Force-reducing type pump cover

A pump cover and pump body technology, which is applied in the field of hydraulic pumps and auto parts, can solve problems such as pump body cracking, power steering function failure, and impact on driving safety, and achieve the effect of reducing the force-bearing area and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

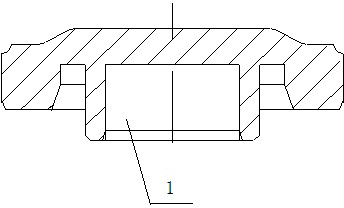

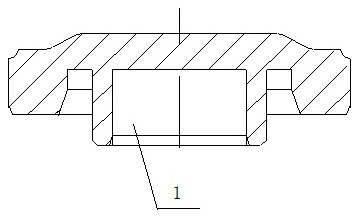

[0009] The pump cover is the basic component of the pump, and the structure of the force-reducing pump cover of the present invention is as follows: figure 1 As shown, there is an inner hole 1 at the center of the pump cover, the diameter of the inner hole 1 is the same as the diameter of the side plate boss, the diameter of the pump cover is D, and the diameter of the inner hole is d. The connection between the pump cover 1 and the pump body is a retaining ring for the hole, and the force on the retaining ring depends on the force-bearing area of the pump cover The product of P and the system pressure, when the pressure increases, the strength of the pump body at the retaining ring is insufficient and it is easy to crack. The inner hole Φd of the pump cover is sealed with the side plate boss Φd, changing the stress area of the pump cover to , the force acting on the pump cover is significantly reduced, so a new cover is used when the pressure is required to increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com