Plunger pump fluid end assembly

A liquid end, plunger pump technology, applied in pump components, variable capacity pump components, liquid fuel engines, etc., can solve problems such as high cost, reduced pump comprehensive life, and inability to operate normally, reducing the force area. , Improve the overall efficiency, the effect of reducing the ineffective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

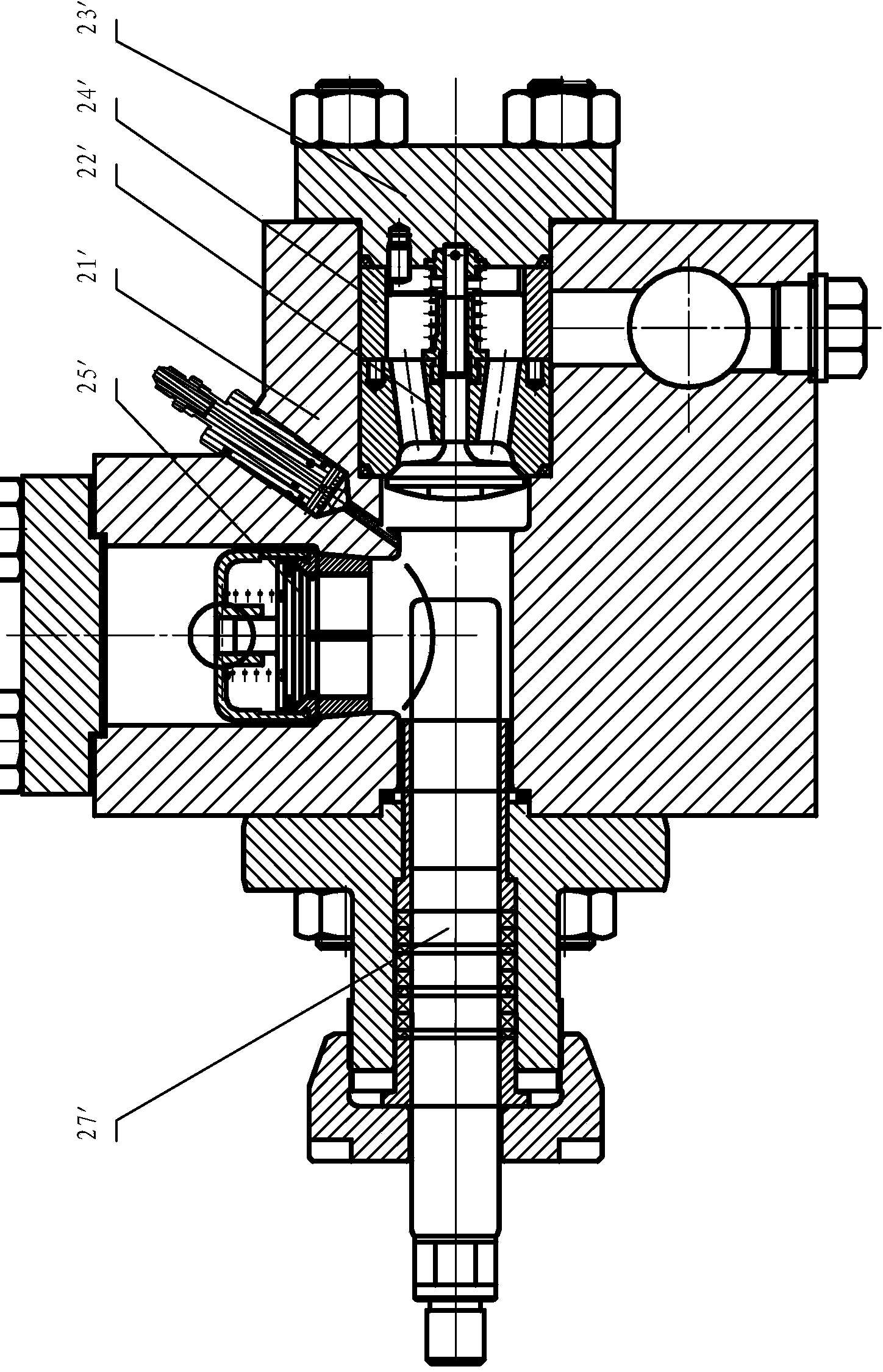

[0028] Such as Figure 4~6 The hydraulic end assembly of the plunger pump shown includes pump body 1, seal 2, combined valve 3, liquid inlet valve 31, liquid discharge valve 32, plunger 6, upper flange 7, mesh plate 8, valve sleeve 9. Front flange 10, plug head 11, front guide sleeve 12, rear pressure ring 13, packing 14, adjusting nut 15, the pump body 1 is provided with a plunger channel 18, and the plunger 6 is movable in the plunger channel 18 Inside, the pump body 1 is provided with a vertical combination valve channel 19 which communicates with the plunger channel 18. The combination valve 3 is arranged in the valve passage, and the structure of the combination valve 3 can adopt the structure disclosed in the Chinese invention patent No. 200510050387.2. The valve 32 is arranged on the upper part, and the pump body 1 is provided with a liquid inlet chamber 16 communicating with the liquid inlet valve 31 of the combined valve 3 , and the pump body 1 is provided with a liq...

Embodiment 2

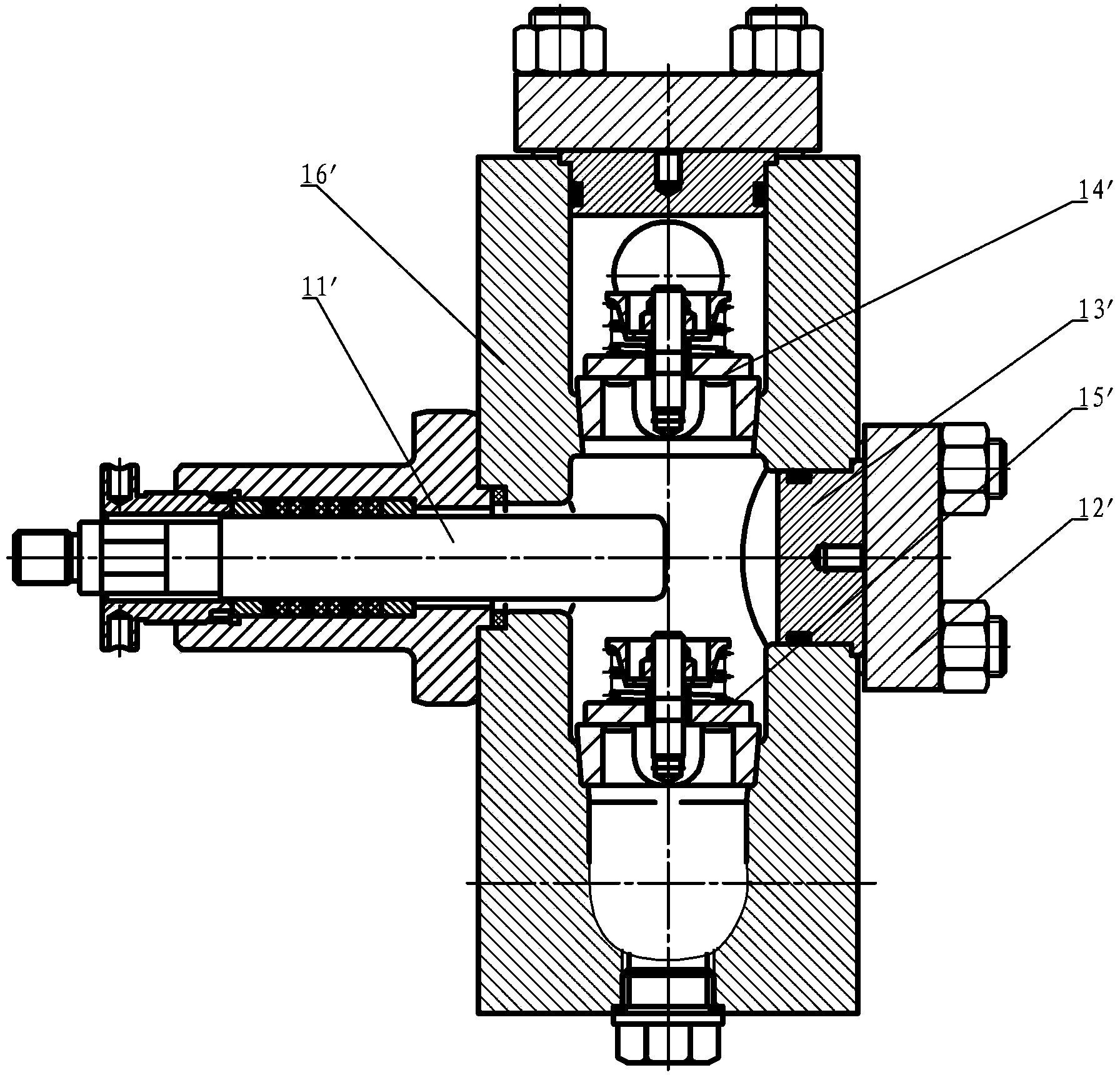

[0037] The difference from Embodiment 1 is that the liquid inlet chamber 16 is arranged in front of the pump body and communicates with the liquid inlet chamber of the liquid inlet valve 31 . In this case, an additional liquid inlet manifold is required. see Figure 7 shown.

Embodiment 3

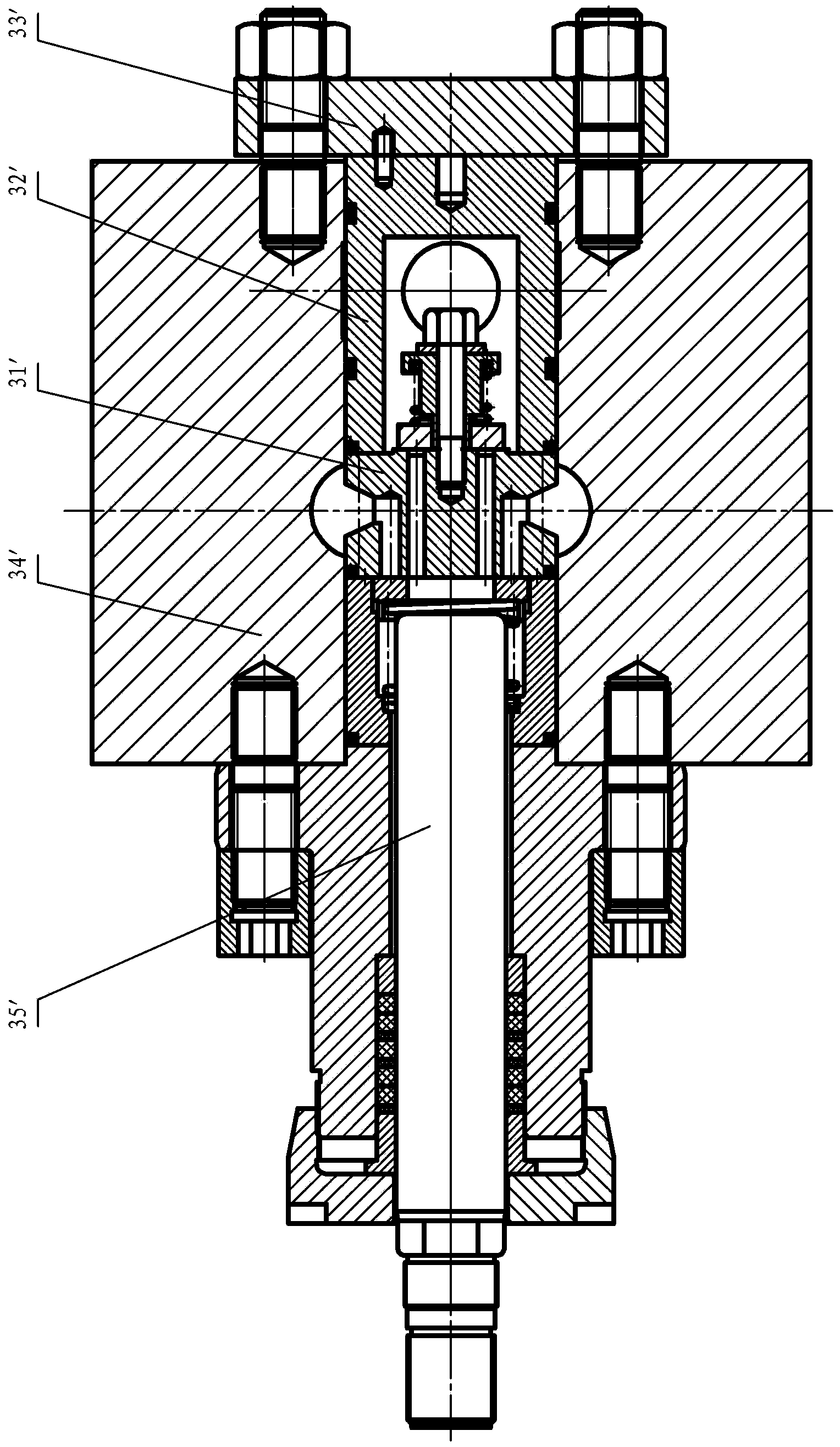

[0039] The difference from the second embodiment is that the liquid discharge chamber 17 is arranged on the upper part of the pump body and communicates with the liquid discharge chamber of the liquid discharge valve 32 , at this time, a liquid discharge manifold needs to be additionally provided. see Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com