Welding method of high-strength steel for pressure steel pipe of 610MPa hydropower station

A pressure steel pipe and welding method technology, which is applied in the field of steel pipe welding and high-strength steel welding, can solve the problems of low welding efficiency, achieve the effects of improving production efficiency, reducing the tendency of cold cracks, and avoiding the deterioration of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

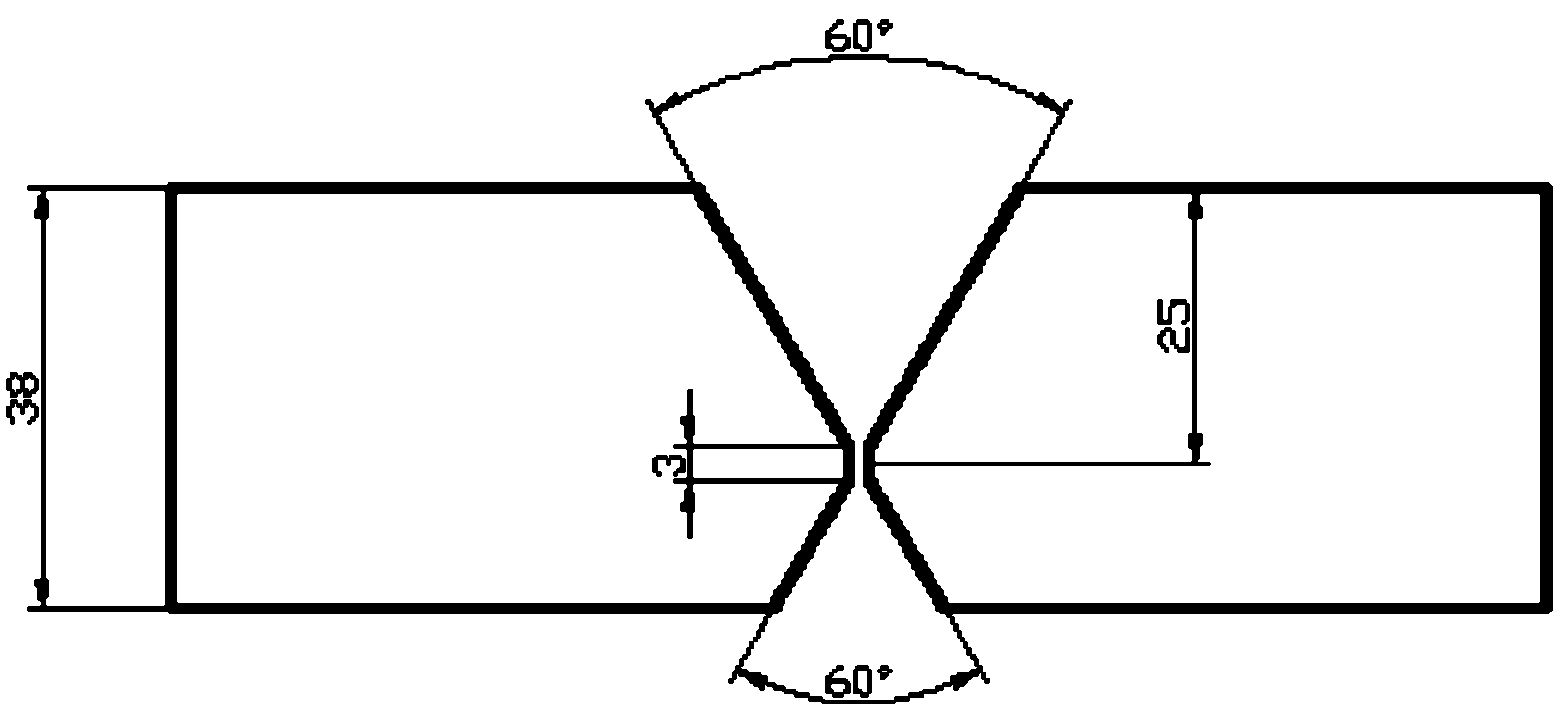

[0018] (1) Low-alloy high-strength steel plates for hydroelectric pressure steel pipes with yield tensile strength ≥ 610 MPa and -20 °C impact energy ≥ 47J produced by TMCP + tempering process, the thickness combination is 38mm + 38mm, and the test plate size is 600mm × 220mm × 38mm ;

[0019] Matching welding materials are:

[0020] Welding material: The chemical composition of its main elements is C 0.061%, Mn 1.68%, Si 0.15%, Mo 0.52%, Cu 0.13%, S 0.007%, P≤0.015%.

[0021] The welding wire is Ф4.0mm directly, and it is welded with SJ101 flux. The mechanical properties of the cladding metal are: tensile strength 690MPa, yield strength 615MPa, elongation 27%, impact energy 100J at -20°C;

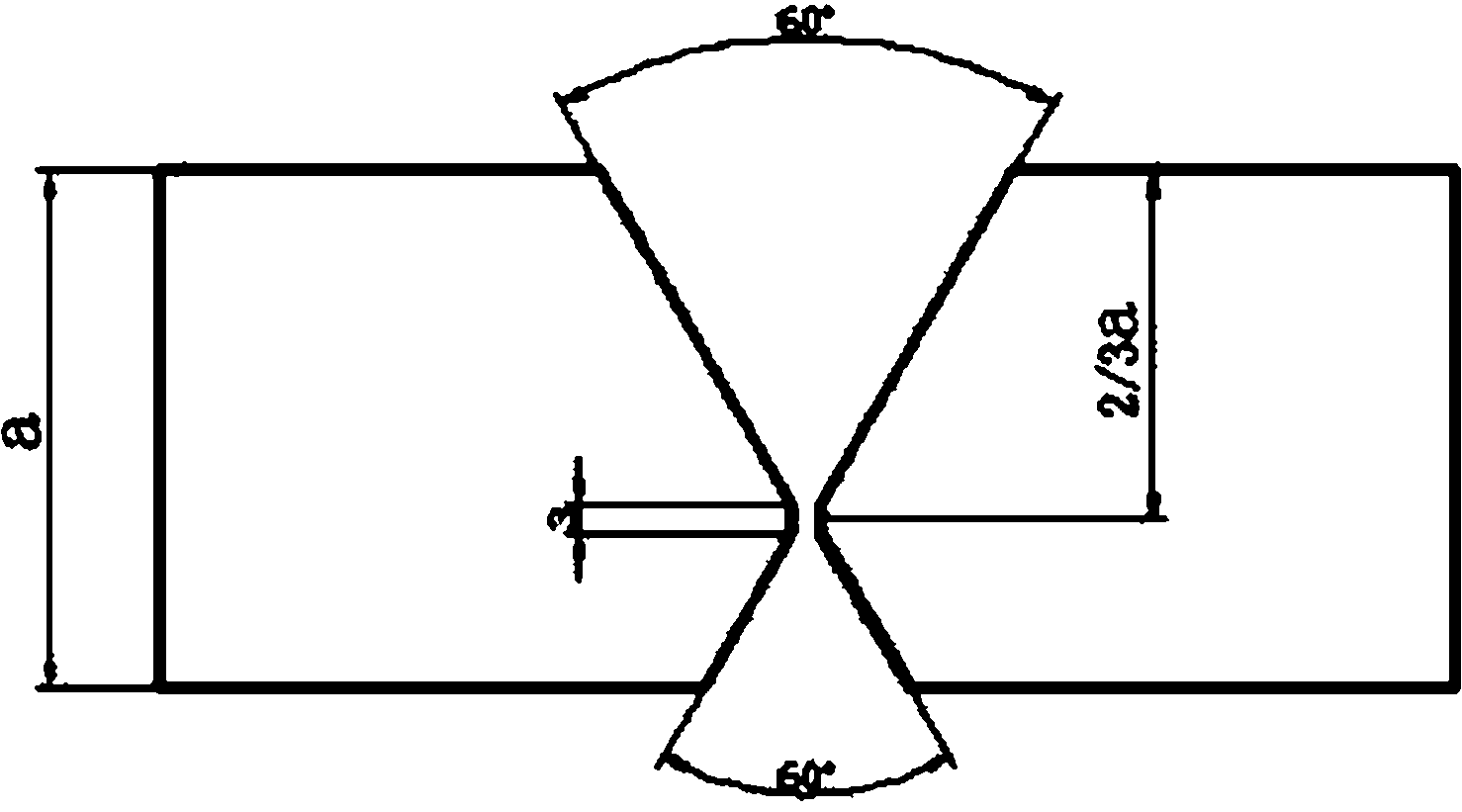

[0022] (2) Double-sided asymmetrical X-shaped grooves are opened at the joint. The large groove surface is 2 / 3 of the plate thickness, the small groove surface is 1 / 3 of the plate thickness and the groove angle is 60°C, leaving a 3mm wide blunt edge;

[0023] (3) During welding, submerge...

Embodiment 2

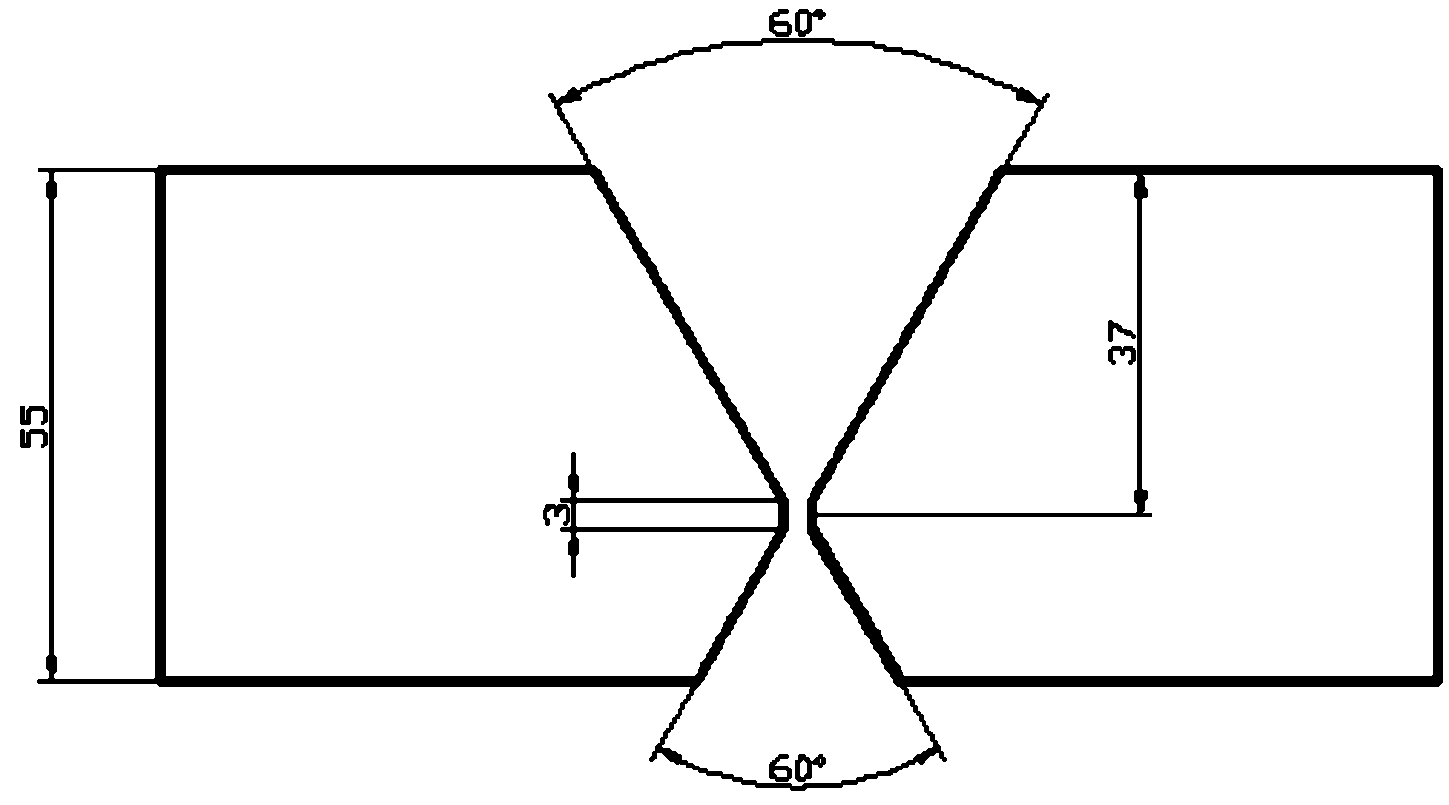

[0027] (1) Low-alloy high-strength steel plates for hydroelectric pressure steel pipes with yield tensile strength ≥ 610MPa and -20°C impact power ≥ 47J produced by TMCP + tempering process, the thickness combination is 55mm + 55mm, and the test plate size is 600mm × 220mm × 55mm ;

[0028] Matching welding materials are:

[0029] Welding material: The chemical composition of its main elements is C 0.061%, Mn 1.68%, Si 0.15%, Mo 0.52%, Cu 0.13%, S 0.007%, P≤0.015%.

[0030] The welding wire is Ф4.0mm directly, and it is welded with SJ101 flux. The mechanical properties of the cladding metal are: tensile strength 690MPa, yield strength 615MPa, elongation 27%, impact energy 100J at -20°C;

[0031] (2) Double-sided asymmetrical X-shaped grooves are opened at the joint. The large groove surface is 2 / 3 of the plate thickness, the small groove surface is 1 / 3 of the plate thickness and the groove angle is 60°C, leaving a 3mm wide blunt edge;

[0032] (3) During welding, submerged a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com