Method for rolling rectangular die block steel ring blank into abnormal-shaped thin-wall ring member

A rectangular ring and die steel technology, applied in the field of rolling and forming of rings, can solve the problems of improper control, affecting the quality of rings, intermittent rolling, etc., and achieve the effect of eliminating ovality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] The main chemical element content (percentage by weight) of the alloy is: C content 0.50% ~ 0.60%, Mn content 0.50% ~ 0.80%, Si content ≤ 0.40%, S content ≤ 0.030%, P content ≤ 0.030 %, Cr content 0.50% ~ 0.80%, Ni content 1.40% ~ 1.80%, the balance is Fe.

[0037] The steps of this method are as follows:

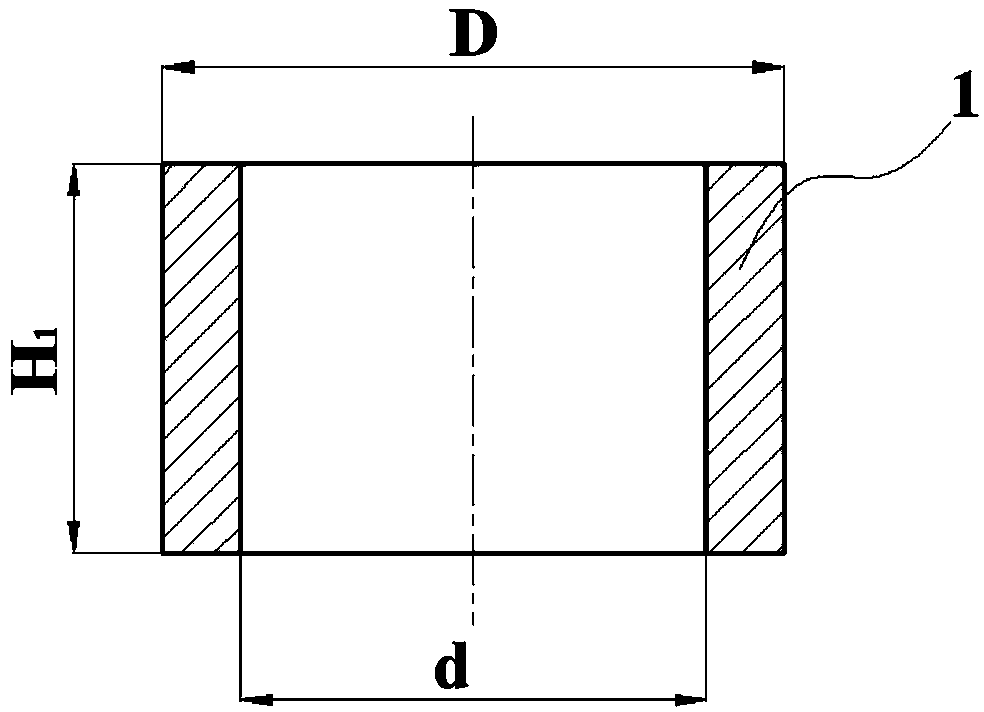

[0038] 1. Design rectangular ring blank 1

[0039] Calculate the rectangular blank dimensions as follows:

[0040] (1) The height of the rectangular ring blank 1 is:

[0041] h 1 =H 2 ;

[0042] Among them: H 1 is the height of the rectangular ring blank 1;

[0043] h 2 is the height of the special-shaped thin-walled ring 3.

[0044] (2) The inner diameter of the rectangular ring blank 1 is:

[0045] d = d max k - ( d max - d min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com