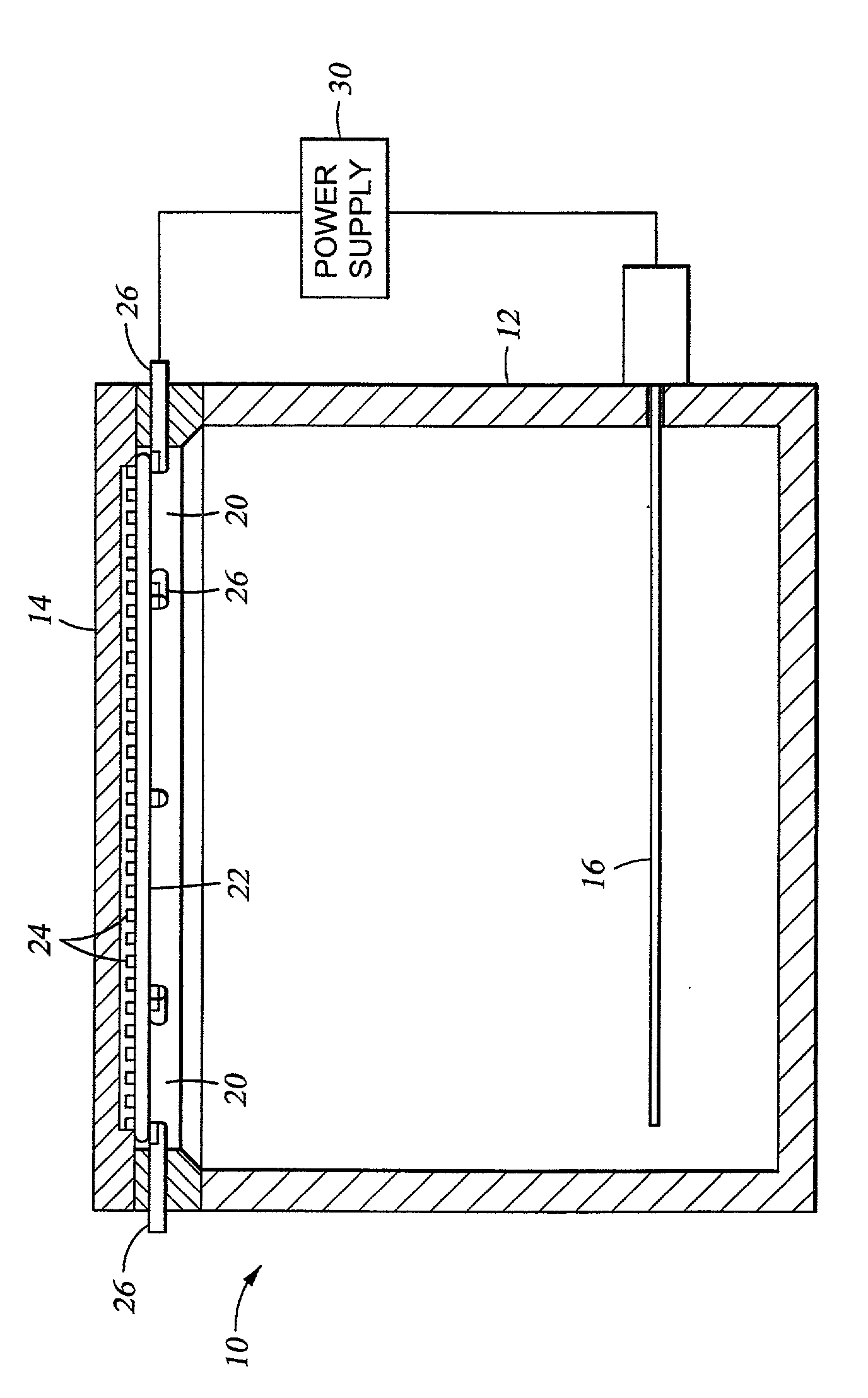

Reverse pulse plating composition and method

A composition and method for electroplating a metal on a substrate. The composition has a chloride to brightener concentration ratio of from 20:1 to 125:1. The method of electroplating, which employs the composition, employs pulse patterns that improve physical properties of metal surfaces.

Owner:SHIPLEY CO LLC

Electroplating Solutions and Methods For Deposition of Group IIIA-VIA Films

InactiveUS20130112564A1Final product manufactureSemiconductor/solid-state device manufacturingPulse electroplatingInorganic chemistry

Owner:SOLOPOWER

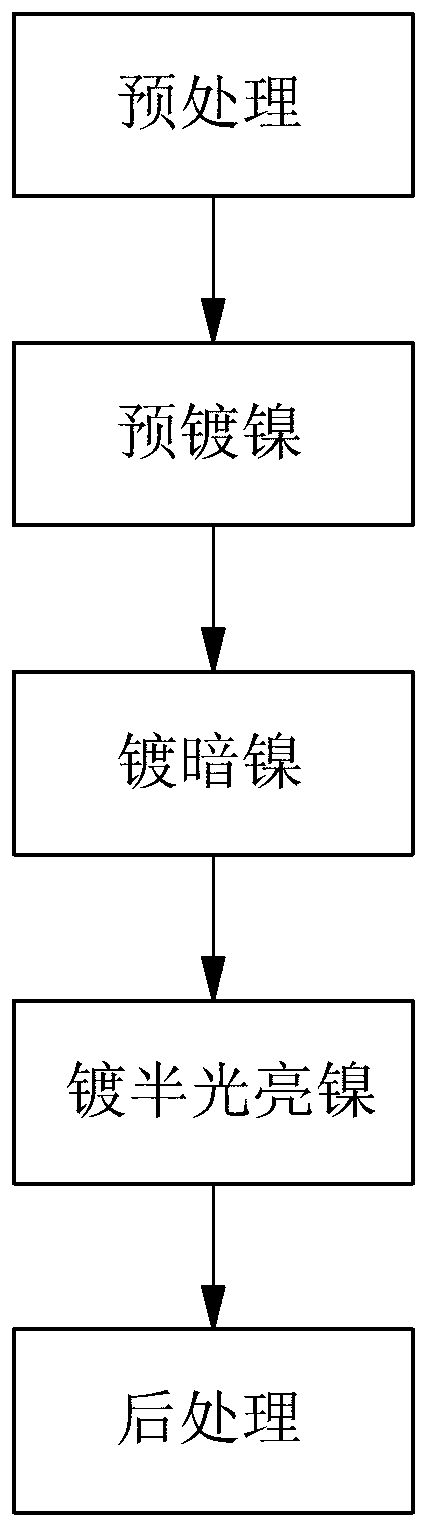

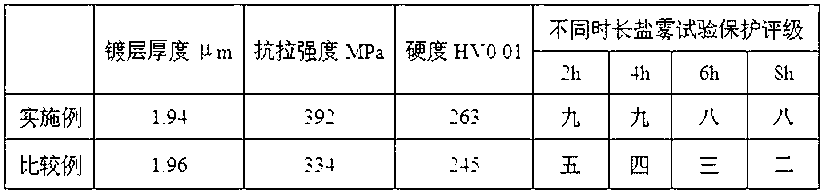

Nickel-plated steel strip and preparation method thereof

InactiveCN103343367AImprove bindingImprove corrosion resistanceMetal layered productsPulse electroplatingNickel binding

The invention relates to a nickel-plated steel strip and a preparation method thereof. The nickel-plated steel strip comprises a steel base strip, wherein a first iron-nickel binding layer, a dark nickel layer and a semi-bright nickel layer are orderly electroplated at two sides of the steel base strip from inside to outside; an electroplating process of the iron-nickel binding layer and the semi-bright nickel layer is a pulse electroplating process; the electroplating process of the dark nickel layer is a direct-current electroplating process. The preparation method comprises the following steps: pretreatment; electroplating, namely electroplating a layer of ultra-thin nickel-plated layer at the outer surface of the steel base strip which is preprocessed by the pulse electroplating process as the iron-nickel binding layer, electroplating a layer of dark nickel layer at the outer surface of the ultra-thin nickel-plated layer by adopting the direct-current electroplating process, and electroplating a layer of semi-bright nickel layer at the outer surface of the dark nickel layer by using the pulse electroplating process; post-treatment, namely cleaning and drying the electroplated nickel-plated steel strip, and finally carrying out thermal treatment. Three layers of different clad layers are formed at the surface of the steel base strip by the electroplating process, so that the binding force of the coating and the steel base strip is enhanced; the performances such as corrosion resistance, soldering resistance and the like are obviously improved.

Owner:深圳市中金高能电池材料有限公司

Method for plating copper on stainless steel

The invention discloses a method for plating copper on a decorative stainless steel plate. The method comprises the following steps of: carrying out chemical oil removal on a stainless steel material and then putting the stainless steel material into a pre-plating solution containing iron, nickel and chromium cations to carry out pulse electroplating to obtain a grey iron-nickel-chromium compound film witch a certain thickness; and finally, enabling the grey iron-nickel-chromium compound film to enter an acidic copper sulfate solution to carry out direct-current copper electroplating. Compared with a conventional stainless steel electroplating method, the method provided by the invention has the advantages that steps of etching, removing hung ash, electrolyzing and activating, pre-plating the nickel and the like are reduced; industrial flows are obviously reduced and seem to be simple; the production efficiency is improved and the industrial production cost is reduced; meanwhile, a lot of strong acids are not needed so that an industrial operation environment is obviously improved and the environmental pollution is reduced; and an oxidized film on the surface of stainless steel does not need to be etched in advance in the process disclosed by the invention so that the method has the very great adaptability to the stainless steel materials with different chemical components.

Owner:红木枋家居科技(湖州)有限公司

Cyanide-free alkaline copper plating method for improving impermeable carbon copper film

The invention relates to a cyanide-free alkaline copper plating method for improving an impermeable carbon copper film, relates to a copper plating method for improving the performance of an impermeable carbon copper film, and aims at solving the problems that negative electrode deoiling alone causes hydrogen brittleness and impurity precipitation and positive electrode deoiling alone results in easy dissolution of parts. The method comprises steps of firstly, removing oil stain and dirt on the surface of a workpiece through an electrochemical method; secondly, activating the surface of the workpiece; thirdly, washing and drying; fourthly, carrying out pulse electroplating in a coating bath with an external overlaying magnetic field; fifthly, washing and passivating. Due to the introduction of the pulse electro-deposition and the overlaying magnetic field, the bonding strength of a plating layer and a substrate is improved, the temperature of plating solution is lowered, the heating cost for electroplating is saved, the problem that citrate is easy to mould because the traditional copper plating method by using citrate is carried out at high temperature is solved, and the method can substitutes for the technology of cyaniding copper plating in impermeable carbon copper plating. According to the method, the bonding strength of the plating layer and the substrate is improved, the temperature of the plating solution is lowered, and the heating cost for electroplating is saved.

Owner:哈尔滨云水工大环保科技股份有限公司

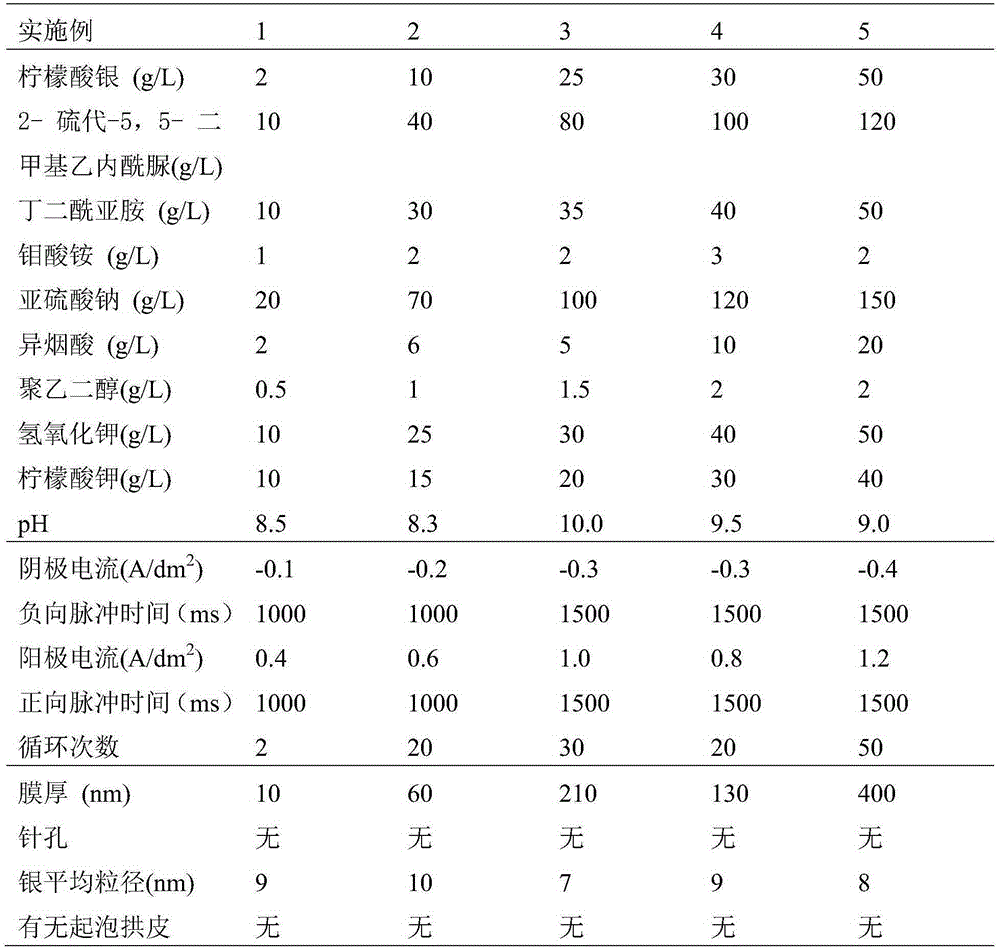

Electroplating liquid for pulse electroplating for compact silver film on ceramic surface and electroplating method thereof

InactiveCN105316716AUniform brightnessUniform film thicknessHydantoin derivativesPolyethylene glycol

The invention discloses an electroplating liquid for pulse electroplating for a compact silver film on a ceramic surface and an electroplating method thereof. The electroplating liquid comprises 2-50g / L of silver citrate, 10-120g / L of 2-sulpho-5,5-dimethyl hydantoin, 10-50g / L of succinimide, 10-50g / L of potassium hydroxide, 10-40g / L of potassium citrate, 1-3g / L of ammonium molybdate, 0.5-2g / L of polyethylene glycol, 20-150g / L of sodium sulphite, and 5-20g / L of isonicotinic acid, wherein the pH value of the electroplating liquid is adjusted to 8-10 by virtue of potassium hydroxide, and the temperature of the electroplating liquid is kept at 25-45 DEG C; and the ceramic pre-plated metal layer surface is electroplated by a square-wave pulse current method, and a layer of compact silver film can be electrodeposited. The electroplating liquid is high in stability; and the plating layers obtained by the pulse electroplating method are smooth and compact, uniform in brightness, and high in performance of binding with a ceramic matrix.

Owner:苏州市金星工艺镀饰有限公司

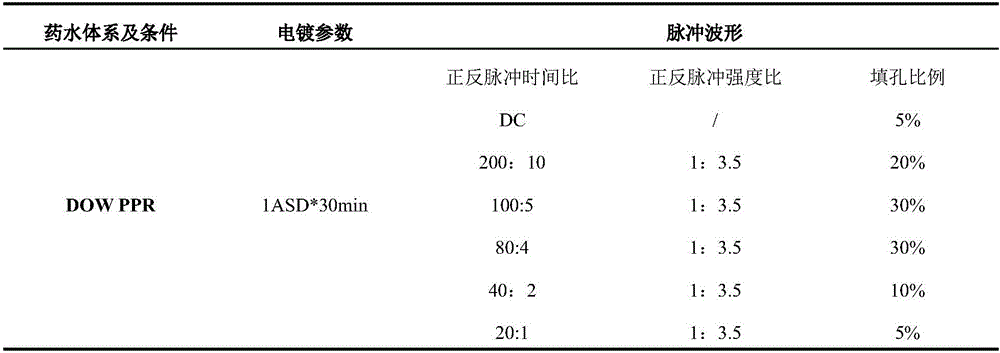

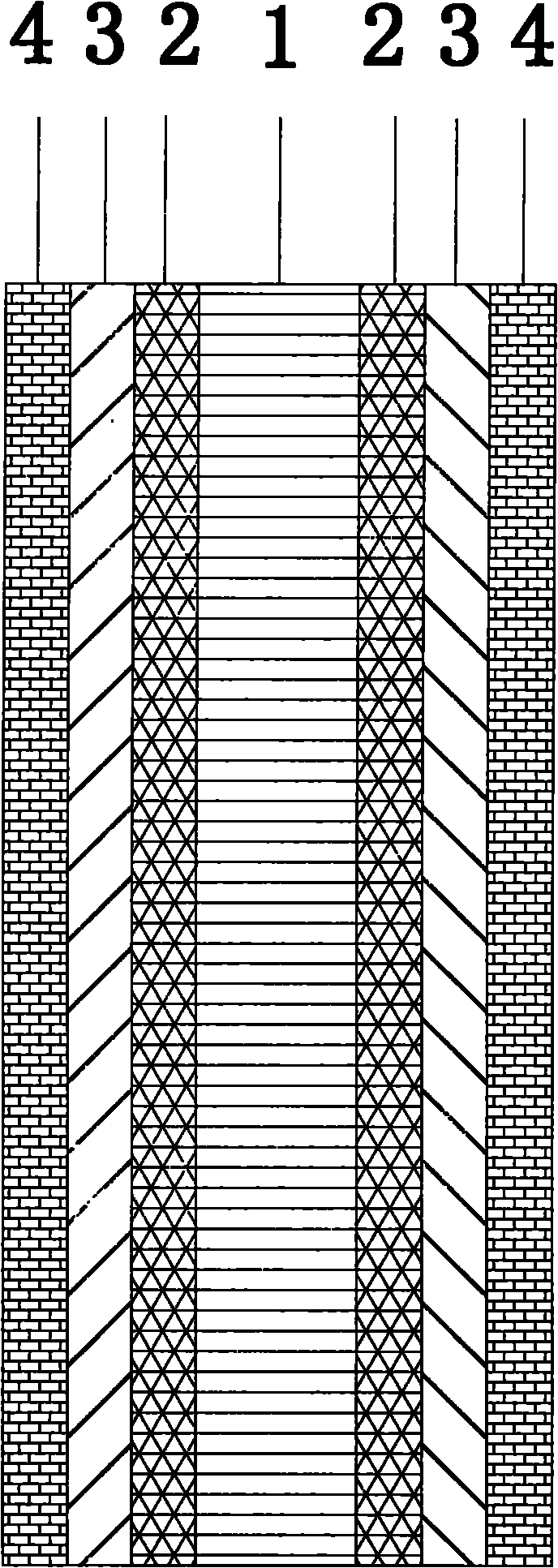

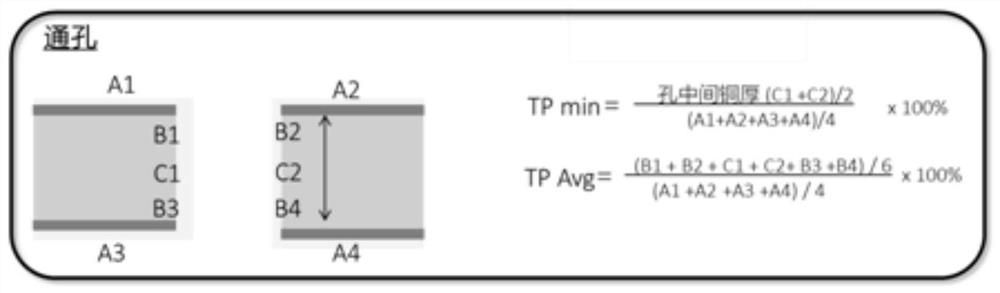

Through hole filling method by electroplating

InactiveCN106793571ACrystallizationImprove bindingPrinted circuit aspectsPrinted element electric connection formationPulse electroplatingEngineering

The invention provides a through hole filling method by electroplating. Pulse electroplating is carried out on a printed circuit board in which a through hole is formed regularly, a coating is fine in crystallization, high in a bonding force and voidless via the electroplating manner, the electroplated through hole is internally enclosed by electroplating copper, and is free of bubble or hole, the two ends of the electroplated through hole are molded into two blind holes whose thickness to radius ratio is lower than 1 respectively, and the blind holes are flattened in a routing electroplating hole filling method. The hole filling method can be used to solve the problem that the user requirement cannot be met due to the fact that cavities tend to form in the hole and an aperture recess is formed finally in a routine hole filling technology; and the hole filling method is simple in technical process, low in production cost and conducive to batch industrial production.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

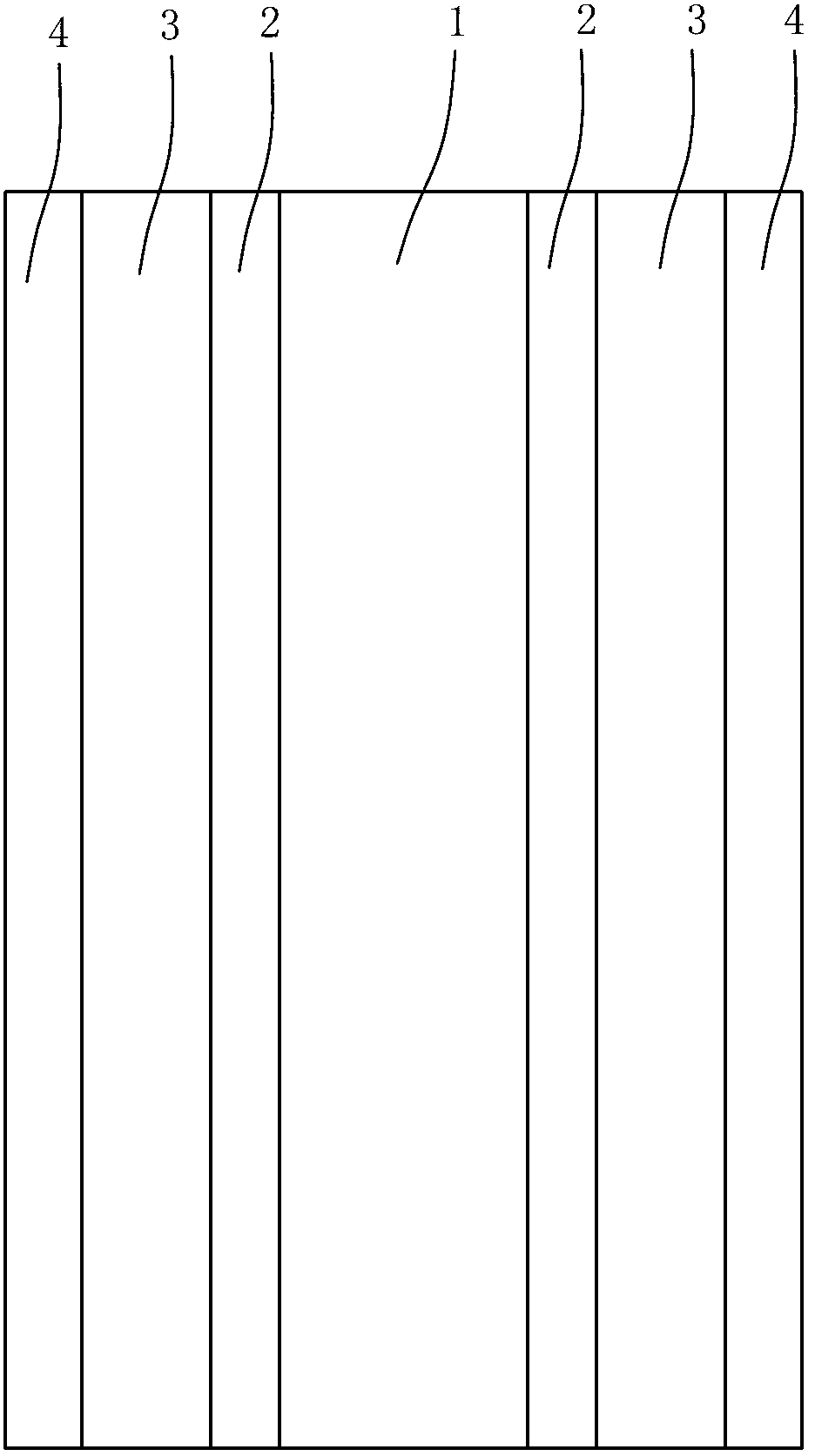

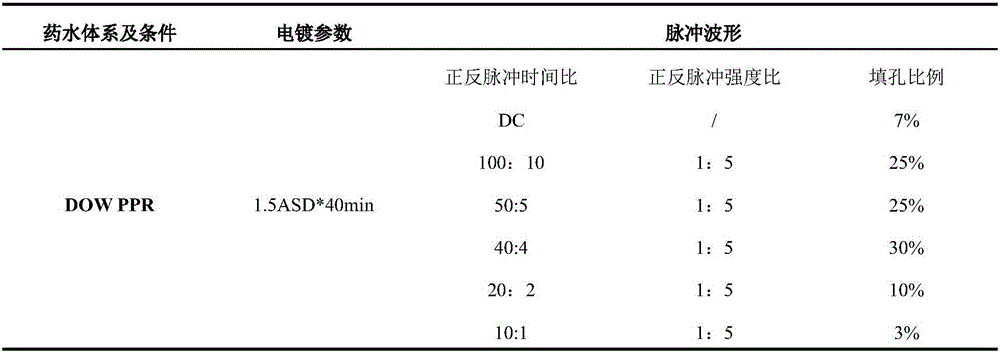

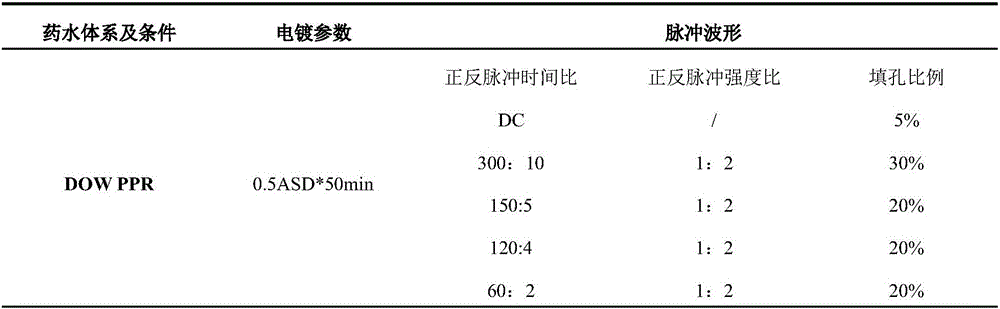

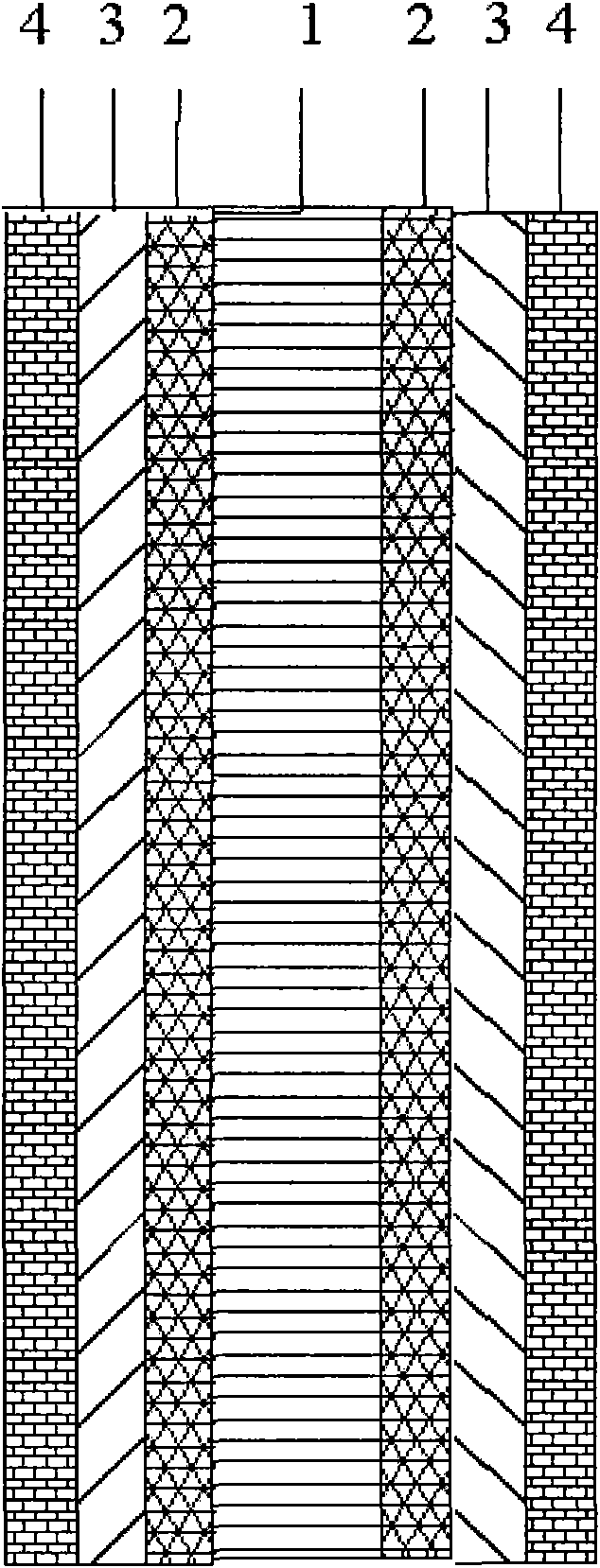

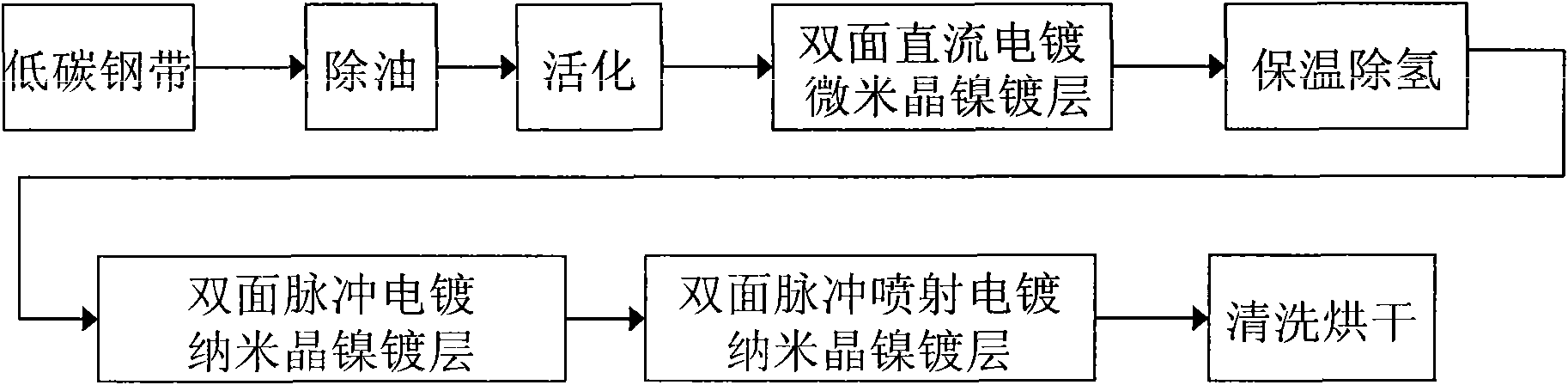

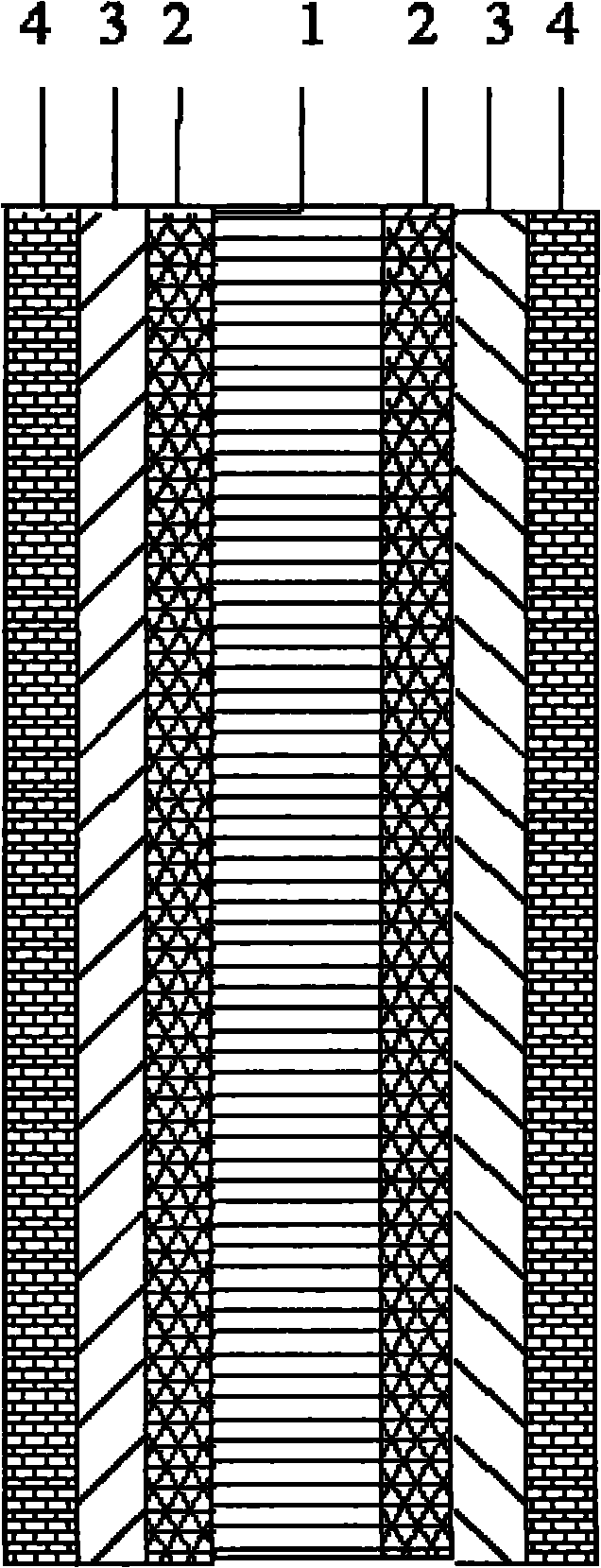

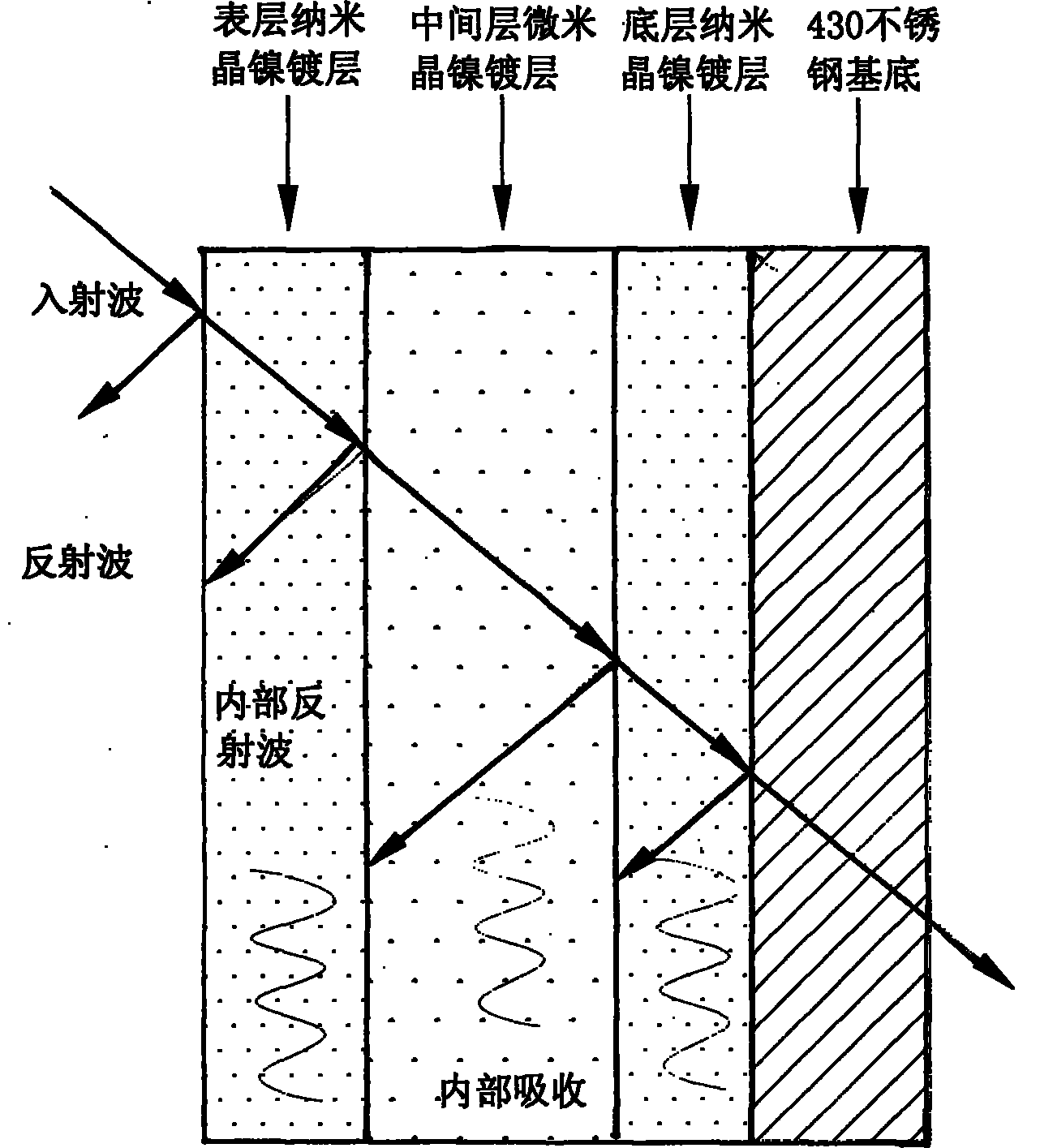

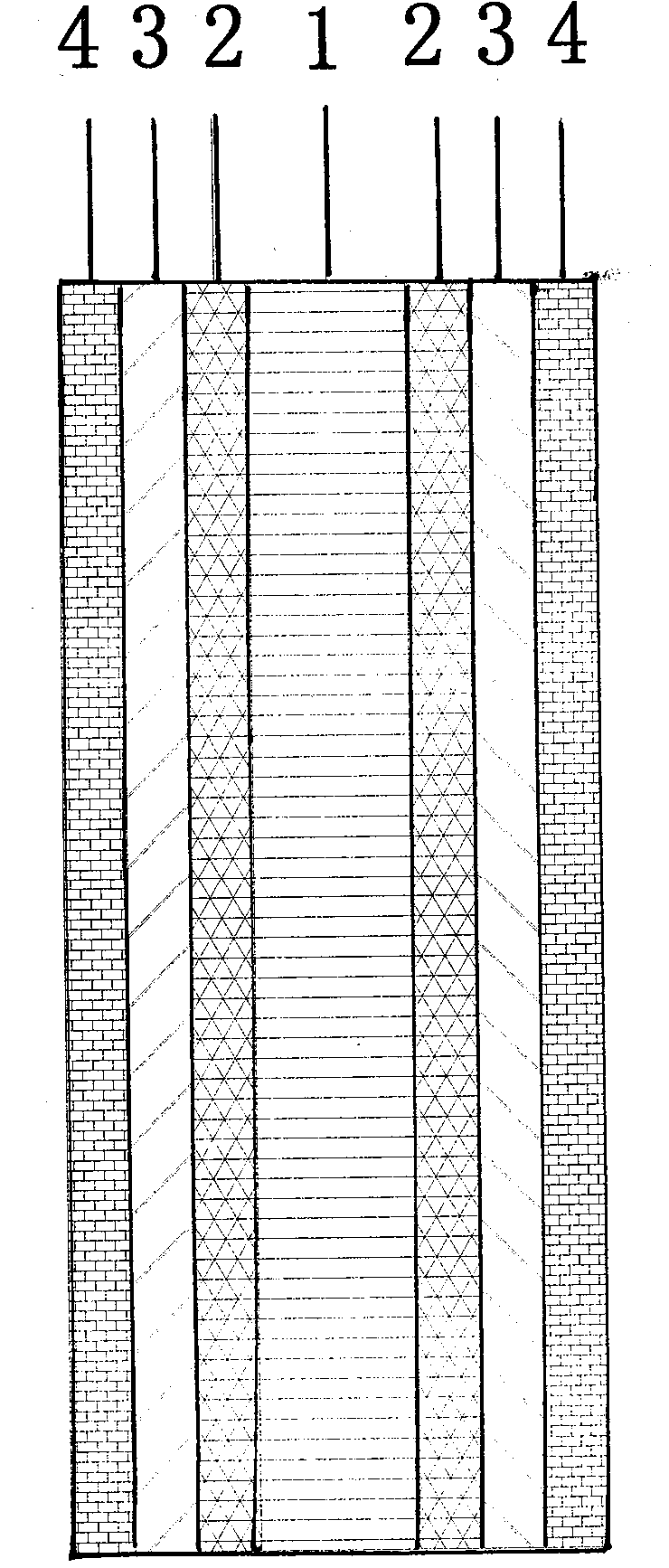

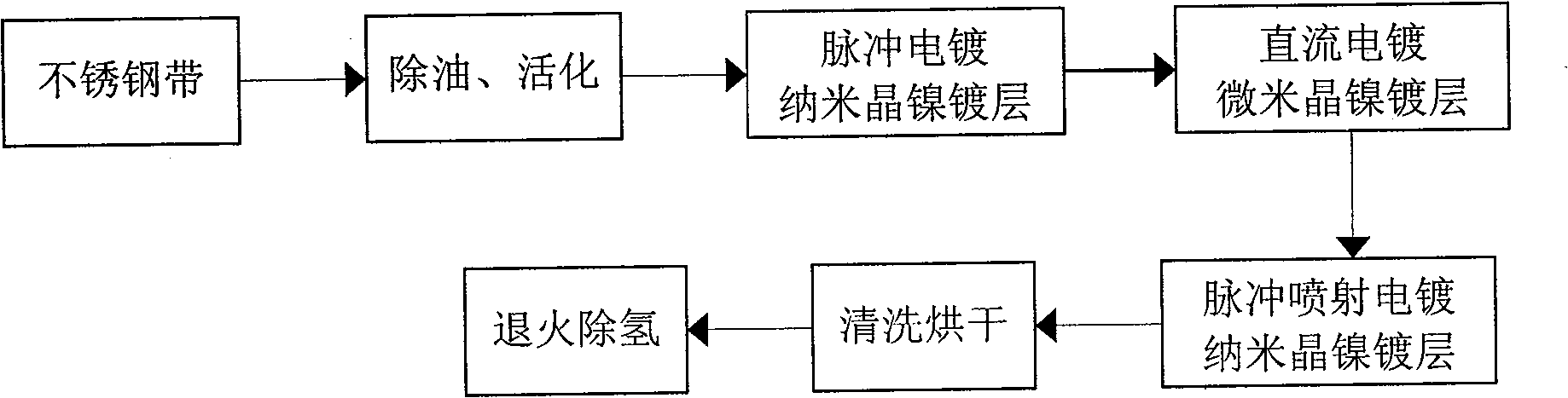

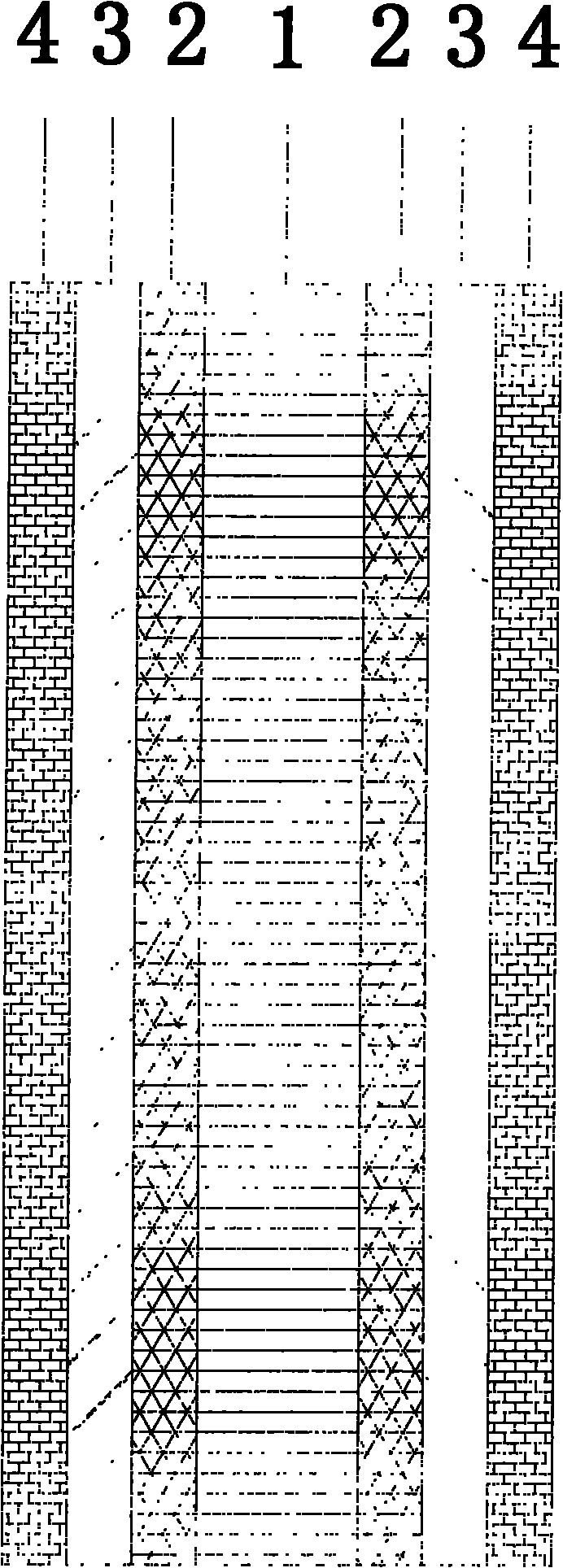

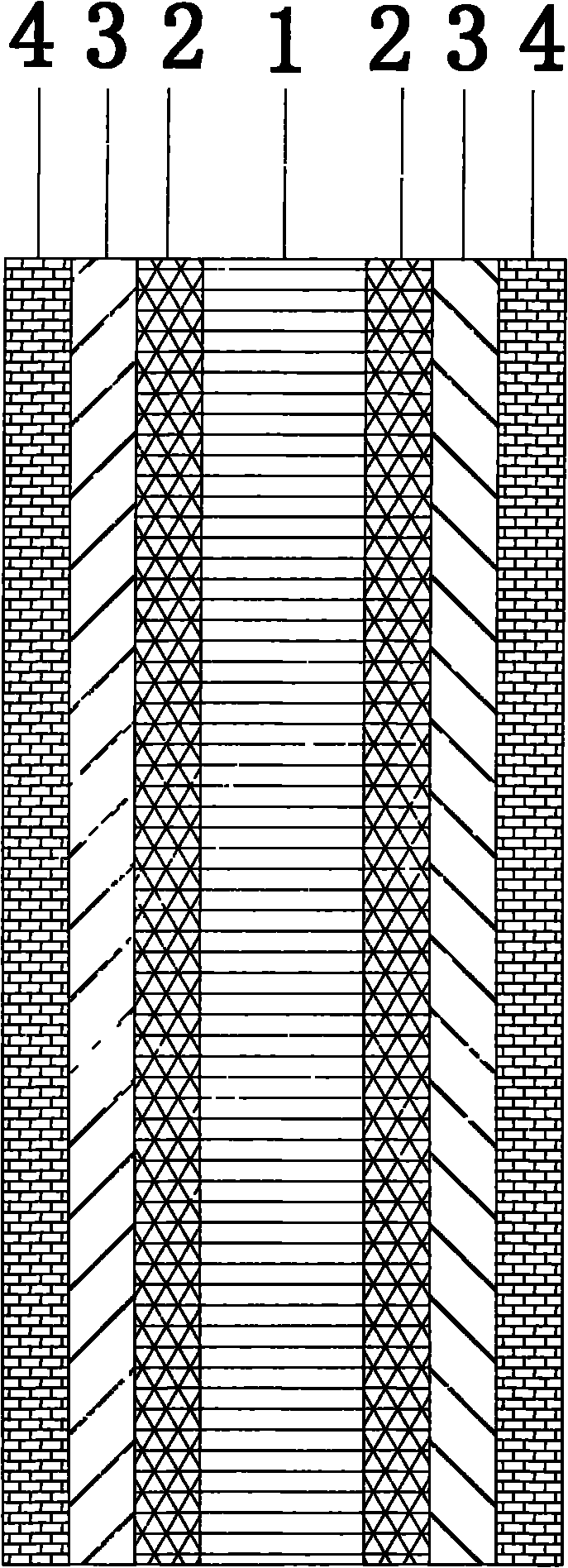

Steel strip plated with multi-layer micron/nano-crystal nickel films and preparation method thereof

ActiveCN102009504AGradient increase in hardnessReduce sheddingCell component detailsMetal layered productsSurface layerPulse electroplating

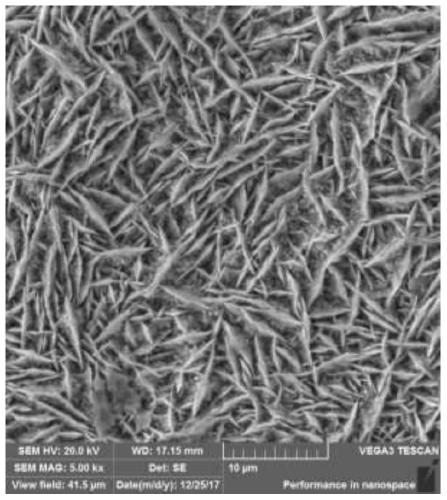

The invention discloses a steel strip plated with multi-layer micron / nano-crystal nickel films and a preparation method thereof. A steel strip is used as a base, and multi-layer micron / nano-crystal nickel films are respectively plated on the two surfaces of the base. The bottom layer of the multi-layer micron / nano-crystal nickel films is a micron-crystal nickel-plated layer, wherein the crystallite dimension of the plated layer is from 0.1 to 0.5 micron, and the thickness of the plated layer is from 0.5 to 2.0 microns. The middle layer of the multi-layer micron / nano-crystal nickel films is a nano-crystal nickel-plated layer, wherein the crystallite dimension of the plated layer is from 50 to 100 nanometers, and the thickness of the plated layer is from 0.5 to 1.5 microns. The surface layer of the multi-layer micron / nano-crystal nickel films is a nano-crystal nickel-plated layer, wherein the crystallite dimension of the plated layer is from 20 to 50 nanometers, and the thickness of theplated layer is from 0.2 to 1 micron. The bottom micron-crystal nickel-plated layer of the multi-layer micron / nano-crystal nickel films is prepared by direct current electroplating, the middle nano-crystal nickel-plated layer is prepared by pulse electroplating, and the surface nano-crystal nickel-plated layer is prepared by pulse jet electroplating. The steel strip has the advantages of excellent elongation, corrosion resistance and stamping properties and can be used as the casing materials of high-performance batteries.

Owner:HUNAN YONGSHENG NEW MATERIALS

Material for shell of connector and preparation method thereof

ActiveCN101826675AImprove corrosion resistanceImprove conductivityCouplings bases/casesMetal layered productsCorrosion resistantCrystallite

Owner:HUNAN YONGSHENG NEW MATERIALS

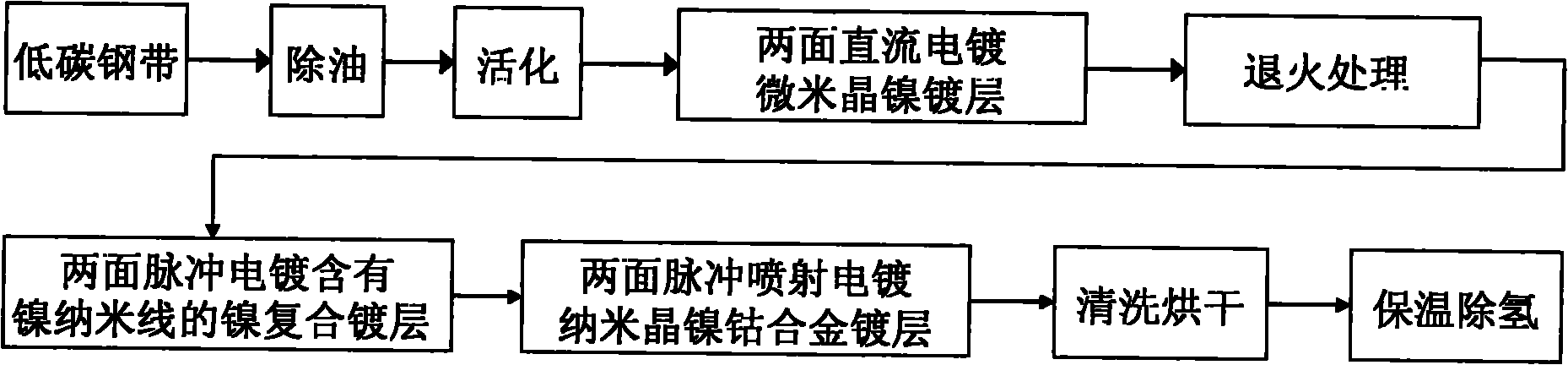

Nickeliferous nanowire laminated film plated steel belt and production method thereof

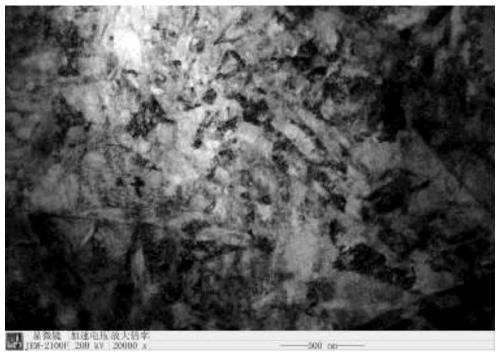

ActiveCN101954763AReduce corrosion rateHigh strengthElectrolytic coatingsCell component detailsNanowireMetallic Nickel

The invention discloses a nickeliferous nanowire laminated film plated steel belt and a production method thereof. A steel belt is used as a base, and both faces of the steel belt are respectively plated with a nickeliferous nanowire multilayer laminated film. The bottom layer of the nickeliferous nanowire multilayer laminated film is a micron-crystalline nickel plating layer, the middle layer isa nickeliferous nanowire nickel laminated plating layer, and the surface layer is a micron-crystalline nickel cobalt alloy plating layer. The invention also provides the production method of the steel belt, which comprises the following steps of: oiling and activating the base steel belt, and firstly preparing one micron-crystalline nickel plating layer on the base by using a DC electroplating mode; after annealing, preparing one nickeliferous nanowire nickel laminated plating layer on the nickel plating layer by using a pulse electroplating mode; then, preparing one micron-crystalline nickelcobalt alloy plating layer on the nickeliferous nanowire nickel laminated plating layer by using a pulse spraying mode, cleaning by using distilled water and drying; and finally, preserving temperature and removing hydrogen. The steel belt is formed by tightly combining the nickeliferous nanowire multilayer laminated film and a mild-carbon steel belt together, has good corrosion resistance, stamping performance and strong load resistance and can be applied to shell materials of lithium ion power batteries and high-performance alkaline manganese batteries.

Owner:XIANGTAN UNIV

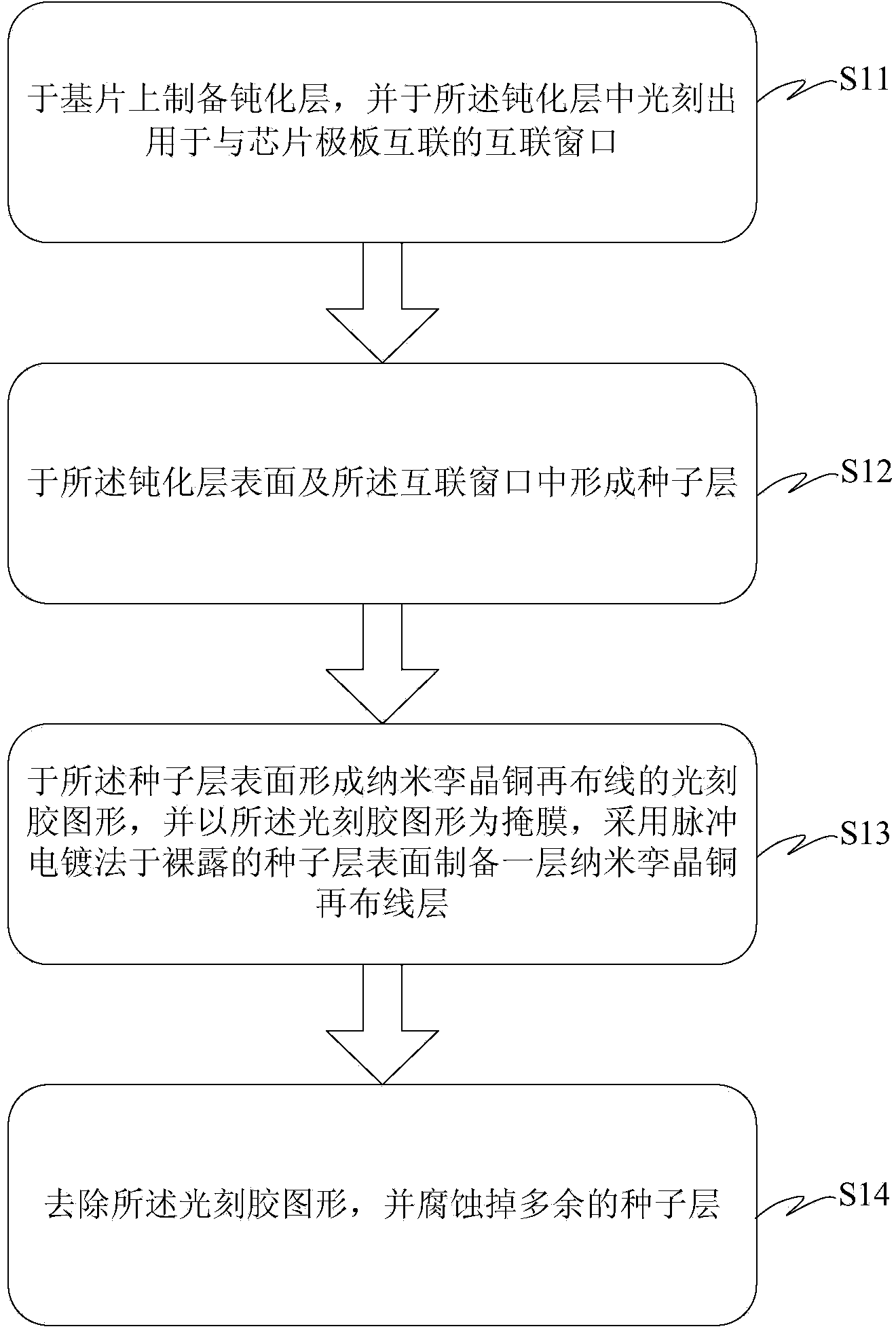

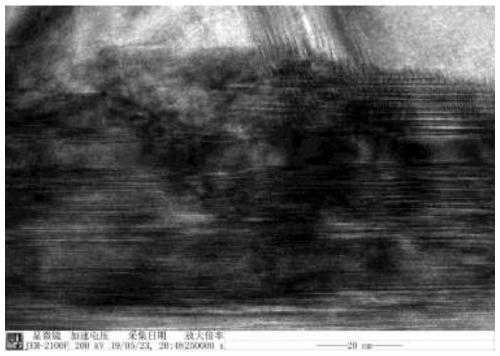

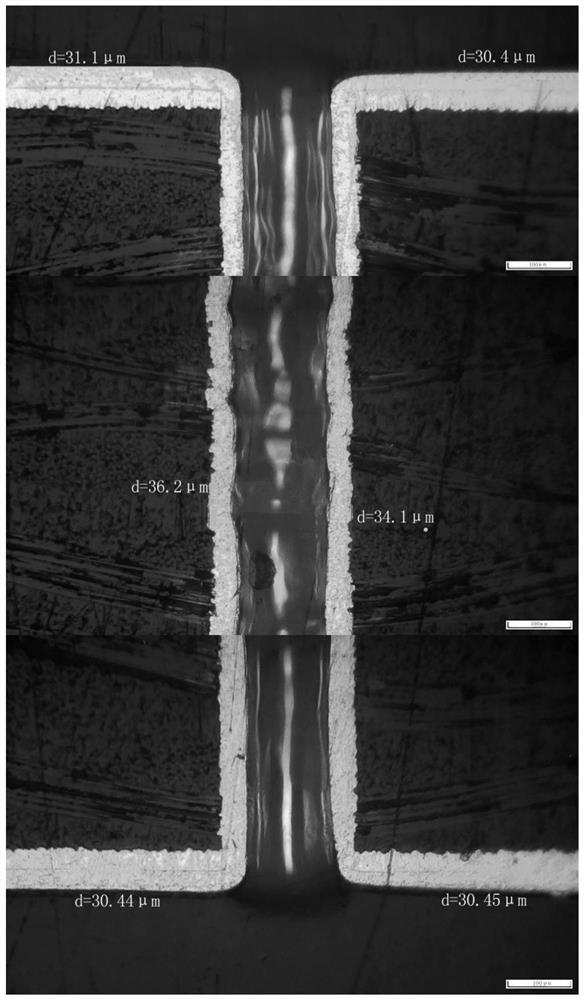

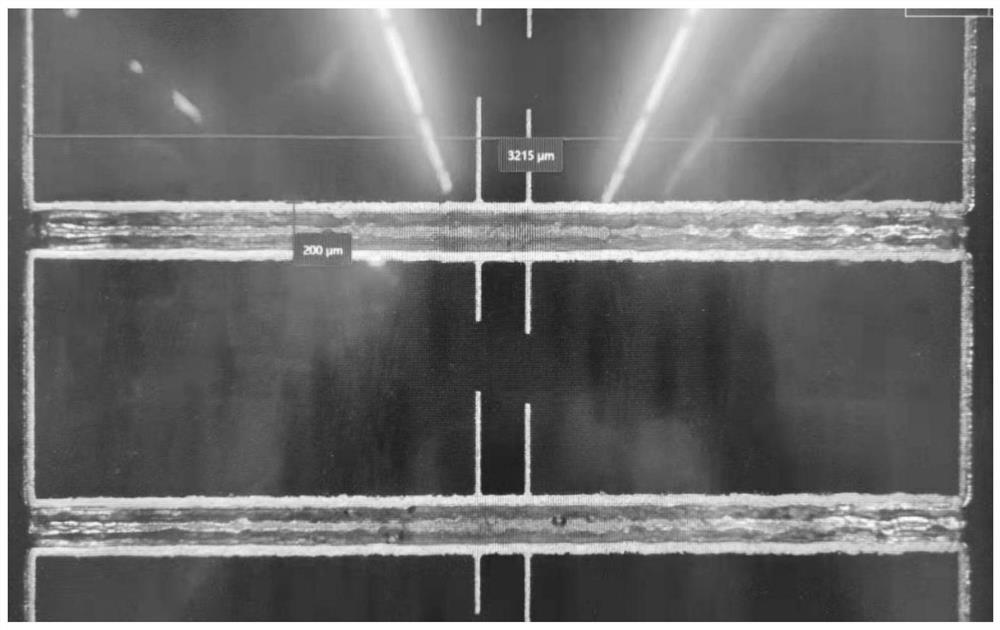

Nanotwinned copper redistribution wire manufacturing method

ActiveCN104392939AImprove mechanical propertiesImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesCrystal twinningPulse electroplating

The invention provides a nanotwinned copper redistribution wire manufacturing method. The method comprises steps: 1) a passivation layer is manufactured on a substrate, and a window interconnected with a chip electrode plate is photoetched; 2) seed layers are formed on the surface of the passivation layer and in the interconnected window; 3) a photoresist pattern of nanotwinned copper redistribution wire is formed on the surface of the seed layer, and a nanotwinned copper redistribution wire layer is manufactured on the surface of the exposed seed layer by adopting a pulse electroplating method; and 4) the photoresist pattern is removed and the extra seed layer is corroded. Pulse electroplating with rapid annealing treatment is adopted, large internal stress formed by pulse electroplating drives copper for re-crystallization, and a high-density nanotwinned copper redistribution wire is formed. Current adopted by the invention is low in density, current equipment can be used, the prior IC technology can be fully compatible, the method belongs to the wafer level packaging technology, the efficiency is high, and the cost is low. The manufactured nanotwinned copper is excellent in comprehensive mechanical performance, the size of the redistribution wire can be greatly shortened to about 10mum, and thermal mechanical reliability is high.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

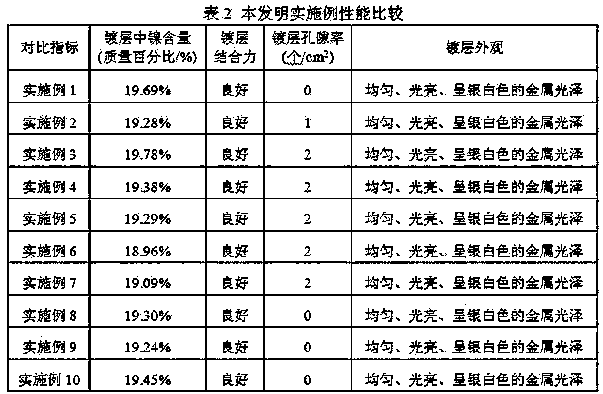

Pulse electroplating method for alkaline zinc-nickel alloy with stable nickel content

The invention belongs to the technical field of electroplated zinc-nickel alloys and particularly relates to a pulse electroplating method for a zinc-nickel alloy with stable nickel content. The pulse electroplating method for the alkaline zinc-nickel alloy with the stable nickel content provided by the invention comprises the following steps: (1) preparing an alkaline zinc-nickel alloy electroplating solution; (2) pre-treating a base body; (3) carrying out pulse alkaline zinc-nickel alloy electroplating; and (4) recycling wastewater and washing a plated layer. Compared with a direct-current electroplated method for the zinc-nickel alloy, the pulse electroplating method has the characteristics that the plated layer has fine crystals, nickel content is stable, stress and porosity are low, corrosion resistance is excellent and the like, so as to realize the real alloy electroplating.

Owner:SHANDONG JIANZHU UNIV

Reverse pulse plating composition and method

Owner:SHIPLEY CO LLC

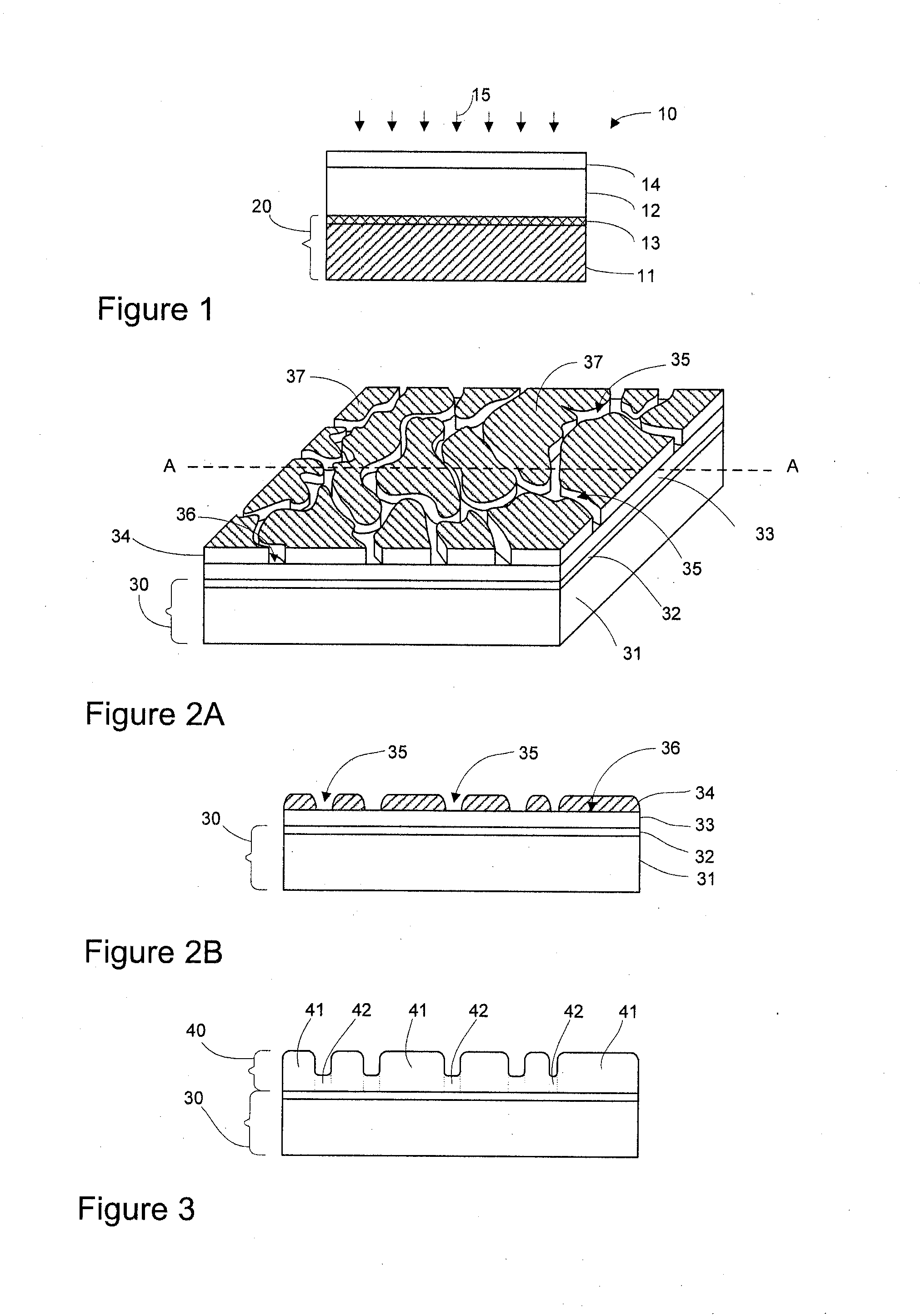

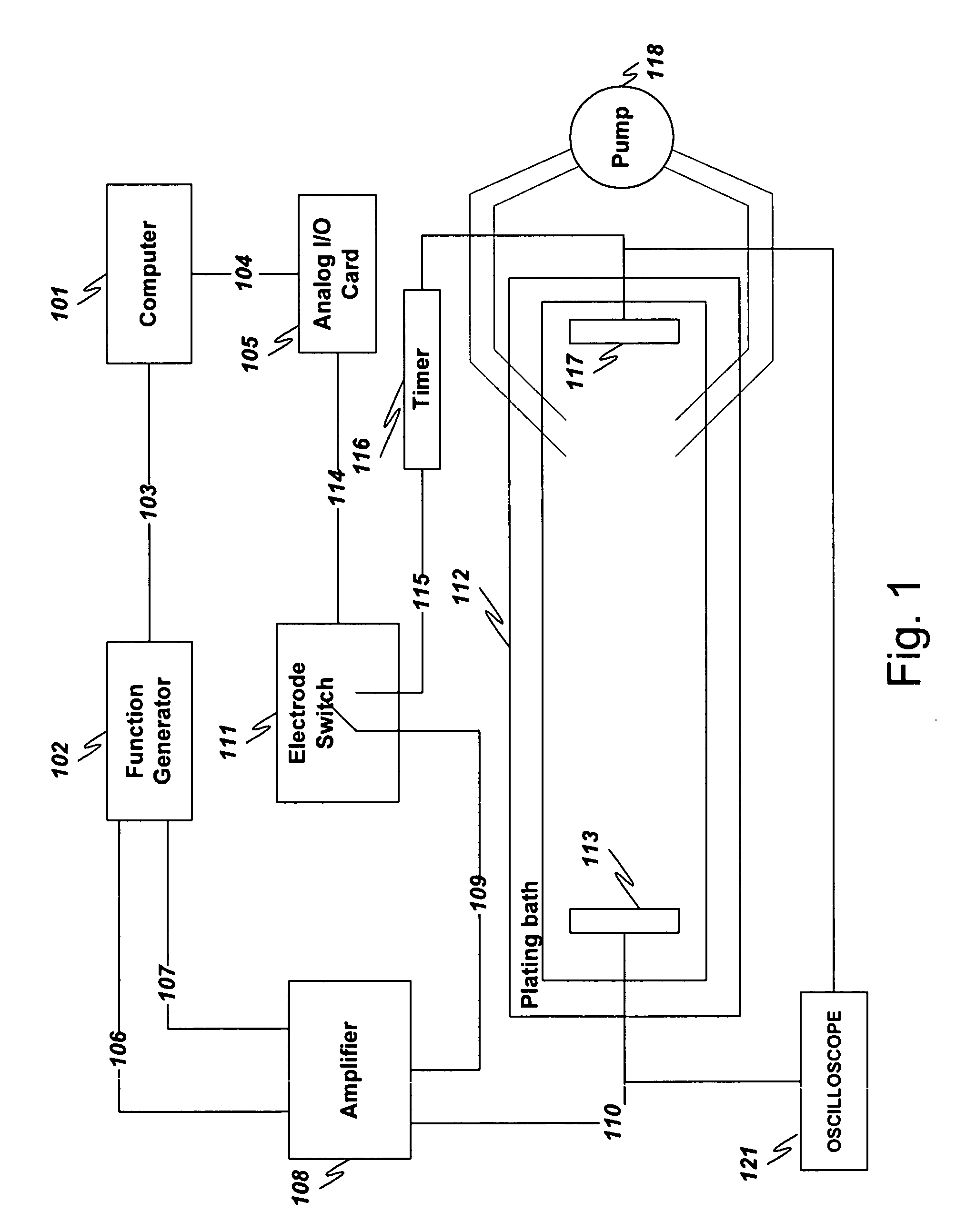

Method of patterning ultra-small structures

We describe a process to produce ultra-small structures of between ones of nanometers to hundreds of micrometers in size, in which the structures are compact, nonporous and exhibit smooth vertical surfaces. Such processing is accomplished with pulsed electroplating techniques using ultra-short pulses in a controlled and predictable manner.

Owner:ADVANCED PLASMONICS

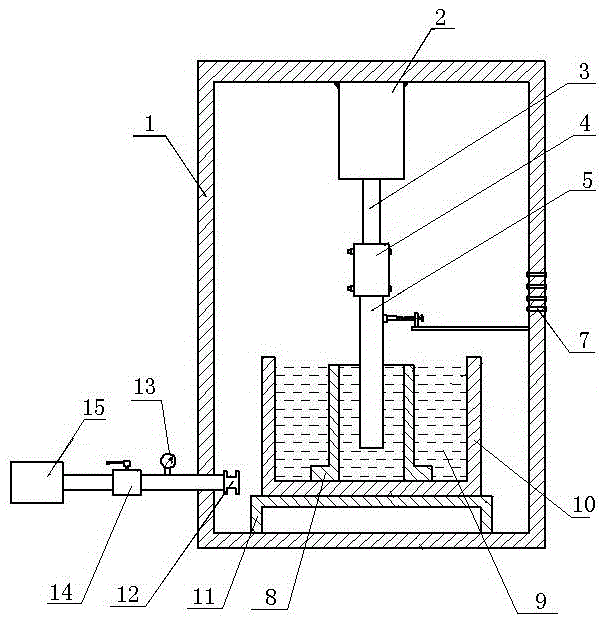

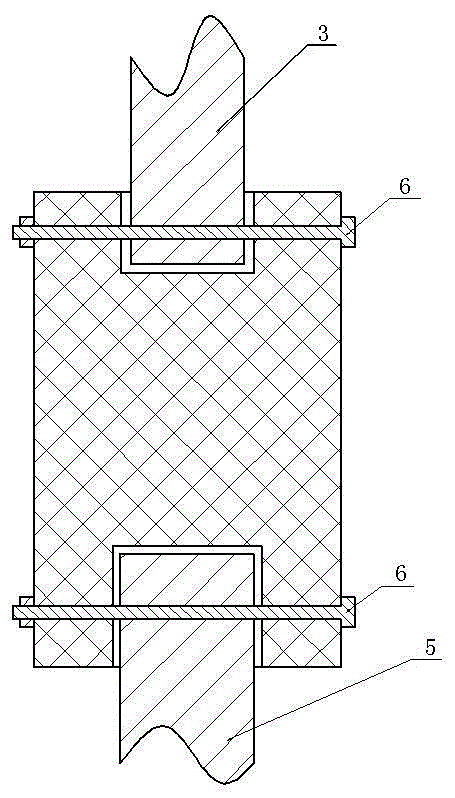

Anode rotary vacuum plating device based on PLC (Programmable Logic Controller) control

ActiveCN105063735AReduce hydrogen contentImprove bindingCellsPulse electroplatingProgrammable logic controller

The invention relates to an anode rotary vacuum plating device based on PLC (Programmable Logic Controller) control. A plating tank of the anode rotary vacuum plating device based on PLC control is placed in a vacuum box, a cathode is placed in the plating tank, a binding post of the cathode is welded on the upper surface of the cathode, an anode is inserted into the cathode and is connected with a motor through a clamping and fixing device, a carbon brush of an anode connecting device is propped against the anode, a plurality of wiring holes are formed in the vacuum box, a wiring sealing block is arranged in each wiring hole, an external electrode wire of the anode is connected with the positive pole of a pulse electroplating power supply through the corresponding wiring sealing block, an external electrode wire of the cathode is connected with the negative pole of the pulse electroplating power supply through the corresponding wiring sealing block, and two external electrode wires of a motor are connected with a PLC through the corresponding wiring sealing blocks respectively. The anode rotary vacuum plating device based on PLC control solves the problem of difficulty in electroplating of negative plating parts having large sizes or complicated structures is solved, and the operation difficulty is lowered.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

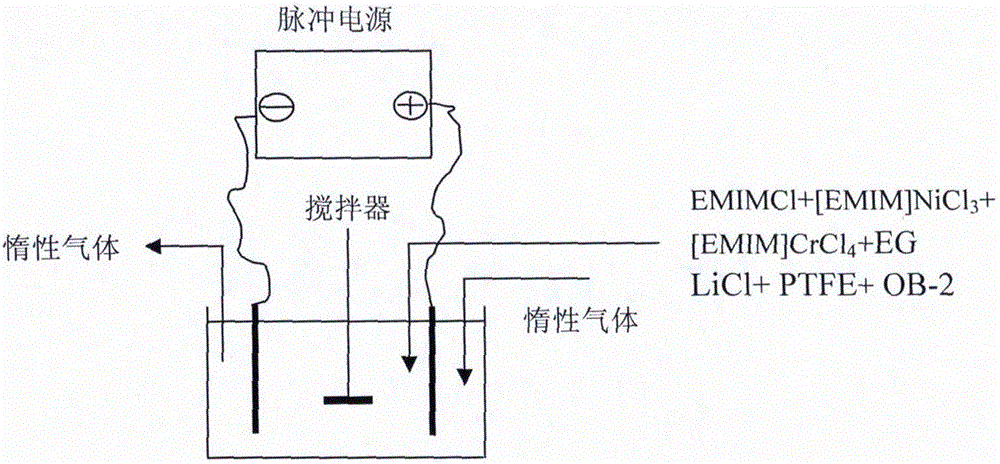

Method for electroplating Ni-Cr-PTFE composite coating in ionic liquid

InactiveCN105862093AEvenly distributedImprove anti-friction performanceElectrolytic coatingsImpulse frequencyAverage current

The invention discloses a method for electroplating a Ni-Cr-PTFE composite coating in ionic liquid. In a non-water system and an inert-gas atmosphere, [BMIM]NiCl3 liquid containing nickel ions, [BMIM]CrCl4 liquid containing chromium ions, LiCl, PTFE and N,N-dimethyldodecylamine oxide (OB-2) are added into a certain amount of mixed solvent of 1-ethyl-3-methylimidazolium chlorine (EMIMCI) and ethylene glycol (EG), mechanical stirring and ultrasonic wave stirring are conducted for a certain time until the mixture is mixed evenly, and electroplate liquid is obtained; a cathode electrode and an anode electrode are placed into an electroplating bath, a certain space between the electrodes, temperature, impulse frequency, pulse duty factor, deposition period and average current density are kept, pulse electroplating is conducted at a certain stirring speed, and after electroplating, washing and drying are conducted, and the Ni-Cr-PTFE composite coating is obtained, wherein a pretreated matrix serves as the cathode electrode, and a platinum sheet or graphite serves as the anode electrode. Due to the fact that the PTFE and Cr are added, the antifriction performance and hardness of the coating are obviously improved, the process procedure is simple, the equipment investment is low, and the method is environmentally friendly and economical.

Owner:ANQING NORMAL UNIV

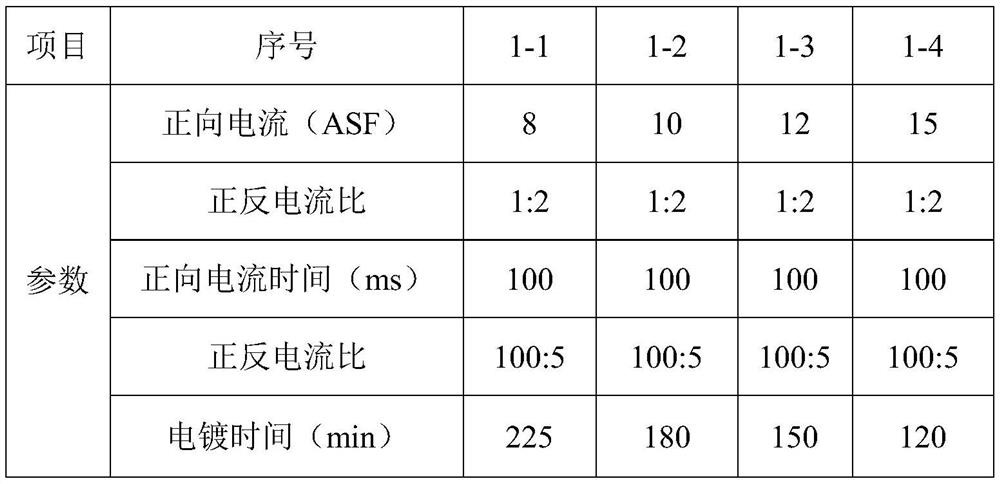

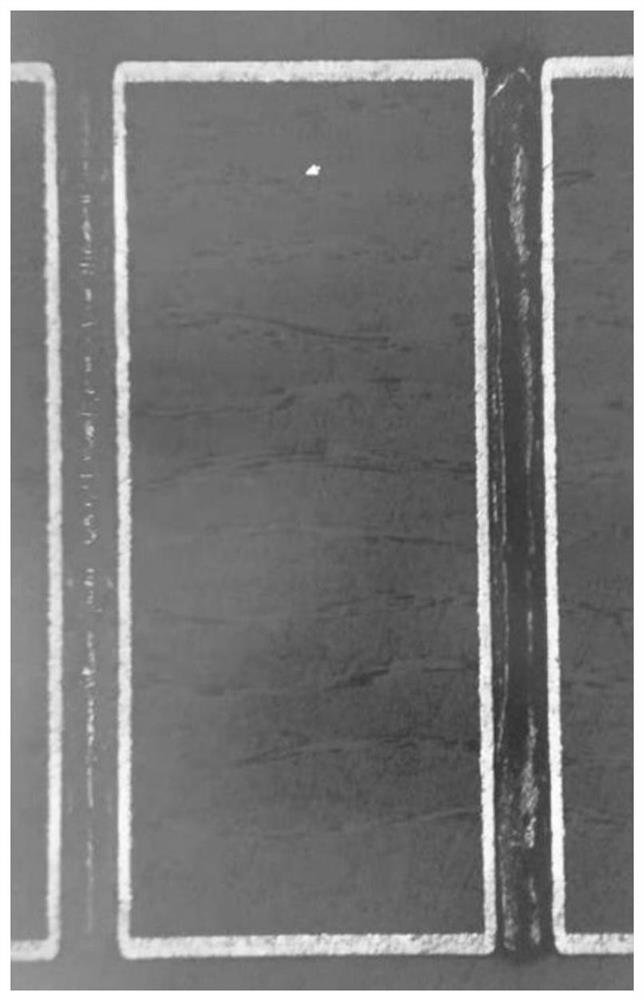

Fabrication method for plating copper in through hole of printed circuit board with high thickness-diameter ratio

ActiveCN106982521APrevent nodulationPrevent the situationPrinted element electric connection formationCopper platingPulse electroplating

The invention discloses a fabrication method for plating copper in a through hole of a printed circuit board with a high thickness-diameter ratio. The fabrication method comprises the following steps of firstly, performing first full-board electroplating on a production board by a DC electroplating mode, plating bottom copper and flattening the through hole, wherein the production board is a board piece subjected to copper deposition; secondly, performing second full-board electroplating by a pulse electroplating mode, and increasing the thickness of hole copper; thirdly, fabricating an outer-layer circuit pattern, opening a window in the through hole, performing first pattern electroplating by a pulse electroplating mode, and further increasing the thickness of hole copper; and finally, performing second pattern electroplating by the DC electroplating mode, electroplating and flattening a pulse copper plated layer, and increasing the thickness of the hole copper until the thickness requirement of the hole copper is reached. Combination of conventional DC electroplating and pulse electroplating is employed during the fabrication process of plating copper in the through hole of the circuit board, the copper plating time of the through hole is effectively shortened, the production efficiency of the circuit board is improved, and the rejection rate and the cost are reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

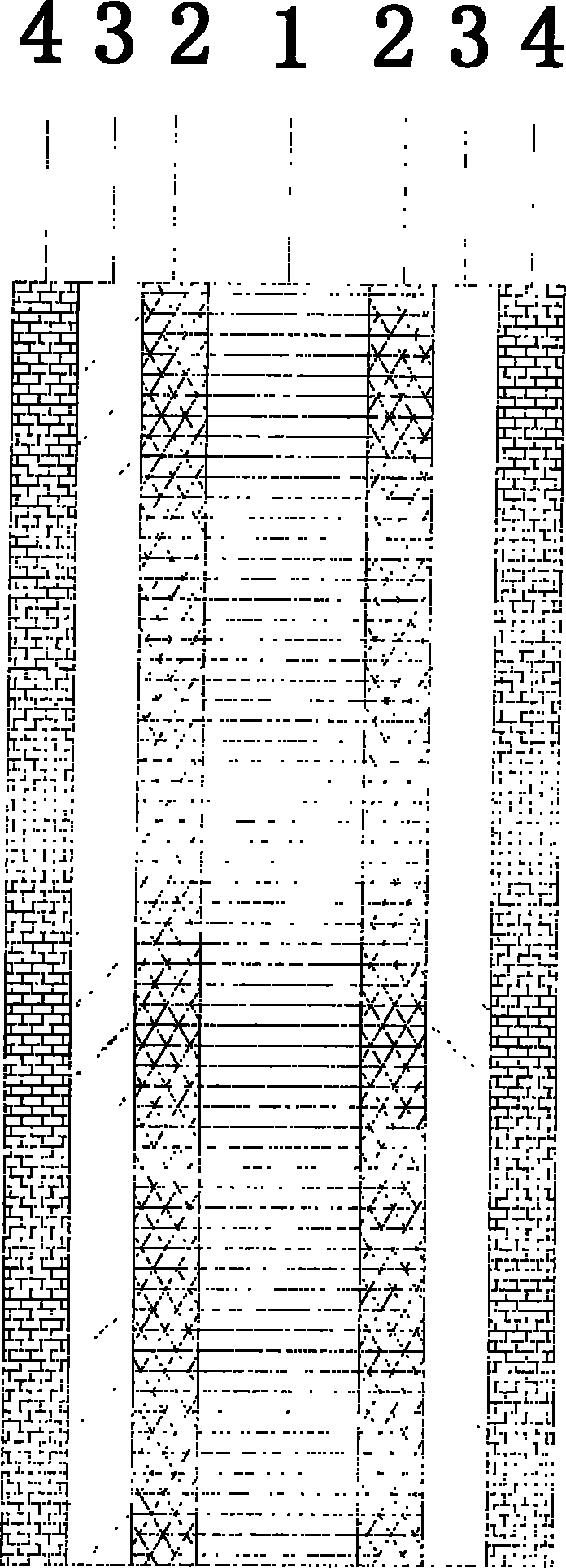

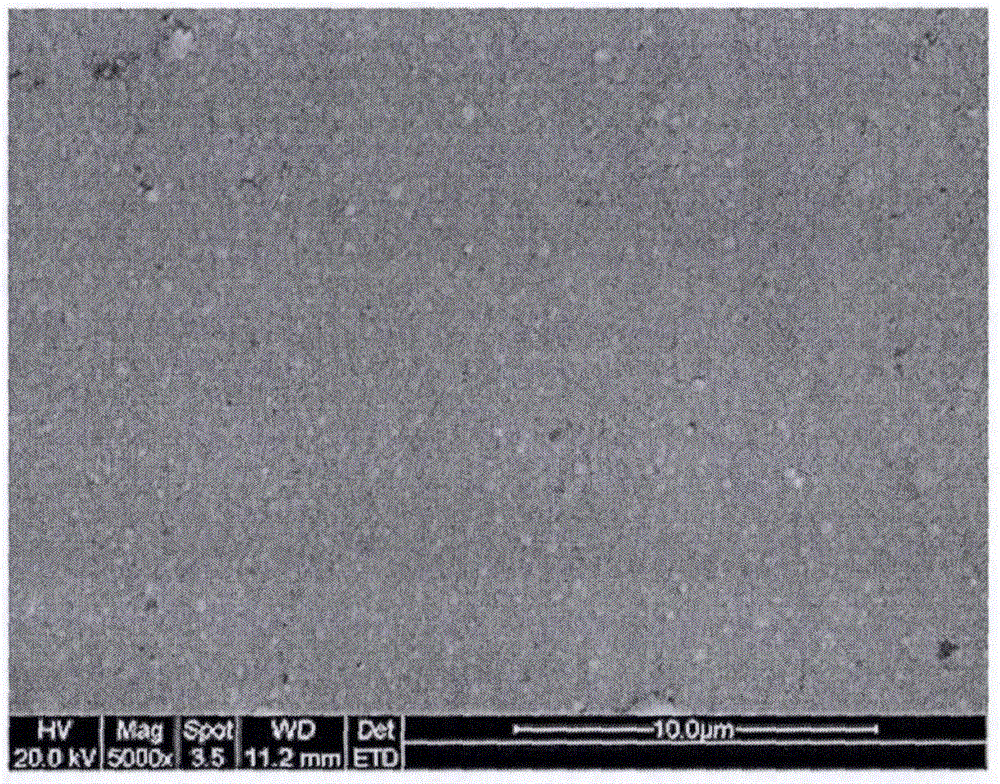

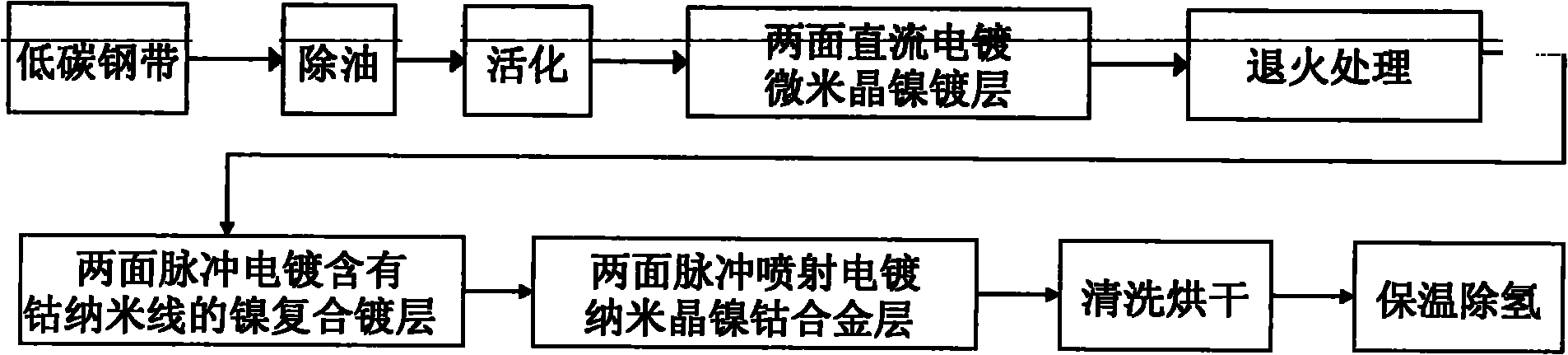

Steel strip plated with composite film containing cobalt nanowires and preparation method thereof

ActiveCN101954762AImprove toughnessDoes not reduce hardnessCell component detailsMetal layered productsLithiumPower battery

The invention discloses a steel strip plated with composite film containing cobalt nanowires and a preparation method thereof. the steel strip of the invention uses a steel strip as the substrate, and the both sides of the steel strip are respectively plated with a multilayer composite film containing cobalt nanowires. The bottom layer of each multilayer composite film containing cobalt nanowiresis a micron crystalline nickle plating, the middle layer is a nickle composite plating containing cobalt nanowires and the surface layer is nanocrystalline nickle-cobalt alloy plating. The invention also provides the preparation method of the steel strip. The preparation method comprises the following steps: degreasing and activating a steel strip, adopting the direct current electroplating mode to prepare a micron crystalline nickle plating on the substrate, annealing, adopting the pulse electroplating mode to prepare a nickle composite plating containing cobalt nanowires on the nickle plating and then adopting the pulse injection mode to prepare a nanocrystalline nickle-cobalt alloy plating on the nickle composite plating containing cobalt nanowires. The steel strip is closely combined by the multilayer composite film containing cobalt nanowires and the low carbon steel strip, has good corrosion resistance, punching property and high load resistance and can be used as the shell material of the lithium ion power battery and high-performance alkaline Zn / MnO2 battery.

Owner:HUNAN YONGSHENG NEW MATERIALS

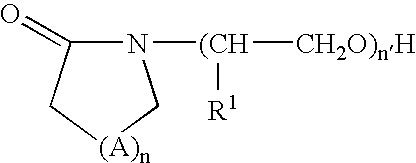

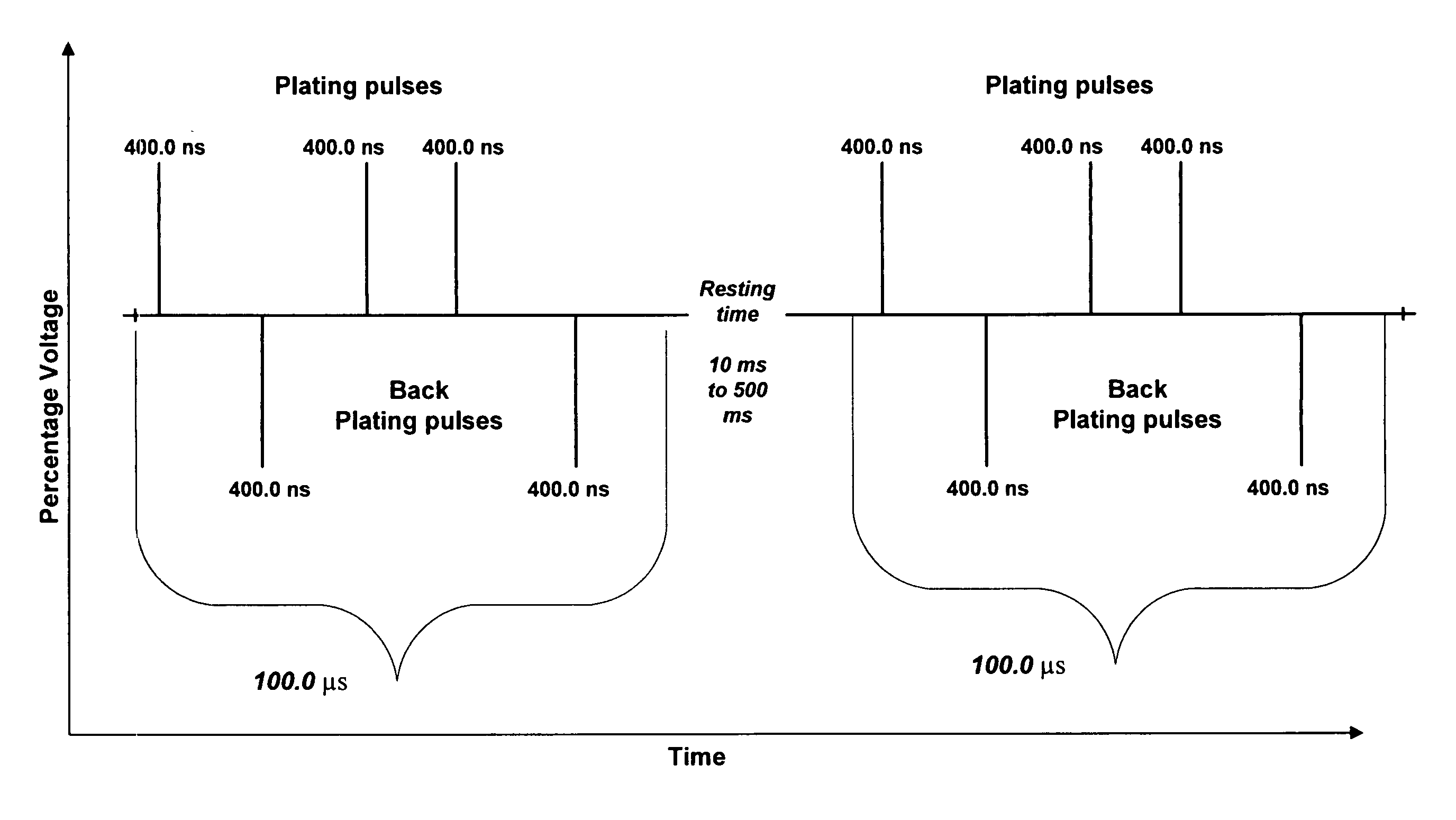

Hole metallization composition for vertical continuous pulse electroplating and electroplating method

ActiveCN111996563AReduce consumptionIncrease current densityPrinted element electric connection formationPulse electroplatingPhysical chemistry

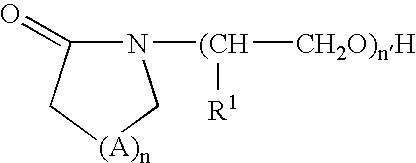

The invention belongs to the technical field of reverse pulse electroplating of hole metallization of a printed circuit board, and particularly relates to a hole metallization composition for verticalcontinuous pulse electroplating and an electroplating method. The hole metallization composition for vertical continuous pulse electroplating comprises water, one or more inorganic acids, one or moreheterocyclic compounds and one or more brighteners, and the one or more heterocyclic compounds are selected from one or more aromatic heterocyclic compounds, one or more epoxide-containing compoundsor one or more products obtained by any combination of the aromatic heterocyclic compounds and the epoxide-containing compounds; and wherein, the concentration of the one or more heterocyclic compounds in the hole metallization composition is 1 to 5000 ppm.

Owner:广东硕成科技股份有限公司

Method for electroplating nickel-cobalt alloy coating on material substrate

The invention is applicable to the field of materials, and provides a method for electroplating a nickel-cobalt alloy coating on a material substrate. The method comprises the following steps that adding the impurity-removed electroplating solution into an electroplating container, adding an anionic surfactant, putting into a surface-treated soluble nickel plate and a cathode material, the pulse electroplating time is 23-24 hours, the average pulse current density is 1.8-3 A / dm2, the duty ratio is 30-50%, the period is 1-2 ms, the stirring speed is 200-300 r / min; and carrying out pulse electroplating under the condition that the temperature of the electroplating solution is 50-65 DEG C and the pH value is 2-3, so that the surface of the cathode material is deposited to form a nickel-cobaltalloy coating containing a nano-twin-phase structure and a double-phase structure. The nickel-cobalt alloy coating obtained by adopting the method has a dual-phase structure with both FCC and HCP, the surface of the nickel-cobalt alloy coating is smooth, is compact in structure, good in flatness and free of cracks, and has good wear resistance and relatively high strength and plasticity.

Owner:JILIN UNIV

Through hole pulse electroplating solution and through hole pulse electroplating coating method

PendingCN113881983AGood deep plating abilityIncrease current densityPrinted element electric connection formationElectrodesCu2 ionsPulse electroplating

The invention provides a through hole pulse electroplating solution. The through hole pulse electroplating solution comprises 60-80 g / L of copper ions, 200-250 g / L of acid, 40-100 mg / L of chloride ions, 0.05-20 mg / L of a brightening agent and 50-4000 mg / L of a wetting agent. Through combination of the electroplating solution and the pulse electroplating technology, electroplating to a PCB through hole reaches the deep plating capacity exceeding 100%, and a circuit board with the aspect ratio exceeding 12: 1 and the board thickness exceeding 3 mm can obtain more excellent deep plating capacity.

Owner:广州市慧科高新材料科技有限公司

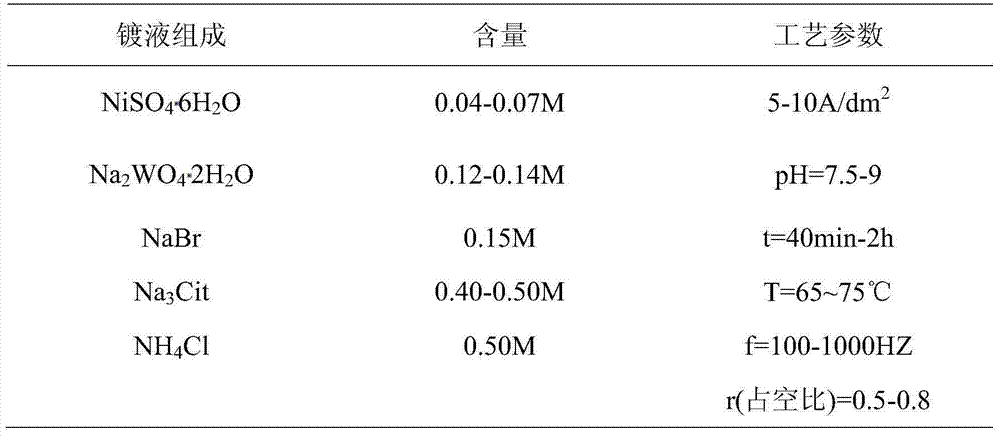

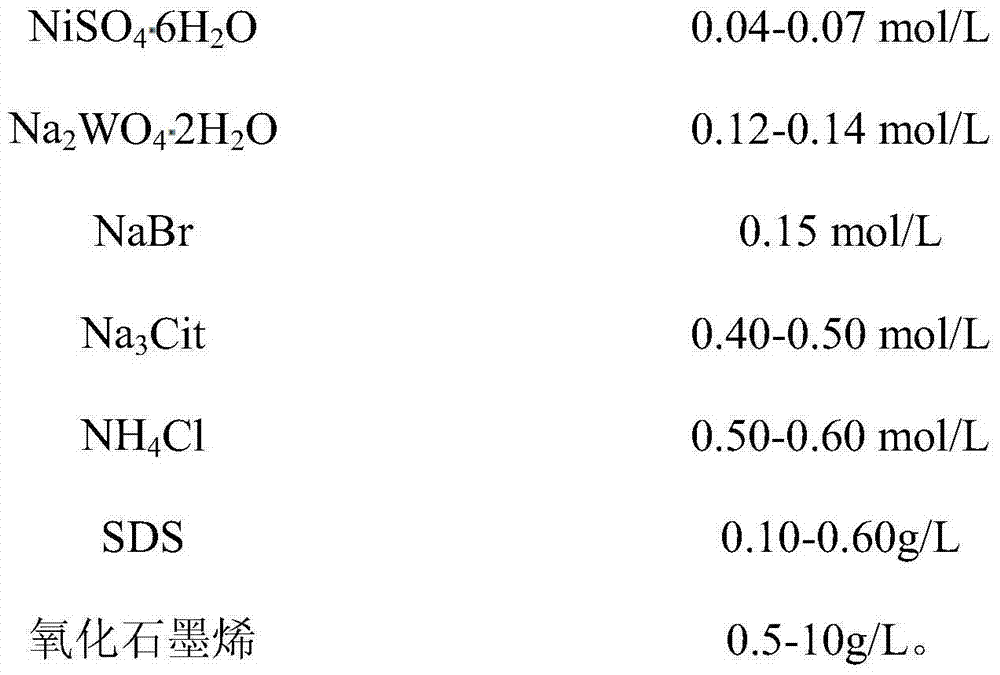

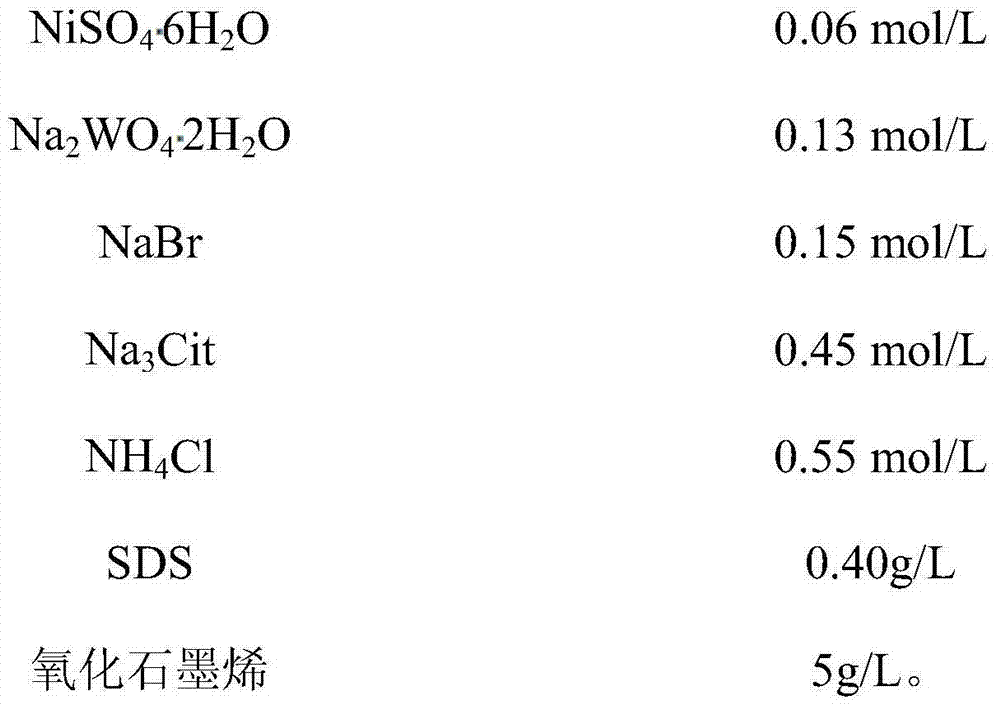

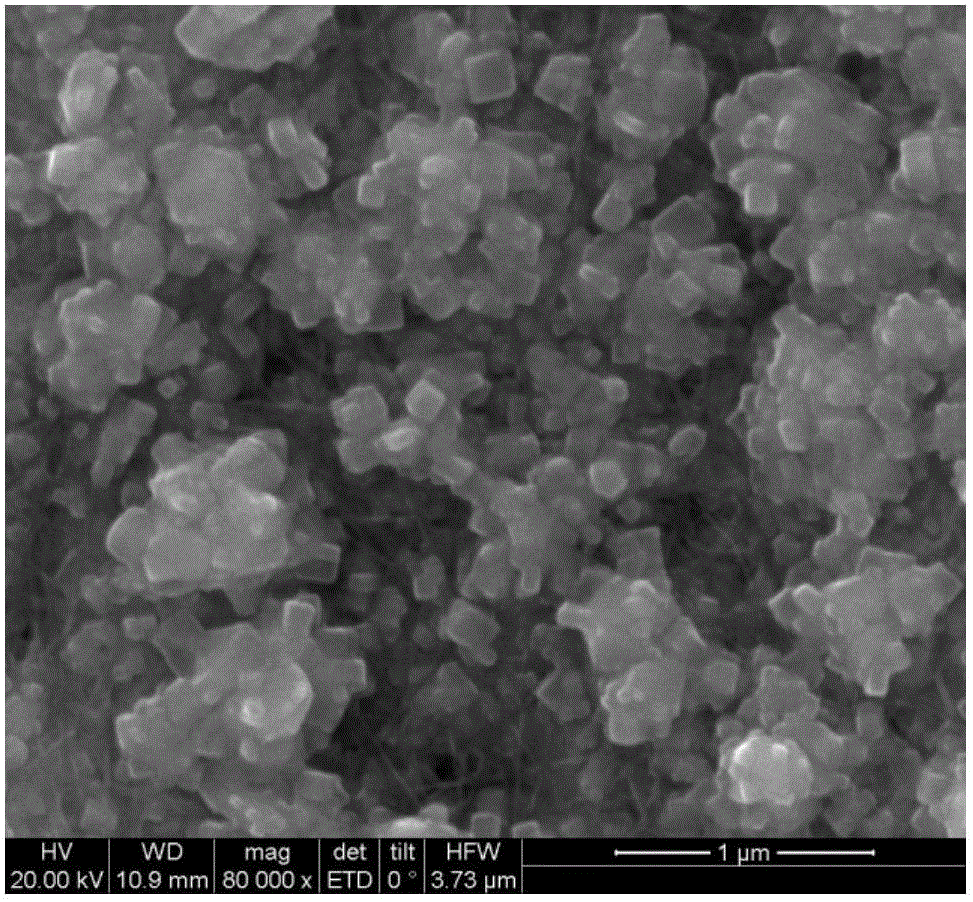

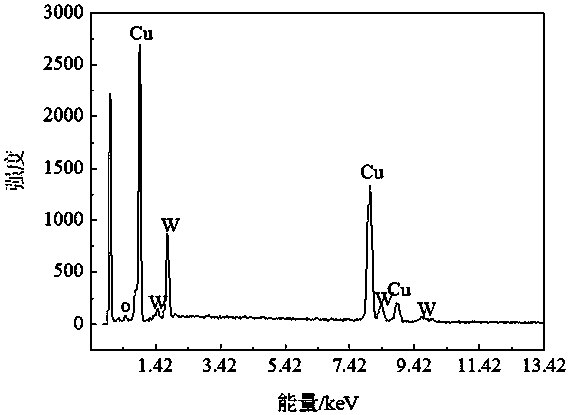

Nickel-tungsten graphene oxide (GO) composite plating solution, plated film and preparation method thereof

InactiveCN104726907AImprove mechanical propertiesEffective dispersionElectrolytic coatingsComposite plateMechanical property

The invention discloses a nickel-tungsten graphene oxide (GO) composite plating solution, a plated film and a preparation method thereof. According to the plating solution, GO which has good mechanical properties and can be effectively dispersed is introduced into the plating solution and is effectively deposited and dispersed in a Ni-W matrix during electroplating. A Ni-W-GO composite plated film is successfully prepared on a carbon steel base body by a pulse electroplating codeposition method. Graphene oxide is dispersed in the Ni-W matrix, so that the coefficient of friction is effectively lowered. The competitive relation between crystal nucleation and growth is effectively changed during codeposition, so that the structure of the plated film is improved, a deposited film layer can become more uniform and denser, intercrystalline corrosion is weakened, the diffusion path of a corrosive medium is prolonged, the self-corrosion potential is increased, local corrosion is effectively inhibited, the stability of a passivation film is improved, and thus, the corrosion resistance of the composite plated film is improved.

Owner:SOUTHWEST PETROLEUM UNIV

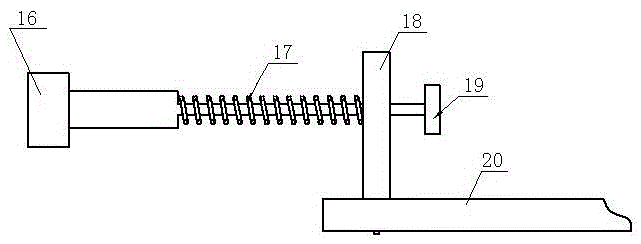

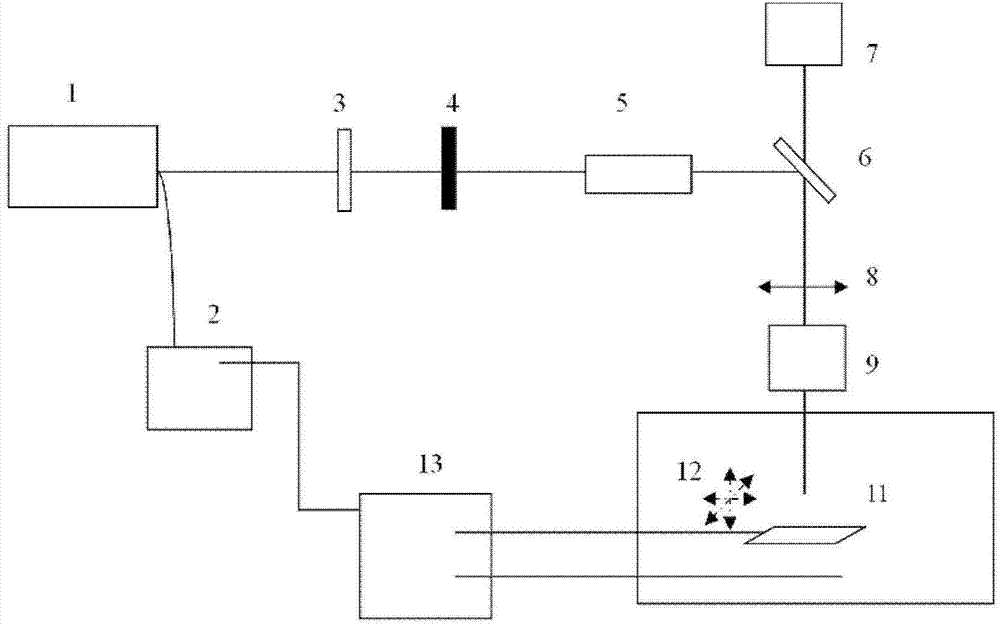

Laser pulse electroplating system

The invention discloses a laser pulse electroplating system. The laser pulse electroplating system comprises a pulse laser, a pulse generation controller, an attenuator, an electronic shutter, a beam expander, a reflected mirror, a charge coupled device (CCD) real-time monitoring system, an optical vibrating mirror, a focusing lens, an electrolytic tank, a three-dimensional moving table and a pulse electroplating power supply. The pulse electroplating power supply and the pulse laser are adopted, the beyond of the performance of the high-frequency pulse electroplating power supply is limited, and laser pulse of the pulse laser which is controlled to send is matched with electronic pulse sent by the pulse electroplating power supply, so that the processing efficiency and the resolution ratio of a plating layer are improved. The application field comprises laser electroplating and laser etching.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

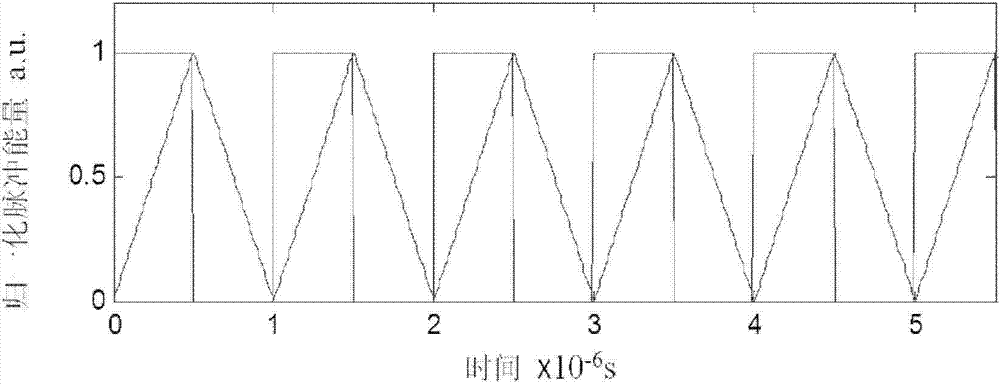

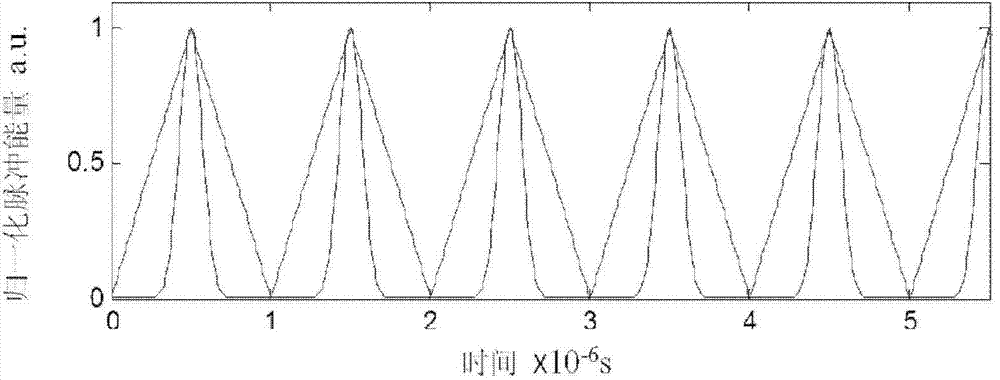

Pulse electroplating method and application thereof

InactiveCN103603018AReduce concentration polarizationImprove physical and chemical propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesPulse electroplatingEngineering

The invention belongs to the field of semiconductor interconnection technology and in particular to a pulse electroplating method and application thereof. The method provided by the invention is as below: a plurality of stages are included, and each stage comprises a plurality of periods; each period is applied with a forward pulse and then a reverse pulse, wherein the current of the reverse pulse is greater than that of the forward pulse, the reverse pulse width is shorter than forward pulse width, and reverse interpulse and the forward interpulse are the same; the forward pulse and reverse pulse in each stage are constant; and forward pulse in a latter phase is shorter than the forward interpulse of a previous stage. The invention has the advantage that reverse pulse current accelerates recovery of ion concentration, a relaxation time is provided in a current turn-off time between two pulses, and the stripping process in the period also improves the smoothness of a coating surface. The method provided by the invention can be used in the preparation of a metal interconnection structure.

Owner:FUDAN UNIV

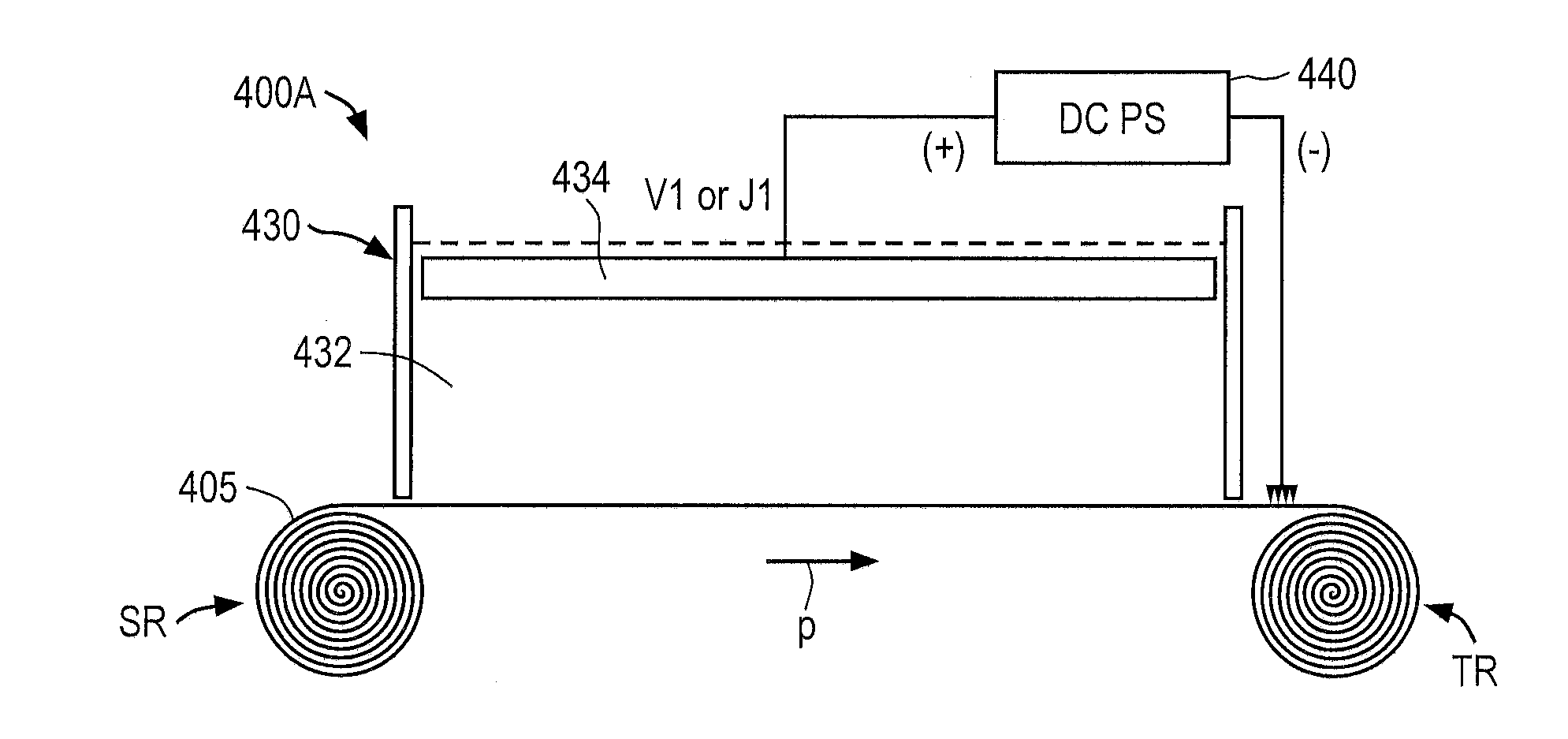

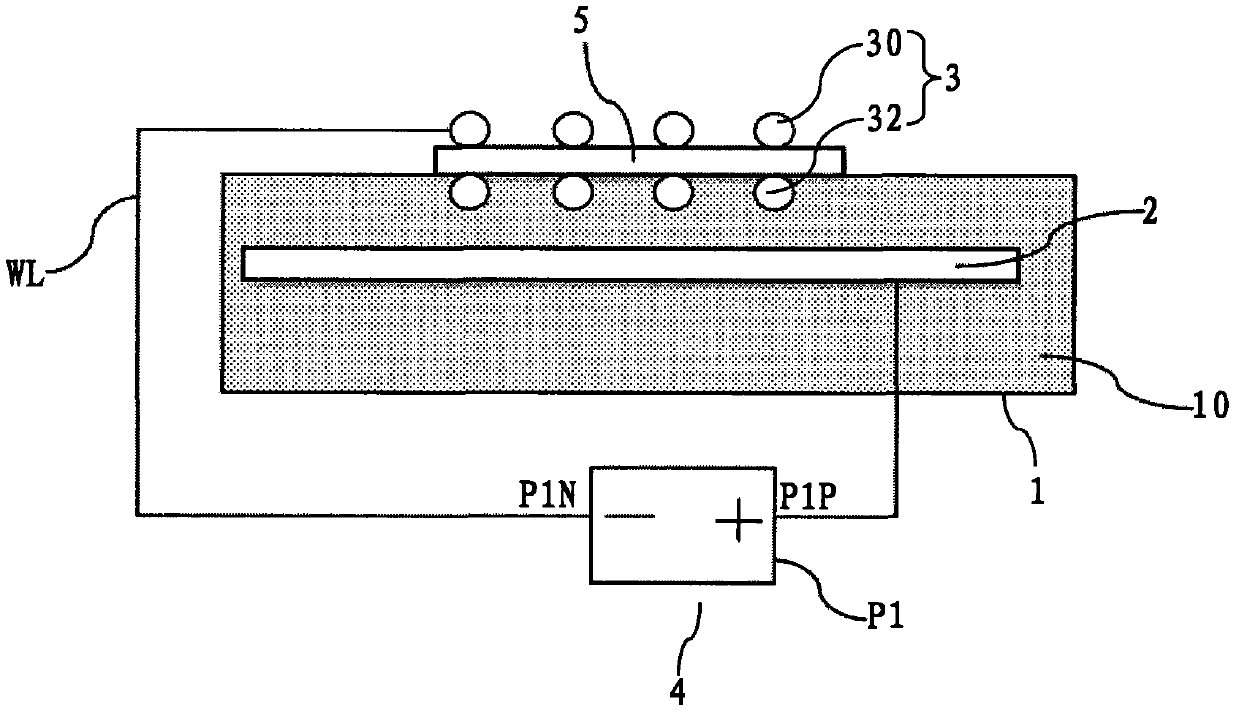

Solar battery coating equipment and coating method

InactiveCN104178787AImprove densification performanceImprove adhesion strengthFinal product manufactureSemiconductor devicesPulse electroplatingEngineering

The invention provides solar battery coating equipment and a coating method. A direct-current power supply and / or a constant-brightness light source is adopted to irradiate electroplating in the prior art, a hole is easily formed in an electroplating grid, and the silicon contact surface is small, so that easy stripping from silicon is caused, and the resistance is higher. The solar battery coating equipment comprises a coating groove for accommodating electroplating solution, a plating solar battery transmission module for horizontally transmitting a plating solar battery with a downward light receiving surface, and a pulse excitation source for inputting pulse electroplating electric energy to the plating solar battery or synchronously inputting and exciting the pulse electroplating electric energy to the plating solar battery; and a plating area of the plating solar battery is coated through the pulse electroplating electric energy. The solar battery coating equipment can use the pulse electroplating electric energy to improve the coating quality so as to improve the adhesion strength of the plated grid and reduce the series resistance, and correspondingly improves the efficiency and quality of the solar battery.

Owner:WUXI SUNTECH POWER CO LTD

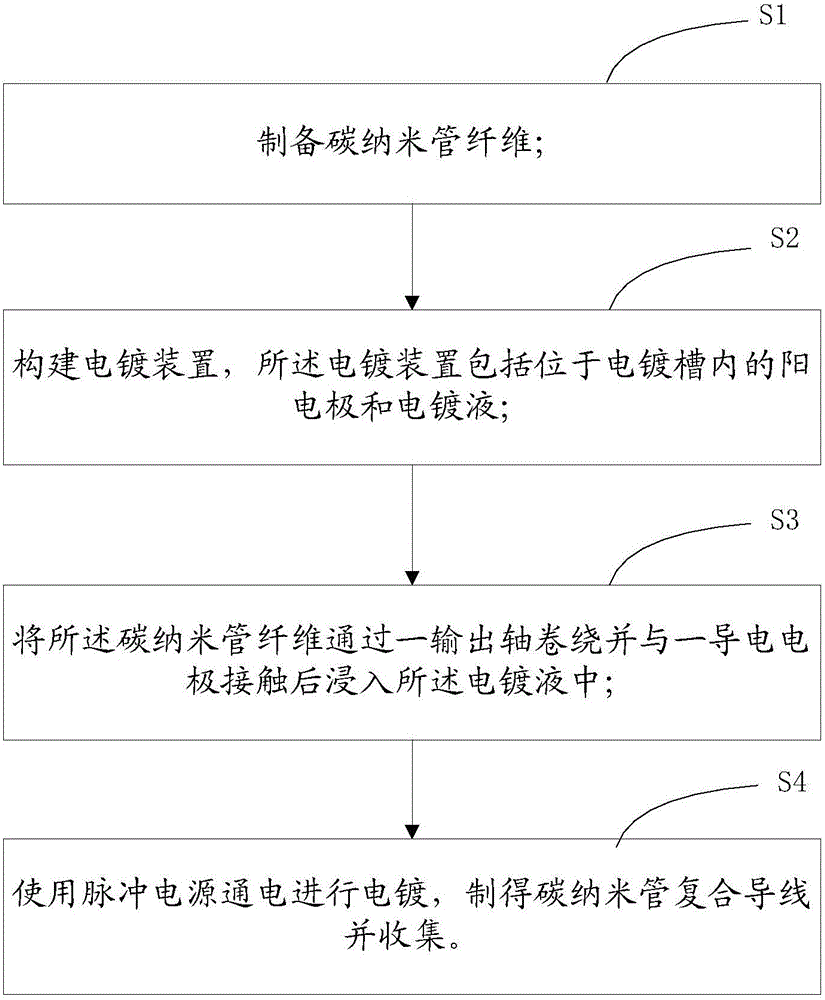

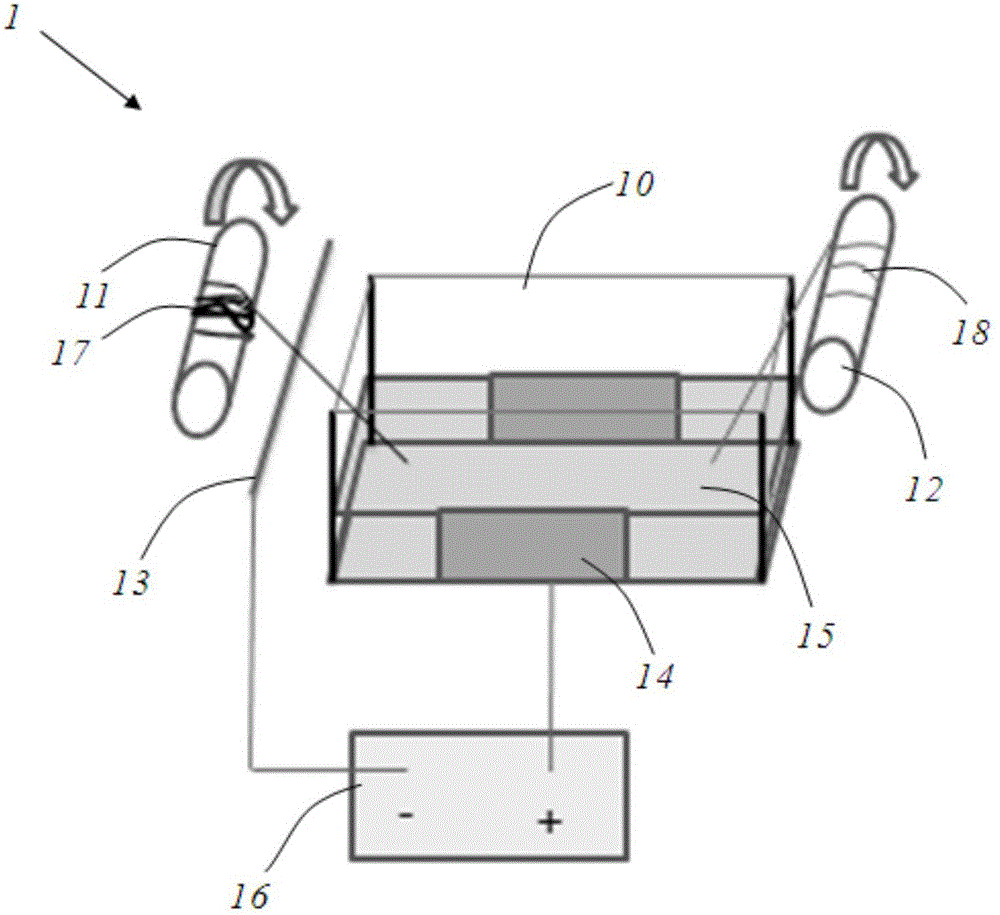

Preparation method of carbon nanotube composite wire

ActiveCN105913972AReduce internal stressImprove the interface binding forceApparatus for manufacturing conducting/semi-conducting layersFiberPulse electroplating

The invention provides a preparation method of a carbon nanotube composite wire. The preparation method comprises the following steps of: preparing carbon nanotube fiber; constructing an electroplating device, wherein the electroplating device comprises a positive electrode and an electroplating liquid arranged in an electroplating tank; winding the carbon nanotube fiber through an output shaft, contacting the carbon nanotube fiber with a conductive electrode and immersing the carbon nanotube fiber into the electroplating liquid; and using a switched-on pulse power supply to carry out electroplating, and preparing and collecting the carbon nanotube composite wire. Compared with the prior art, the pulse electroplating method is adopted, copper nano-crystal grains are directly and uniformly deposited on the surface of the carbon nanotube fiber and in the intervals among carbon nanotubes, the interface binding force between the carbon nanotubes and copper layers is effectively improved, the interaction among crystal boundaries effectively increases the strength and conductivity of the carbon nanotube composite wire, and by adopting the method, the carbon nanotube composite wire light in weight, high in conductivity and high in strength can be prepared.

Owner:SUZHOU CREATIVE CARBON NANOTECH

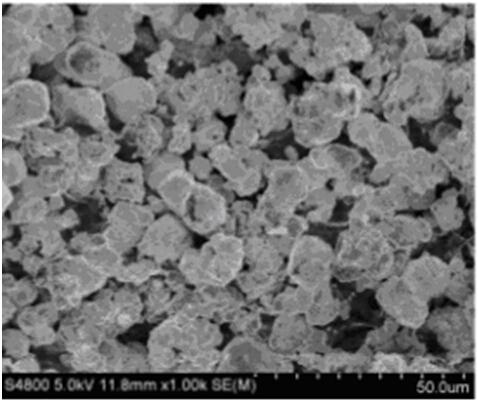

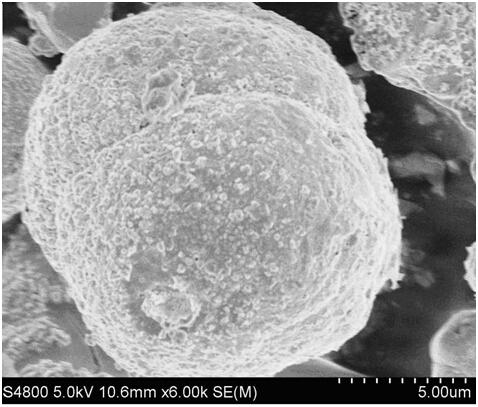

Dispersed pulse electroplating method for heavy powder

ActiveCN109183102AImprove bindingUniform thicknessTransportation and packagingMetal-working apparatusElectrolysisChemical plating

The invention relates to a dispersed pulse electroplating method for heavy powder. The dispersed pulse electroplating method comprises the following steps of (1) pretreatment, wherein the heavy powderis subjected to degreasing, water washing, drying, pickling activation, water washing and vacuum drying to obtain pretreated heavy powder; (2) dispersed pulse intermittent electroplating, wherein thepretreated heavy powder is placed in an electrolytic bath containing a metal plating solution to be subjected to pulse intermittent electroplating, filtration and washing so as to obtain a crude product with the heavy powder coated with metal; and (3) passivation treatment, wherein immersion passivation, vacuum filtration and vacuum drying are carried out to obtain metal coated heavy powder. A coating layer of the metal coated heavy powder obtained by the method has strong binding ability to the powder, coating is complete, the coating layer is uniform in thickness, compact and pure, the powder is not agglomerated, uniform dispersion is achieved, and the metal content and the coating ratio are both better than those of existing chemical plating and electroplating technologies. The methodis simple in process, low in cost, high in production efficiency and suitable for industrial production.

Owner:湖南鋈鎏科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com