Patents

Literature

57results about How to "Meet the design and use requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

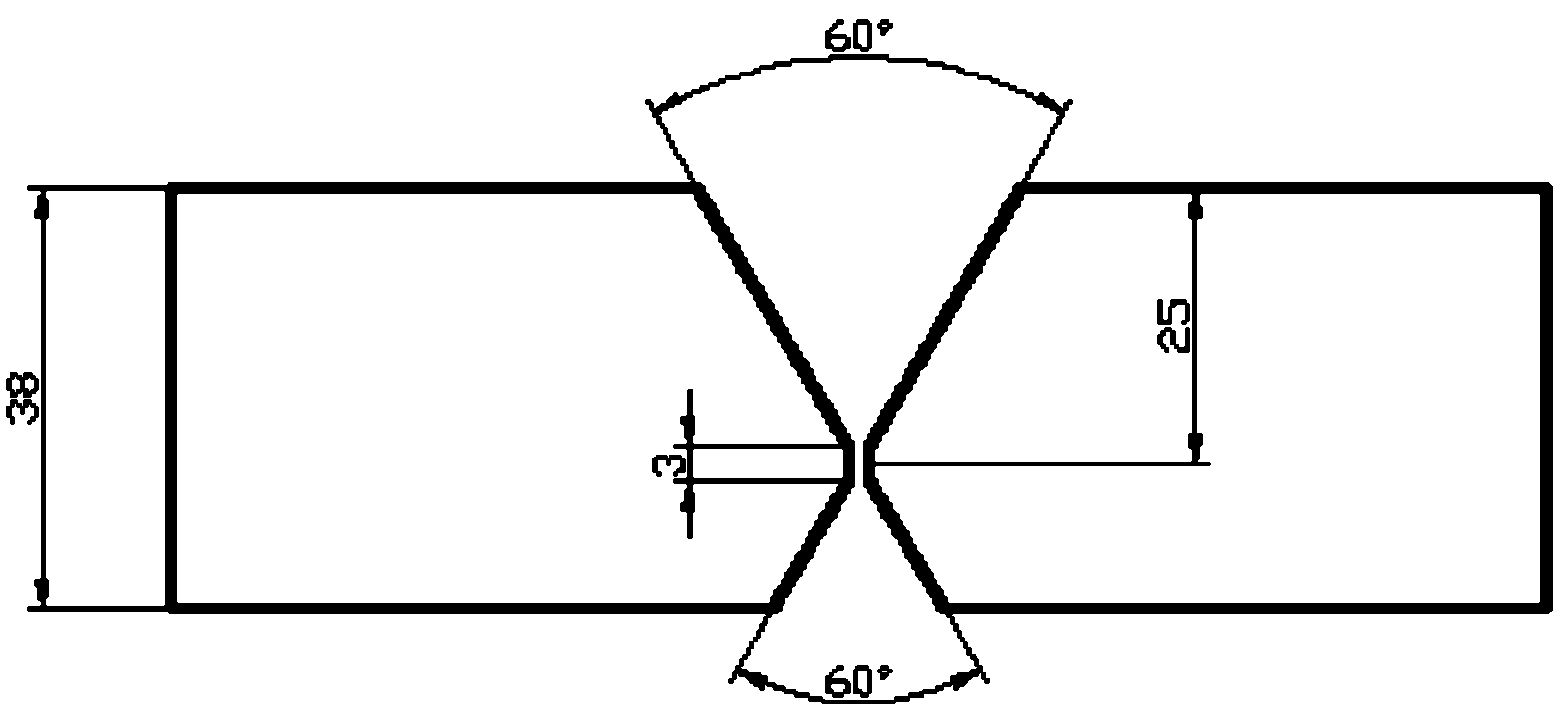

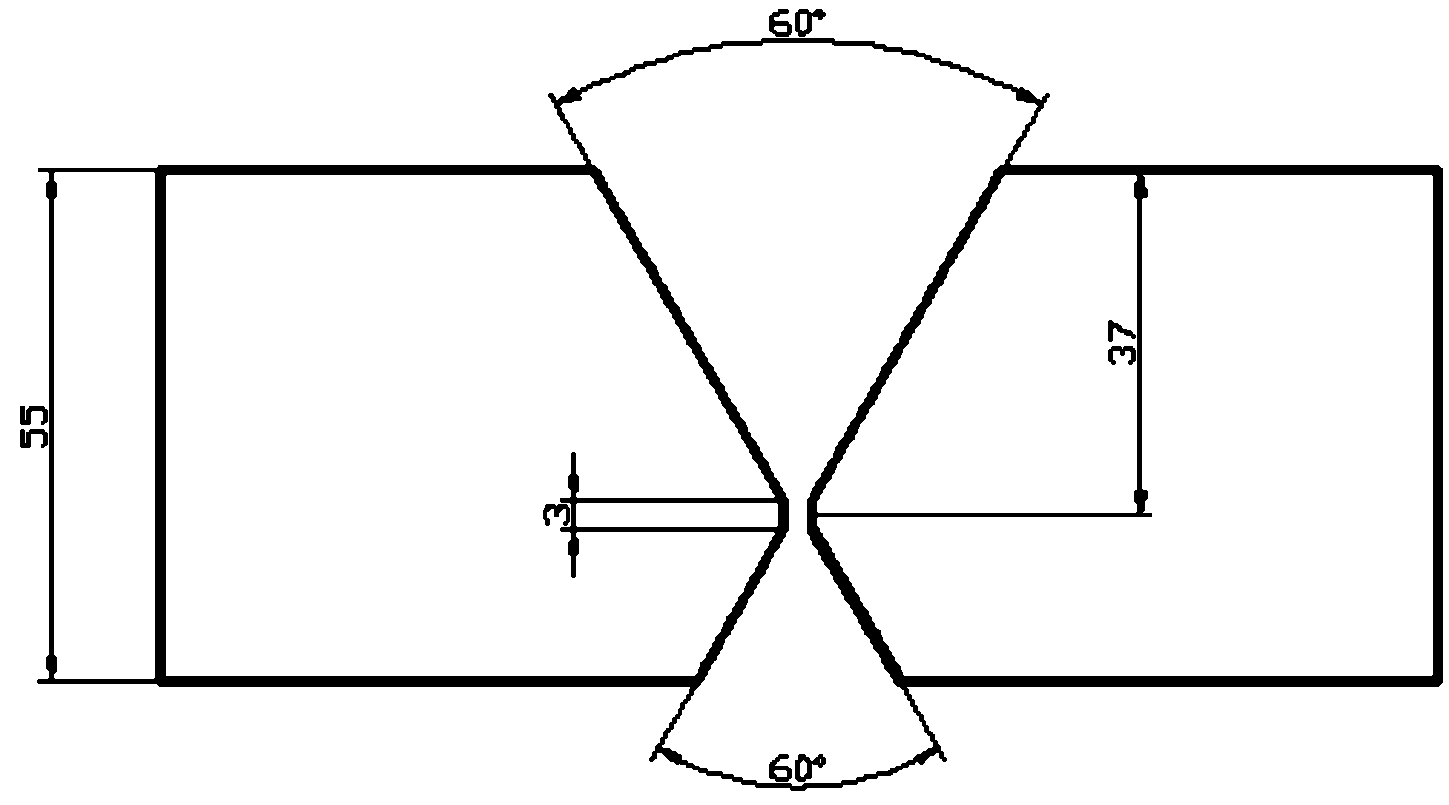

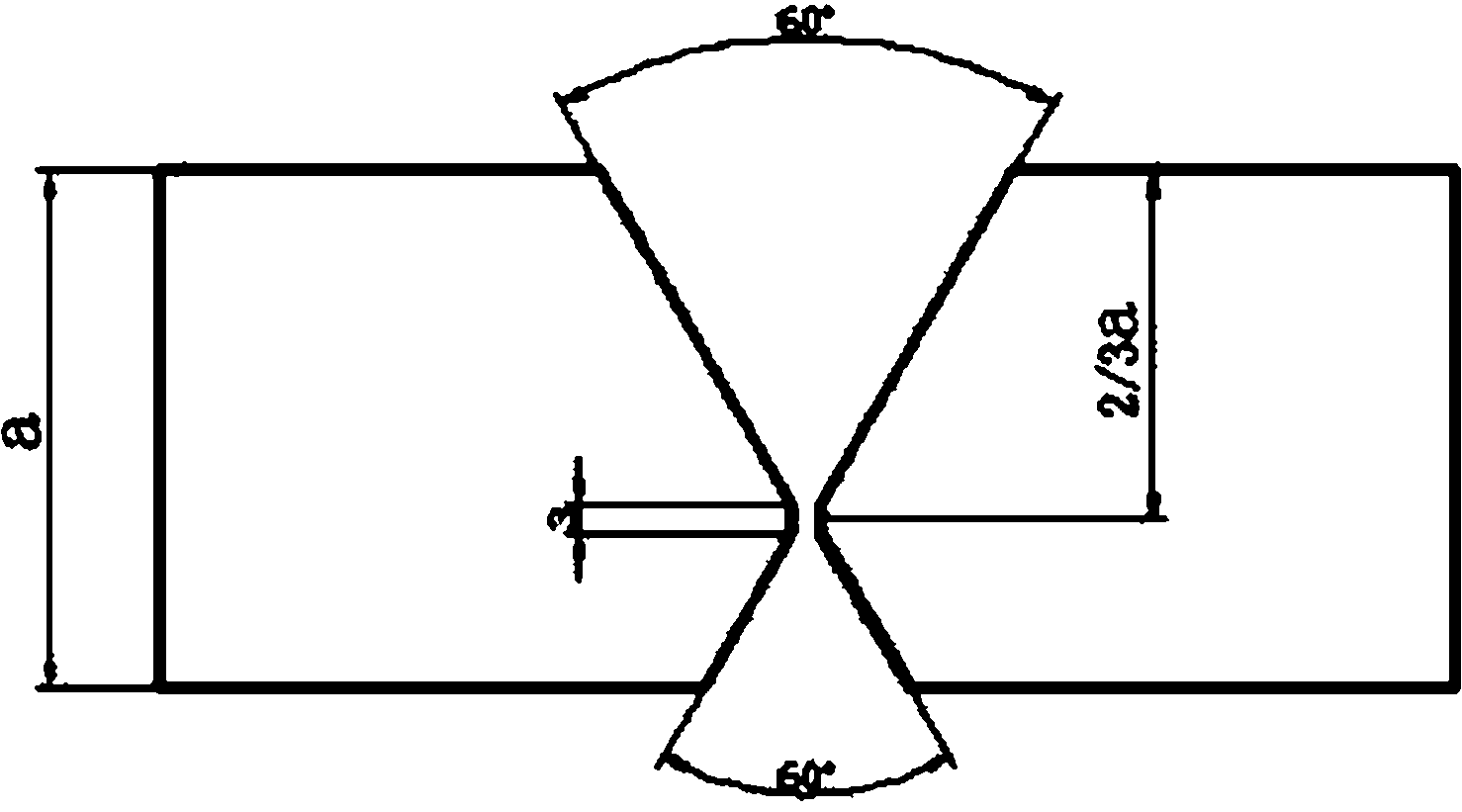

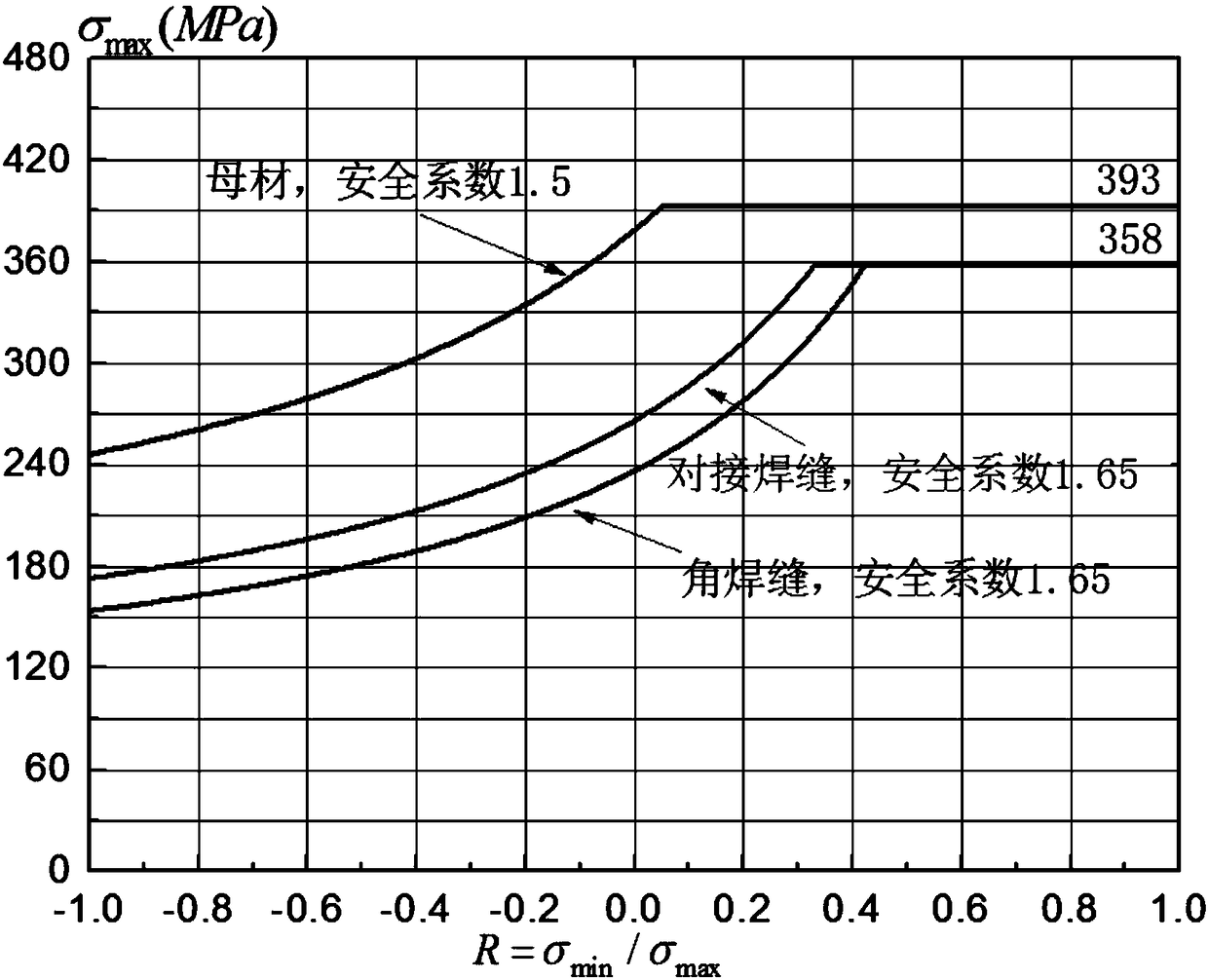

Welding method of high-strength steel for pressure steel pipe of 610MPa hydropower station

InactiveCN102101210AReduce the tendency to produceImprove toughnessArc welding apparatusAluminum silicateStress relief

The invention relates to a welding method of high-strength steel for a pressure steel pipe of a 610MPa hydropower station, belonging to the technical field of steel pipe welding. In the method, a constant-strength low-hydrogen electric welding rod is used for priming, and a constant-strength matched welding rod is adopted to continuously weld and fill a weld pass by adopting a submerged-arc welding method, wherein the welding line energy is strictly controlled to be about 30-40kJ / cm, and the interpass temperature is controlled to be 100-150 DEG C; and after welding, an aluminum silicate plate is used for covering a welding joint for slow cooling so as to realize the welding of a steel plate for a steel pipe for a 610MPa hydropower station without preheating before welding and heat treatment after welding. The method solves the problems that the traditional steel for the pressure steel pipes of the 610MPa hydropower station needs to be preheated before welding and subjected to stress relief heat treatment after welding, and the welding efficiency is low.

Owner:SHOUGANG CORPORATION

Construction method for large scale high-performance cement concrete road panel

InactiveCN1521362AMeet the design and use requirementsImprove flatnessIn situ pavingsRelative humidityForeign matter

The construction method of large size cement concrete road slab includes connecting formwork without crack in the joints, using blended concrete material with fiber, water reducing agent or swelling agent, completing spreading, vibrating and other steps at 5-38 deg.c within 60-120 min after the concrete material is discharged from the stirrer, spreading in wind speed less than 2 m / s and relative humidity higher than 60 %, adopting twice vibrating, face work for 3-4 times, twice crack cutting, and spraying film and adding protecting layer for curing after surface grain treatment. The said construction method can ensure the road quality, reduce side cracks between slabs, reduce the damage of road slabs caused by foreign matter and water, lower the road maintaining cost and prolong the service life of road.

Owner:CHINA AIRPORT CONSTR 2ND GENERAL TEAM

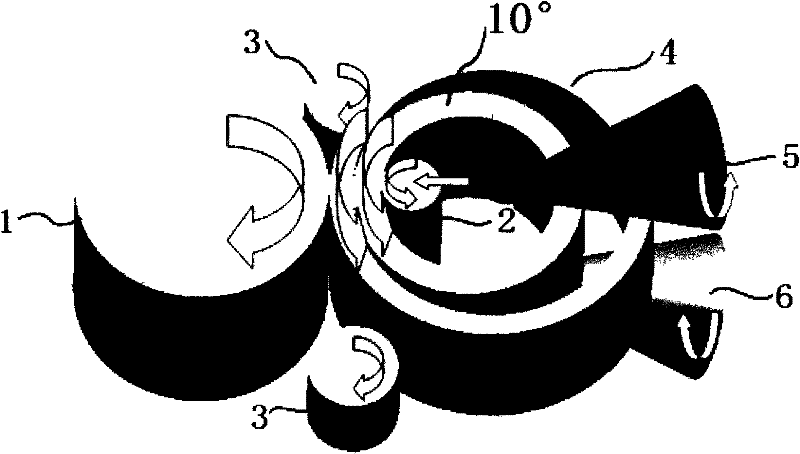

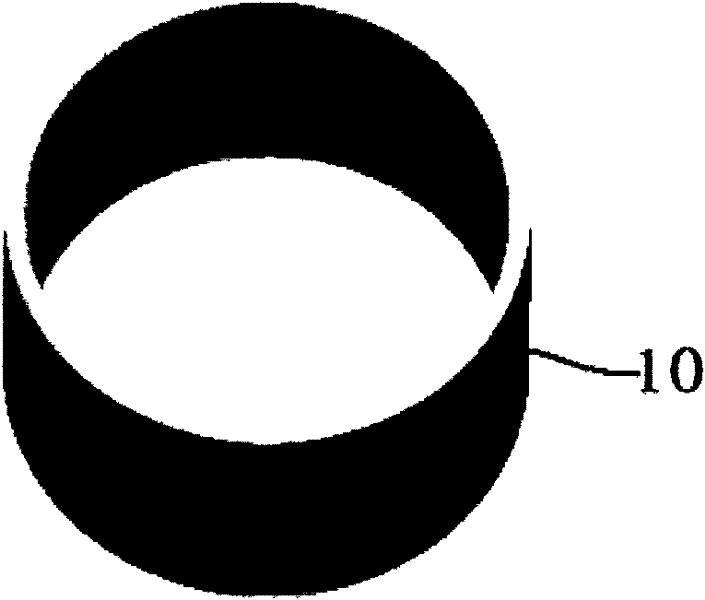

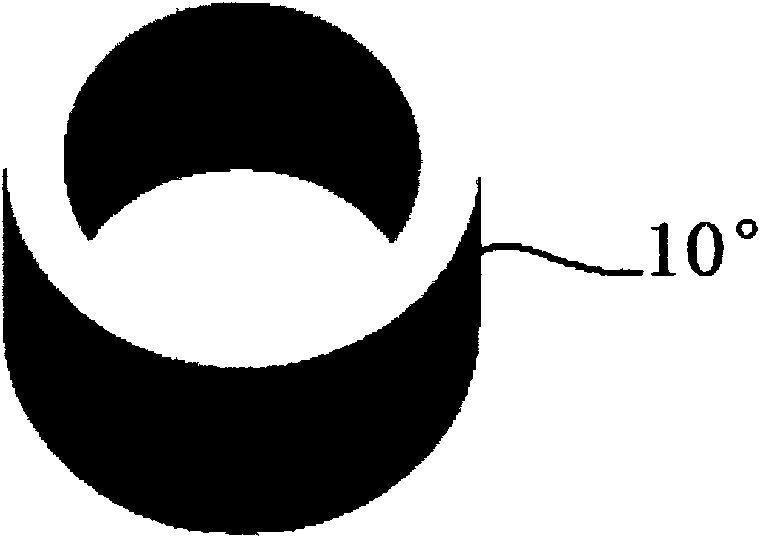

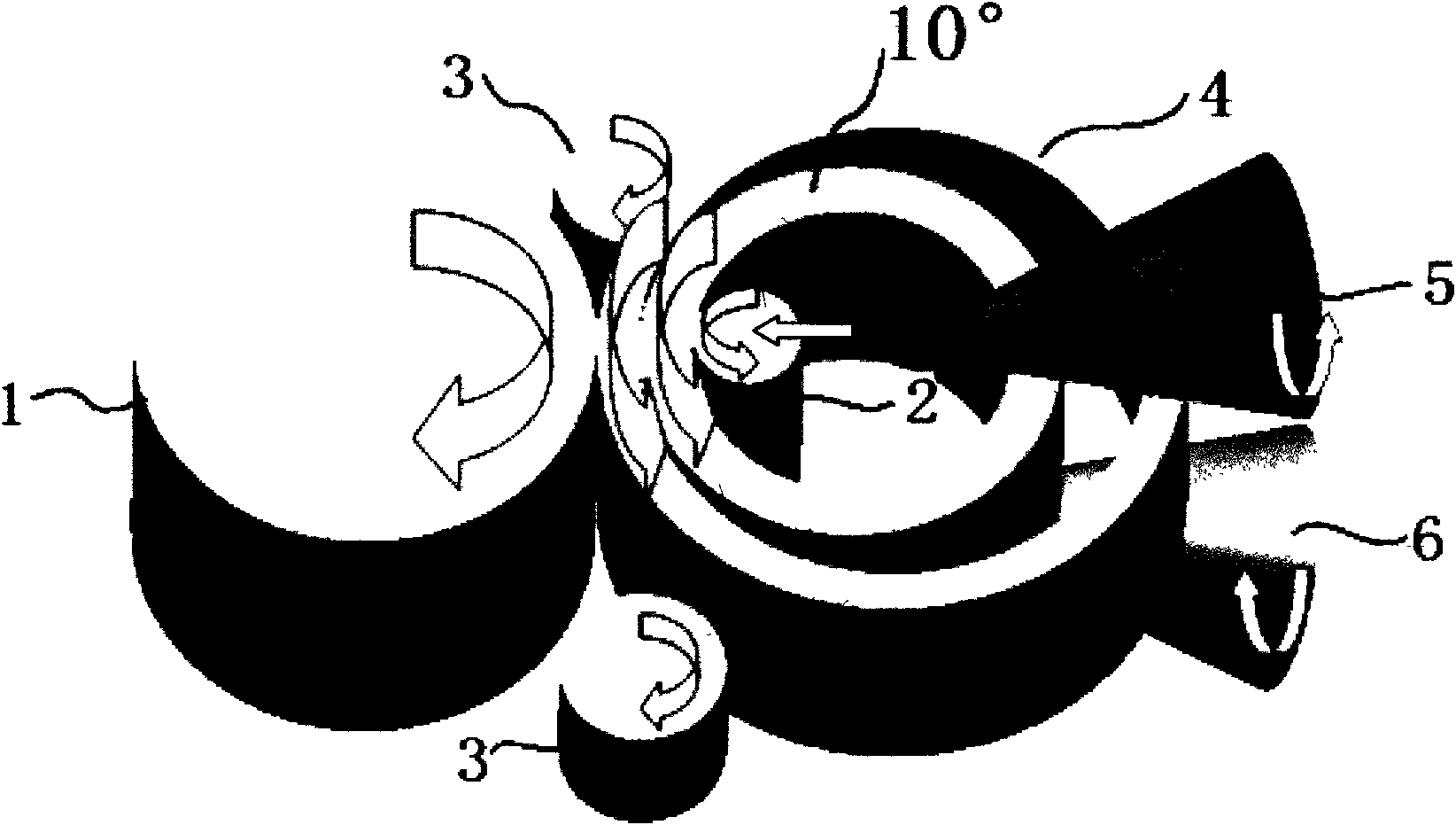

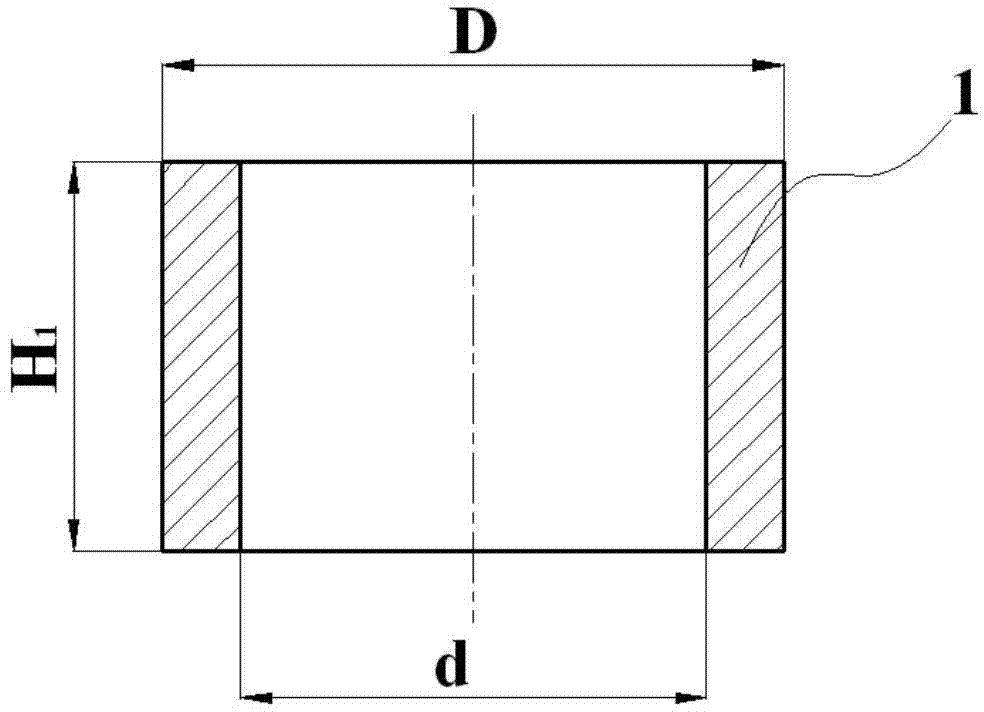

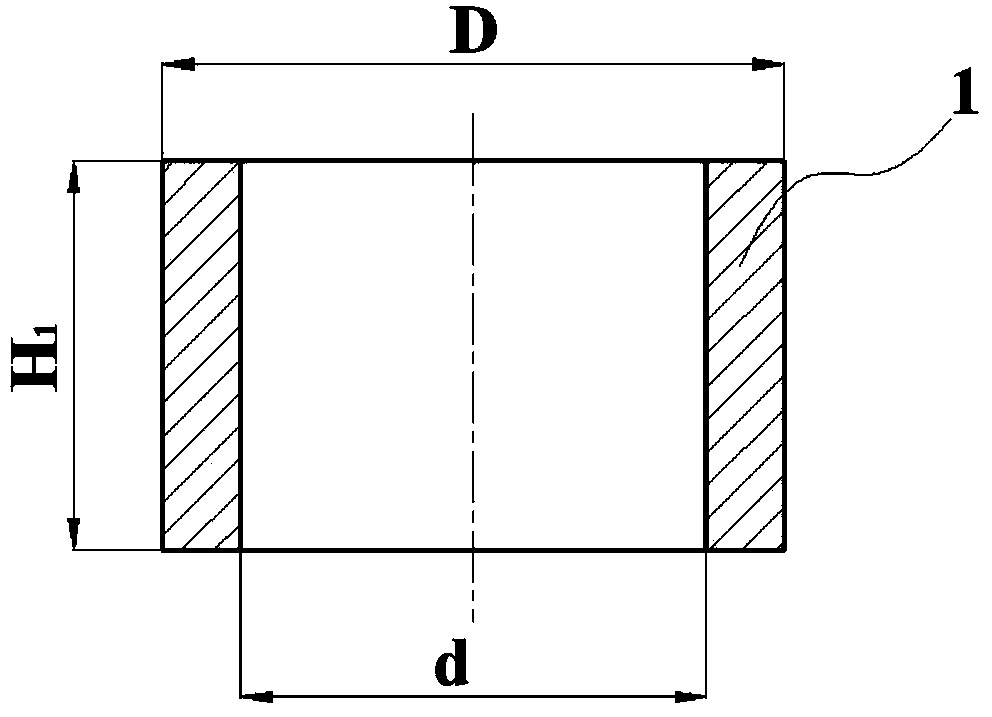

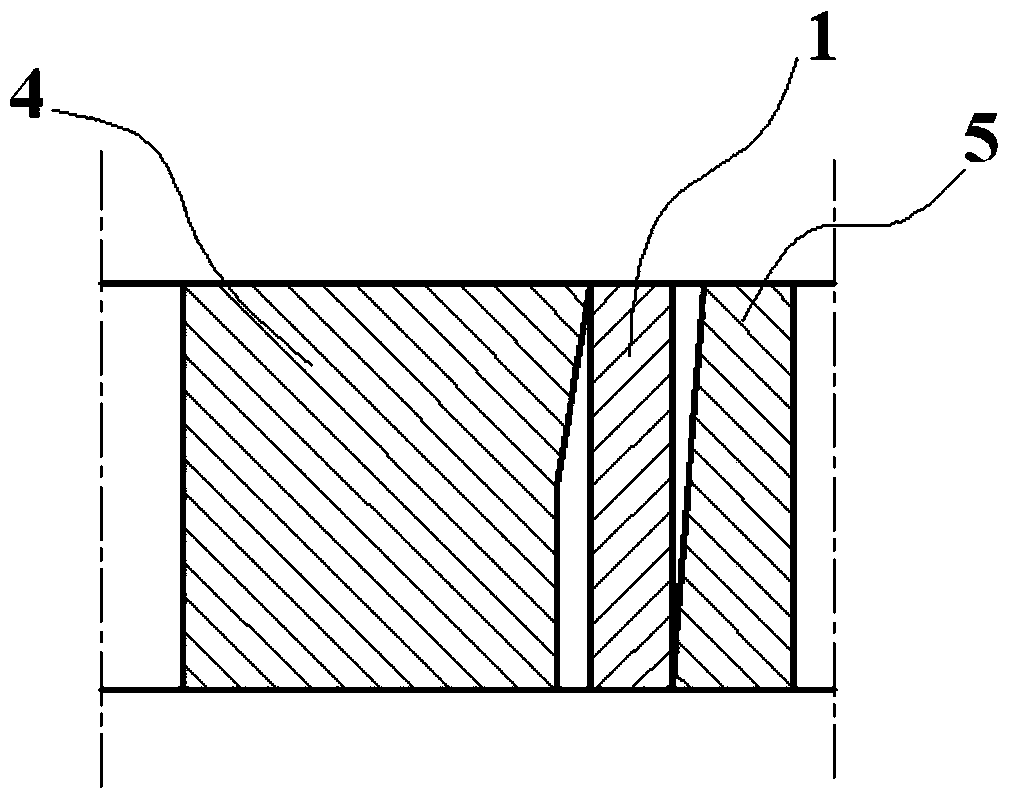

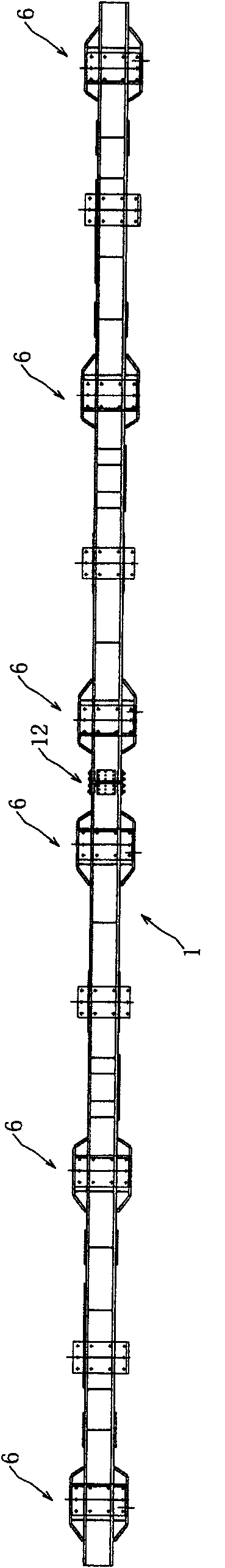

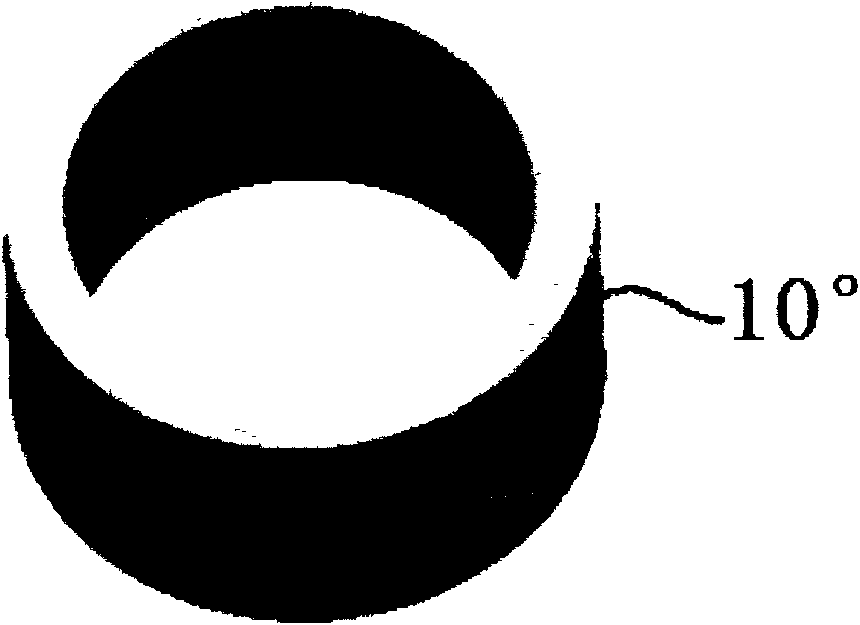

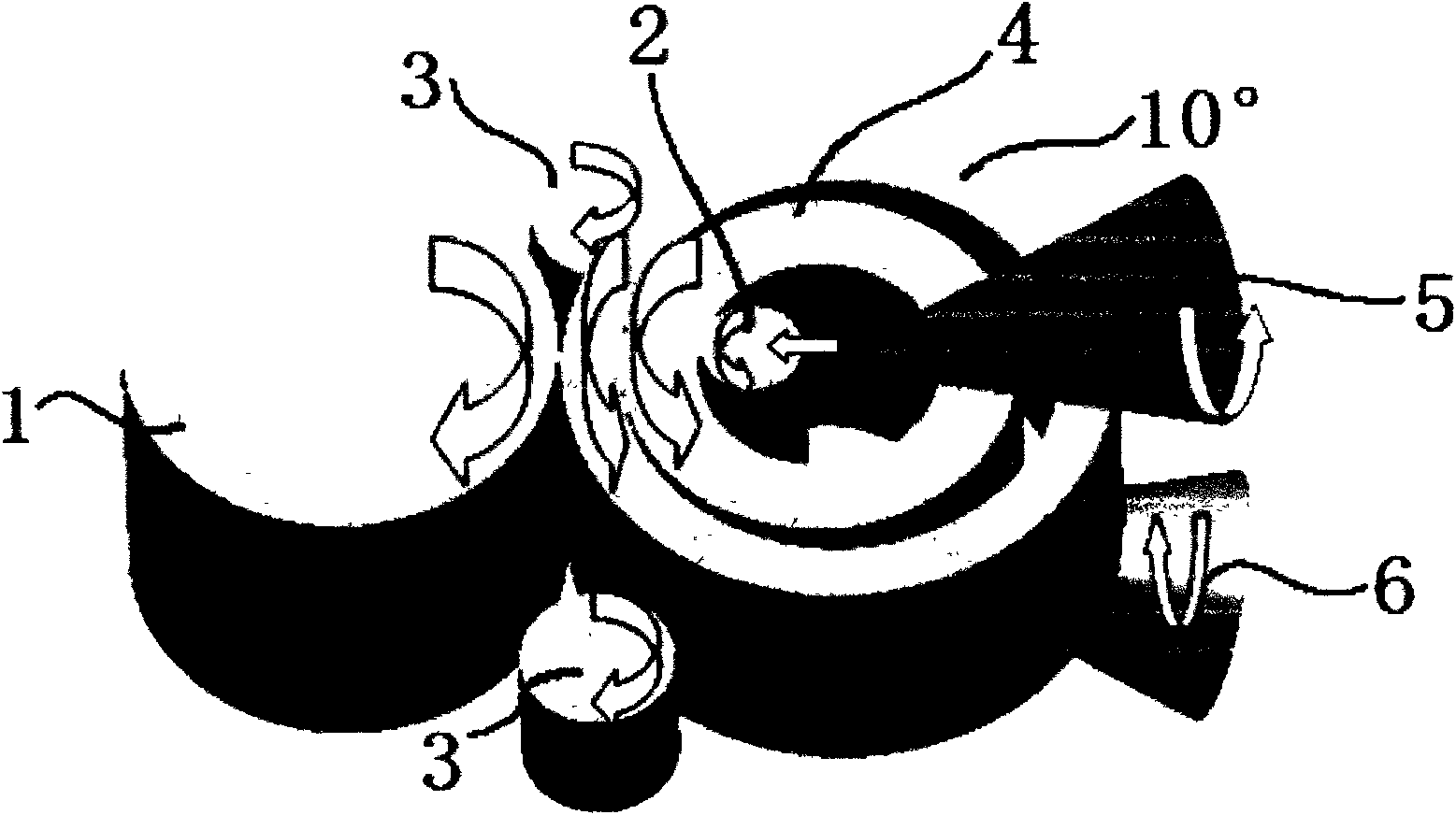

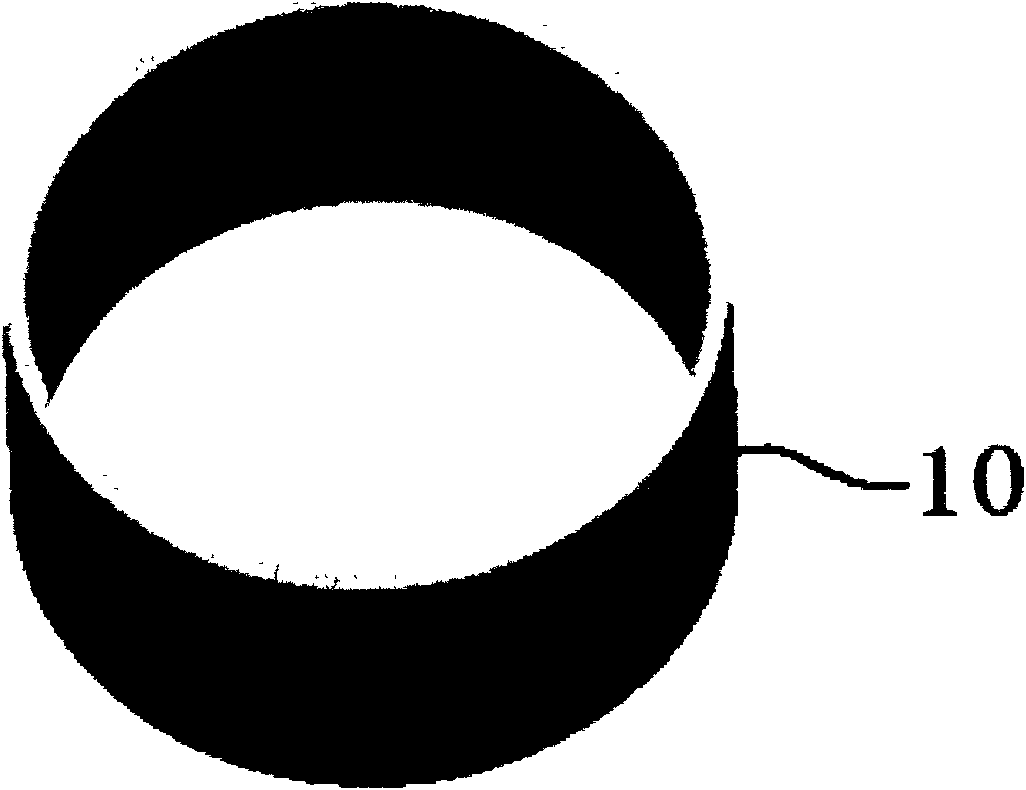

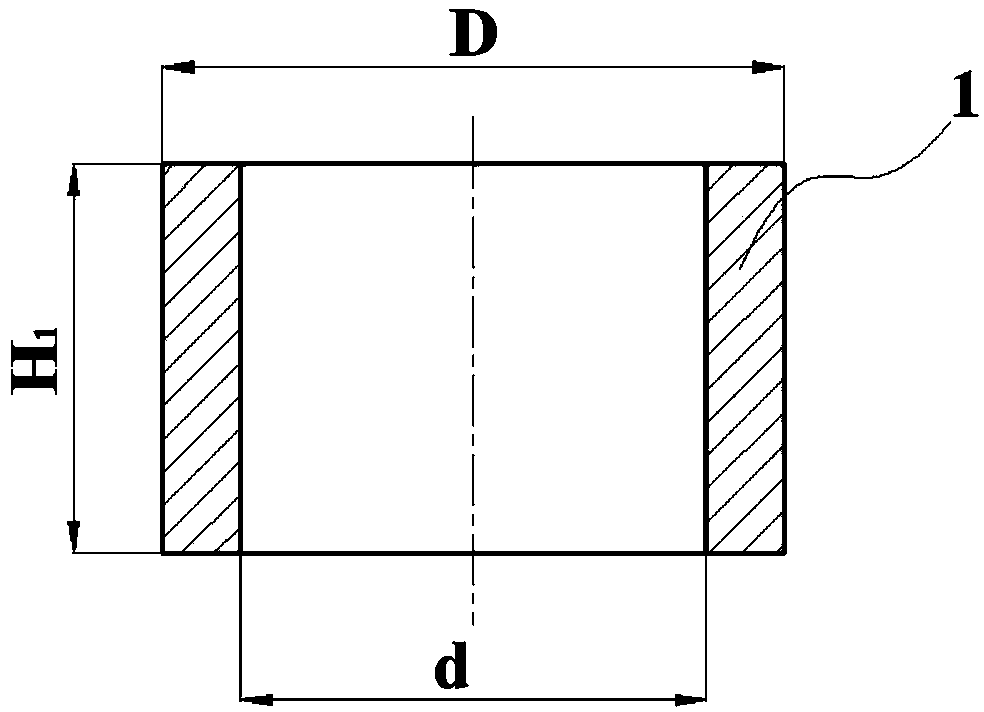

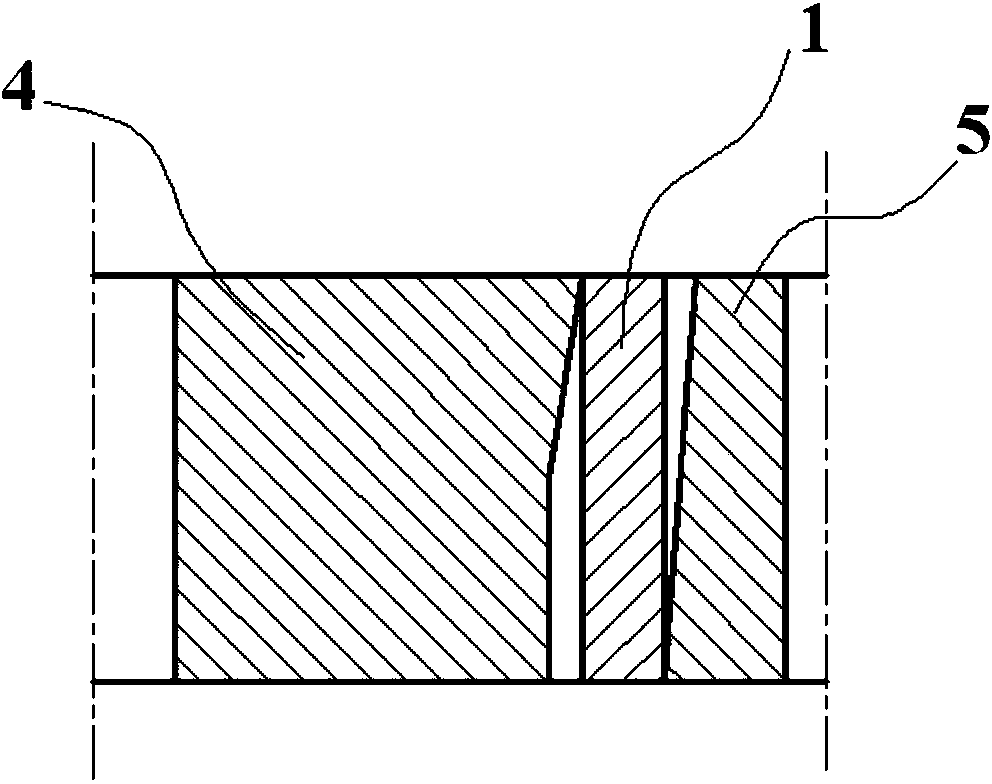

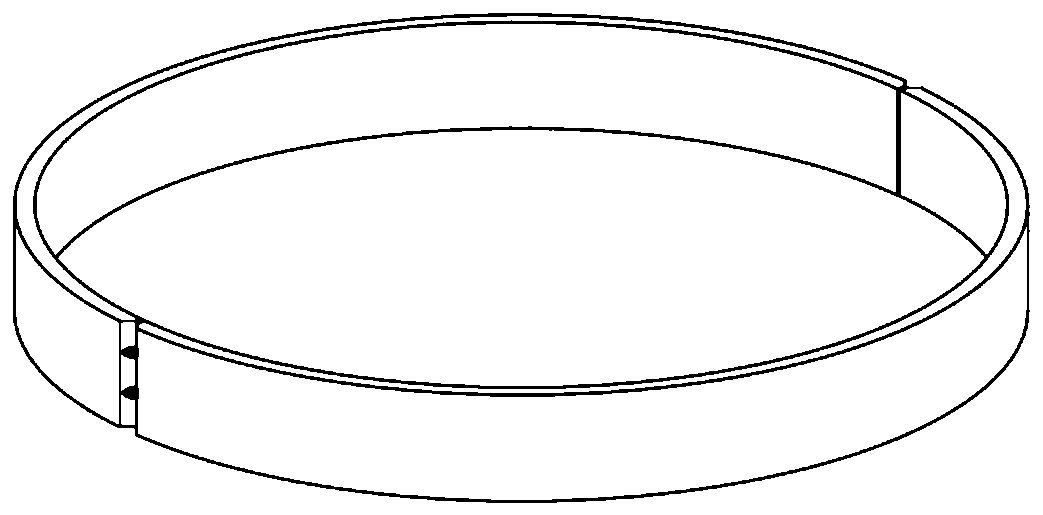

Method for rolling and shaping structural steel high cylindrical ring forged piece

The invention discloses a method for rolling and shaping a structural steel high cylindrical ring forged piece. The method is used for rolling and shaping the high cylindrical ring with thin wall and excellent texture and performances. The technical scheme is as follows: firstly sheathing a preheated follow-up die sleeve and a structural steel pre-rolled billet which is heated to the deformation temperature into a ring rolling mill, and positioning two workpieces through a main roller, a core roller, holding rollers, an upper conical roller and a lower conical roller of the ring rolling mill; and further starting the ring rolling mill, enabling the core roller to do feed motion to the main roller along the radial direction, rolling the pre-rolled billet in the follow-up die sleeve by 180KN-3800KN rolling force together with the main roller, enabling the pre-rolled billet to expand the width along the radial direction at the speed of 6mm / s-15mm / s and gradually reduce the wall thickness, and rolling the pre-rolled billet into the high cylindrical ring forged piece after the deformation amount achieves 30%-50%, wherein the upper and the lower conical rollers and the two holding rollers can be prevented from moving outwards along with the radial width expansion of the pre-rolled billet during rolling. The minimum value of the wall thickness of the structural steel high cylindrical ring forged piece which is rolled and shaped by adopting the method is 25mm, the maximum value of the height-thickness ratio is 25mm, and the forged piece is mainly used for cylindrical housings and other rotary parts used in the fields of aviation, spaceflight and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Rolling and forming method of cobalt-base superalloy high cylindrical ring forging

The invention discloses a rolling and forming method of a cobalt-base superalloy high cylindrical ring forging, which is used for rolling and forming the high cylindrical ring forging with thin wall and excellent texture and performance. The technical scheme of the rolling and forming method is as follows: putting a preheated follow-up die sleeve and a pre-rolled titanium alloy blank which is heated at deformation temperature into a ring rolling mill; positioning two workpieces by the main roller, the core roller, the snubber rollers, the upper cone roller and the lower cone roller of a ring rolling mill; then, starting the ring rolling mill; carrying out feed movement on the core roller of the ring rolling mill toward the main roller along with the radial direction; rolling a pre-rolled blank in the follow-up die sleeve at the rolling force of 420-4600KN by the core roller and the main roller to cause the pre-rolled blank to widen at the speed of 2-10mm / s along with the radial direction; and when wall thickness is gradually reduced and after the deformation amount of the re-rolled blank is 20-40%, rolling the re-rolled blank into the high cylindrical ring forging, wherein an upper cone roller, a lower cone roller and two snubber rollers do not move outwards along with the radial widening direction of the pre-rolled blank. The minimum wall thickness of the titanium alloy high cylindrical ring forging rolled and formed by the method is 25mm, and the maximum height to thickness ratio is 25mm. The cobalt-base superalloy high cylindrical ring forging is mainly used for revolved body parts, such as cylinders and the like used in the fields of aerospace and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for rolling rectangular structural steel ring blank to form irregularly-shaped thin-walled ring part

The invention discloses a method for rolling a rectangular structural steel ring blank to form an irregularly-shaped thin-walled ring part. According to the rolling method, a reasonable core roller feeding mode is provided, and the rectangular structural steel ring blank is inversely designed according to the shape and the size of the irregularly-shaped thin-walled structural steel ring part to realize the rolling of the rectangular structural steel ring blank into the irregularly-shaped thin-walled ring part, so that a rolling process can be continuously and stably implemented; the rolling method is mainly used for the forming of the irregularly-shaped thin-walled structural steel ring part in the fields of aviation, aerospace, industrial machinery and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method of rolling titanium alloy rectangular ring blanks into special-shaped thin-walled rings

The invention discloses a method of rolling titanium alloy rectangular ring blanks into special-shaped thin-walled rings. A mandrel reasonable feeding manner is provided to achieve a continuous, stable rolling process; titanium alloy rectangular ring blanks are reversely designed according to the shape and size of titanium alloy special-shaped thin-walled rings; accordingly, the titanium alloy rectangular ring blanks are rolled into the special-shaped thin-walled rings. The method is mainly applied to forming the titanium alloy special-shaped thin-walled rings in the fields of aerospace, industrial machinery and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Bearing ball made of cermet

InactiveCN101187401AMeet the design and use requirementsImprove heat resistanceBearing componentsVolumetric Mass DensityTitanium carbide

A bearing ball is made from ceramet with following weight percentages of nickel powder 15-25%, molybdenum powder 5-15%, and titanium carbide nitride powder as the rest. The process of the bearing ball comprises mixer-granulating raw powders on a tumbling ball mill by using absolute ethyl alcohol as mixing agent, adopting 6:1of ball-to-powder weight ratio, mixing powders for 48h, and granulating 40 meshes by rubbing a sieve, and then pressed green compacts on a hydraulic press through adopting a steel die with green compact density of 2.5-3.0g / cm3, shaping on a cool isostatic press with 200MPa of isostatic cool pressing pressure for 2 min, sintering on an atmosphere pressure sintering furnace with 1400-1450 DEG C of sintering temperature for 1-1.5h, using 1.5-3 MPa of the atmosphere pressure. The bearing ball which is made from ceramet is significantly superior to the traditional bearing steel material under the conditions with high speed, high temperature and corrosion, and is obviously superior to silicon nitride ceramics material in regard to manufacturing and processing costs and difficulty respect, which has spreading application space in operating modes with high speed, high temperature, corrosion and the like.

Owner:LUOYANG BEARING SCI & TECH CO LTD

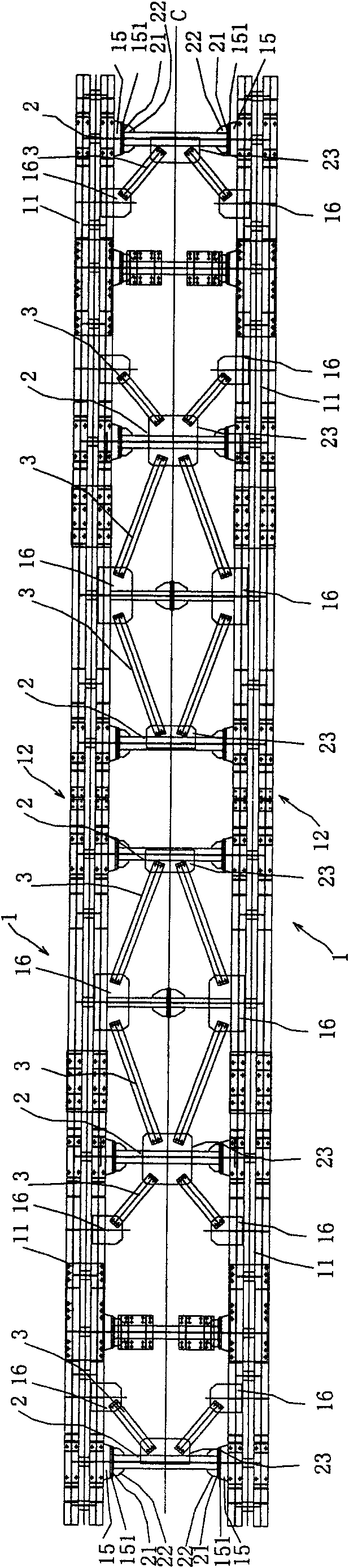

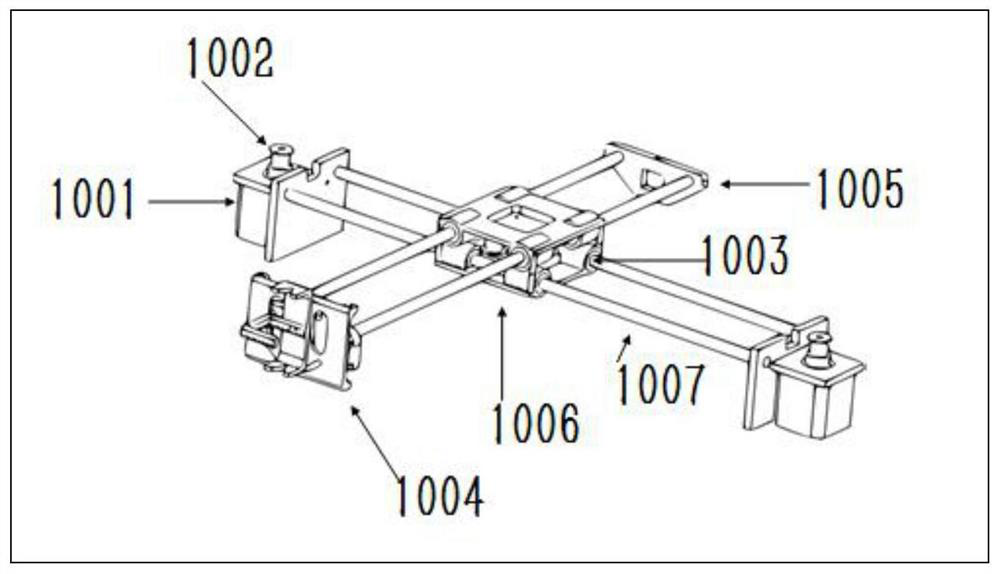

Assembly welding technology of lifting frame of heating furnace

InactiveCN102019511AGuaranteed lateral distanceGuaranteed vertical distanceWelding apparatusEngineeringStress relief

The invention discloses an assembly welding technology of the lifting frame of a heating furnace. The lifting frame of a heating furnace comprises two longitudinal beams, a plurality of crossbeams which are transversely connected between the two longitudinal beams, and a plurality of oblique beams which are connected between the crossbeams; the assembly welding technology comprises one step, two steps, three steps or four steps selected from the following four steps: A) uniformly assembling and marking the two longitudinal beams, welding them, and subjecting them to a vibration stress relief process after welding; B) reversely assembling the integral body, utilizing holes in rollers assembled on the longitudinal beams to determine the positions of the holes of roller fitting seats on the longitudinal beams, and satisfying each dimensional requirement after welding and assembling rollers; C) preassembling and grinding the crossbeams and oblique beams, to ensure the vertical dimension of the frame; D) processing holes on connecting positions by matching drilling manner. The invention ensures the overall dimensions of the whole frame to meet the design and use requirements, and improves production efficiency and product quality greatly, moreover, saves working hours and time of assembling and debugging.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

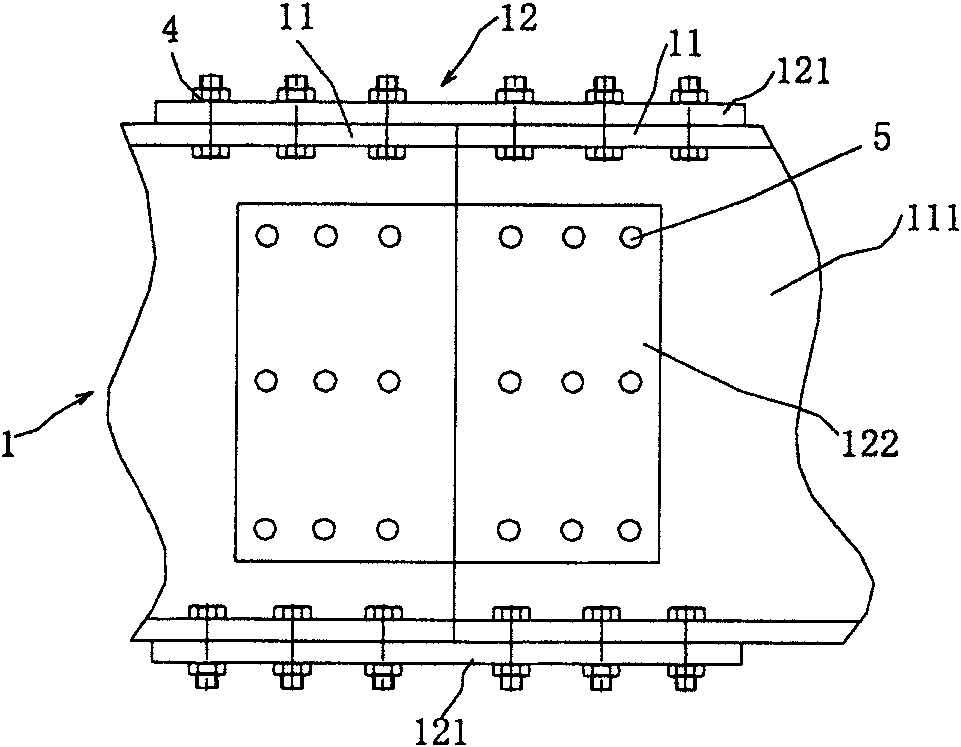

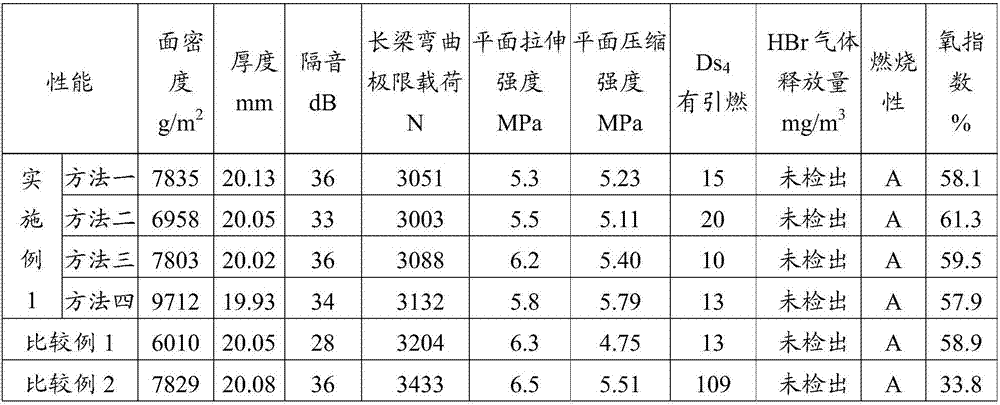

Flame-retardant composite material floor with sound isolating function and preparation method thereof

InactiveCN107984858ASimple structural designImprove matchSynthetic resin layered productsCarboxyl rubber adhesivesRubber materialNitrile rubber

The invention relates to a flame-retardant composite material floor with a sound isolating function and a preparation method thereof. The composite material floor comprises skin, a core material and adamping rubber layer, wherein the damping rubber layer is arranged between the skin and the core material and is separately connected to the skin and the core material in a bonding manner; the skin is prepared from a continuous fiber enhanced phenolic resin prepreg; the damping rubber layer is prepared from a polybasic damping rubber material by taking nitrile rubber as a base body; the core material is prepared from an aramid fiber paper honeycomb or a structural foam plastic. The composite material floor disclosed by the invention is simple in preparation process and good in economical benefit, and has the characteristics of being light in weight, load-bearing, environmental corrosion resistant, impact resistant and excellent in bending and compressing properties and the like. In particular, the sound isolating ability of the integral floor can reach up to 33dB which is remarkably higher than that of a conventional composite material floor. The composite material floor meets the demand on sound isolation and noise reduction in a traffic vehicle compartment, and the released smog and toxic gas are relatively low, and the flame-retardant composite material floor is excellent in flame retardance and can be fully popularized and applied to the field of rail traffic.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Roll forming method of GH4033 high-temperature alloy thin-wall ring piece

The invention discloses a roll forming method of a GH4033 high-temperature alloy thin-wall ring piece, wherein the thin-wall ring piece is roll-formed and has high size precision and excellent structure and performance. The technical is as follows: sleeving a titanium alloy pre-rolled blank which is heated to a deforming temperature and a pre-heated follow-up mould sleeve into a ring rolling mill; sleeving the follow-up mould sleeve in the pre-rolled blank; positioning the two workpieces by utilizing a main roller, a core roller, holding rollers and upper and lower conical rollers of the ring rolling mill; and starting the ring rolling mill, wherein the core roller of the ring rolling mill performs radial feed motion toward the main roller and rolls the pre-rolled blank together with the main roller under the support of the follow-up mould sleeve with a rolling force of 220-4,200 KN so that the pre-rolled blank is widened radially at a speed of 5-8 mm / s and the wall thickness is gradually reduced; and after the deformation of the pre-rolled blank reaches 25-45%, the pre-rolled blank is rolled into a thin-wall ring piece. The minimum of the wall thickness of the titanium alloy thin-wall ring piece roll-formed by the method is 25 mm, and the maximum of the height-thickness ratio is 25 mm; and the ring piece is mainly applied to the rotational parts such as a cylindrical shell and the like used in the fields of aerospace and the like..

Owner:GUIZHOU AVIATION TECHN DEV

Method for rolling rectangular die block steel ring blank into abnormal-shaped thin-wall ring member

InactiveCN103658168AGuaranteed final sizeSize qualifiedMetal rolling arrangementsRoll speed control deviceAviationAbnormal shapes

The invention discloses a method for rolling a rectangular die block steel ring blank into an abnormal-shaped thin-wall ring member. With the purpose of continuous and stable operation in a rolling process, a reasonable feeding type of a core roller is provided, the rectangular die block steel ring blank is designed according to the shape and the size of the abnormal-shaped thin-wall ring member in a backward reasoning mode, and therefore the rectangular die block steel ring blank is rolled into the abnormal-shaped thin-wall ring member. The method is mainly used for forming of the abnormal-shaped thin-wall ring member in the fields of aviation, aerospace, industrial machinery and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for rolling and forming TC11 titanium alloy thin-walled rings

The invention discloses a method for rolling and forming TC11 titanium alloy thin-walled rings, which is used for rolling and forming thin-walled rings with high size precision and good organization and performance. The method comprises the following steps: firstly, nesting a pre-rolled titanium alloy billet which is heated to a deformation temperature and a preheated follow-up die sleeve into a ring rolling mill, and positioning the two workpieces by a main roller, a core roller, a holding roller, an upper cone roller and a lower cone roller of the ring rolling mill, wherein the follow-up die sleeve is nested in the pre-rolled billet; and then, starting up the ring rolling mill to enable the core roller to make a feed motion radially towards the direction of the main roller and roll the pre-rolled billet together with the main roller by the rolling force of 200KN-4000KN under the support of the follow-up die sleeve, so that the width of the pre-rolled billet is expanded radially at a speed of 5-10mm / s, the wall thickness of the pre-rolled billet is gradually reduced, and after the deformation of the pre-rolled billet reaches 25%-45%, the pre-rolled billet is rolled into a thin-walled ring. The minimum value of the wall thickness of the titanium alloy thin-walled ring rolled by the method is 25 mm, and the maximum value of the height-to-thickness ratio thereof is 25 mm. The ring is mainly used for components of revolved bodies such as cylindrical shells and the like used in the fields of aviation and the like.

Owner:GUIZHOU AVIATION TECHN DEV

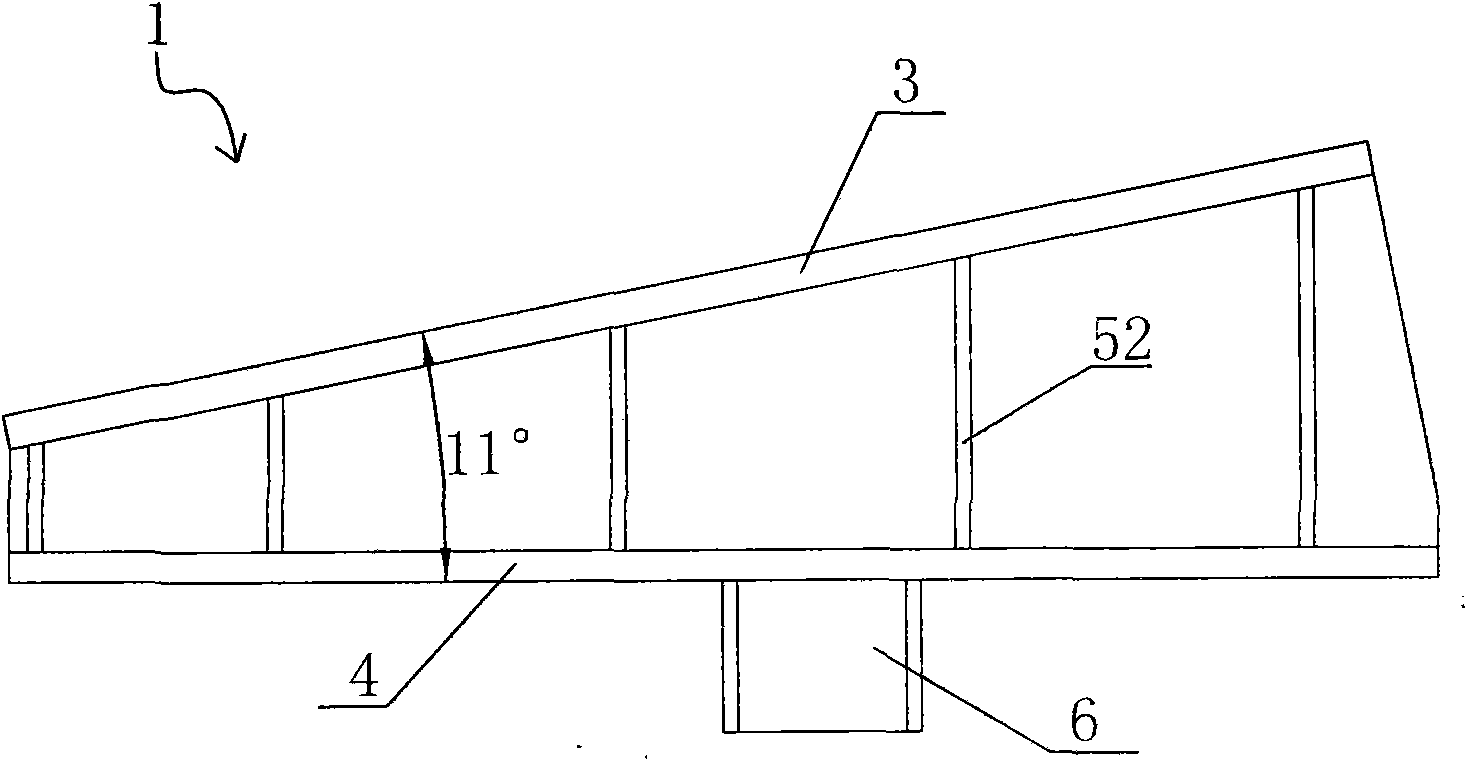

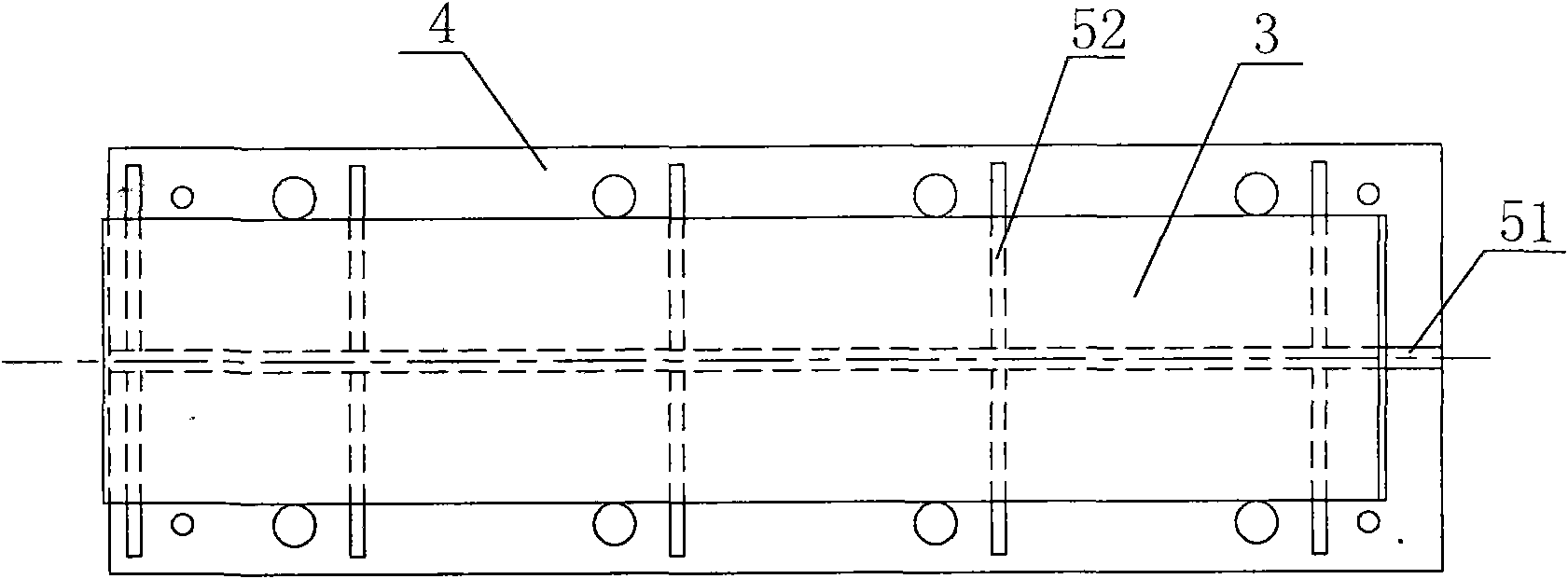

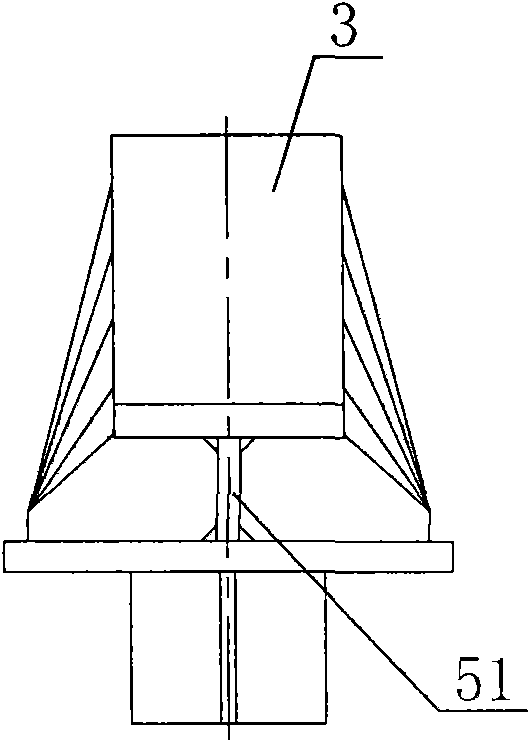

Assembling and welding process of inclined rail seat of stepping type heating furnace

InactiveCN101885146AReduce distortionSuitable for mass productionOther manufacturing equipments/toolsHeating furnaceWelding process

The invention discloses an assembling and welding process of an inclined rail seat of a stepping type heating furnace, which comprises the following steps of: manufacturing a plurality of inclined rail seats; identifying one of the inclined rail seats; after inclined rail seat is identified and qualified, identifying to be a standard inclined rail seat; processing other inclined rail seats by adopting the standard inclined rail seat as a tooling of other inclined rail seats; and drilling and mounting antiskidding ribs at the bottoms of all the inclined rail seats. The invention can overcome the defects of low size precision and low yield in relevant technology and improve the required accuracy of an angle of the inclined rail seat.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

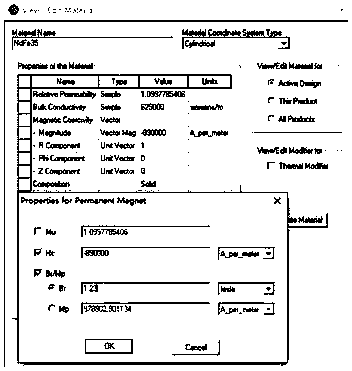

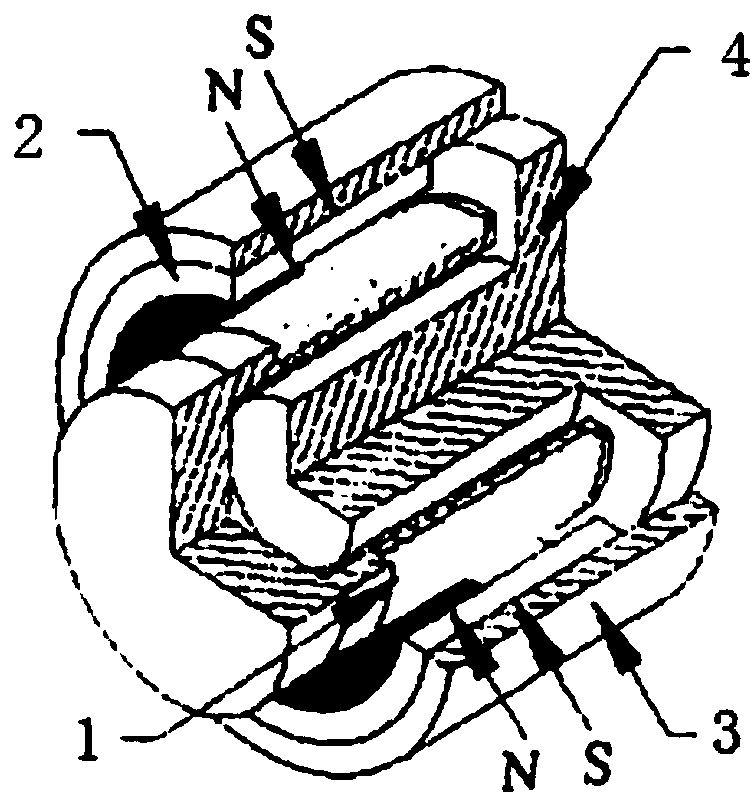

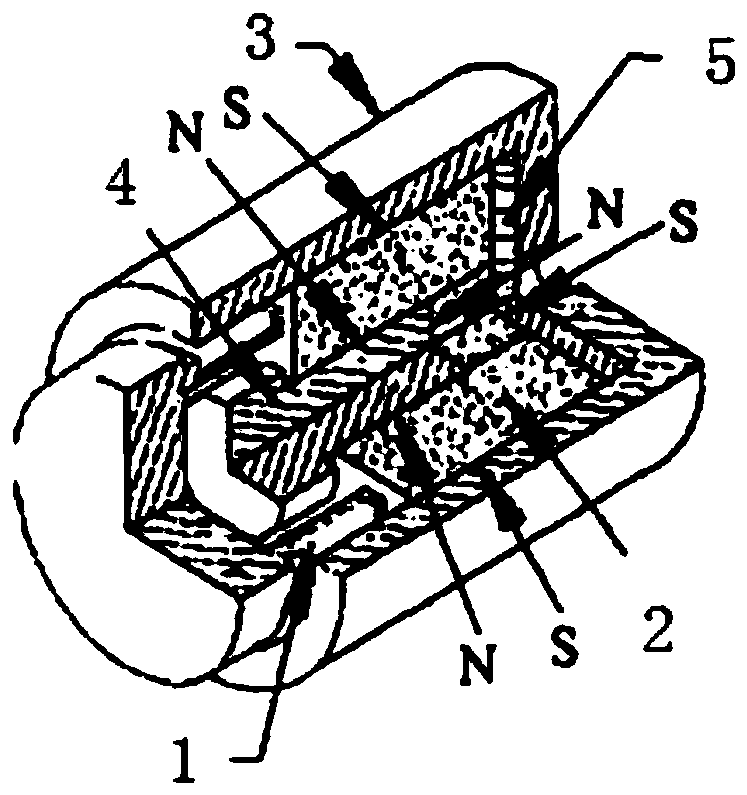

Voice coil motor used for large-aperture adaptive deformable mirror

InactiveCN108712055ASimple structureReduce volumePropulsion systemsOptical elementsMagnetic tension forceAstronomical telescopes

The invention provides a voice coil motor used for a large-aperture adaptive deformable mirror. A cylindrical coil is arranged. A tiny gap is formed between the top of the cylindrical coil and a magnet. A soft iron shell is arranged on the exteriors of the magnet and the central shaft. The voice coil motor is of a moving iron type structure and is characterized in that the cylindrical coil is installed in the soft iron shell at the bottom; the cylindrical coil and a mirror plane isolation permanent magnet are arranged in a position which is arranged in the axial direction of the cylindrical coil and are directly adhered to and fixed to the mirror plane of an astronomical telescope. According to the invention, the radial size and the occupied space of the voice coil motor are reduced; traditional hidden risks of short-circuit faults are eliminated; mover quality and movement inertia are reduced; effects on the mirror plane imposed by heating of the coil of the voice coil motor are overcome; through design of optimized magnetic fields, the voice coil motor has quite high motor efficiency; quite big pushing force can be achieved through high frequency small current; the electromagnetic force can reach 1N or over and reaches 0.6 N; the efficiency of the motor reaches 0.45N / W; and requirements of the large-aperture adaptive deformable mirror can be met.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

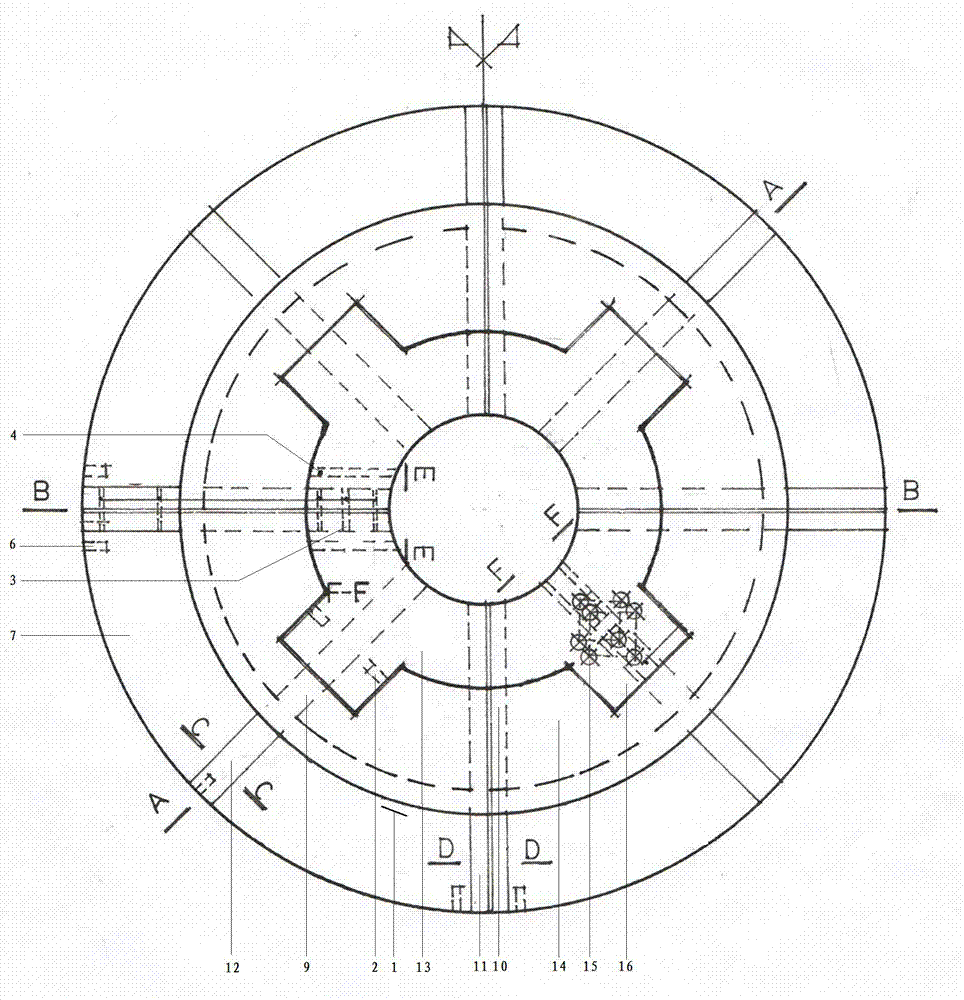

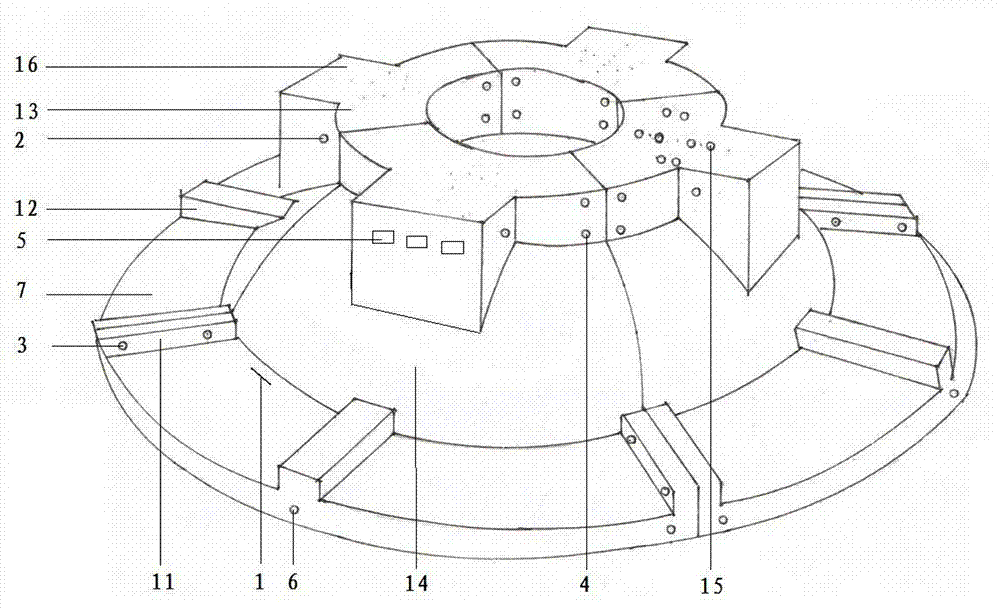

Fabricated tower footing

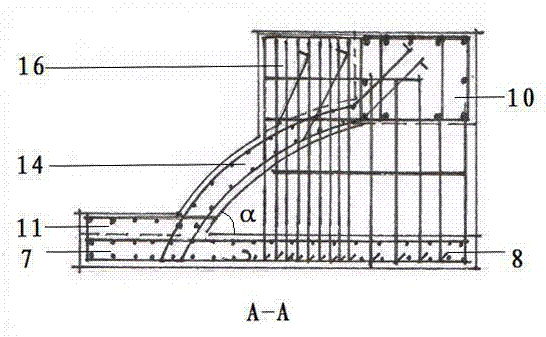

InactiveCN102900096AOverall stabilityLower center of gravityFoundation engineeringEngineeringAngle alpha

The invention discloses a fabricated tower footing which consists of a bottom foot plate which contacted with the ground, an arch shell and a pile cap ring beam arranged at the top. The arch shell is arch-shaped and the angle Alpha between the arch shell and the bottom foot plate is 45-75 degrees; the thickness of the arch shell is 150-200mm; and the bottom foot plate is annular. The entire tower footing is divided into four identical parts along the axial section, and when the tower footing is used, the four parts are fabricated in the shape of the arch shell to form an integral body. The tower footing is added with a counterweight equilibrium and stabilizing column foot according to design; and the tower footing can be dismantled, can be used repeatedly for multiple times, is strong in adaptability, simple to dismantle and assemble, resources are saved and waste is reduced.

Owner:刘绍国

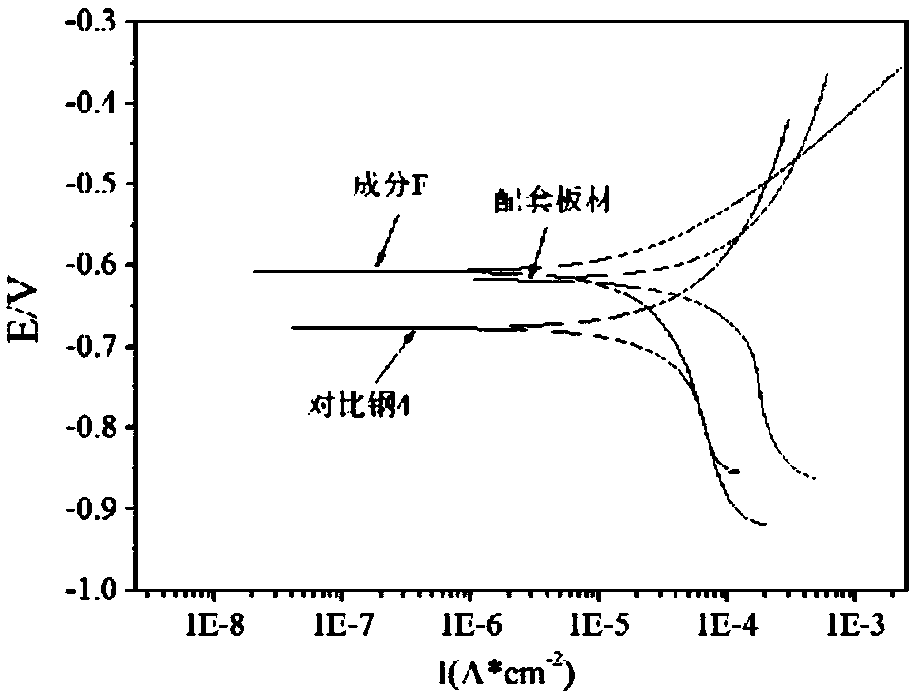

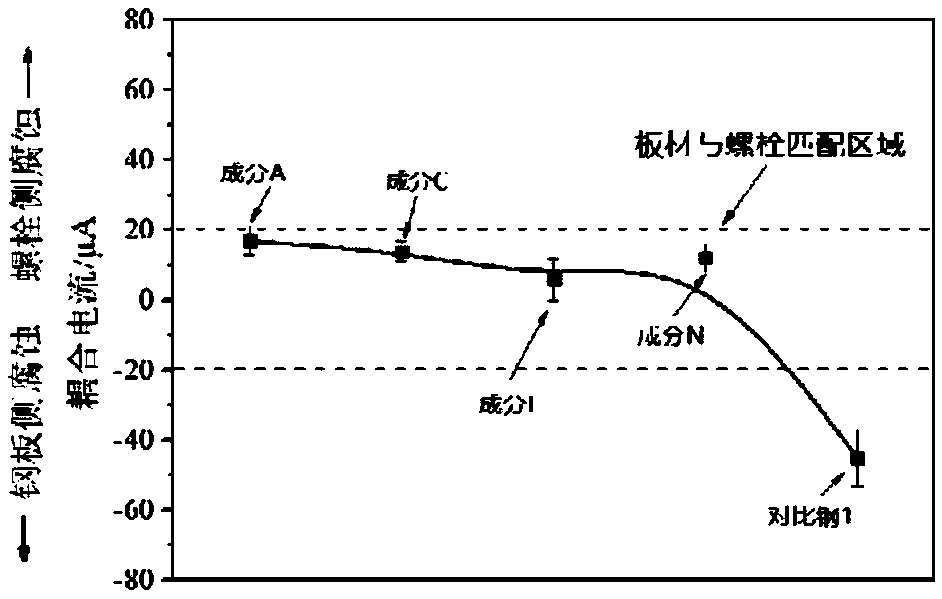

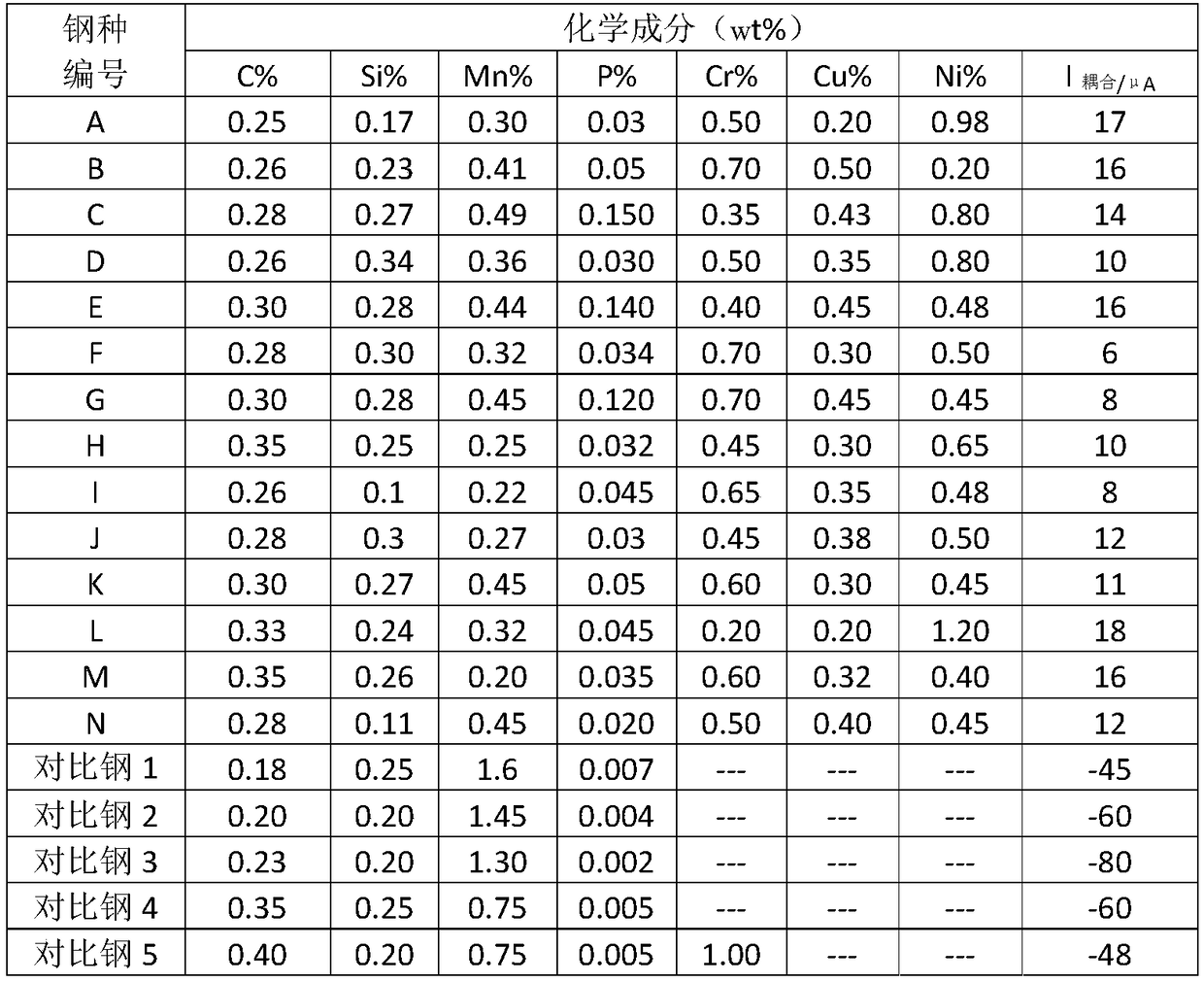

600Mpa level weather-proof bolting steel self-corrosion matching method for transmission tower

ActiveCN109234509AMeet the design and use requirementsAccelerated corrosionTransmission towerPower flow

The invention relates to a 600Mpa level weather-proof bolting steel self-corrosion matching method for a transmission tower, and belongs to the technical field of weather-proof bolting steel for a transmission tower frame. The method comprises the steps that firstly, high-strength bolting steel which meets the use requirements of the 600Mpa level transmission tower frame and has high atmosphere environment corrosion resistant and fire-resistant performance is selected, wherein the weight percent of Cr, Ni and Cu elements meets the formula that 1 / 2[Cr]+1 / 6[Ni]+1 / 3[Cu]+2 / 5[Cu].[Ni]-1 / 5[Cr].[Ni]-2 / 5[Cu].[Cr].[Ni] is greater than or equal to 0.45 but is smaller than or equal to 0.55; the self-corrosion coupling current of the produced high-strength screw bolt and matched angle iron is controlled to be within + / -20muA. The method has the advantages that the method is used for the matched connection use of a coating-free iron tower structure; excellent atmosphere corrosion performance and self-corrosion matching performance are realized.

Owner:SHOUGANG CORPORATION

Preparation method for high-boron stainless steel plate

ActiveCN106392077AOvercoming Manufacturing Technology BottlenecksImprove performanceBorideChemical composition

The present invention discloses a preparation method for a high-boron stainless steel plate. The preparation method comprises: powder encapsulation, namely loading a high-boron stainless steel alloy powder meeting the requirements on chemical components into a frame box, compacting by vibrating such that the box is full of the powder, and covering the box with a cover plate for welding encapsulation; free forging, namely placing the encapsulated frame box into a high-temperature furnace to undergo heating, warming, and temperature preservation, and then carrying out free forging to obtain a thick plate; hot rolling, namely placing the forged thick plate into the high-temperature furnace again to undergo heating, warming, and temperature preservation, and then carrying out hot rolling to obtain a thin plate of a desired thickness; and profile processing: subjecting the hot-rolled plate to frame removal, solid-solution treatment and straightening, thereby obtaining a finished plate with boride uniformly distributed in austenite and having a density of 97-99%T.D. The finished plate manufactured according to the preparation method for a high-boron stainless steel plate has the same excellent properties as a plate manufactured by means of a process in the prior art, but is lower in requirements on equipment and also lower in manufacturing cost.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

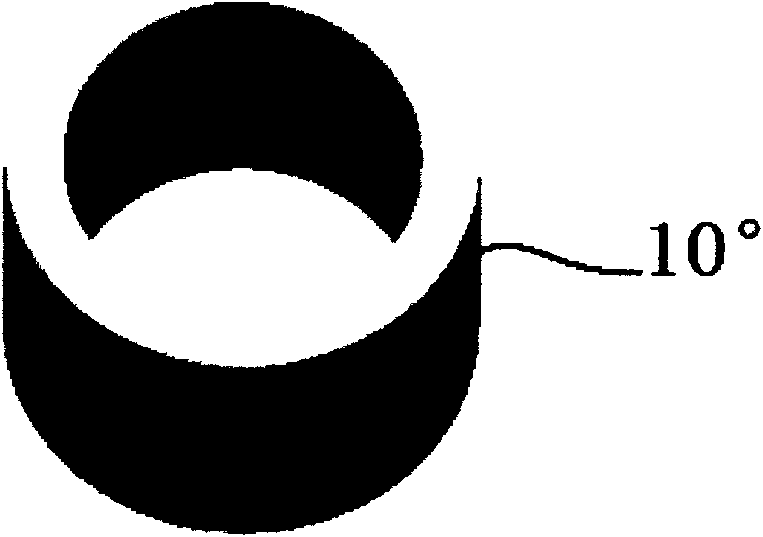

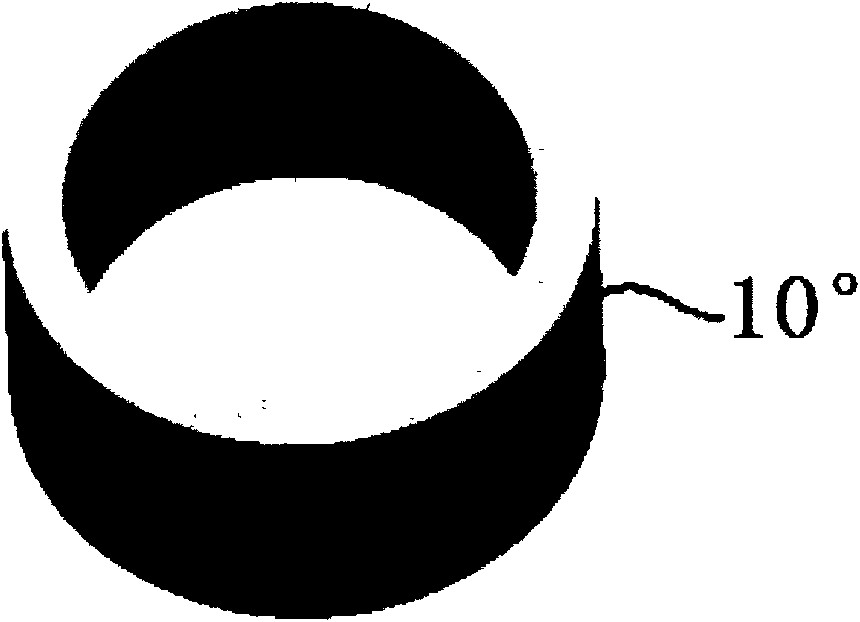

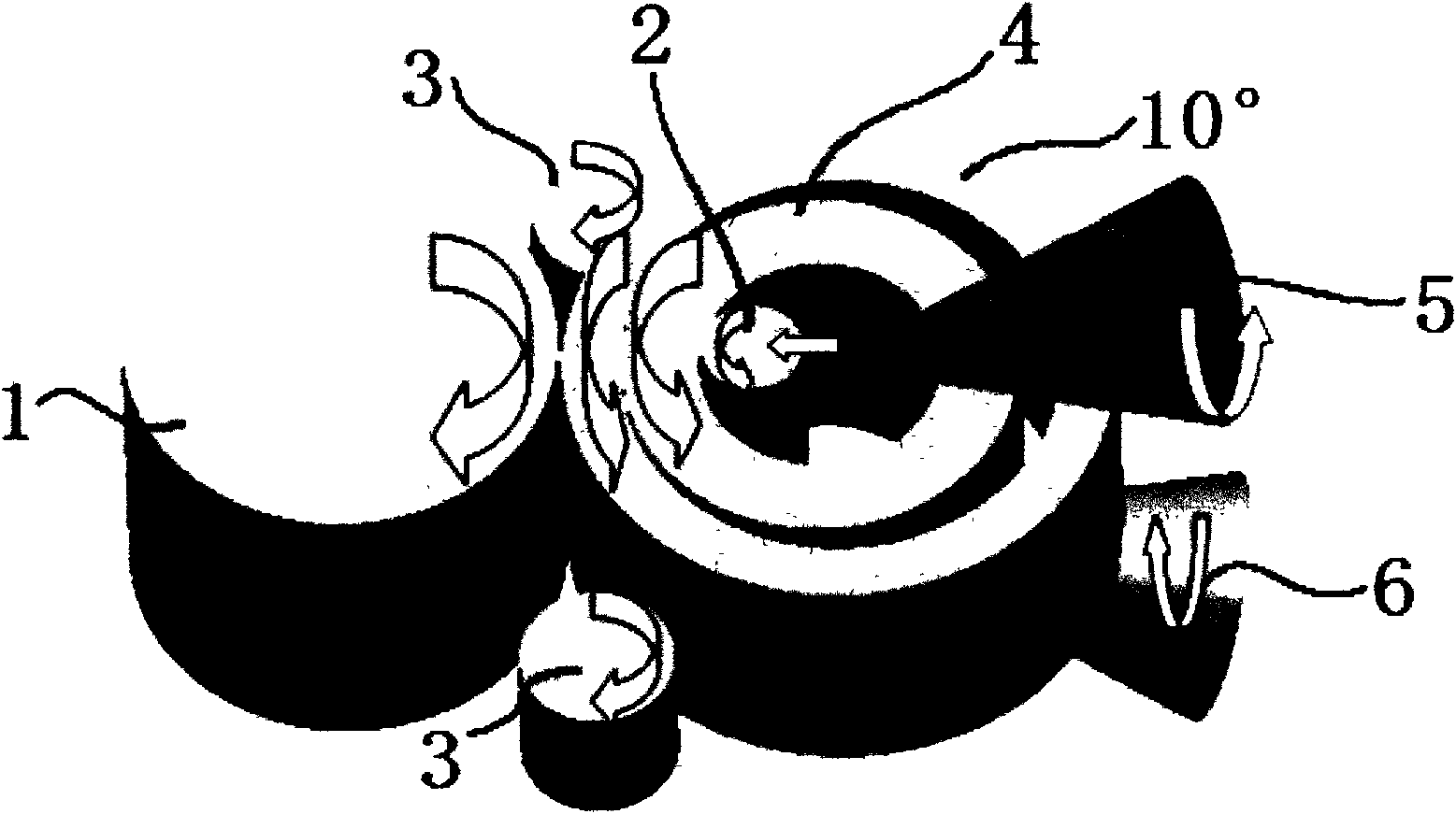

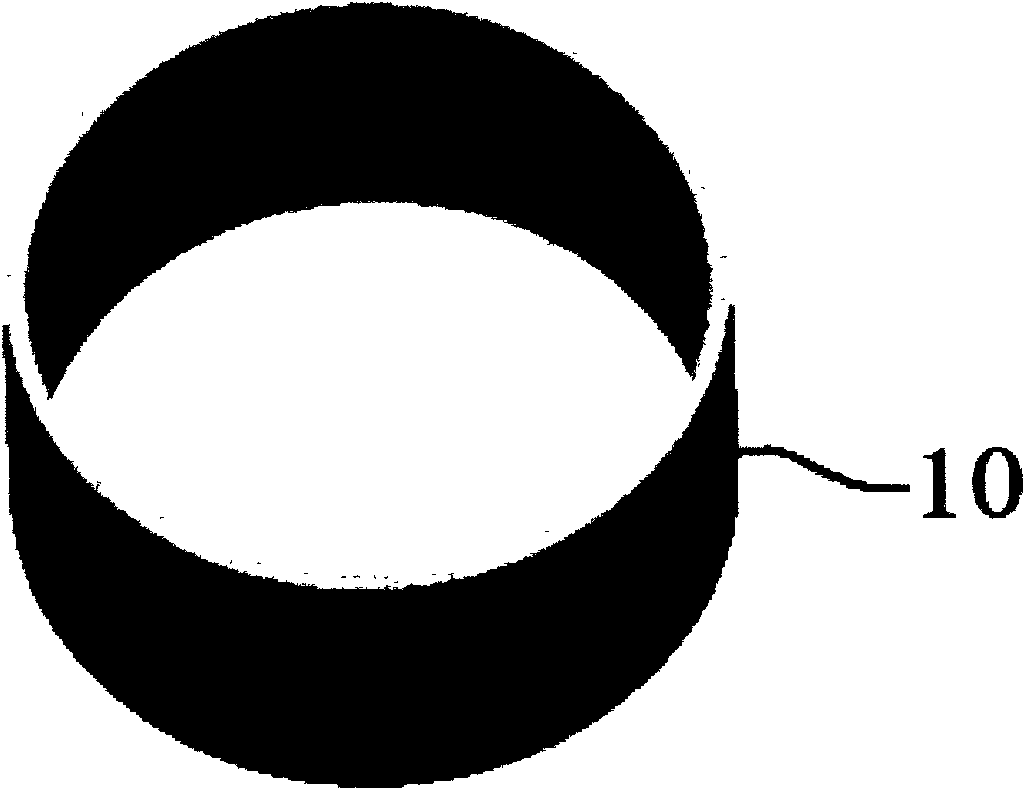

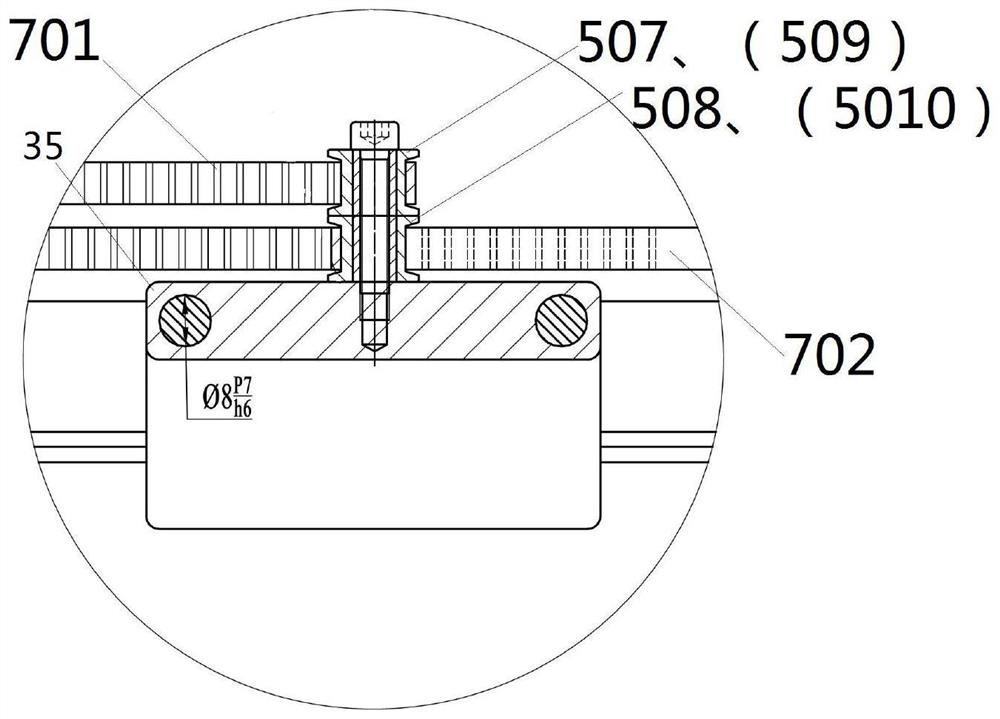

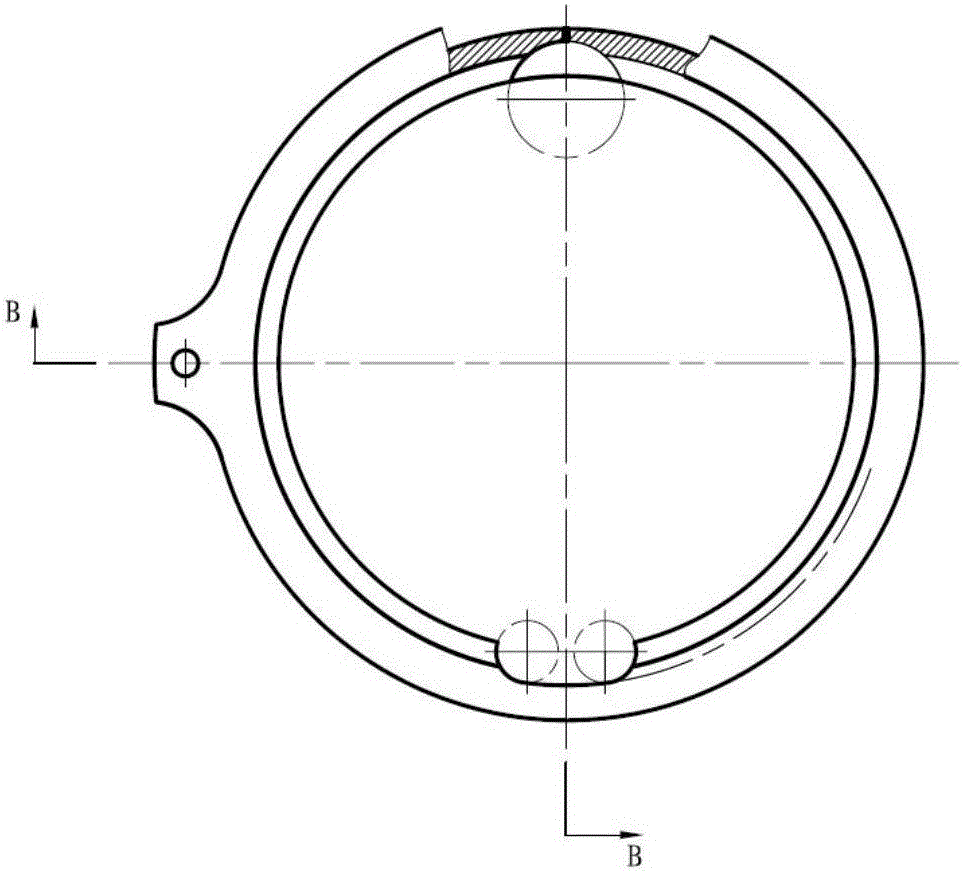

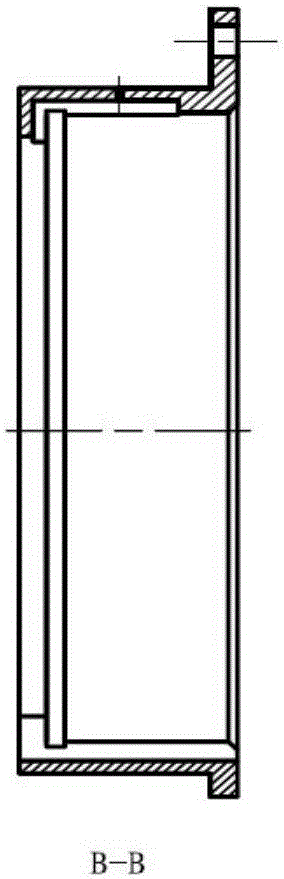

Snap ring machining process for asynchronous motor

InactiveCN110814653AGuaranteed accuracyMeet the design and use requirementsWire cuttingStructural engineering

The invention relates to a snap ring machining process for an asynchronous motor. Each semi-ring is made from stainless steel, the inner hole diameter is Phi341.6D8(+0.21 / +0.299), the wall thickness is 7mm, the width dimension is 40, the semi-ring and a snap ring groove are subjected to matching machining, and the gap is 0.03-0.09mm. When a method of halving after finish machining rounding is completed is adopted, the dimensions of the halved semi-rings are changed due to stress change, so that the halved semi-rings cannot meet the use requirements; in the machining method, rough machining iscarried out at first to obtain dimension allowances, joint surfaces are milled after wire cutting halving, the two semi-rings are combined through spot welding, rough turning is carried out to obtaindimensions, the joint surfaces are milled, finish machining is carried out after the spot welding for the joint surfaces, and grinding machining is carried out to obtain the grinding allowances of thethickness dimensions during the finish machining. The method is capable of ensuring that the dimensions after final machining cannot be changed due to the stress change, so that the accuracy of dimension tolerance, and form and location tolerance, and the assembly accuracy in the later period are ensured.

Owner:HARBIN ELECTRIC POWER EQUIP

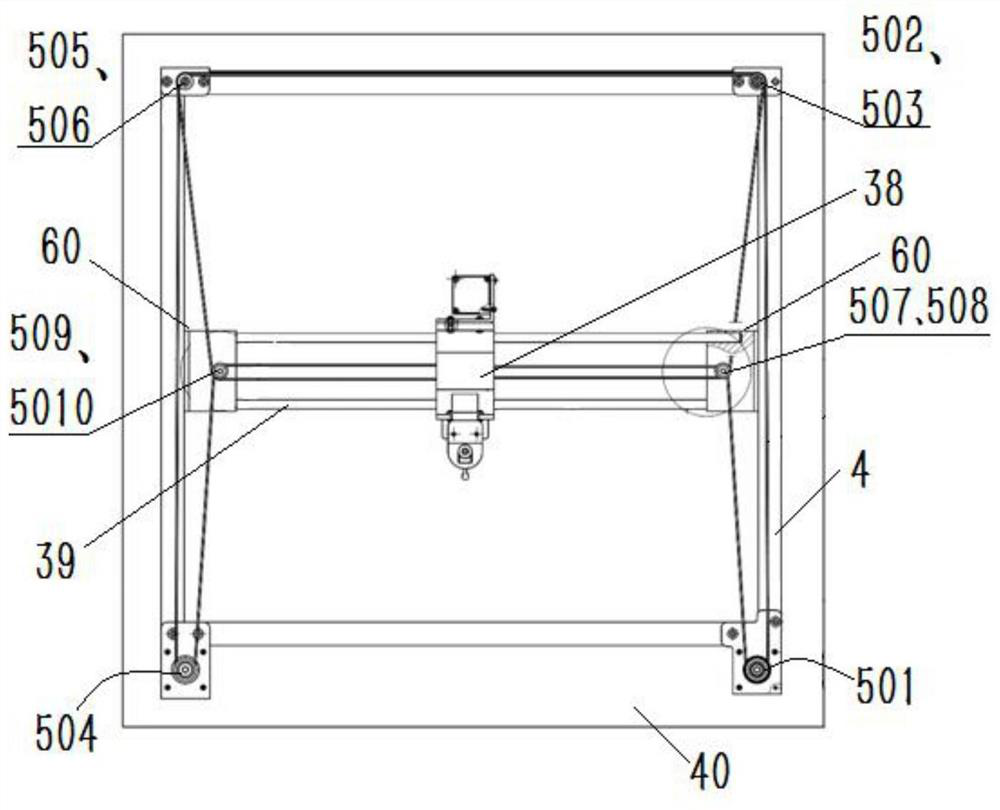

Laser engraving and plotting instrument integrated machine based on COREXY structure

InactiveCN111872570AExtend your lifeSimple structureWriting aidsLaser beam welding apparatusLaser engravingElectric machinery

The invention relates to a laser engraving and plotting instrument integrated machine based on a COREXY structure. The laser engraving and plotting instrument integrated machine comprises three partsincluding a base, a transmission mechanism and an integrated mounting mechanism; the base comprises aluminum alloy section square tubes and a bottom working plate, and the four aluminum alloy sectionsquare tubes are sequentially connected end to end through section connecting fixing pieces to define a frame structure in an enclosing manner and are fixed to the bottom working plate through squaretube supporting frames; and according to the transmission structure, two stepping motors are fixed to the bottom working plate through motor positioning blocks, an X-axis motor mounting plate and a Y-axis motor mounting plate and are located at the head end and the tail end of any aluminum alloy section square tube, and idler wheels I are mounted on rotating shafts of the stepping motors. The laser engraving and plotting instrument integrated machine solves the problems that an existing engraving structure is single in function and insufficient in stability and cannot meet the actual requirement easily.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

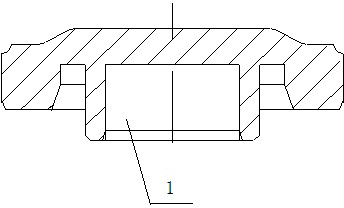

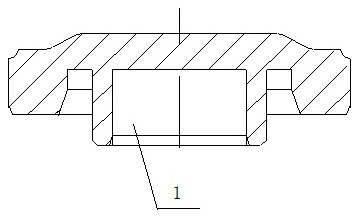

Force-reducing type pump cover

InactiveCN102330671AReduce the stress areaGuaranteed reliabilityPositive displacement pump componentsLiquid fuel engine componentsSystem pressureBiomedical engineering

The invention relates to a force-reducing type pump cover, wherein an inside hole is arranged at the center of the pump cover; the diameter of the inside hole is identical to that of a lug boss of a side plate; and the inside hole are the lug boss of the side plate are mounted in a matching manner; and the pump cover is connected with a pump body through a retainer ring. With the adoption of the force-reducing type pump cover provided by the invention, the diameter of the inside hole is identical to that of the lug boss of the side plate, and the inside hole and the lug boss of the side plate are mounted in a matching manner, so that the stressing area of the pump cover is reduced, and the strength of the pump cover still can satisfy with the requirements of design and use after the system pressure is increased; and meanwhile, the reliability of the pump body is ensured through the decrease of the force which is transferred onto the retainer ring through the pump cover and exerts on the pump body.

Owner:DALIAN HYDRAULIC COMPONENT

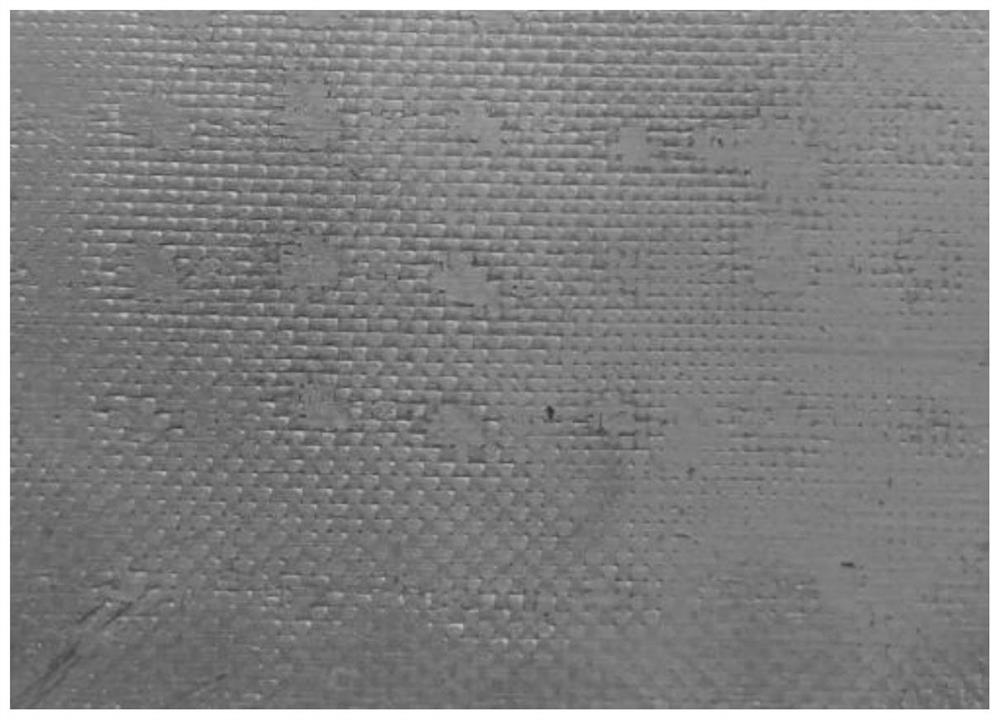

Ceramic matrix composite satellite lightweight structural member surface flatness treatment method and structural member

PendingCN112495735AImprove flatnessEasy to meet the design and use requirementsPretreated surfacesEpoxy resin coatingsEpoxySuperfinishing

The invention relates to a ceramic matrix composite satellite lightweight structural member surface flatness treatment method and a ceramic matrix composite satellite lightweight structural member, and aims to solve the problems that the flatness requirement is difficult to meet by general machining and high-precision scraping cannot be performed due to relatively high material hardness of the ceramic matrix composite satellite lightweight structural member, the processing difficulty is increased, and the product quality is difficult to guarantee. The ceramic matrix composite satellite lightweight structural member surface flatness treatment method comprises the following steps: carrying out preliminary machining, cleaning and drying on the surface of the ceramic matrix composite satellitelightweight structural member; smearing a glue solution prepared from epoxy resin glue on the surface of the ceramic matrix composite satellite lightweight structural member; carrying out super-finish machining on the surface of a glue layer after the glue solution is cured to form the glue layer; and finally, scraping to enable the surface flatness of the structural member to meet the requirement. The structural member manufactured through the ceramic matrix composite satellite lightweight structural member surface flatness treatment method has the advantages that the surface flatness meetsthe design and use requirements, and the performance is good.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

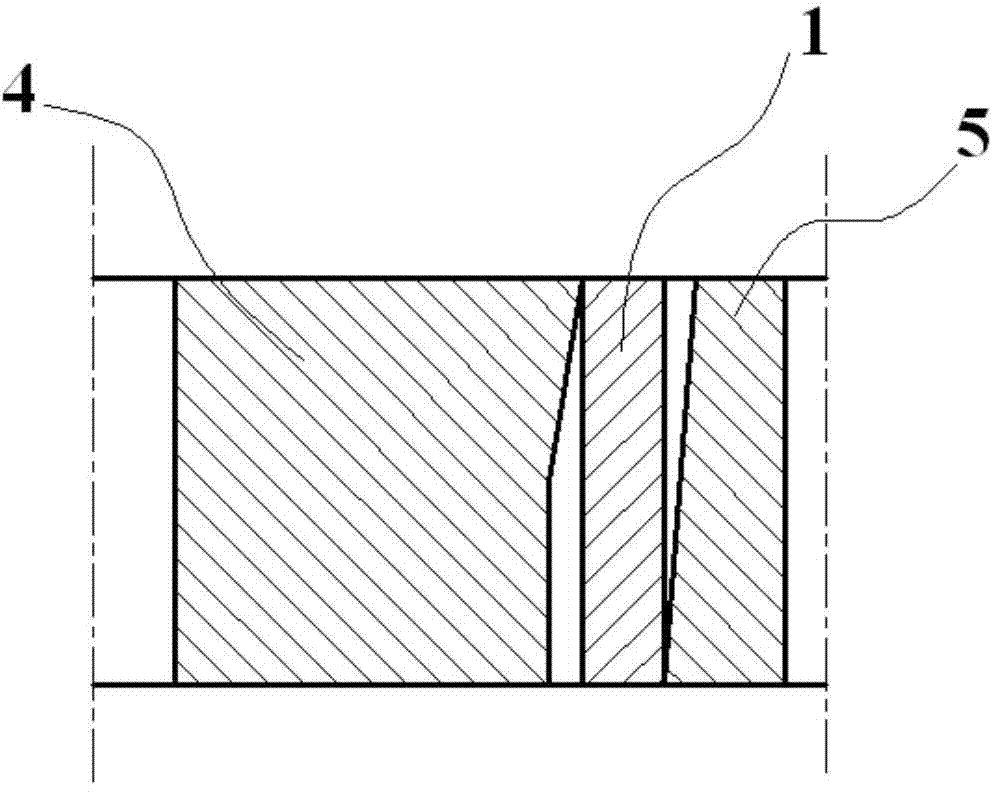

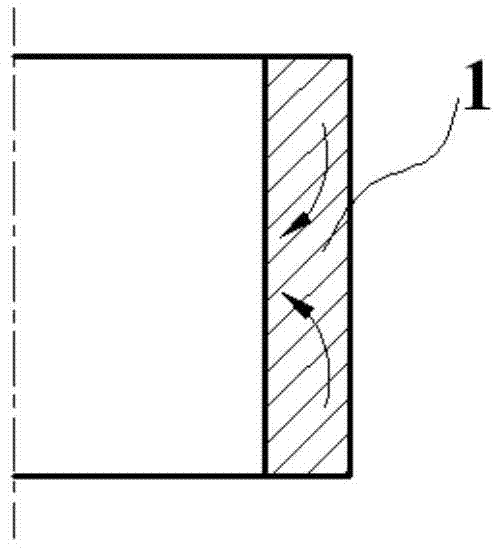

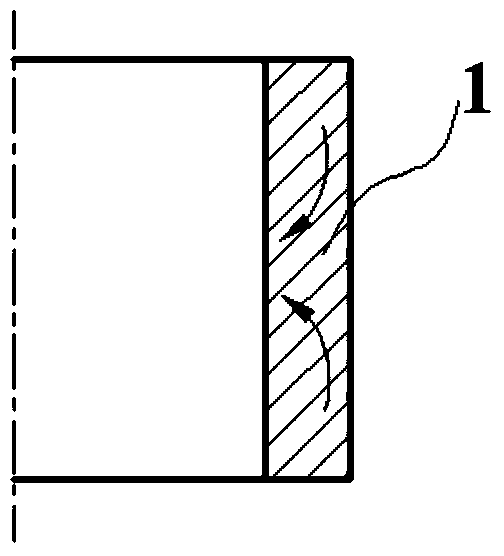

Control Method of Machining Deformation of Bushing Thin-walled Parts

ActiveCN104384825BSolve the processing stress problemReduce stressBearing componentsNumerical controlMachining deformation

The invention provides a machining deformation control method of a bushing thin-wall part, and aims to provide a deformation control method for effectively controlling the machining deformation of an aluminum alloy thin-wall part, enabling the deformation in a controllable range and having stable and reliable quality. The method is realized through the following technical scheme: the stress finite element analysis and the stress strain state tendency analysis are performed by a finite element analysis model file and a simulation module; the meshing is performed by a partitioning second-order 20-node hexahedral unit to find out specific deformation areas and deflections; a smallest deformation scheme is selected to formulate a process machining scheme; and the heat treatment destressing is added after the semi-finishing for removing the machining stress deformation generated in the semi-finishing, and then, the finishing is performed for controlling the roundness of an outer circle and an inner hole within 0.02 mm. The inner hole and the outer circle are finished by the numerical control turning, so that the wall thickness difference is not bigger than 0.01; and a clamping part is cut off, and an end surface is machined, so that the total length is guaranteed. The method solves the machining difficulties of the bushing thin-wall part; and the pass percent can be improved above 90%.

Owner:PLA NO 5719 FACTORY

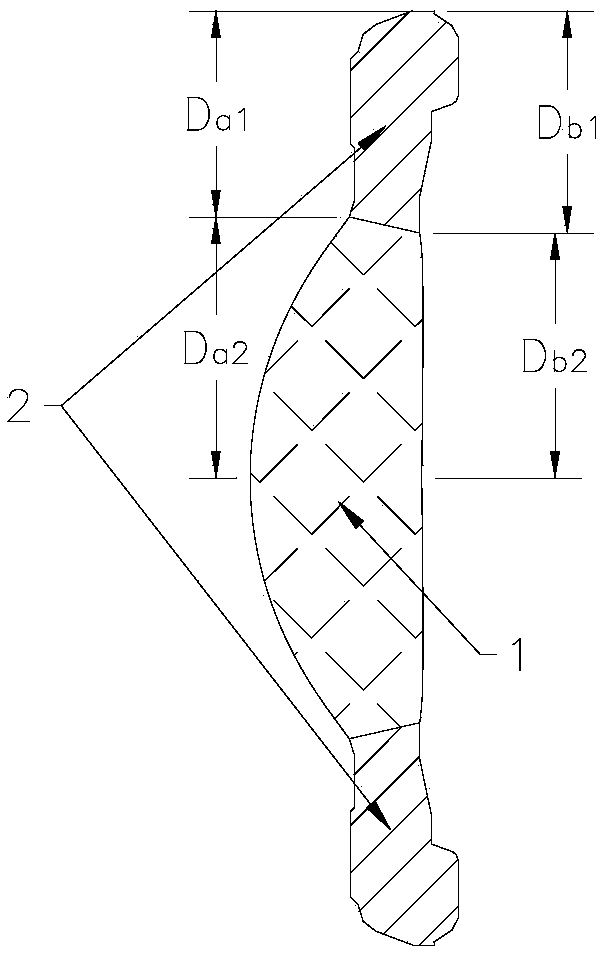

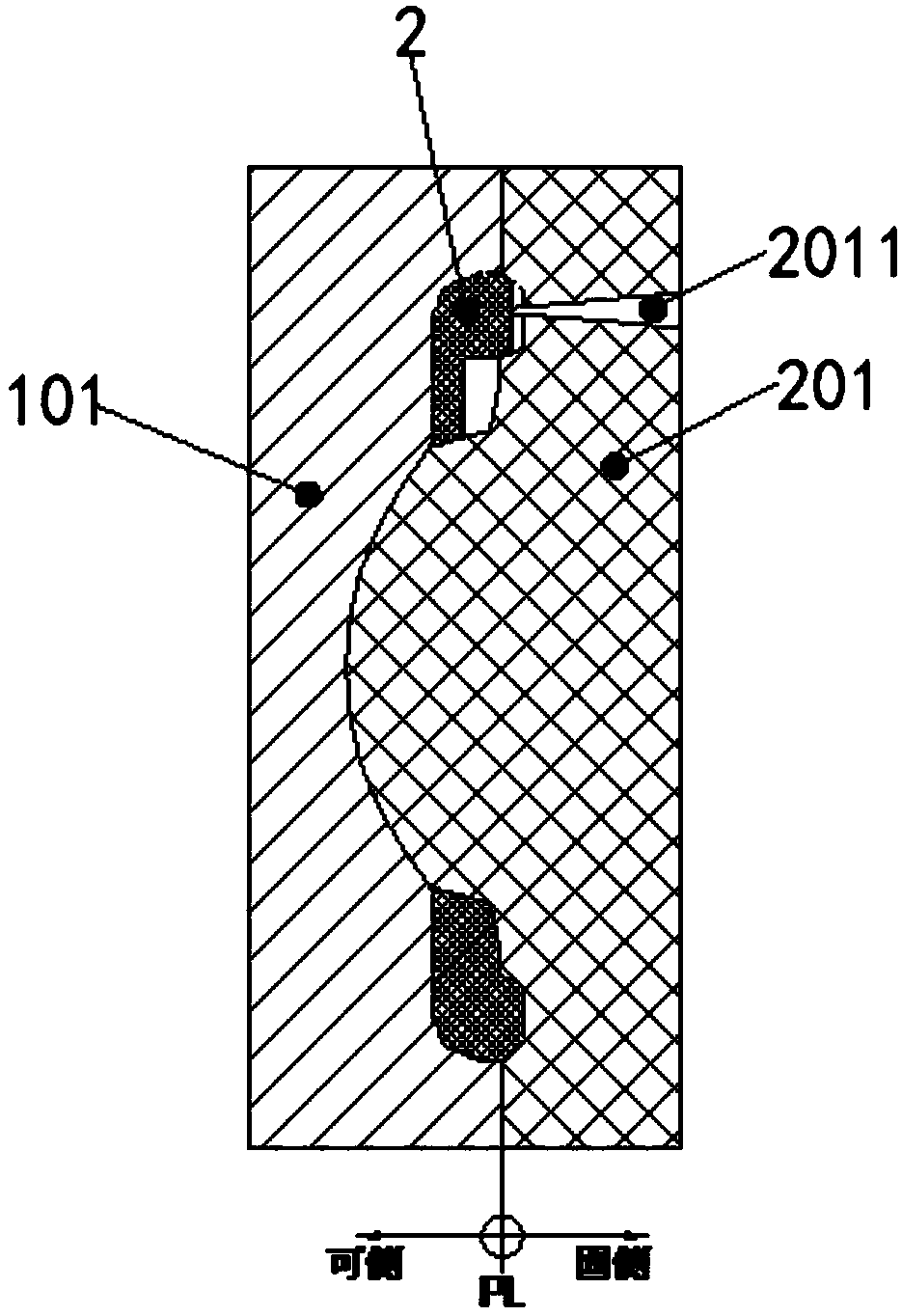

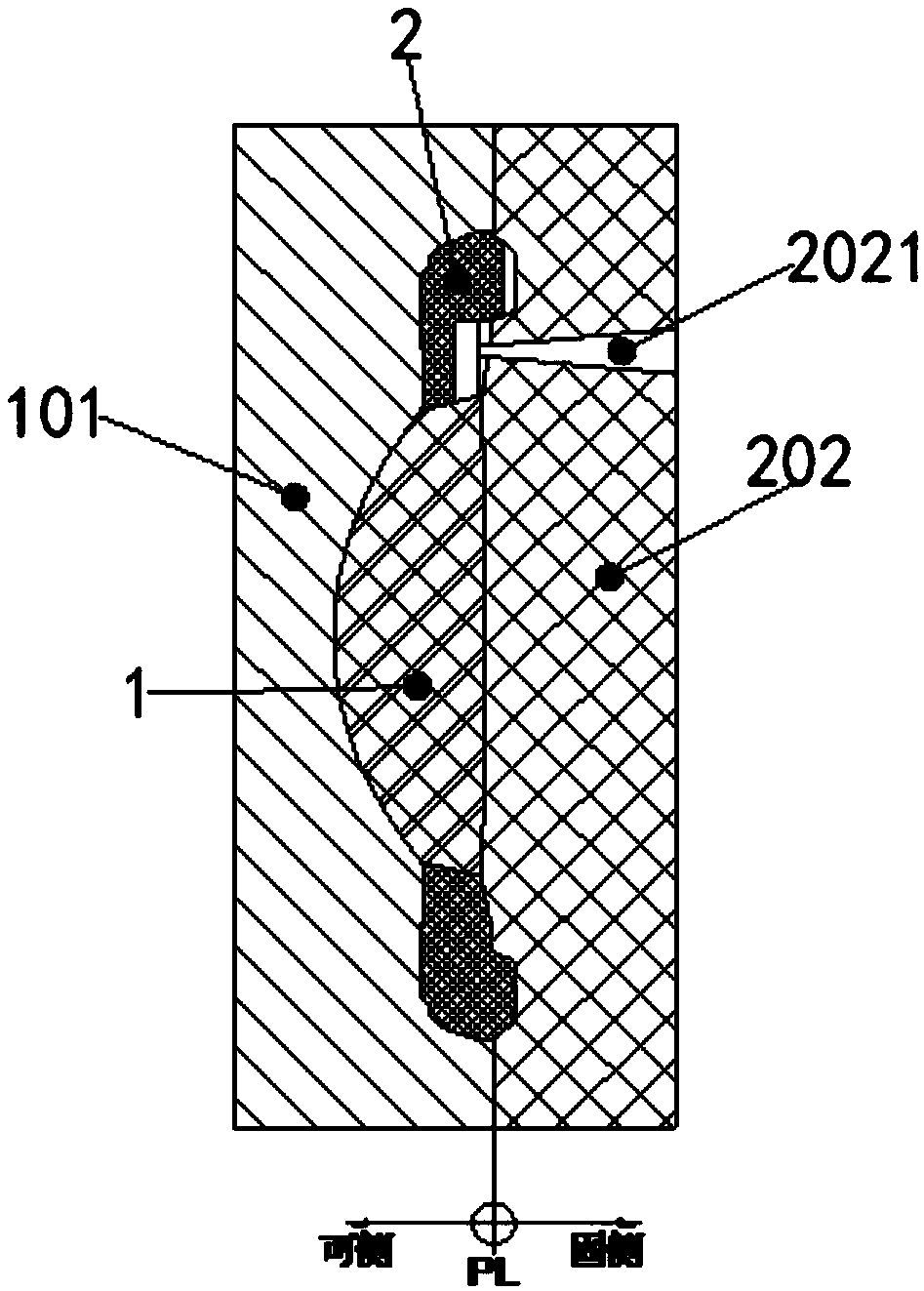

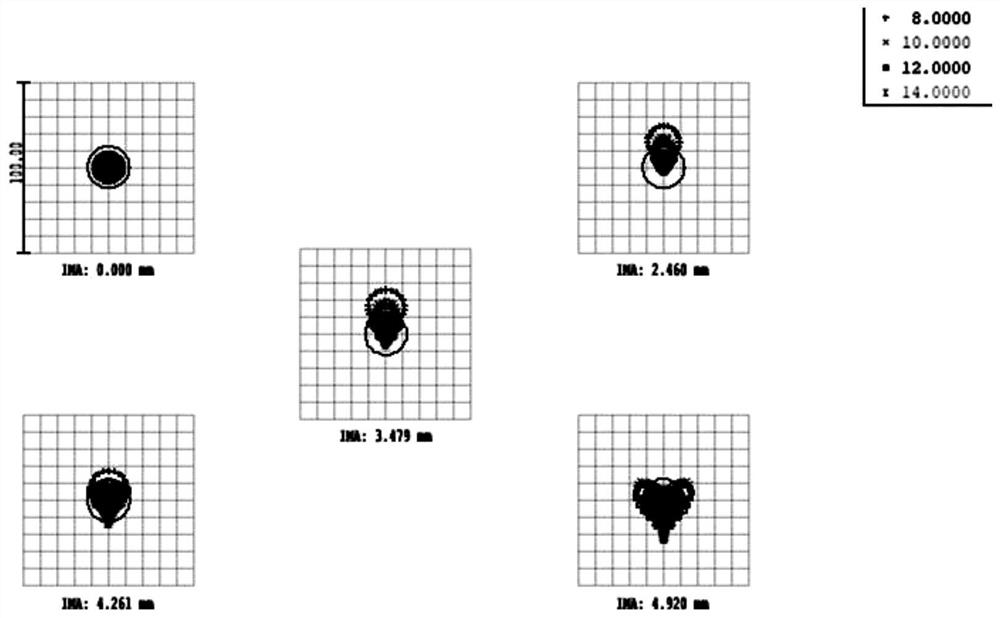

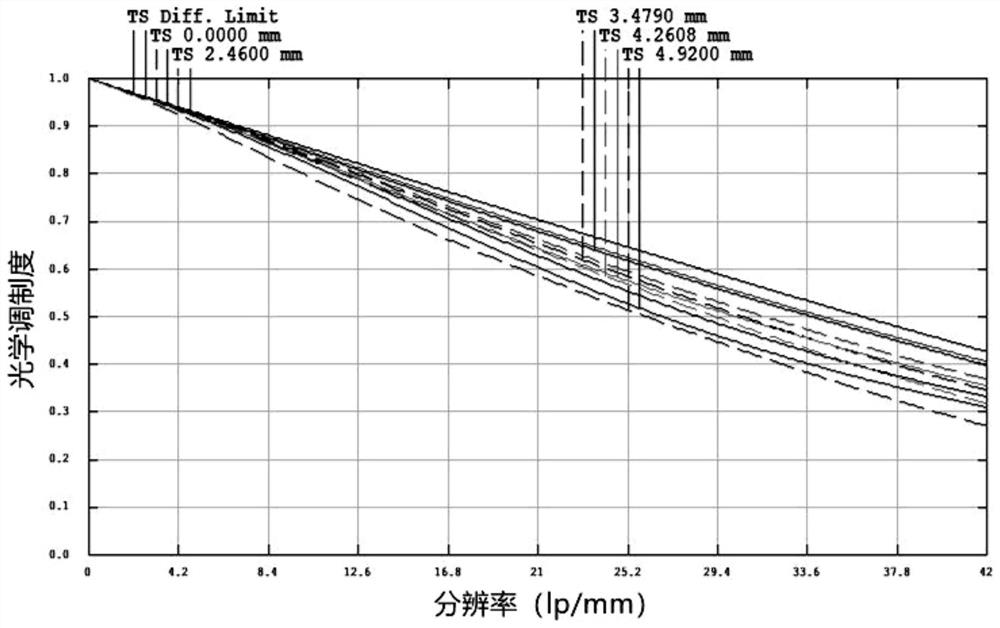

Lens, camera lens and image device

InactiveCN109298499AGuaranteed Optical PerformanceHas an optical effectMountingsCamera lensImaging quality

The invention relates to a lens, a camera lens and an image device. The lens comprises an optical part (1) and a fixing part (2) which surrounds the optical part (1) and is connected with the opticalpart (1), the optical part (1) is made of transparent materials, and the fixing part (2) is made of ray adsorption materials. The lens can effectively eliminate stray light and improve imaging quality, the use amount of light isolation sheets can be reduced when the lens is assembled to the camera lens so as to be favorable for reducing the accumulation assemblage errors of the camera lens, imaging quality is further improved, meanwhile, the lengths of a lens cone can be reduced, and the volume of the lens is reduced.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Tile installation technology

The invention relates to a construction technology of building materials, in particular to a tile installation technology. The tile installation technology comprises the steps of placing a built-in buried bolt in a stone and a magnetic tile groove, filling the stone and the magnetic tile groove with epoxy resin glue, flattening the stone and the magnetic tile groove, guaranteeing the perpendicular connection, filling the epoxy resin glue for the second time and waiting the epoxy resin glue to be solidified naturally. The tile installation technology replaces a traditional technology method that a pendant is installed and glue is filled by cutting a groove. The tile installation technology is simple and completely meets the requirements of design and use.

Owner:DUJIANGYAN KEPUDA NEW MATERIALS

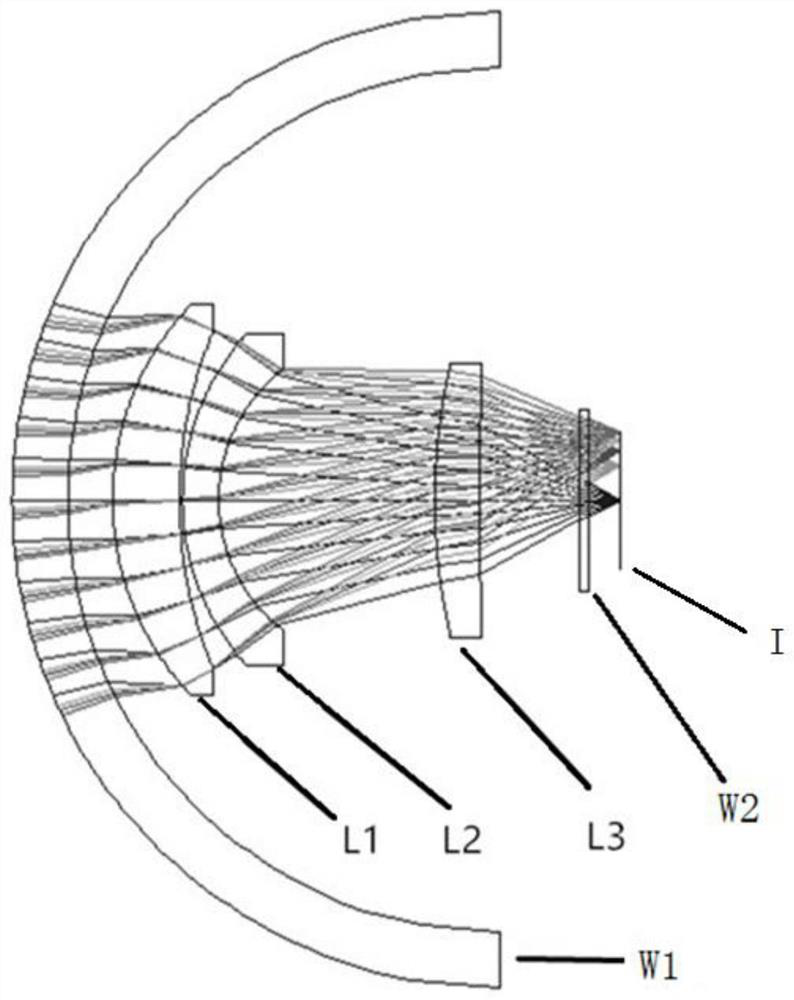

Long-wave infrared imaging optical system

ActiveCN113534420ASimple systemReduce overall weightOptical elementsImage-forming optical systemOptical axis

The invention relates to a long-wave infrared imaging optical system. The system is sequentially provided with a window W1, a lens L1, a lens L2, a lens L3 and a CCD window W2 which share the same optical axis in the light propagation direction. The lens L1 and the lens L3 are positive meniscus lenses, the lens L2 is a negative meniscus lens, and the convex surfaces of the lens L1, the lens L2 and the lens L3 face the light incidence direction; the front surface of the lens L1 is a spherical surface, and the rear surface is an even-order aspheric surface; the lens L2 and the lens L3 are spherical lenses. The system is greatly simplified, the overall weight of the imaging system is reduced, and the imaging quality of the optical system can be close to the diffraction limit within the temperature range of-40 DEG C to 60 DEG C.

Owner:苏州东方克洛托光电技术有限公司

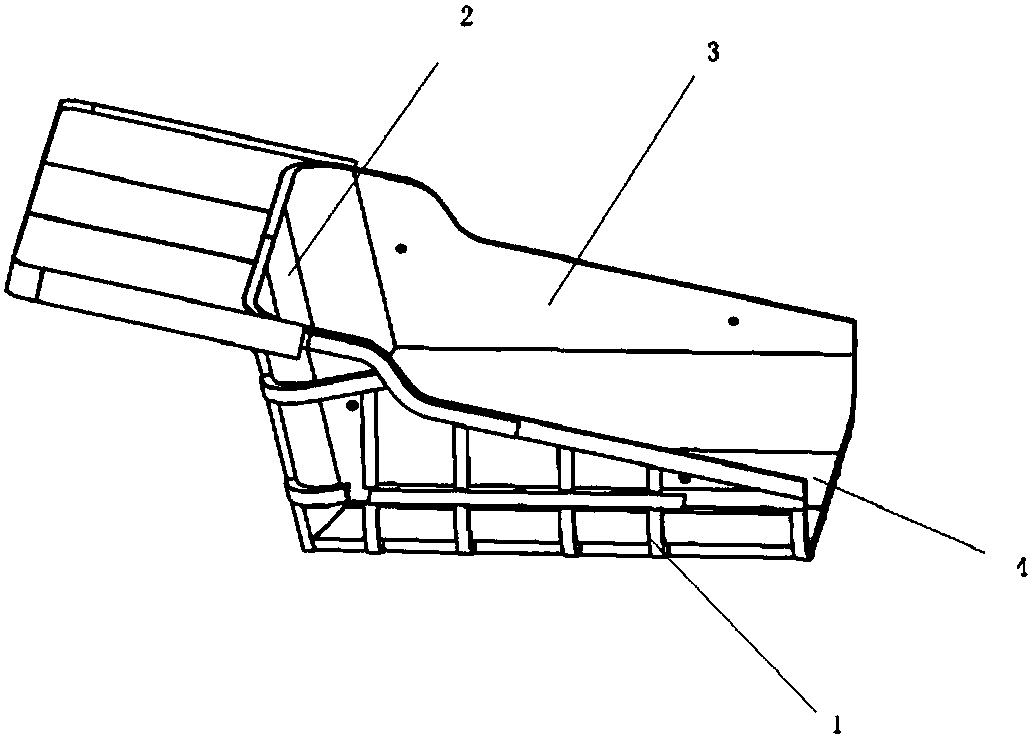

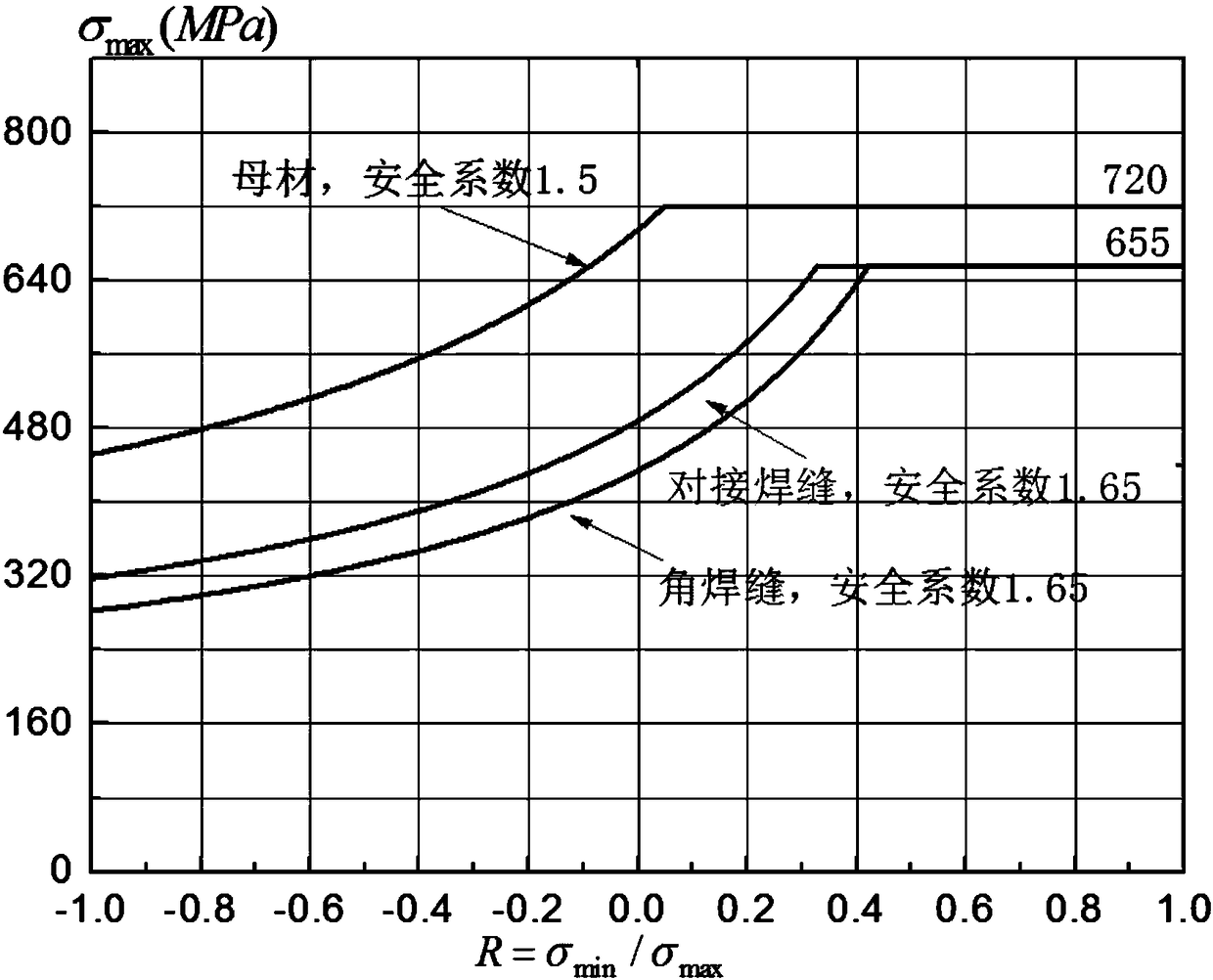

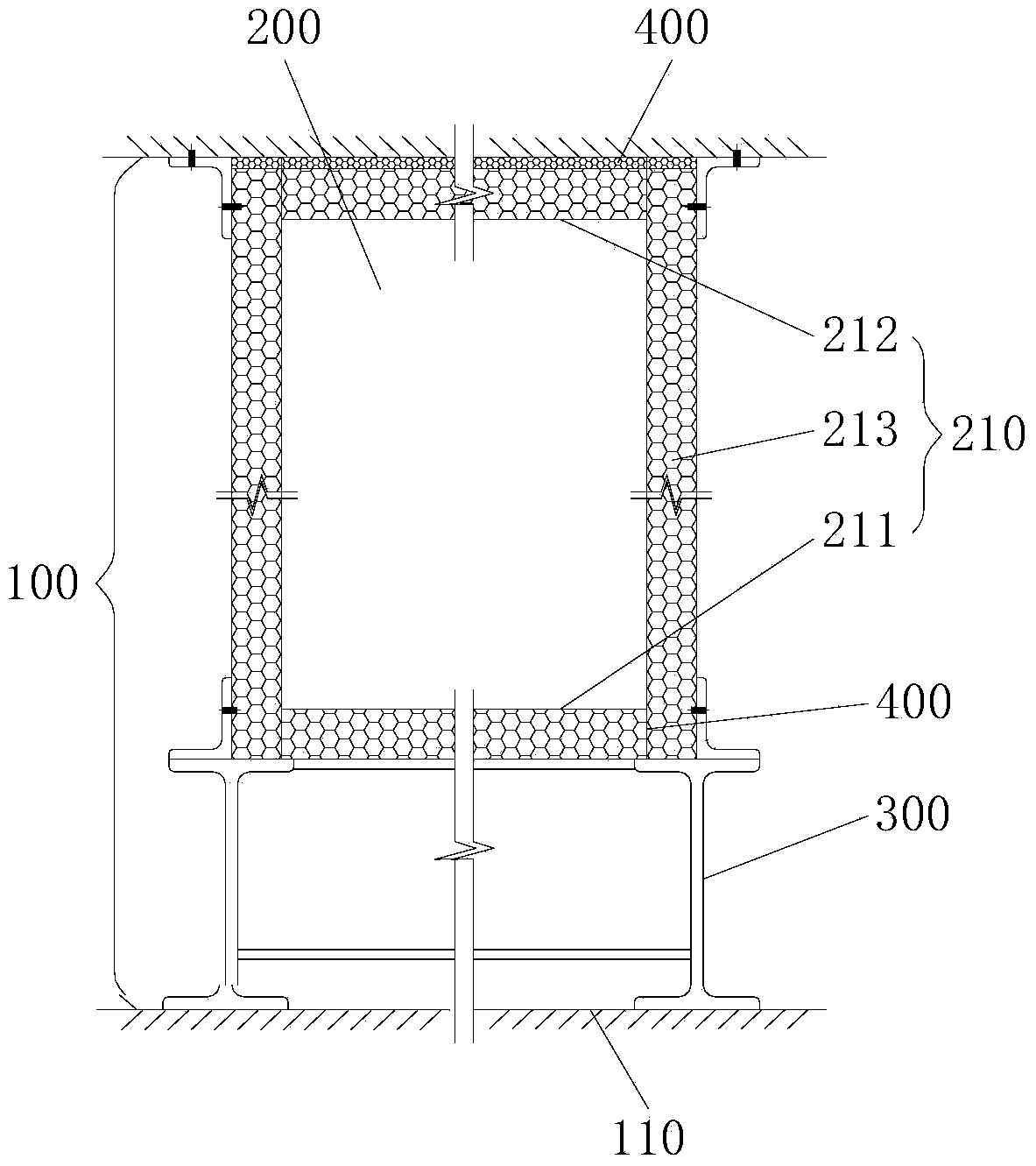

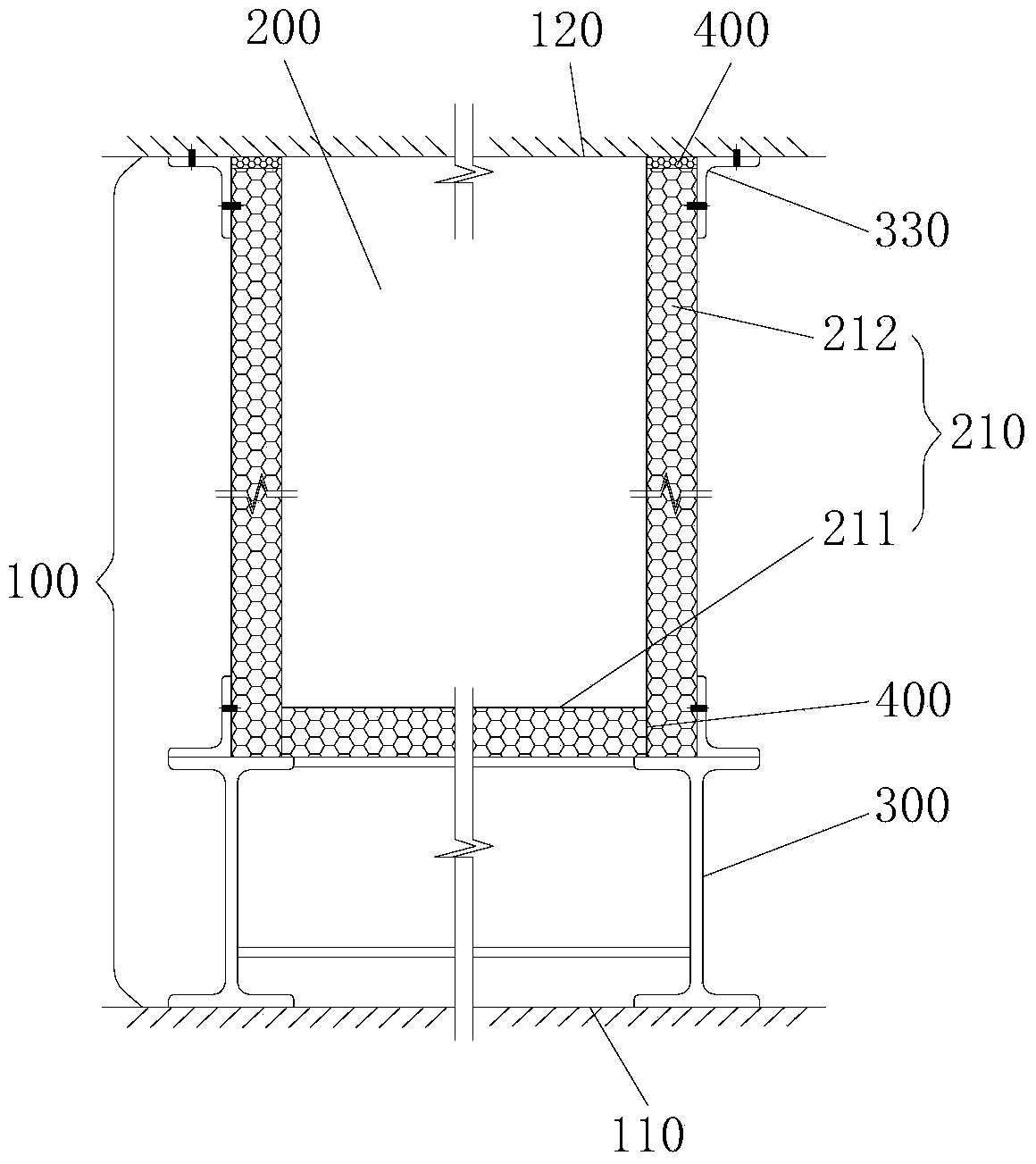

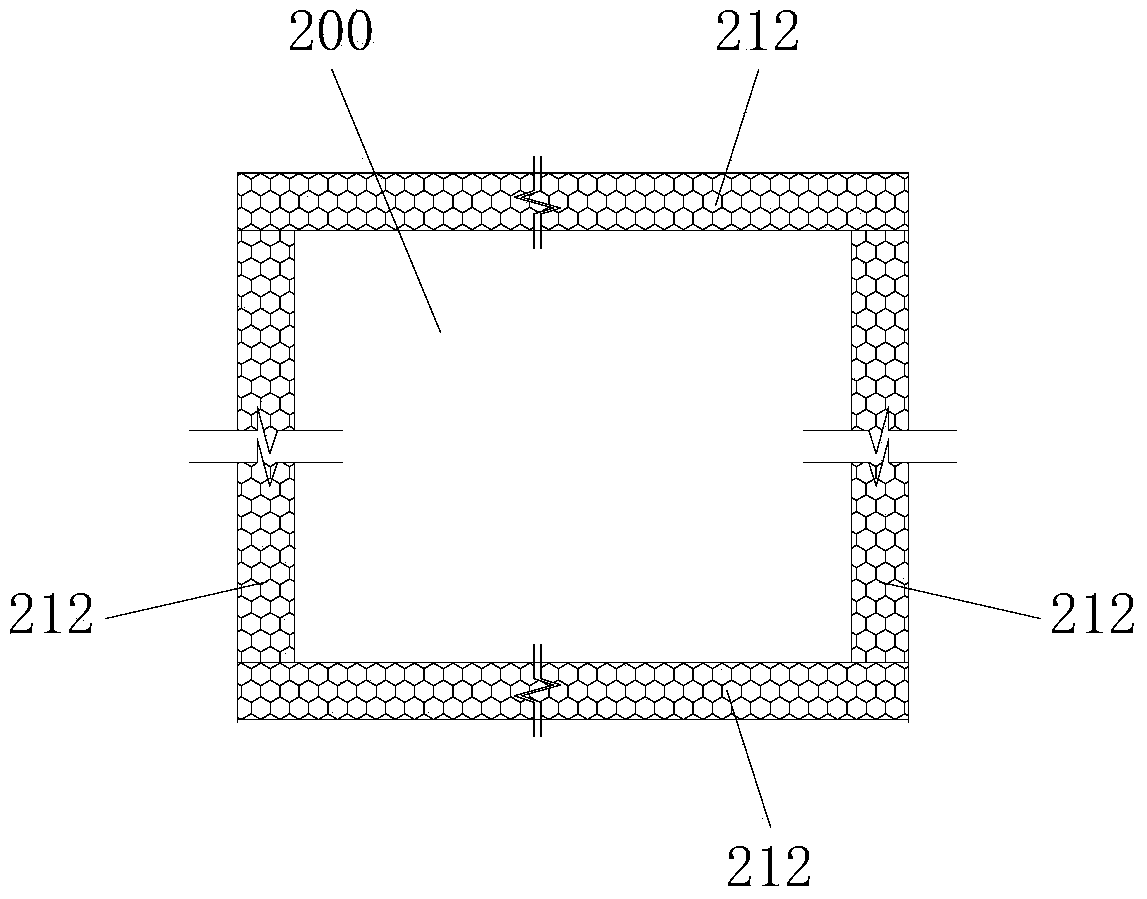

Design method of dumper packing case

InactiveCN108062441AMeet the design and use requirementsGeometric CADDesign optimisation/simulationEngineeringUltimate tensile strength

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

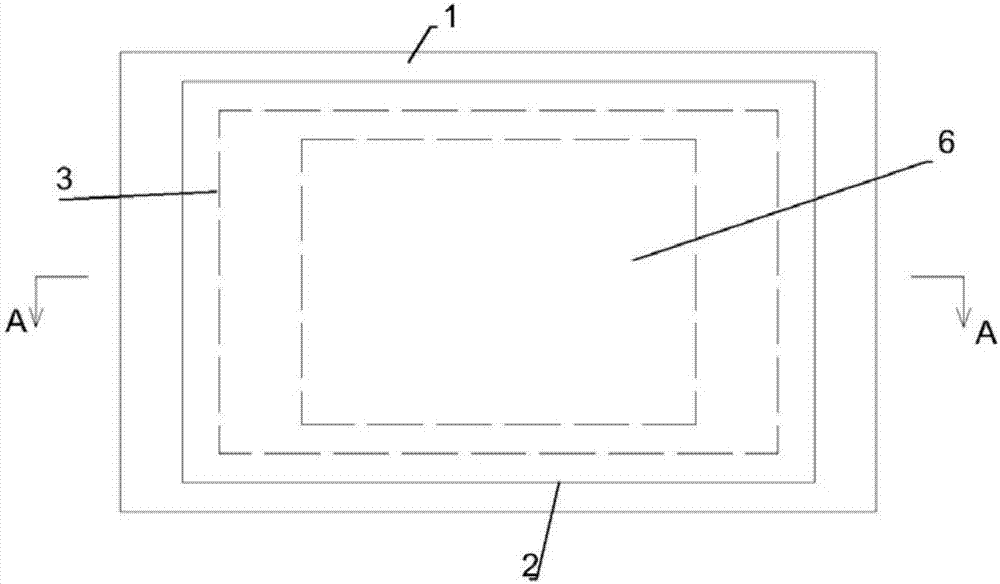

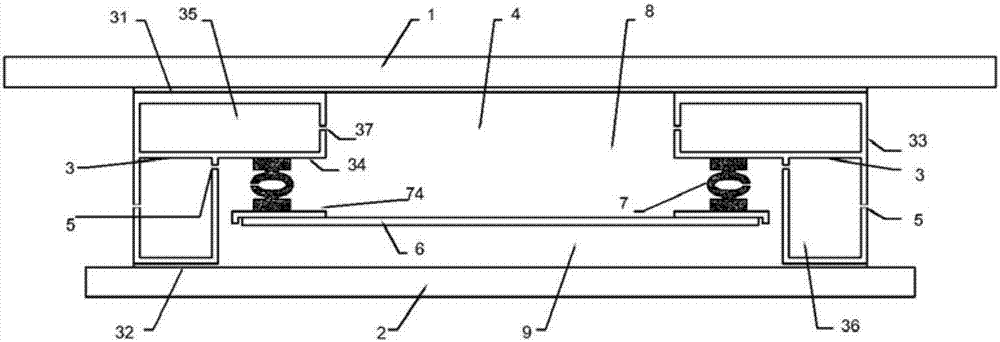

Air-conditioner plenum chamber

InactiveCN104061666AEasy constructionLight weightLighting and heating apparatusSpace heating and ventilation detailsAerospace engineeringEngineering

The invention relates to the technical field of air delivery regulating systems, in particular to an air-conditioner plenum chamber arranged in a sandwich space below a seat floor system. The air-conditioner plenum chamber comprises a plurality of sandwich panels or a plenum chamber cavity structure and a fixing structure, wherein the plenum chamber cavity structure is formed by the sandwich panels and the inner wall surface of the sandwich space and arranged in the sandwich space, and the fixing structure is arranged in the sandwich space and used for fixing the plenum chamber cavity structure. The air-conditioner plenum chamber not only can ensure the design requirements of an air conditioner, but also is simple to construct, convenient and rapid to mount, reasonable in cost and suitable for being used in design of the air conditioner air delivery below the seats of places, such as large venues.

Owner:SHENZHEN GENERAL INST OF ARCHITECTURAL DESIGN & RES

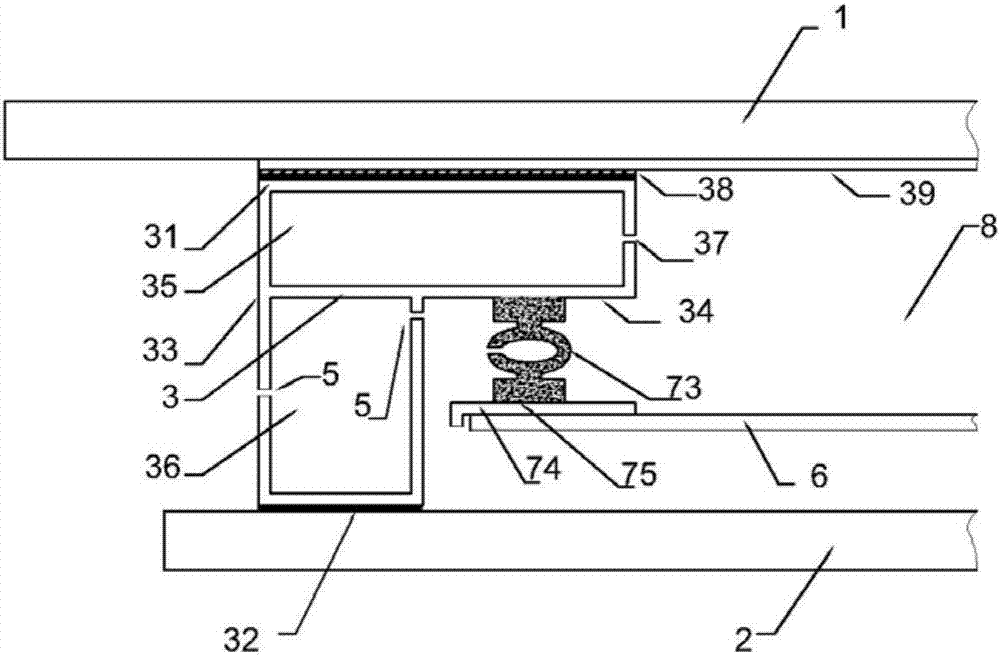

Hollow glass assembly capable of automatically adjusting air pressure

ActiveCN106869701AGood body appearanceReduce weightUnits with parallel planesGlass windowFixed frame

A hollow glass assembly capable of automatically adjusting air pressure comprises an outer layer plate and an inner layer plate. The outer layer plate and the inner layer plate are fixedly connected through fixing frames and form a hollow cavity. The fixing frames and the outer layer plate are in airtight connection. One or more through holes are formed in the fixing frames. The hollow cavity is provided with a sealing plate and one or more elastic connecting devices which can deform; the sealing plate is in airtight connection with the outer layer plate or the fixing frames through the elastic connecting devices to form an airtight cavity with the volume being changeable; and a communicating cavity, except the airtight cavity, in the hollow cavity communicates with outside air through the through holes. A hollow glass window capable of automatically adjusting the air pressure can adapt to the problem of internal and external pressure difference, faced by hollow glass, caused by elevation change in the railway train running process, the weight of the glass is reduced as much as possible, energy is saved, consumption is reduced, and the service life can reach 20-30 years.

Owner:青岛金晶股份有限公司

Method for accurately straightening spindle of centrifugal compressor in cold state

InactiveCN109108112AMeet the design and use requirementsMetal working apparatusOvervoltageEngineering

The invention provides a method for accurately straightening a spindle of a centrifugal compressor in a cold state. The method for accurately straightening the spindle of the centrifugal compressor inthe cold state comprises the following steps that a suitable-size straightening press is selected; a set of auxiliary straightening tools is designed and manufactured, the auxiliary straightening tools are adopted to clamp the spindle, and press straightening treatment is carried out by using the press; during the straightening process, the deflection variation quantity in spindle straightening engineering is measured; and after straightening is completed, vibration aging equipment is used for eliminating the residual stress after spindle pressing. According to the method for accurately straightening the spindle of the centrifugal compressor in the cold state, a precision straightening tool, an overvoltage prevention protective device, a precision measurement tool and bill during the straightening process, and subsequent schemes for eliminating cold deformation residual stress are designed, The method for accurately straightening the spindle of the centrifugal compressor in the cold state can be applied to straightening of the plastic deflection deformation produced in the production process of the spindle of the centrifugal compressor under different working conditions and materials, and ensure that the straightened spindle fully meets the design using requirements.

Owner:SHENYANG TURBO MASCH CORP

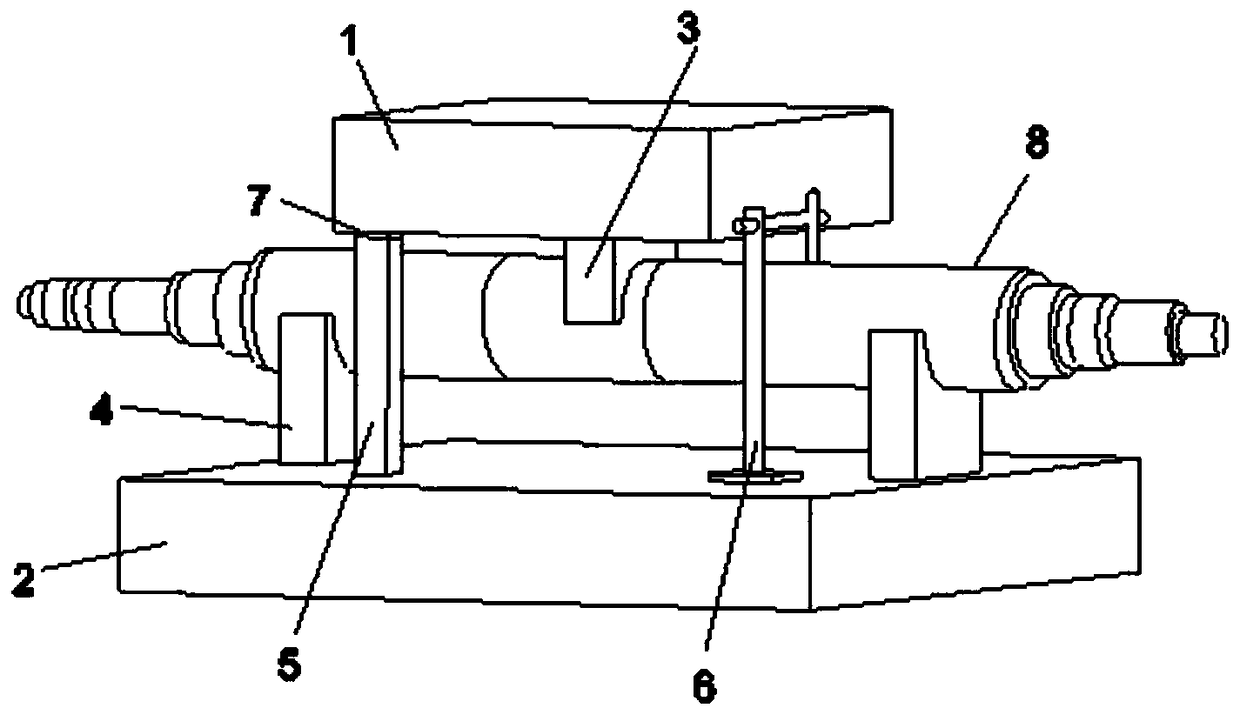

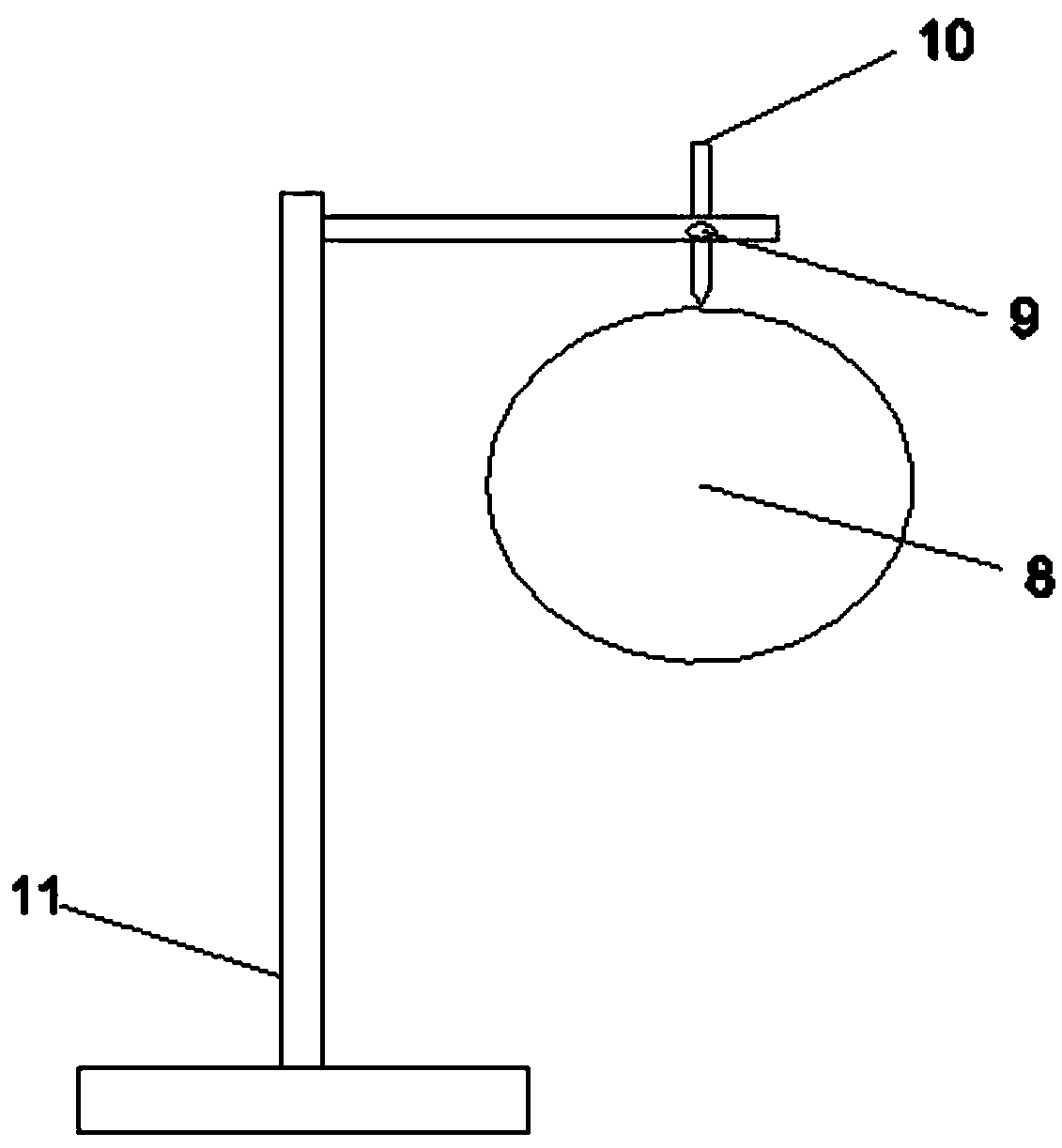

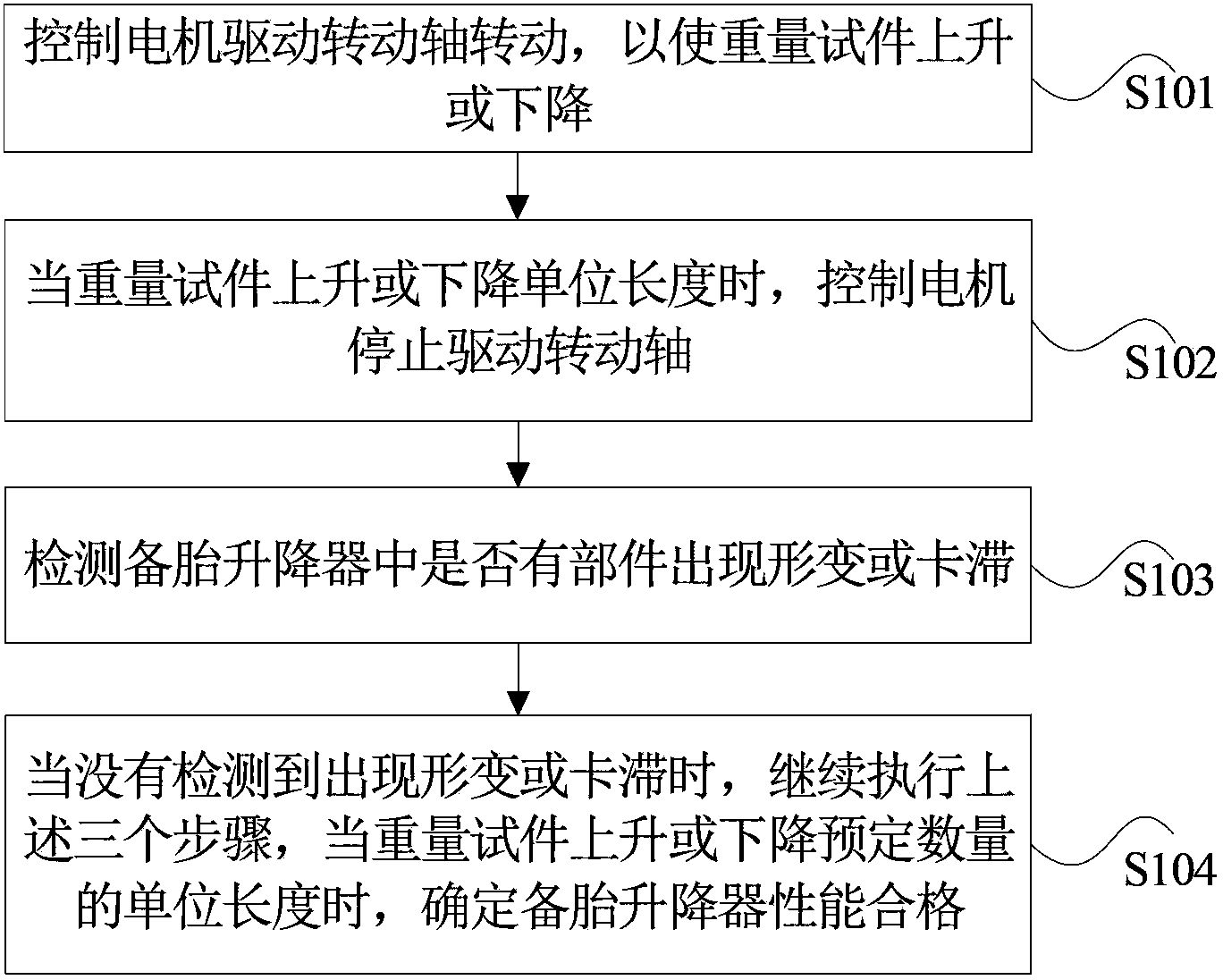

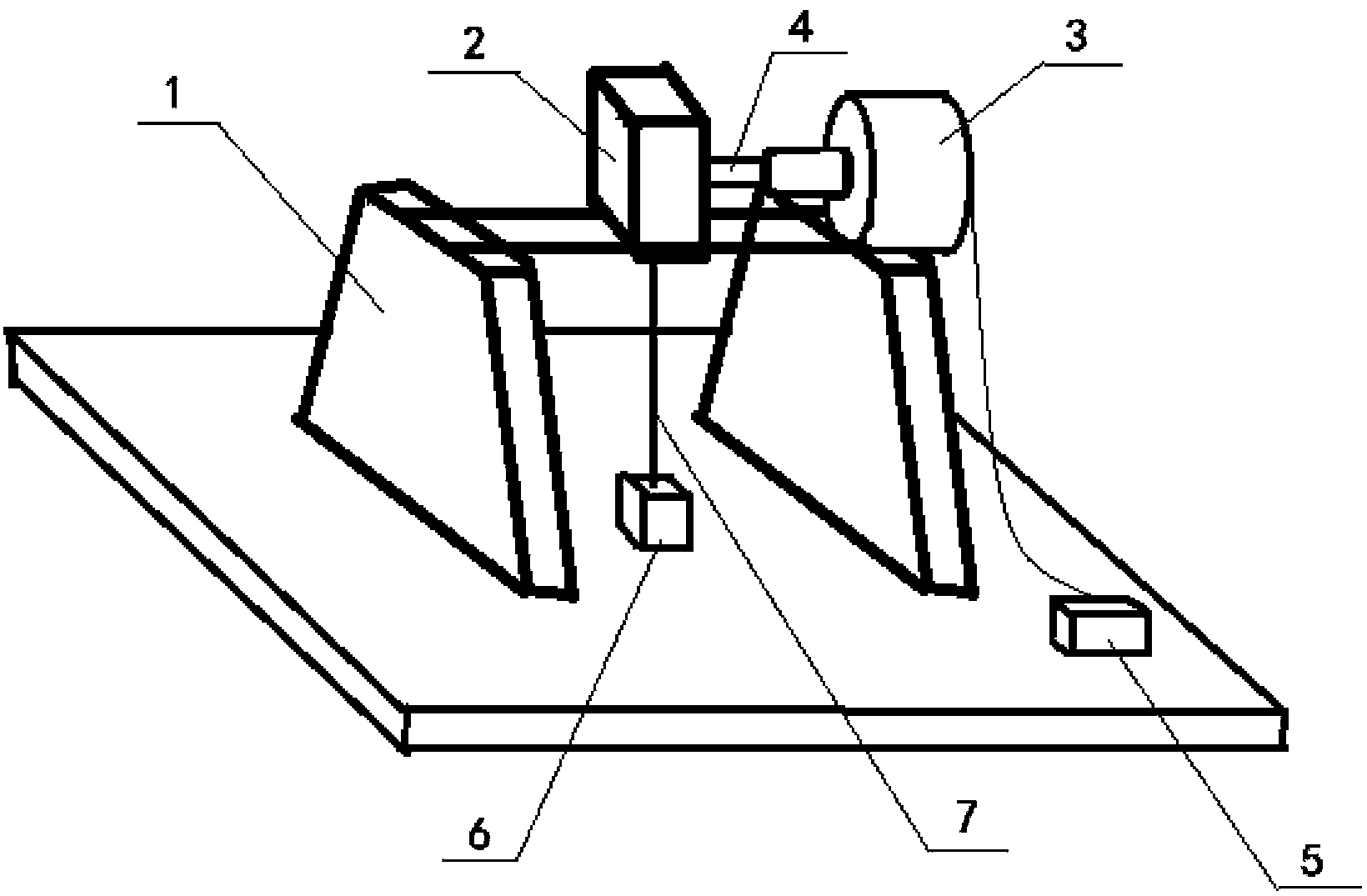

Method and device of testing performance of mechanical rotary spare wheel up-down regulator

InactiveCN104236873AMeet the design and use requirementsMachine part testingElectric machineryEngineering

The invention discloses a method and device of testing the performance of a mechanical rotary spare wheel up-down regulator. The spare wheel up-down regulator comprises a rotating shaft and a winding lifting part. One end of the winding lifting part is fixed to and wound around the rotating shaft, and the other end of the winding lifting part is the free end connected with a weight test piece. The method comprises the steps of controlling a motor to drive the rotating shaft to rotate and enabling the weight test piece to ascend or descend; when the weight test piece ascends or descends by a unit length, controlling the motor to stop driving the rotating shaft; detecting whether any component in the spare wheel up-down regulator is deformed or clamped; when no deformation or clamping is detected, carrying out the above steps, and when the weight test piece ascends or descends by the unit length of a certain number, determining that the performance of the spare wheel up-down regulator is qualified. According to the scheme, the performance of the spare wheel up-down regulator can be tested, and therefore whether produced spare wheel up-down regulators are qualified can be determined.

Owner:BEIQI FOTON MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com