Quantum dot/polymer microsphere composite material, preparation method and application

A composite material and polymer technology, applied in luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of decreased quantum fluorescence efficiency, complex chemical environment, difficult to achieve optical parameters, etc., and achieve the effect of performance optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

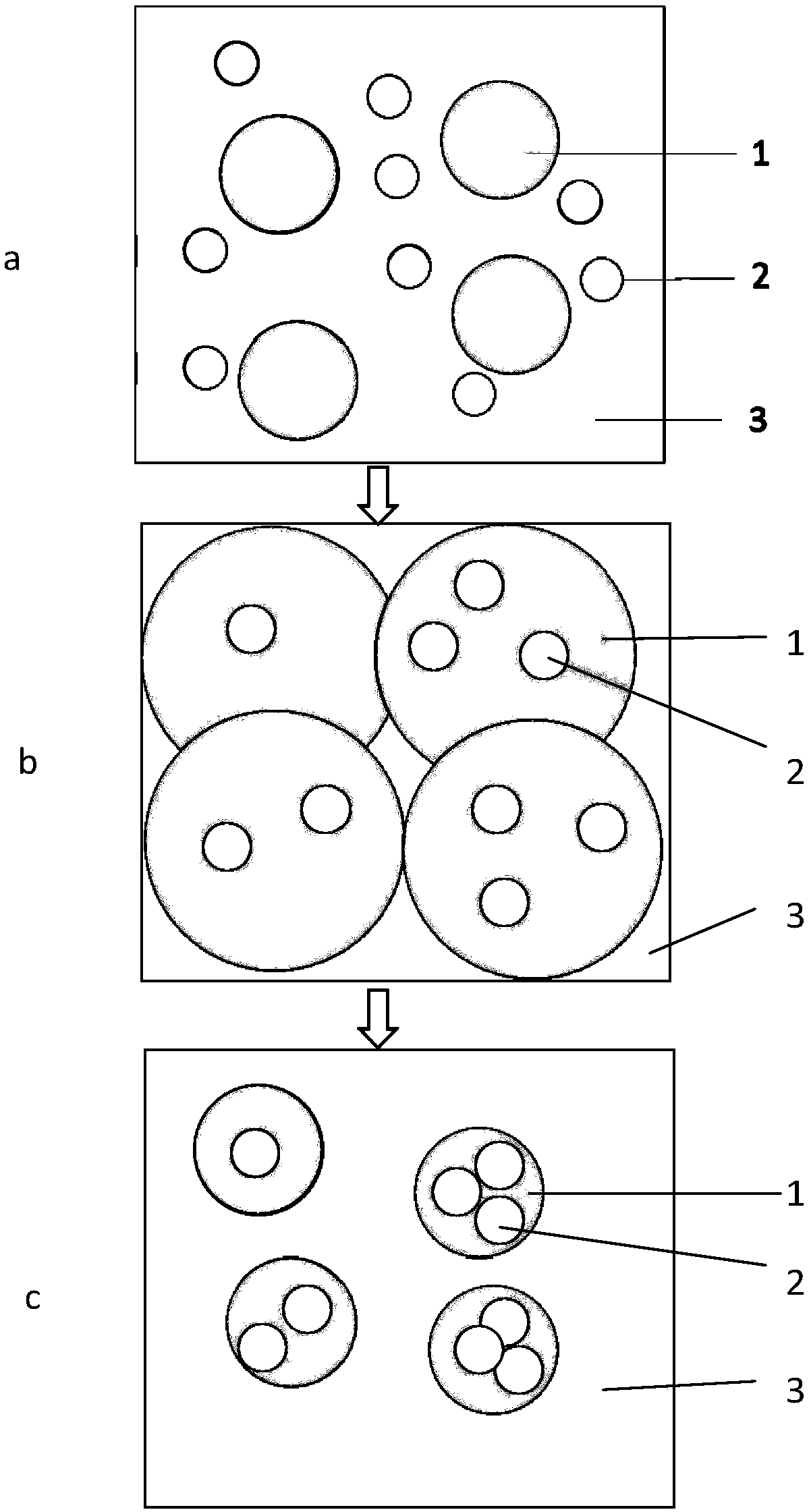

[0033] The quantum dot / polymer microsphere composite material of this embodiment includes quantum dots and polymer microspheres, the polymer microspheres physically wrap the quantum dots, and the quantum dots are dispersed in the balls of the polymer microspheres In vivo, the quantum dots are CdSe / ZnS quantum dots, and the polymer microspheres are polyacrylic acid / polystyrene microspheres.

[0034] Its specific preparation method is as follows:

[0035] (1) Preparation of polyacrylic acid / polystyrene microspheres for wrapping quantum dots: 80g styrene monomer, 70g ethyl methacrylate monomer, 85g methacrylic acid monomer and 5g, p-divinylbenzene mono The mixture was fully mixed to form a mixed monomer solution, and 31.5g of the mixed monomer solution was added to 550g of water, and at the same time, 2g of sodium lauryl sulfate, 4g of potassium monohydrogen phosphate, and 15g of ammonium persulfate were added. In the reaction kettle, mix the above mixed solution evenly, and hea...

Embodiment 2

[0044] The quantum dot / polymer microsphere composite material of this embodiment includes quantum dots and polymer microspheres, the polymer microspheres physically wrap the quantum dots, and the quantum dots are dispersed in the balls of the polymer microspheres In vivo, the quantum dots are red quantum dots and the polymer microspheres are poly(isopropylacrylamide / styrene) microspheres.

[0045] Its preparation method comprises the following steps:

[0046] (1) The synthesis method of poly(isopropylacrylamide / styrene) microspheres used to wrap quantum dots is similar to Example 1, the difference is that in the configured mixed monomer solution: isopropylacrylamide: styrene: divinyl The mass ratio of phenylbenzene is 33:66:1. The same emulsion polymerization method as in Example 1 was used for preparation, and the method for modifying the double bond on the surface of the microspheres was to mix 100 g of the product prepared above with 12 g of hydroxyethyl methacrylate, heat...

Embodiment 3

[0051] The quantum dot / polymer microsphere composite material of the present invention is applied to the field of LED display. Its specific application method can be, but not limited to, the application of the following methods: dispersing the quantum dot / polymer microsphere composite material in different resin systems (glue), including but not limited to acrylic resin, polyurethane resin, epoxy resin etc., and then the glue with the quantum dot / polymer microsphere composite material of the present invention is coated and cured and then applied in the display panel as a backlight film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com