Anode rotary vacuum plating device based on PLC (Programmable Logic Controller) control

A vacuum electroplating and anode technology, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of difficult electroplating and large volume of cathodic plating parts, and achieve the goal of improving concentration polarization, reducing operation difficulty and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described further below:

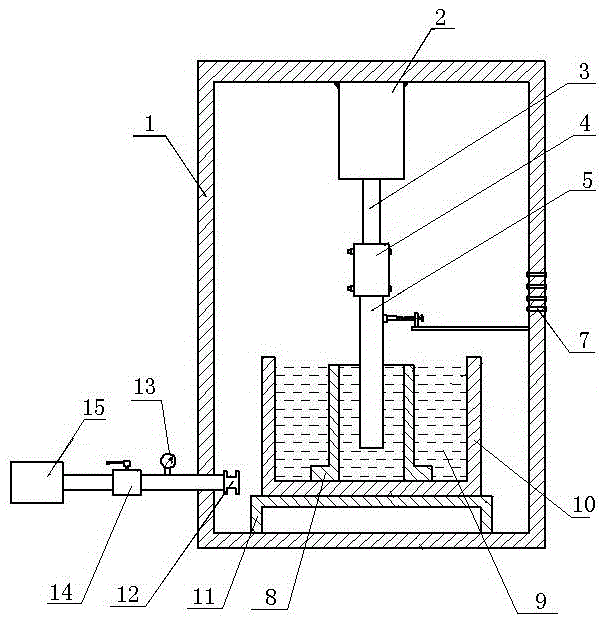

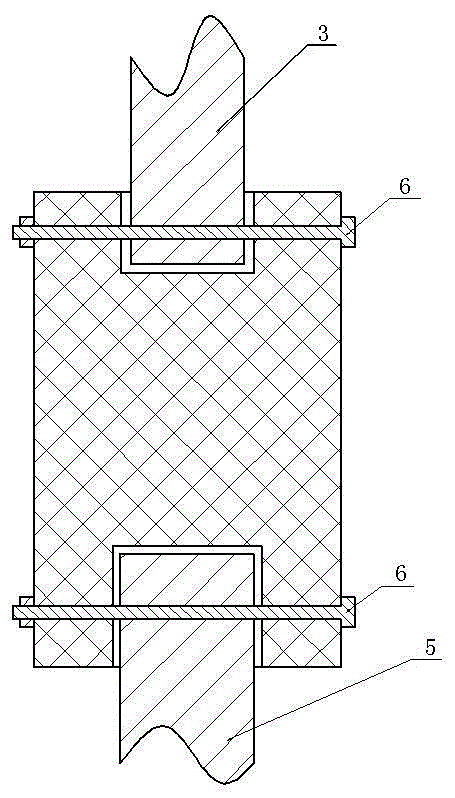

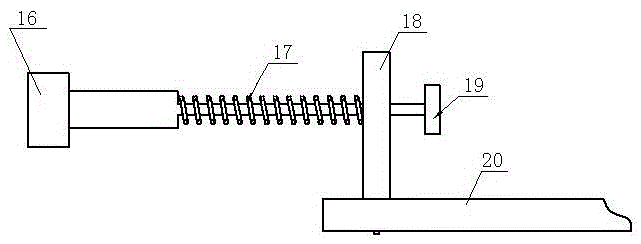

[0029] Such as figure 1 As shown, this anode rotary vacuum electroplating device based on PLC control includes a vacuum box 1, an anode 5, a cathode 8, a plating tank 10, an anode connection device, a wiring sealing device, a vacuum pump 15, and an air filter 12 is installed in the vacuum box 1. Filter 12 links to each other with the vacuum valve 14 outside vacuum box 1 by rubber tube, and vacuum meter 13 is installed on the rubber tube, and vacuum valve 14 links to each other with vacuum pump 15 by rubber tube. There is a base 11 at the bottom of the vacuum box 1, the plating tank 10 is placed on the base 11, the cathode 8 is placed in the plating tank 10, and the terminal post of the cathode 8 is welded on the upper surface of the cathode 8 to ensure that it does not contact the plating solution 9 to prevent current connected to the plating solution 9. The anode 5 is made of Ni, the anode 5 is inserted into the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com