Lens, camera lens and image device

A lens and lens technology, applied in the field of imaging equipment, can solve the problems of difficult to guarantee the accumulation of lens assembly errors, unfavorable to the development of lens miniaturization, stray light of imaging systems, etc. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

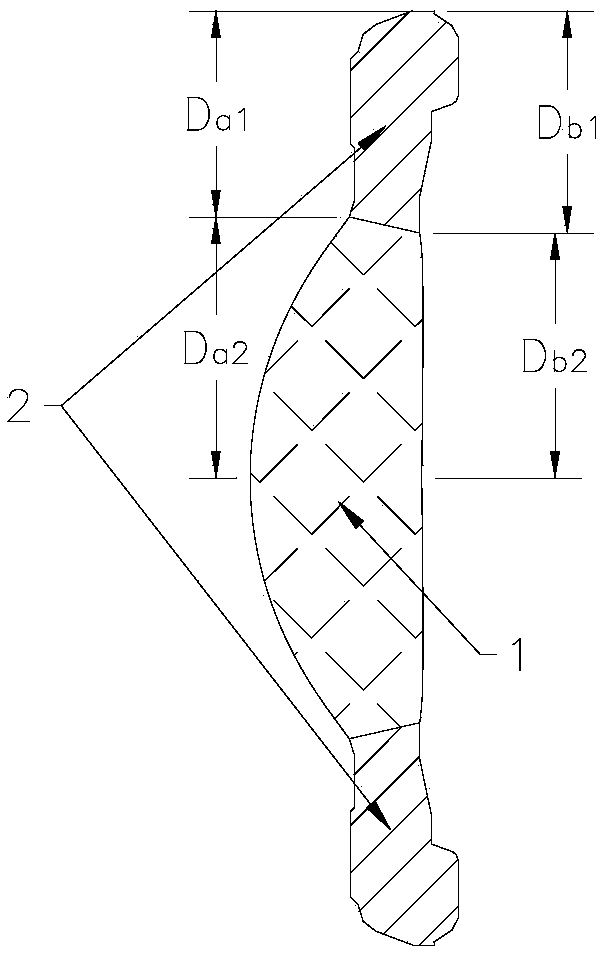

[0040] According to the second embodiment of the present invention, the width of the left and right sides of the lens fixing part 2 can also be different, for example, the width of the left side of the lens fixing part 2 is D a1 , the width of the right side is D b1 , and the optical radius of lens optical part 1 is also D a2 and D b2 , then satisfy: 0.1≤D a1 / D a2 ≤4, 0.1≤D b1 / D b2 ≤4. That is to say, no matter whether the left and right sides of the fixed part 2 of the lens have the same width, the ratio of its width to the optical radius of the optical part 1 of the lens should be within the above numerical range.

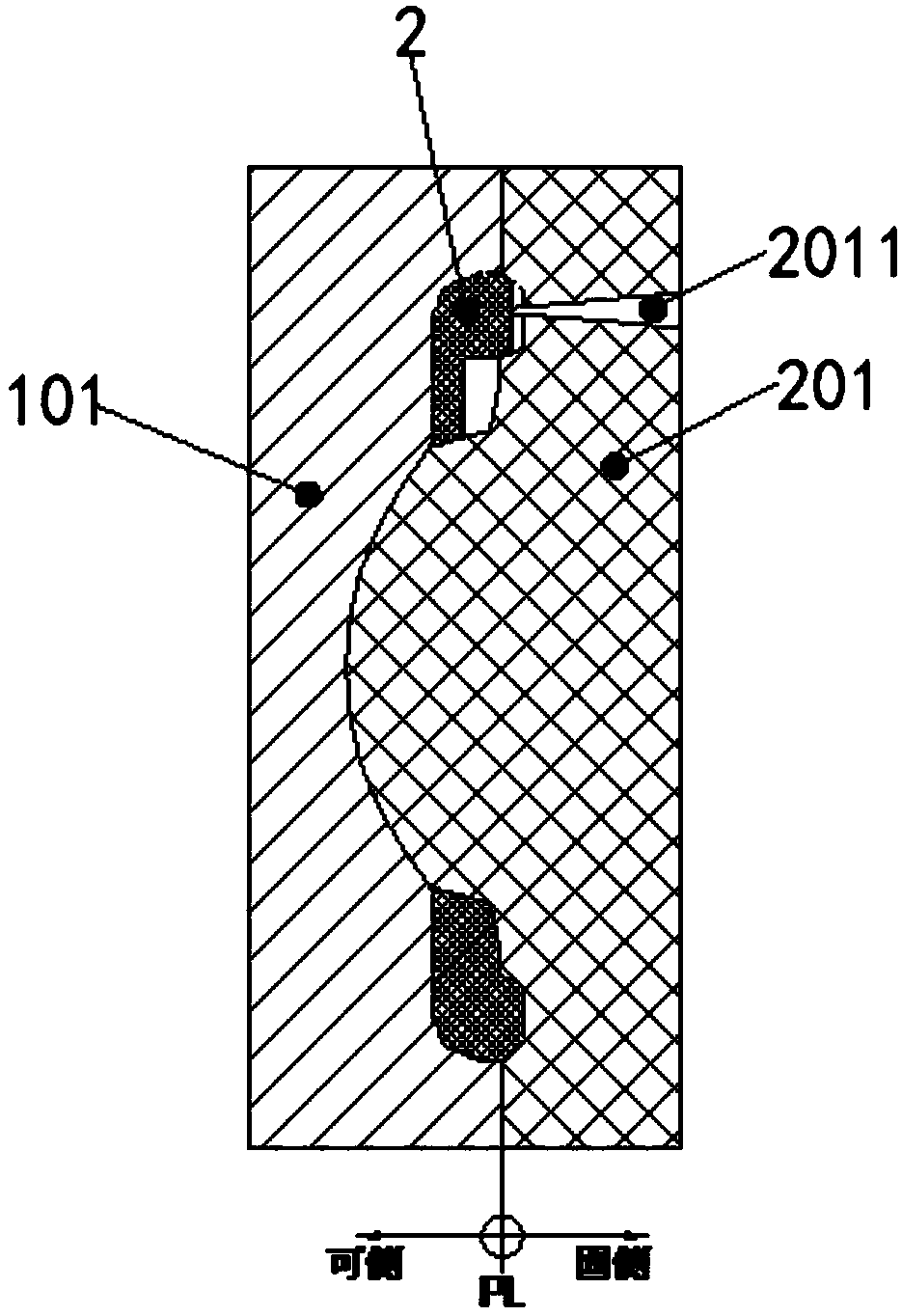

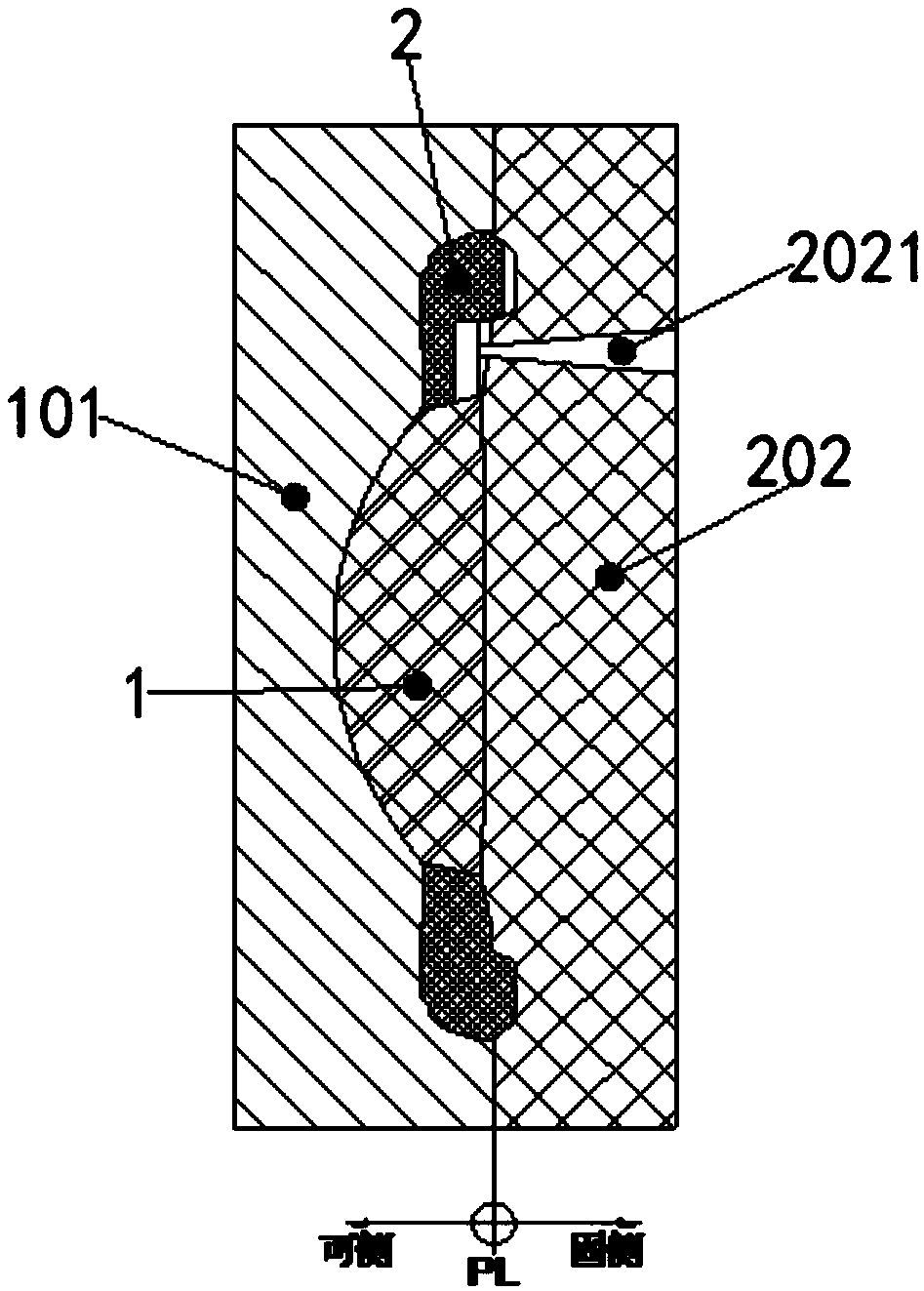

[0041] The lens of the present invention is a secondary molded lens, that is, the optical part 1 and the fixed part 2 of the lens are molded twice. According to the concept of the present invention, the optical part 1 can be molded first and then the fixed part 2 can be molded, or the fixed part 2 can be molded first and then the optical part 1 can be mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com