Preparation method of lithium triborate crystal high-laser-damaged-threshold antireflection film

A technology of laser damage threshold, lithium triborate, applied in superposition layer plating, ion implantation plating, coating and other directions, can solve problems such as shortening the service life of LBO crystal substrate, unsatisfactory use results, and inability to guarantee dual-band , to achieve good economic benefits, strong practicability, and enhanced environmental stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

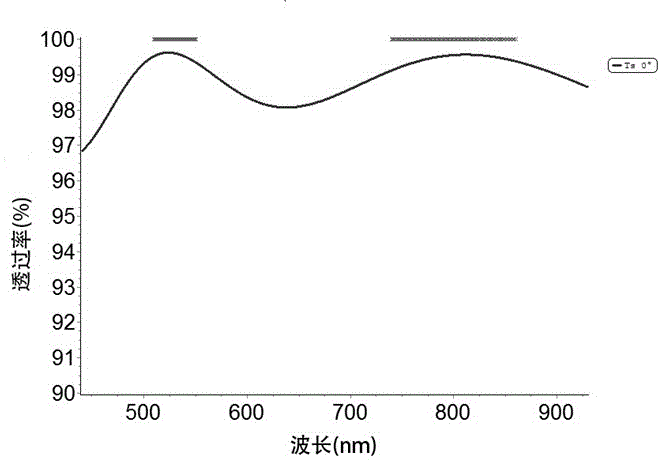

[0025] LBO crystal 800nm and 527nm dual-wavelength anti-reflection coating coating

[0026] 1. The LBO crystal size of the plated sample is 10*10*3mm. The structure of the film system is: SMLA, S is the substrate LBO crystal, A is air, and M is a single layer of SiO under the IAD process. 2 , the refractive index is about 1.48, L is a single-layer chemical film plated by sol-gel method, the refractive index is about 1.3, and the thickness of each layer is 326nm / 128nm. Configure the ion source as a 17cm radio frequency ion source. The pulling coating equipment is DipMaster 200 (CHEMAT TECHNOLOGY, INC).

[0027]2. Plating is carried out according to the above-mentioned process steps, and the LBO crystal is cleaned by ultrasonic wave in the mixed cleaning solution of alcohol and acetone, and then dried by dry nitrogen gas. After the LBO crystal is placed on the tooling, it is not advisable to close the door and pump air immediately. Instead, it should be left to stand for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com