A Compensation Method for Shot Peening Elongation of Large Aluminum Alloy Parts

A technology of aluminum alloy parts and shot peening, which is applied in the field of aircraft manufacturing, can solve the problems of poor accuracy of digital and analog correction and compensation of parts, difficult to extend the value, and long cycle, so as to reduce the probability of quality problems, ensure product quality and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

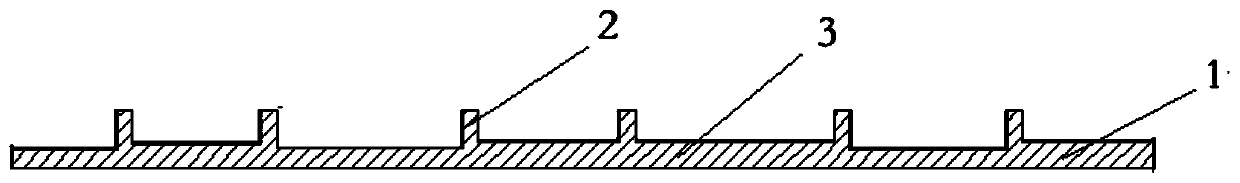

[0017] Referring to the attached figure, a certain beam part, the part 1 is composed of a web 3 of variable thickness and a protruding rib 2, its theoretical length is 6911mm, and the shot peening intensity is 0.15-0.25mmA, and it is shot peened with ASH230 projectile. According to the method above, the amount of elongation of shot peening is compensated, and the specific steps are as follows:

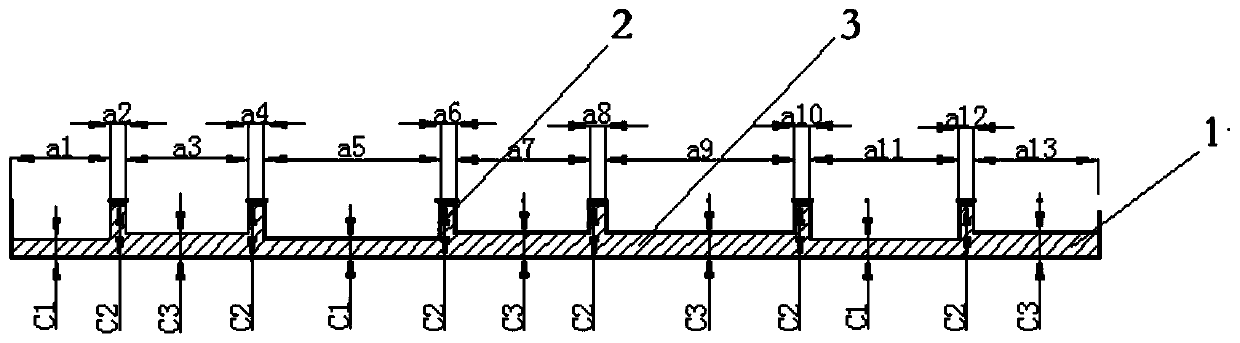

[0018] First, analyze the theoretical digital model of the part, such as figure 2 As shown, the part is divided into multiple regions along the length of the part. In the implementation, the maximum thickness on the section of each region is measured, and the lengths of the regions with the same or similar thickness are recorded together. For example, the wall plate 3 of the part is divided into two thickness areas, area 1 and area 3, the thickness of area 1 is C1=7.75mm, the length of area 1 is A1=a1+a5+a11=2100mm; the thickness of area 3 is C3=8.25 mm, the length A3 of the area 3 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com